This section is a diary of the things that I found about and did to each loco.

The first one I tried was a Bachmann Spectrum FP40PH as Amtrak 396. The prototype was last known to be in Los Angeles MetroLink service. The loco buzzed with DCC on the track so it was clear that it had not been converted to DCC, but it ran. The couplers were Kadee's but they were nearly non-functional due to kludged coupler boxes, somebody had done an inadequate coupler conversion. After I opened it up and lubed it, it ran pretty well although it was fairly noisy.

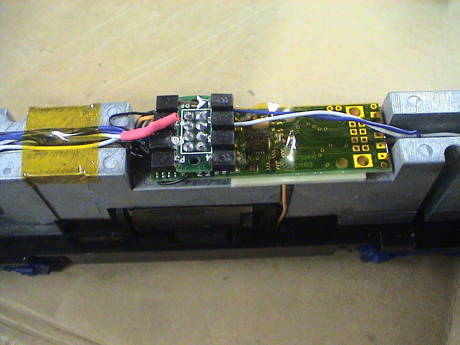

This loco was deemed worth fixing but I needed a decoder. The N scale decoder from UP x1614 (which was already on the dead line) went into the Amtrak FP40PH. This Bachmann loco was not designed to accept DCC. It was built from two large weights halves that mostly filled the shell. These halves form the structure and electrical distribution system for the loco. The loco also had an analog lighting board attached inside the top of the shell that drove the strobe lights on the top of the cab.

I first tested the motor for commutator shorts and found it free of problems so that I deemed it safe to install the decoder in it.

The loco came apart (easily) and I cut the spring tabs that connected each motor contact to a weight. I then soldered and insulated wires to stubs of the motor contacts and then reassembled the loco. After a check that the power pickups still worked and that the motor worked and it was now isolated from everything else, I installed the DN142 decoder. The loco ran under DCC.

The lighting board was mostly scrapped. I retained the ends of the board because they held the front and rear incandescent headlight bulbs in their proper position but the rest was cut out. I wired the headlights (no series resistor needed) back to the decoder. I then rewired the two incandescent "strobe" lights in series with a 120 ohm resistor to the green (F1) function wire of the decoder and fired it up. All the lights worked. The strobes, however, had a MARS light attribute assigned to them. A quick reprogram with DecoderPro turned them back into strobes. Then the loco was reassembled and tested.

The couplers themselves were ok, but the centering springs were ruined. I replaced those with new Kadee springs using Kadee #5 boxes.

Based on my experience with Amtrak 227, I pulled Amtrak 346 back and lubed two spots that I had missed. The residual noise went away. Steve had also certified the loco in the meantime so it is back in service.

Since Amtrak 227 was being scrapped, I pulled the handrails off the rear of 227 and put them on 346.

I tried to use this one at the club last night and it didn't run well. It's power pickup was flakey. I put it in a box to take home. As it turns out there was nothing wrong with it but dirty wheels.

Amtrak 346 made it back to the bad order box with a note of intermittent operation. It looked like dirty wheels and that was the problem. I cleaned them and it ran fine.

This one finally came back with a bad order report of intermittent running. The wheels were just incredibly dirty. I cleaned them with alcohol. A visual inspection indicated that the wheels were suffering from wear, but they are not worn out. In any event, the loco runs smoothly now.

The Life-Like RDC (Baltimore and Ohio 6516) was also clearly not converted to DCC. It ran on DC pretty well, but it made a terrible buzzing racket in the higher speed ranges. It needed lubrication. It's couplers were not Kadee's and were clearly non-functional.

After opening the RDC, I found that would be fairly easy to convert to DCC but it would take a wired decoder, there is no socket or connector. After a lube job, I worked on the buzz. This resulted from an imbalance in the flywheel that was transmitted to the motor and from there through the motor's electrical connection tabs to a plastic box that enclosed the motor. The box acted like a sounding board and made the buzz really loud. After adding some padding (folded piece of paper towel) and securing the box better, the buzz went away. So far, so good. It ran smoothly, but not real fast but it would be ok.

Then I ran a test on the motor by monitoring the motor current on a scope. What I found was disturbing. This motor behaved identically to the one in my USRA 0-6-0 in that it would draw indicated intermittent current spikes of more than 20 amps on my bench power supply. This behavior tends to be hard on decoders, I blew one up in the 0-6-0. Good motors don't do this. After running the motor for awhile, the spikes did not go away. Further, the hack of adding resistance in series with the motor to isolate it would just slow the thing down. I deemed it unsuitable for conversion to DCC and set it aside. I may get back to it later to see if a resistor would actually work in this unit but it draws about twice as much current as the 0-6-0 (about 200 mA) so that it may not work well enough with a resistor in place.

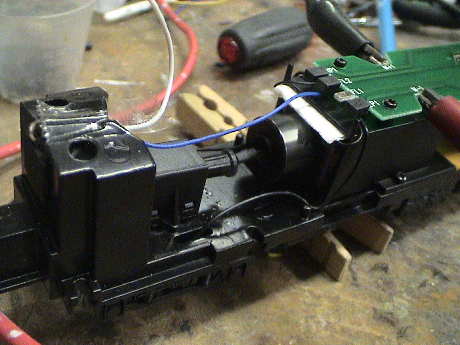

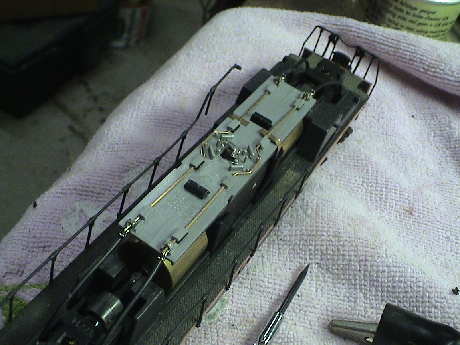

I wasn't ready to give up on the RDC so I took it apart again and ran more tests. This photo shows it connected to a bench supply with the motor being run in to see if I can get most of the spikes to go away.

I think that the very large current spikes I was seeing before were due to an interaction between the autoranging on my scopemeter and inductive kick backs from the motor. When I added a 5.6Ω resistor in series with the motor and ran it from 6 volts, the worst spike I should be able to get would be about 1 amp. The huge ones went away but I would still occasionally see spikes exceeding 2 amps. Good motors will not do this with the same test rig so that this motor still has some difficulties. However, it runs ok with 5.6Ω resistor in series so if I convert it, it will get a current limiting resistor just provide a maximum possible current limit to the decoder of about 3 amps. The motor running by itself averages about 150 mA. The stall resistance of this motor is about 15Ω which would result in a normal stall current of less than an amp at the club's track voltage (14 volts).

The PWB is wired rather oddly. The headlights are 2.5 volt 50 mA bulbs with the voltage controlled by diode stacks. The two stacks have 3 diodes wired one way to provide a little less than 2 volts for the bulb and one diode wired the other way to provide directionality and to allow bidirectional current flow for the motor. The two stacks are wired in series with the motor to give the headlights a head start. This takes about 3 volts away from the motor which one reason that it ran so slowly.

This is the motor mount. The white thing is a double layer of paper towel that mechanically damps the connection between the motor tabs (on top of the motor) and the plastic housing. The RDC is driven only by the front truck which is fine because it only has to haul itself, and maybe one trailer car, around and it doesn't need a lot of traction.

This is the motor mount. The white thing is a double layer of paper towel that mechanically damps the connection between the motor tabs (on top of the motor) and the plastic housing. The RDC is driven only by the front truck which is fine because it only has to haul itself, and maybe one trailer car, around and it doesn't need a lot of traction.

It also appears that I can salvage the couplers from the UP FA to put Kadee couplers on the RDC.

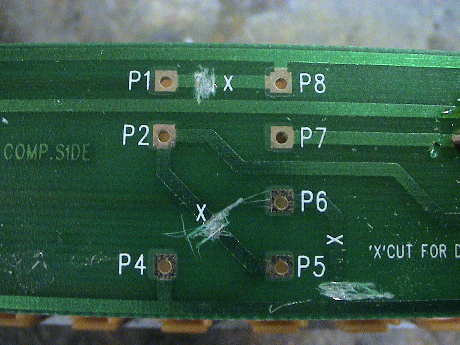

The PWB is marked in 3 places to cut for DCC. These didn't make sense to me until I had traced out the board and determined the wiring. I took this photo because it was easier for me to visually verify that the traces were cut in the photo instead of by eyeball at 1x. Growing old is a bitch. The 7 terminals are the ones that would be used on a standard 8 pin DCC socket. There is a 300Ω resistor on the board that isn't used for DC operation. It ends up in series with the decoder blue wire to provide current limiting for the headlights. The diode stacks still limit the bulb voltage such that the headlights run fairly dim.

The PWB is marked in 3 places to cut for DCC. These didn't make sense to me until I had traced out the board and determined the wiring. I took this photo because it was easier for me to visually verify that the traces were cut in the photo instead of by eyeball at 1x. Growing old is a bitch. The 7 terminals are the ones that would be used on a standard 8 pin DCC socket. There is a 300Ω resistor on the board that isn't used for DC operation. It ends up in series with the decoder blue wire to provide current limiting for the headlights. The diode stacks still limit the bulb voltage such that the headlights run fairly dim.

I wired a 9 PIN JST socket to the terminals on the board, plugged in a used DH123 and it worked.

I wired a 9 PIN JST socket to the terminals on the board, plugged in a used DH123 and it worked.

| Terminal Number | Decoder Wire |

|---|---|

| 1 | Orange |

| 2 | Yellow |

| 3 | n/a |

| 4 | Black |

| 5 | Gray |

| 6 | White |

| 7 | Blue |

| 8 | Red |

I used a resistor in series with the orange wire to the motor. The bands indicate that it is 2.7Ω, but it is an old 20% part and actually measures 3.5Ω.

The RDC runs, still slowly, and the lights were fairly dim. I lifted lift one of the stack diodes and decreased the resistor in the blue wire to 220Ω to brighten them. It turns out that headlight is wired across only two of the stack of 3 diodes so it's voltage was limited to 1.3 volts. Now they get 2.2 volts or so at the club voltage and at least they burn white in color but they are still not overly bright.

I also removed the 3.5Ω resistor in the orange motor lead to try to speed it up a little at the risk of maybe toasting a cheap decoder. It ran a little faster, but it is still slow and my track voltage is a little higher than the club voltage.

Then it occurred to me what was going on. This wasn't a new decoder. The decoder probably came out of a rubber drive Athearn F7B and CV2 had probably been set to keep it from running at warp 6. CV2 was indeed set at 150. Resetting it allowed the loco to run fast enough at the club track voltage even with the 3.5Ω resistor reinstalled. This is the way that it will stay. The decoder itself is placed to fit in the radiator blister on the top of the shell.

I took the couplers and pockets off the Life-Like FA and put them on the Life-Like RDC, adjusted the trip pin height and it's done.

I had installed one of my own decoders in the RDC. I got a DH140 from the club to substitute in for a my DH123. This is an older style decoder that uses a low PWM frequency, but it worked fine in the RDC with audible but not objectionable motor growl. The RDC started to make more high frequency motor buzz again so I need to get back in there AGAIN to work on that some more.

I worked over the acoustic buzz again and suppressed some of it but the rest may be there until the whole side of the motor box is cut out. The buzz is not a mechanical problem but it is annoying.

Every time I thought that I had the buzzing under control, it came back. This is probably why the thing had never been converted to DCC. I hacked off the motor cover box everywhere the motor touched it and then the chassis itself ran with only gear whine left. When I put the shell back on, the buzzing came back. There were still two sources, a loose window segment on the left side near the motor was buzzing against the shell. Some CA took care of that as it was not attached well. Then the shell itself was buzzing against the frame. The folded paper towel, no longer needed at the motor, help damp that. It still makes some noise do the vibration of the motor, but it's not nearly as bad as it was.

Every time I thought that I had the buzzing under control, it came back. This is probably why the thing had never been converted to DCC. I hacked off the motor cover box everywhere the motor touched it and then the chassis itself ran with only gear whine left. When I put the shell back on, the buzzing came back. There were still two sources, a loose window segment on the left side near the motor was buzzing against the shell. Some CA took care of that as it was not attached well. Then the shell itself was buzzing against the frame. The folded paper towel, no longer needed at the motor, help damp that. It still makes some noise do the vibration of the motor, but it's not nearly as bad as it was.

The RDC and the dummy were run at the LAMRS Christmas Open House and did just fine. The couplers on the dummy still need work to be fully in spec but the pair ran. I'll submit 6516 for certification at the next meeting and hopefully pick up some couplers.

The Life-Like UP FA (x1614) didn't buzz on the track. It had a DCC address on a label on the bottom, but it did not respond to that address. It sort of responded on the DCC programming track, but the command station indicated that all the CVs I tried contained 255. This indicates a problem because many CVs, like the 2 digit address, don't allow values exceeding 127. There was a 4 digit address reported, but it wasn't the one on the loco label.

After opening the loco I found that it had a DN142 decoder in it. I first substituted a DH123 for the DN142 and it's response on the programming track did not change. Clearly there was something wrong in the loco. I connected an 8 pin DCC jumper plug to the socket in the loco to convert it back to DC and put it on the track. It was a dead short.

Then I attached some test wires to the DCC jumper plug so that it would be easy to inject DC into the loco on the bench and it drew 10 amps with only a few volts on it. This was not good. I manually turned the motor with very low voltage on it and the motor turned a little more by itself but it stalled again in less than half a turn. The current draw bounced all over, but it was always very high and I couldn't get more than a few turns from the motor before it would stall again at very high current. Then I noticed that a wire had broken out of the motor windings and was flopping around. The motor was clearly toast. I was not going to get much further with this loco. I did plug the decoder into an HO SD45 (which was already open) and the decoder worked.

After consulting with some club members, I elected to declare the FA1 as scrap and sent it to the dead line but not before recovering the decoder and couplers. The club wanted me to try to fix it so I'll swap the guts from UP 1642 with this dead one.

I've done a guts swap with UP 1642, an FB1. I needed to move the headlight assy, engineer, fireman and panel from the old FA1 chassis to the chassis from the FB1. Otherwise, the chassis are identical. Now x1614 needs a decoder and couplers as the FB1 didn't have couplers either.

It also needs a new front truck which I can get from the remains of UP 1642. I have an MRC AD350 decoder for it. I'll use this one instead of a Wangrow decoder because the MRC has a Mars light simulation. The matching B unit (1614b) also has an MRC AD350. The AD350 is not the greatest decoder, but it is current production. A PDF file of the manual is at the link.

I installed the MRC AD350 decoder and set up the special functions. F0 operates normally following Rule 17. The number boards are actually wired to the ditch light function but both are wired in parallel so that there is no flashing. A double click on F1 turns them on or off or if they are off F5 toggles them. There are actually two bulbs in the upper headlight position, the other bulb has been configured as a MARS light. F4 turns it on or off.

The loco needs a Kadee #6 long shank coupler for the front. The rear coupler is a Kadee #5.

Steve and I tried to certify this loco at the club a few days ago and it didn't run so I brought it home again. For some reason, CV29 was set for 2 digit addressing, I reset it to 4 digit and it ran. However, during test I smelled some plastic burning. Then I noticed that the headlight was showing through the top of the hood. It was running too bright on my higher track voltage and melting the shell.

The shell damage was not severe. I increased the resistance in series with the headlights from 39 to 51 ohms and things looked better. I then painted the side of the bulb engine black and painted the inside of the shell next to the headlight engine black as well to prevent the light from shining through the damaged plastic.

This one failed certification tonight. It has one undergauge wheelset. I will get a part from the basket case UP 1642. It also would not speed match so we elected to pull the MRC decoder and replace it with a better one for further evaluation.

I pulled a DH121 from SP 4823 (going to the scrapper) and installed it in x1614. This is a two function decoder so I could not test the numberboard or MARS lights but the headlight works and I wired those missing functions to the 9 pin JST socket so that a 4 function decoder could drive them.

The front coupler was easier to deal with than I thought it was going to be. The frames for these locos are set up as a B unit. The old A unit frame (which I recovered last night) had a plastic extension piece screwed to the frame. This extension was just right to install a Kadee #5 at the front, done.

One wheelset was under gauge last night. By the time I got to it, it was over gauge. Something was amiss. The plastic gear on that axle was cracked so it wasn't holding the half axle firmly. I rummaged through the remains of UP 1642 and also recovered a single wheelset that wasn't cracked and installed it. That fixed that problem. Then the thing started to derail. On this loco, the square axle bushings tend to fall out of the slot in the metal frame of the truck. Unless they are carefully held in place with the bottom cover of the truck is snapped on, they will fall out of the frame and the axle will not be positioned in the right spot. The cover spaces them properly IF they are in the right place to begin with.

Eventually, this one will need a better decoder. I don't know why this one would not speed match while it's matching B unit did but we should probably pull the MRC decoder out of UP 1614 (the B unit) and replace it with a better decoder.

Before the OPS session today I had a chance to test UP x1614 on the club layout. It failed with flakey power pickup. This is odd because it was stable on my own layout just before I boxed it up.

I put it back on my track and the headlight doesn't even flicker. The wheels are clean and they all work individually. It'll have to go back to the club for more testing there.

Yesterday, it went back on the club layout and ran fine. The problem must have been a dirty stretch of track.

It got the DH121 pulled and a TCS T4X installed so that the extra lights will work. It also got power jumpers, using SIP connectors, to cross-connect power to it's B unit, UP 1614b.

UP x1614 actually got certified along with UP 1614b. However in later running, it developed a problem. From the sound, it appears that an axle gear has cracked. This is not a big deal as Athearn gears will fit this loco BUT I don't have any. It'll wait until I purchase some replacement gears.

I stopped by Milepost 38 and picked up two bags of Athearn #60024 axle gears ($4.98 per package of 6). The 2nd axle of UP x1614 had a split gear and made a clunking sound. This fixed it.

Last week I noticed that x1614 was clunking again. Last night, Steve and I tested it and it was indeed clunking. This time, the lead axle on the front truck was cracked. It got fixed again.

This is the Ford Area Rapid Transit (FART) car. I believe that this is the car that ran on the trolly line in the town of Ford over a decade ago. It is a die cast model with a very odd power truck. The motor is vertically mounted and drives a worm, pointed down, that then drives skew cut gears to drive the axles.

Initially, this car didn't run, but looking through the windows revealed a wire hanging loose. I took it apart and indeed the power pickup wire from the rear truck was broken. I soldered it back on the very old motor and the car tried to run. The wheels are brass and were totally packed with crud, I took that off with a brass wire wheel in a Dremel tool. Then after some lubrication it ran fairly well but it makes some noise. I need to spend more time with this car to see if will be worth investing a decoder in. The motor draws about half an amp while running but an inexpensive decoder should work in it. I am suspicious that the brass wheels will be an operational problem and the car may require more wheel cleaning than it is worth. Also, due to a small clearance between the wheels and the metal frame, it tends to short out when derailed.

Initially, this car didn't run, but looking through the windows revealed a wire hanging loose. I took it apart and indeed the power pickup wire from the rear truck was broken. I soldered it back on the very old motor and the car tried to run. The wheels are brass and were totally packed with crud, I took that off with a brass wire wheel in a Dremel tool. Then after some lubrication it ran fairly well but it makes some noise. I need to spend more time with this car to see if will be worth investing a decoder in. The motor draws about half an amp while running but an inexpensive decoder should work in it. I am suspicious that the brass wheels will be an operational problem and the car may require more wheel cleaning than it is worth. Also, due to a small clearance between the wheels and the metal frame, it tends to short out when derailed.

The car is missing it's trolly pole.

I messed with FART 65 more today and finally gave up on it. The biggest problem is that it tends to spit fire from beneath the power truck at times and it has only 4 wheel power pickup. This car will not be a reliable runner.

This traction work car was also in the pile. Number 45 ran poorly drawing about 300 mA, but it sputtered a lot. The motor is up in the body and drives the truck via two spring belts. Worms in the truck then drive the axles. It also has brass wheels and they needed cleaning badly. It picks up power from two wheels on one side of the rear truck and the other side of the power truck. I suspect that the power pickup will be too poor for reliable operation.

The car appears to be a scratch built model. The body is wood and cardboard totally unlike the description on the box it came in. This car may not be worth recovering but some traction guy may want it. I think that this one is evilBay fodder.

ATSF SD40 5036 sort of ran but it made awful gear noise and drew a lot of current, about an amp on DC. It needs some mechanical work before I can determine if it is worth salvaging.

I worked on this one some and it is pretty clear that this loco has been used up. The whole gear train was completely dry but lubrication didn't help it. The motor was virtually stalled when taken out of the unit. The commutator is worn but I faced it a little and it ran better but the other motor bearing is bad and vibrates badly.

The loco derails constantly on tight radius track

It's a pity because the loco looks pretty good but sadly, I must recommend to sell on this one.

This undecorated RDC dummy was a little easier to deal with. It needs coupler work but otherwise seems fit for service. I tested it with the powered RDC and it handled my 18" radius curves fine so I suspect that it will run on the LAMRS layout without difficulty.

I replaced the centering springs on both couplers, adjusted their height and glued the loose trip pin on one of them. This one should be ready for service. While I was there working on the couplers, it was obvious that a powered version of this RDC would be a rubber drive unit.

The dummy RDC had plastic wheels. It ran fine with them, but I found a club rule that required metal wheels on club owned equipment so I changed them with some older metal wheels. This required drilling out the swedging that held the cast metal trucks together and separating the truck halves, then drilling and tapping the trucks to accept #2-56 screws and reassembling them with screws. The insulated wheel tends to touch the truck frame so I added a thin styrene insulator to keep the wheel from rubbing on the frame and causing a track short. The rolling resistance is higher than I would like but that won't matter much in it's service attached to a powered RDC.

BN 248 is an SW12 made by Life-Like. This one has not been converted to DCC, but it should be. It runs really sweetly.

This MAY be a privately owned loco. There is a label on the bottom that says "Totten."

There is precious little room inside the SW12 and it's not set up to take DCC. If the low voltage lighting board is removed, there is probably room for a very thin, N or Z scale decoder. The lights themselves are attached to the shell and connect with spring contacts to the board. The front headlight does not work anyway. It should be possible to mount a new front headlight on the front of the weight. The rear headlight would be more of a problem, it would probably have to be wired to the decoder with an appropriate current limiting resistor for a 1.5 volt 120 mA bulb. The cab area could be difficult to get into.

I was told that John Totten has donated this loco to the club and Lloyd gave me an N scale MRC AD332 decoder to install in it. The headlights were 1.5 volt bulbs and the front one had failed anyway so I pulled both of them out and replaced them with warm white LEDs. The GOW bulbs drew nearly 150 mA which was just too much anyway. As of today, the headlights are replaced (no easy task to get the cab apart) and the decoder will go in shortly.

This one is finished and it runs really well. The shell is a little loose, but it won't come off because the coupler pockets hold it in place.

This one did not want to speed match the standard loco, the MRC decoder just doesn't have the programmability. It will get the DZ143 from Amtrak 227.

I took the decoder from Amtrak 227 and installed directly into BN248. There were no problems, it ran fine.

I left this one at the club this morning for certification.

The wheels on this one just wore out and started collecting dirt like crazy. It got a new set of Kato wheels.

This one had suffered some drop damage, the cab was busted off and the loco was in a pile in the bad order box. I glued the cracked cab wall back together so that it would actually latch in place. The cab grabs were also broken but I elected NOT to glue them because then the cab couldn't easily be taken off again. They will stay in place by themselves if they are not molested.

After the cab had set up, I reassembled the loco and it made a lot of noise. There were wires dragging on a flywheel or universal joint. I took it apart and rerouted the wires and taped them over the top of the motor and then tried to reassemble it. Whatever features had been there to hold the shell on (4 clips on the shell that go through the frame) were all broken off. I fabricated some new features with 0.040 x 0.125 styrene strip mounted behind the pilots to use the coupler pockets to hold the shell on.

ATSF 2790 is a GP7 or GP9. The model does not run on DC nor does it respond to the DCC programming track.

The problem was there there was nothing in the jumper plug. Apparently, somebody had taken decoders OUT of some locos that didn't run all that well and didn't reinstall the jumper plugs.

Once I put a plug in, it ran, but made a lot of noise. I lubed as much as I could get to and after a minute or so to get the grease spread around inside, it quieted right down. I plugged in a test decoder and it ran fine. A small HO decoder will barely fit over the motor, an N scale one would be an easier install.

This loco is worth saving.

This loco was tested at LAMRS tonight and passed. It will get the test decoder pulled and a TCS T4X decoder installed as soon as the new decoders arrive.

ATSF 2790 was bad ordered for a clunking sound. Sure enough, the wheels on the rear axle would rotate with respect to each other indicating that the axle gear had split and was not holding fast to the half axles. I replaced that gear with a new one and tested it again, it still clunked, but from the other end. The 2nd axle gear was partially split. Only one wheel would turn. I replaced that one too and all the clunking is gone for now anyway. These gears die of old age and need occasional replacement.

I had some troubles with ATSF 2790. When I connected one of club's Wangrow decoders, the decoder would become non-responsive. After some careful examination of the wiring, I found two problems. Somebody had jumped around the plug to connect the lighting outputs back to the track. This confused the decoder. Further, the PWB itself jumps pins 3 and 7 which does not conform to the NMRA RP 9.1.1. Pin 3 is supposed to be left NC or used for a function, commonly the green wire. With the jumper on the socket, a function output is directly connected to the blue wire. If you put the loco on the track that way and turn on the function... poof. The club's decoders wire the violet wire to pin 3.

Further, the plugs on the club's decoders are so tall that if the plug is used, the shell won't fit back on. There are two ways around this, 1) use a decoder with a flush plug (which most of the newer ones are) or, 2) throw the little PWB overboard and hard wire the decoder. I am taking the 2nd route.

The decoder went in without difficulty and doesn't make a lot of PWM hum either. The loco didn't have any lights so I installed a couple of 5 mm warm white LEDs with 560Ω current limiting resistors. The LEDs fit nicely in the slots in the weights that were intended for them. The number boards are lettered and illuminate nicely. The front headlight is on F0 and is not directional. The rear headlight is on F1.

2790 got tested at LAMRS last night and didn't do so well. The bad order card says "no go." I ran it this morning on my layout and it ran like crap, nothing like what it was when I worked on it last month. It had two problems, one was obviously poor power pickup, but the other problem was similar to other locos that were tested with the Wangrow decoders. The lights would continue to burn and the motor would cut out or not run at all. My track current was all over the place while it was misbehaving and the motor buzz tracked the motor movement. Either this motor is intermittent (possible) or the decoder is behaving oddly (likely). After a few minutes of running on the bench, the loco smoothed out and then it ran fine. I did a minor handrail repair and put it back in the box for more test. Maybe the source of the problem will become apparent as I test other locos that had similar difficulties.

The club supplied a DH121 decoder for this loco. It was an easy 7 wire cut and splice job to install it. The loco runs fine and doesn't make a lot of noise.

The loco got retested at the club and it ran fine and passed muster. It is now waiting for the delivery of it's final decoder, a TCS T4X.

The TCS T4X went in without difficulty. I did reglue the shell to the walkways but that was all it needed.

I ran 2790 at the club last night and it simply didn't work. The wheels were so dirty that it would go only a few inches and stall again. I brought it home and found that the wheels were packed with hard crud. I cleaned it off abrasively and then used a grit block to polish the wheel surface. Then it ran fine. We'll see how it holds together. If it doesn't it will need new wheels.

ATSF 2790 had reliability problems. The wheels were just worn out with bare brass showing and a hazed surface. These wheels just collected crud from the track and it needed wheel cleaning every half hour or so, not acceptable. Since this was an Athearn loco, the club has used wheels that are in much better condition so I changed them out. There is was a complication however. There are 40" and 42" wheels that are otherwise identical. I had only 7 usable wheels in 40" without going through the sell box to recover just one wheel. I did have enough 42" wheels though so the loco got "regeared" to a higher speed service. There was a cracked gear too, it got replaced with another used gear that wasn't cracked. This raised the couplers about 15 mils so I replaced the Kadee #5 couplers with low offset Kadee #42 couplers, which I had in club stock. The loco will require recertification due to the coupler change and it will need speed matching again, but it runs without fouling the wheels.

Harbor & Western 2500 is a brass ten wheeler (4-6-0) that runs pretty well drawing about 700 mA. However, it requires the tender for power pickup and may or may not be reliable enough for the club layout. It is a nice looking loco that is in good physical condition.

After a tuneup, this loco is not making the grade. It's power pickup is marginal at best on track that other locos run on without hesitation. The current draw of the motor is without a load which implies that the motor will get quite hot. This is a shame because this is a well proportioned and detailed model of an attractive prototype. It is sturdy and heavy. This loco would be better suited to somebody's DC layout for light duty service.

UP FB1 1614b is a Life-Like model that is part of the set with the UP FA1 that has the shorted motor. It has been converted to DCC but it runs slowly at the club track voltage. It does run smoothly, just not real fast.

I pulled the DH163 that was in UP 1614b and replaced it with a Wangrow 8 pin decoder. Then I could use the JST connected DH163 in Amtrak 809.

I got a couple of MRC AD350 decoders from the club. This is a basic decoder, but it does have some lighting functions that were suitable for the matching FA so I put the other one in the FB so at least the locos would be using the same decoder.

The MRC decoder got ripped out for being too different and messing with Steve's process. It got a TCS T4X.

UP x1614 and 1614b ran as a consist all day today at the OP session. At the very end of the session, it started to howl indicating a dry bearing. I brought it home opened up and ran it slowly on it's side on the bench. It was howling. I hit the 4 of the 6 potential bearings starting with the motor. When I got to the forward gear tower bearing, the noise immediately stopped. The other two gear tower bearings are under a weight and are hard to get to so I skipped those.

UP FB1 1642 is the third loco in the set. It was marked "bad motor." It did not run. I took off the shell and found that it was missing the jumper plug. I put a jumper in and then it ran on DC, but not very fast. I plugged in a DH123 and it ran about the same as 1614.

If the speed of 1614 is acceptable to the club, then I think that I should swap shells and make the one that is now 1642 into FA1 x1614. That one will need some couplers and a decoder as I salvaged those parts to get the RDC and Amtrak 346 going. Then I should convert the frame that was in the FA1 to a dummy and put the FB1 1642 shell on it.

I've done the shell swap with UP x1614 so now UP 1642 has the bad motor. I looked at converting it to a dummy, but the trucks will have to be completely disassembled to remove some gears. This is not worth the effort. This loco should be retained for parts to fix the other two when needed.

The hulk that was 1642 has surrendered a truck to WM 81, but the truck was not much good either. This loco now resides in a bag, it is truly a basket case.

I've also pulled the front truck to use on UP x1614 as the one that was on 1642 and got transplanted into x1614 had a bad gear.

Amtrak 227 is another FP40PH that is pretty much identical to Amtrak 346. It does not run and also does not respond to the programming track. It also needs coupler work.

The loco has been fixed, it had a corroded motor contact and it needed lubrication. It still makes some bearing noise once in a while. While I was in there fixing the motor contacts to the frame halves I cut them off and wired them with orange and gray wires (polarity is right, I think) and then soldered the wires back to the frame halves where a decoder's red and black wires will eventually go. I need an N-scale 2 function decoder to put in it. The lighting is identical to Amtrak 346 and can be modified the same way.

The loco had Kadee couplers but they did not work. Both would not center and one needed a knuckle spring. I installed new parts from my stock and hacked up some new covers to fit so that now the couplers work properly.

I test ran this one this morning to measure the slipping current and it started to howl again. I took it apart and found the problem, it needed more oil at both shafts of the worms on both trucks. Now, no howl but the current is a little high, 600 mA running light (with lights) and 1 amp slipping. The clubs MRC332 N scale decoders are rated at 750 mA, they won't do.

The club came up with a Digitrax DZ143 decoder for this loco. It will fit and has the current capacity so I installed it in the same fashion as Amtrak 346. It ran fine.

I did notice one odd thing that may come back to bite us. The right front wheel is 7 mils smaller than the rest of them so that the front truck doesn't sit exactly flat on the track. We'll need to watch this one for derailments. This hasn't been a problem on my layout.

Amtrak 227 got a road test at LAMRS tonight, but it tended to derail the front truck which is the one with the small wheel. We don't have another similar loco to recover parts and getting parts from Bachmann is currently nearly impossible. The club elected to scrap it so I'll pull the decoder and put it in BN 248 in place of the MRC decoder.

I pulled the Z scale decoder for use in BN 248 and rewired the engine to run on DC but I did not reconnect the headlights. The DCC color coded wiring is there, the next owner can figure it out.

After I made an initial pass at the first batch of locos, the club loaded me up with another box full. At that point, I had only triaged most of the first batch.

This one has serious motor problems. It draws 1.5 amps at only 6 volts and increases in current rapidly at increasing voltages. This indicates weak motor magnets. To recover this one, it will require a new motor.

Sometime in the following weeks, the club elected to scrap this one.

This one runs poorly on DC out of the bad order box. It needs more investigation.

Upon opening the loco revealed that it was a straight up Athearn "Classic" loco. I ran it on the bench and the commutator was having difficulties, it was spitting fire. Further, it would go dead short at times. After picking some conductive crud from between the commutator segments, lubricating it with conductive oil and then cleaning off the black crud, it settled down to run well enough. It draws about 300 ma running light with some current spiking. The wheels are pretty throughly pitted but after cleaning, the loco had good power pickup and ran smoothly.

It had been awhile since I last ran this loco and I was looking for something I could make progress on so I rechecked this one. Initially, it seemed to run fine. After a minute or so of running, the current meter on my power pack pegged and the loco intermittently stalled, then picked up again. This shorting continued a few times before I pulled it off the track for inspection. I found that the commutator segments were packed with crud and there COULD be shorting across the segments from one brush to the other. I used a knife blade to break up the bridging between segments and cleaned the commutator. It seemed to be better as I saw no more shorts on the bench. However, a track test indicated that it was NOT fixed. It still shorts out. There appears to be nothing else in the loco that could be shorting, I wiggled whatever was left and there were no shorts.

I looked at the commutator again and the gaps between the segments were packed up again, not as badly, but there was more stuff in there. I cleaned it out again and I apparently turned up some edges on the commutator as the motor drag and noise increased, but it didn't short again.

I don't trust this one so I recommend that it goes to scrap.

WM 81 runs pretty well on DC as received. It needs wheel cleaning and lubrication for further evaluation.

When I got the Life-Like model apart, it looked pretty much the same inside as an Athearn "Classic" loco. However, all was not well. There is a gearing problem in the upper part of the rear gear tower and when it will hang up and stall the whole loco. This one is going to need some mechanical parts, perhaps from another Life-Like loco.

I went ahead and robbed the rear truck from the now dead UP FB1 1642 and put it on the BL2. It was close enough to fit. The stalling in the rear truck is gone now but there may be other minor gearing issues. It does run but not well. The replaced truck has problems too. Further after some run in, the front truck is having difficulties AND the motor tended to short at times. I think that this one is scrap.

This one runs ok on DC out of the bad order box. It is an Athearn "Classic" loco with a mechanism virtually identical to Conrail 8276. The current is a bit high, but not a lot higher than 8276. This one may be privately owned by Danny McKeever. It obviously has seen lots of miles as the wheels are heavily pitted, but it runs ok and appears to have stable power pickup.

I put a System One decoder into this straight up Athearn loco. The first decoder ran for awhile and then failed with melted shrinkwrap. A replacement decoder worked fine although it was hard to get the shell back on without wires dragging on the flywheels. This loco has no lights and I didn't install any. It would be well suited to helper or secondary unit service where lights are not needed.

I cleaned the wheels as best I could. I also found that some of the square bushings that the wheels ride in don't always ride in the metal collars so that sometimes a wheel or two doesn't pick up power. This is a high milage loco but it looks good and runs well enough for Period 3 or Modern service.

I put a club supplied Digitrax DH121 into 4823 but I did not install lights yet. I want to see if the noise level is acceptable to the club.

SP 4823 didn't perform up to expectation at the club tonight so the club elected to scrap it. I'll pull the DH121 and transplant it into another loco that needs road testing.

This is yet another Athearn "Classic" GP-38. The couplers need work. It runs at marginally high current on DC but it is nearly identical to the other two Athearn GP38's. It doesn't make quite as much gear noise as SP 4823.

I test ran this one on DC and while it didn't short like Conrail 8276 it is obviously having commutation issues as there is a lot of sparking at the brushes and the motor is making lots of current transients. It also tends to derail when running in reverse.

This one is going to the scrapper too.

Milwaukee 365 draws about 800 mA on DC even after lubrication. Besides that, it is virtually identical to the other three Athearn GP38's.

Based on the current draw, the club elected to scrap this one.

This one was sold to a member of the public at the swap meet today.

SP 7415 does not run at all and the couplers are mounted about 1/8" too high.

After opening it, I find that a decoder has been hard wired to the 8 pin socket, effectively ruining the socket. There is also a JST 9 pin socket in there. The decoder appears to be a Tsunami. This is probably why it doesn't respond to my programming track.

This is one of three Life-Like locos in this batch (including GN 3022 and a Milwaukee loco without a number) that had DCC installed, probably by the same person because the installations look pretty much the same. None of the locos work in any fashion.

I'll did find my SPROG and reinstalled the software to drive it on my iMac. The SPROG is a decoder programmer that I bought so that I could talk to a Tsunami decoder that is installed in a large scale USAT Speeder. I did get it to work. The Speeder responds. It was also able to see Digitrax decoders installed a couple of HO locos so that I know that my HO programming track works. However, the SPROG does not detect any of the three LAMRS locos with Tsunami-looking decoders in them. Without being able to read back the decoders, I cannot get an idea of what they might be, or what their addresses are. Without knowing what the decoder is, I can't actually reset it either because I don't know what to stuff into CV8.

If worse comes to worse, I can desolder the decoders from the 8 pin socket. I can then find replacement sockets and install those. THEN I can plug in an 8 pin jumper plug to see if the locos will actually run on DC. I can also test the decoders outside the locos, provided that I can find a way to program them, to see if the decoders are actually any good.

The decoders that I thought might have been early Tsunami's were really something much more generic. They were ones supplied by Wangrow as part of their System One. I don't know who manufactured them. The only documentation that I have access to is in this PDF data sheet.

SP 7415 had one of these in it. I thought that the wires had been soldered directly to an 8 pin socket in the loco. It turns out that the 8 pin plug that came with the decoder had been soldered to holes for socket contacts on the loco's PWB. Since the loco acted like a DC loco on the DCC programming track (buzz while trying to read anything) I assume that the decoder is toast, probably shorted motor drivers, and the motor was seeing the programming track more or less directly. I desolderd the plug (it came apart in the process) and used the 9 pin JST jumper plug from Amtrak P42 to plug into the 9 pin JST DCC decoder connector that was installed in the loco. Then the loco ran on DC and it ran quite well, drawing less than 200 mA and making only light noise. I'll test this decoder later. However, for now, it looks like what we want is some cheap 9 pin JST decoder like a DH123 or DH163 and this loco would be good to go after the couplers get mounted properly.

I put a DH121 in this loco and things got a little weird until I figured out that the shell was on backwards. 3 of the 4 GOW headlight bulbs had fallen out too so I reattached the wires to the shell with CA. They will stay in place now.

The loco reacts badly to the low PRF of the DH121 making some serious buzz at low speeds, but it smooths out at higher speeds. This one clearly needs a newer "silent" decoder such as a T4X or a DH163.

This loco was tested at LAMRS tonight and passed. It will get the test decoder pulled and a TCS T4X decoder installed as soon as the new decoders arrive.

This was the easiest upgrade of the bunch. All I had to do was pull off the dynamic break pod, unplug the JST socket from the Digitrax test decoder and plug in the TCS T4X.

Apparently, I never fixed the coupler mounting height and nobody else did either. This loco caused some problems with inadvertent uncoupling during a recent open house and was bad ordered. Dave got some low set couplers for it and I have the couplers, but not the loco. Next time I get to the club I'll recover the loco from where ever it is stashed and replace the couplers to get the mounting height correct.

I think that when I delivered this loco back to LAMRS, I hadn't fixed the coupler height because I didn't have any couplers for it. The ones that were on it were plastic. Somebody had changed them out to Kadee couplers with whiskers but they were still a full half knuckle height too high and this was causing serious unintended uncoupling problems.

Last night, I recovered the loco and installed the Kadee #42 low set couplers on the loco in place of the center set ones that were there. This brought the height right down to where it was supposed to be.

This GE 70 ton switcher sort of runs on DC but it has obvious mechanical problems as some of the wheels are not being driven. The couplers are mounted too high and some of the external detail is not in the best shape.

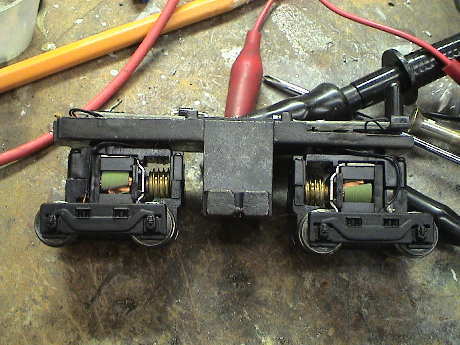

I was a little surprised when I opened this loco. It has a small motor on each truck. Each motor is connected to the pickups within it's own truck. One motor does not run. Further, some wheels on BOTH trucks freewheel. Since this is such an odd puppy and one motor probably has bad brushes, I think that this one is a candidate for the scrap heap.

I was a little surprised when I opened this loco. It has a small motor on each truck. Each motor is connected to the pickups within it's own truck. One motor does not run. Further, some wheels on BOTH trucks freewheel. Since this is such an odd puppy and one motor probably has bad brushes, I think that this one is a candidate for the scrap heap.

The club wanted me to take another crack at fixing this one because it is only one of two lettered and painted for the Great Lakes and Western, the namesake road for the club's railroad. I got some truck parts from another similarly built dead loco to try to use for parts.

GL&W 56 has several problems. One motor does not run, but this is probably due to a bad spring contact between the power pickup contact and the motor. It also has two wheels, one on each truck, that free spin. This photo shows why. The drive gear that separates the half axles is split on both trucks. Bachmann axles gears often fail this way in large scale locos. Over a period of time, the plastic that the gear is molded from shrinks as it outgasses and eventually the hard axle inside splits it. In large scale, this is usually the end of the gear because even if it is glued back together, the teeth won't mesh properly. In this loco, there is quite a bit of slop in the gears so that a slightly wider space between a couple of teeth simply isn't noticed. I dropped some CA into the crack in the hopes that it would find it's way to the axle and bind the axle back to the gear. Once the CA has set, I'll disassemble the truck with the bad motor and try to determine if the motor is bad or it's just the contact. If it's a bad motor, I have two working spares.

The CA patch worked on both the axles BUT the rear truck had other problems. The motor itself was bad, it got replaced. Then the rear truck would stall. After disassembling it again, I found that the other axle gear was cracked and split in such a way as to make the CA patch not practical.

The CA patch worked on both the axles BUT the rear truck had other problems. The motor itself was bad, it got replaced. Then the rear truck would stall. After disassembling it again, I found that the other axle gear was cracked and split in such a way as to make the CA patch not practical.

It was then time to resurrect one of the other spare trucks. One of them was complete except for sideframes and it ran. However, when I went to install it into the loco, it didn't fit. Bachmann had made a change in the mounting configuration and the truck would not rotate. Both the weights and the truck top frames were indeed different between this loco and the one that surrendered the parts. Both trucks would fit the other weight but the other weight wouldn't fit into the shell, the mounting points had moved. I could not just swap the upper truck frames because Bachmann had also moved the fasteners that hold the trucks together so 56's upper truck frame would not fit on the replacement truck. Out came the Dremel tool and I shaved some plastic off the replacement truck's mounting ring until it fit over the pedestal on the 56's weight.

In the process, I had removed both trucks from the loco so I ran each on the HO layout. The replacement truck ran faster but not so much faster that it would be a problem. Both needed lubrication and run in, which they got. However, one of them was running the wrong direction. I guessed that it was the replacement truck because I had had it apart. I disassembled it again and flipped over the motor and then it ran in correct direction with respect to the other one.

Then I had to deal with the sideframes. The replacement truck didn't have any and the ones on the original truck were very firmly fixed to the truck. I just pried it off hoping that the studs that stuck out from the original truck would just break off, which they did. I then drilled out the remainder of the studs by hand to 0.060", the diameter of the mounting studs on the new trucks. They fit but are loose, I'll eventually glue them back on.

I reassembled the loco so that it would run on DC and FINALLY it works. It draws about 200 mA with the headlight on and runs smoothly and quietly enough to actually use. I reattached some handrails and adjusted the couplers. The front one is a tad high, but it is close enough.

DCC conversion will be somewhat involved. The trucks will have to come back off the loco and disassembled again so that the spring contacts to the motors can be cut off. Orange and gray wires will be wired back to the motors and brought up top to reach a decoder. The only space for a decoder is in the cab. An HO sized one won't fit well, this loco should use a Z scale decoder.

The headlights are incandescent and run directly from track voltage so that they can be wired directly to the decoder after the PWB is cut up a little. The are really bright at 10 VDC drawing about 30 mA. A 100Ω resistor would about right to dim them so that they will last.

I got a DZ123 from the club and it was about a big a decoder as would easily fit. I took the trucks apart again and isolated the motors. As much as I tried to keep everything straight, I reversed the orange/gray wires to the rear truck. I also had to improvise a little on the wire routing as the smallest wire I had was too stiff to route along with the power pickup wires without interfering with the truck rotation. In any event, the installation went without major hassle and now the little loco runs on DCC.

Sometime later, the club certified this loco. It is now in service on the Sierra Pacific logging line.

GL&W 56 had been used a lot at the club on the logging line but it had become flakey with power pickup issues. I figured that the contact wipers were not reaching all the way to one or more wheels when they were pushed all the way to the side. This is what I found on FOUR wheels, all on the same side. Further two more are loose in the axle gear and actually spin. This one will require complete disassembly to repin the half axles with CA and to form the contact wipers enough so that they will touch the wheels all the time.

I've been messing with GL&W 56 for a couple of weeks and it isn't responding to treatment. The original problem with poor contact is easy to solve, pull out the wheelsets, bend the wiper a little and reinsert the wheelsets. However, all of the axle gears are cracked and the gears don't hold the wheels tightly. They were sort of glued in place, but getting them to stick again has been a problem. This loco is going to need new axle gears and I doubt that Bachmann has them. I have an email into them to ask, but I don't expect results soon.

This loco may be down for the count. Bachmann does not appear to have parts. I've moved it back to the "in work" status until something changes. In the meantime, I removed the decoder to use it in Shay #11.

GN 3022 may have a decoder installed but it does not run. It also needs coupler work.

After opening it, I found that it was in the same condition as SP 7415. It appears to have a Tsunami installed (speaker leads cut) with the wires directly soldered to the 8 pin socket.

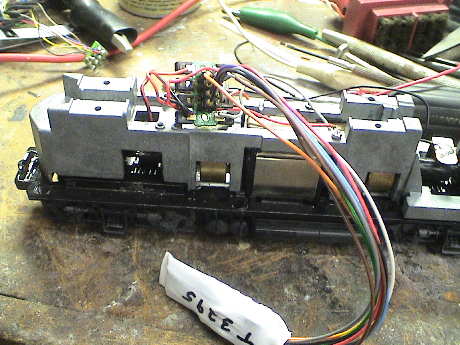

The decoder is a Wangrow Basic decoder and it the 8 pin plug is hard soldered to the PWB. The decoder is marked T3295. The decoder does respond to DecoderPro and I have set up an address of 8922 and enabled analog conversion. After finding and fixing the motor wire that was not connected, the loco started to run. It was well lubricated already and it runs as smoothly and quietly as the 28 speed step, low PWM frequency decoder will allow. The headlights are non-directional. The front headlight is on F0, the rear one on F1. I adjusted the couplers so that this loco is ready to certify.

GN 3022 was tested last week at the club and it ran like the others with a Wangrow decoder, it was not acceptable. The club supplied a Digitrax DH121 and I installed it. This loco had a 9 pin JST plug so I desolderd the plug that was on the Wangrow from the PWB to make some room and plugged the DH121 in. It ran fine right off.

This loco passed muster during testing tonight. It is waiting for an upgraded decoder.

GN 3022 got it's decoder changed out. This was a very easy swap. I pulled off the dynamic brake assembly and the old decoder was accessible. I pulled the DH121 and plugged in a DH163D. A quick check on the programming track and an adjustment to the address was all it needed. It runs fine.

This U23 has a decoder in it of unknown make. It presents a 4 digit address but it does not run. The decoder is the same as the ones in SP 7415 and GN 3022.

I am slowly prying open the Wangrow decoders in these locos. I got this one to respond on the programming track and used DecoderPro to download it's contents assuming that it was a Wangrow Basic decoder. It reports 0 in CV7 and CV8 so DecoderPro cannot determine what the decoder is until I tell it what it is. The loco was set to respond on analog so I put on DC powered truck and slid it on the track and it started to do something. The mechanism was bound up but eventually freed itself and it started to run fairly smoothly drawing about 400 mA. DecoderPro indicated that it had a 4 digit address of 8900 enabled so I dialed that up in 28 speed step mode and it actually ran. The headlight is not directional and there is no rear headlight. I adjusted the couplers but the rear one doesn't center every time, it needs a new spring and I haven't got a loose one.

The Wangrow got tossed, a Digitrax DH121 went in. The loco is good to go.

This loco was tested at LAMRS tonight and passed. It will get the test decoder pulled and a TCS T4X decoder installed as soon as the new decoders arrive.

This one had a DH121 in it so I just plugged in a T4X. There was no rear headlight. The club gave me a couple of bags of 14V GOW bulbs so i added one. I also removed the long shank couplers and substituted regular whisker ones. The long ones can go somewhere else where they are needed.

I got this one back, this time with a road number of 5502. All that I could find wrong was that a cut lever had come off. I reattached it with CA.

The wheels on this one just wore out and started collecting dirt like crazy. It got a new set of Kato wheels.

Amtrak 809 is a P42 that is in pretty good shape. It isn't marked but it appears to be a Life-Like product. It runs on DC and is a little noisy before lubrication, however it doesn't draw a lot of current, about 200 mA. The couplers will need some work. It has a JST socket with a jumper plug installed so that DCC conversion MIGHT be easy. I've not done one with a JST socket so I'm going to do a little wire tracing before I just plug one in.

I lubed the loco and the noise faded some to about the level of the wheels noise. I pulled the JST jumper plug and plugged in a test DH123 and it ran quite well. The plug is out right now as I am using it to test some other locos but it could go back in there easily. I adjusted the couplers. With the addition of a DH123 or DH163 or some sound equipped 9 pin JST decoder, this loco would be good to go.

Eventually, I pulled the DH163 from UP 1614b and replaced it with a Wangrow decoder because the FA, UP x1614, is going to get one of those also. The DH163 is a 9 pin JST decoder and plugged right into Amtrak 809. The Wangrow decoders have 8 pin plugs and plug into the UP units.

Amtrak 809 is done and ready to certify.

Amtrak 809 did get certified. I pulled it down from the cabinet because one of the other club members said it didn't run well. It didn't. It had obvious power pickup issues and when it ran, it ran sluggishly, not making speed.

The speed problem was due to commutator issues. It was sparking at the brushes pretty badly. I put a very small amount of AeroCar conductive oil on the commutator and it started to run better, but there black crud all over the commutator. Extended light abrasion with the end of a wooden toothpick rubbed most the black stuff off and the motor started to run smoothly with no visible sparking.

Then a track test indicated that the power pickup was bad too. An alcohol clean helped that a lot but there was still obvious crud on the wheels. I faced them lightly with a Bright Boy while running the engine with a Kadee brush and shined up the wheel treads. This helped more and the headlight flicker went away.

It'll go back to the club, but I'm going to keep a close eye on this one.

I tried to run 809 at the club last night and it had a problem. It would uncouple from the following car and when running in reverse, the rear coupler was so loose that the trip pin would hang up on the ties. I don't think that I left the couplers in that state, very badly mounted with an entirely wrong coupler box. In any event, I replaced the partial box in the rear with a Kadee #5 box, cleaned the wheels and the loco is good to go.

SP 5669 is an SD9 which appears to be manufactured by Athearn. The engine runs with a moderate amount of noise before lubrication. The couplers are very high and will need some significant remounting work. It does not like 18" radius track very much.

I took SP 5669 apart for inspection and I found that it had been remotored with a good can motor. Most of the noise was coming from a contact tower on one truck rubbing against a U-joint, an easy fix. After lubrication and a little run in to spread the stuff around, it ran pretty well. It now runs on 18" curves, but it picks the points on some Atlas Snap switches.

I installed a Wangrow decoder. I now believe that these are probably a DH-155. This particular decoder is one I cut out of another loco as it just did not seem to operate. However, after learning more about these things, I was able to coerce it into working.

This loco has NO lights, nor any provision for them. There isn't even a hole in the shell for any light to shine out. If somebody wants to light this loco, they'll have to remove the lenses from the outside, drill some light passages and reinstall the lenses.

In any event, the decoder worked. It will read back on a SPROG programming track but not a DCS100 programming track. The loco is ready to return to LAMRS.

I tested the "Cadillac" at LAMRS last night. I apparently installed the shell backwards as it ran in reverse, but it ran well except that it picked the points of a turnout at Edison a couple of times. It is also intolerant of some of the tighter curves on my own layout.

It has no lights so I could not see if it had the same problem as 2790, but I could hear the motor cutting out on my own layout. A commutation problem would not cut out for so long so I suspect that the decoder is doing something odd. This one could use a better decoder and some lights. The shell was never drilled for lighting so the headlight lenses would have to be removed or drilled out.

I elected to upgrade the headlights on this one in preparation for a new decoder. Lloyd has some DH121's that will do ok for testing, much better than the Wangrow ones. When I get some of those, I'll cut out the Wangrow and install the DH121. If we elect to upgrade past that, a DH163 or T4X will plug right in.

The headlights were very small blobs of plastic with a metalized back that were glued into the headlight housings. There were 4 on each end. I popped the two on the upper housing out and drilled a 5/64" hole behind each one. Then I mounted a 5 mm white LED inside the shell so that it would shine out the resulting holes. This actually makes an acceptable headlight. The LED current is set with a 1KΩ resistor at each end so that the LEDs should run at 9 or 10 mA.

The club provided a Digitrax DH121 decoder to install in this loco for further testing as the Wangrow decoder was just not cutting it. The DH121 is a 28 step decoder with a low motor switching speed and no BEMF. However, it appears to work quite well and it works with 128 step commands.

The loco ran quite well with this decoder in it. It is ready to test again on the layout. If it runs well enough, it could possibly keep the decoder.

The headlight installation worked quite well. I also repaired some broken handrails and rebuilt a section that was missing from 25 mil music wire for the uprights and 15 mil phosphor bronze wire for the handrail proper.

This loco was tested at LAMRS tonight and passed. It will get the test decoder pulled and a TCS T4X decoder installed as soon as the new decoders arrive.

The decoder swap to a TCS T4X was uneventful, the loco runs fine.

SP 5015 is a PB1 dummy unit. It is missing one coupler and the other one is poorly mounted. It doesn't roll all that freely and it doesn't like 18" curves at all.

5015 got a new coupler, centering spring and cover. The other coupler got adjusted.

At the meeting tonight, the club determined that they didn't need this dummy, it goes to scrap.

SLSW 300 is an Athearn PA1 that has probably been remotored. It is fairly noisy on DC but it draws only about 200 mA. It also does not like 18" radius curves.

This one had been remotored and after some lubrication, run in and adjustment of the contact stands, it runs well. It got a Wangrow decoder, there is plenty of room for it. The unit had a 1.5 volt 80 mA GOW bulb. I retained that and used a 240Ω current limiting resistor wired to F0. It got a new coupler spring in the front.

I tested this one at the club last night and I had to pull it off the track. It was too intermittent, it would intermittently sit there with the lights burning and no movement. When I retested it this morning, I could not reproduce that behavior. It had flakey power pickup until I cleaned the wheels, but the motor would still cut out while it was running, I could hear the buzz drop out and my track current meter was bouncing. This time, however, the headlights were flickering so the dropouts could be just power pickup issues.

This loco has talgo mounted couplers with the metal clip on covers, both are not acceptable to LARMS. This one may meet a grim fate. It's semi-matching B unit (SP 6146) and a dummy B unit (SP 5915) may meet a similar fate.

The club elected to dispose of this loco primarily because of the coupler situation and that it really isn't needed.

SP 6146 is an Athearn PB1. It has been remotored and draws about 200 mA. It is fairly noisy before lubrication. Like the other C-C locos, it does not like 18" radius track.

This one needed the motor glued back down as it was flopping around loose. It also got a Wangrow decoder. It needed a new coupler, centering spring and cover on one end and a new centering spring on the other end.

The club elected to abandon this loco as it was not needed.

SP 3343 is a Fairbanks-Morris HW-24-66 Trainmaster. It is probably a Life-Like unit. It has been remotored, draws about 200 mA and makes a lot of noise before lubrication. This loco has the plastic coupler retainer clips that tend to fall off. It also doesn't like 18" radius curves.

SP 3343 had been remotored with a can motor and it actually ran pretty well after I reattached the motor which was just flopping around loose. It had what appeared to be 1.5 volt GOW bulbs in it, but none of them worked. There was some sort of regulator installed to control the bulb voltage, but it was clearly damaged too. All that stuff got hacked out.

The unit ran pretty well on the bench but every time I put it on the track it shorted out. Eventually, I let the short circuit current rise high enough, above 2 amps, so that I hoped to see some arcing at the location of the problem. There was some arcing and smoking on the top of one of the trucks. The steel contact that rises above the drive shafts was very close to a metal plate on the top of the truck connected to the other side. The pieces were a little loose and when the weight of the loco was on the wheels, they tended to move together and short. A small piece of styrene was glued into each truck to keep those pieces apart and the shorting went away.

The headlights were replaced with 3 mm warm white LEDs fed through 560Ω resistors. The LEDs were glued to the roof of the shell and generally pointed at the main headlight lens with some spill over to the 2nd headlight.

The couplers were mounted in the plastic clip covers that never stay on, one was missing a knuckle spring and both centering springs were bad. I drilled out the coupler pad for a #2-56 screw on both ends and installed Kadee #5 boxes, then replaced the bad springs.

I essentially got the whole thing together, THEN I realized why the shell never fit quite right. The damn thing was on backwards when I got it. I had to turn the shell around, which was straightforward, but the decoder would not recognize the NDOT (normal direction of travel) bit in CV29 and I had to reverse the motor wires too. Further, I had difficulty getting it together and keeping the decoder from rubbing on a flywheel so I had to build a little stand made of styrene to prop the end of the decoder up. The decoder is fastened to that frame with a piece of double backed foam mounting tape. It just barely fits. This puppy is done.

I essentially got the whole thing together, THEN I realized why the shell never fit quite right. The damn thing was on backwards when I got it. I had to turn the shell around, which was straightforward, but the decoder would not recognize the NDOT (normal direction of travel) bit in CV29 and I had to reverse the motor wires too. Further, I had difficulty getting it together and keeping the decoder from rubbing on a flywheel so I had to build a little stand made of styrene to prop the end of the decoder up. The decoder is fastened to that frame with a piece of double backed foam mounting tape. It just barely fits. This puppy is done.

I also tested the Trainmaster at the club last night and it behaved similarly to the other locos, it had very intermittent operation. However, I was able to see what is happening in this case. The decoder has poor restart response when power drops for a very short time and is restored. This loco has 12 working wheels which had been cleaned. The track is clean, it should have good pickup. It seems the decoder's firmware is just not up to the task.

I did substitute the Wangrow decoder with a DH123 from my stock. I didn't have a normal JST harness for it so I used a function harness from a DG583S. It is the same connector with the same function wire colors, but the motor and track wires are different from the standard. It went in fine and all the weirdness simply vanished. This loco is waiting a retest at LAMRS.

I tested this one at the club and it ran fine, MUCH better than it did with the Wangrow decoder. It will wait for a good club decoder, preferably with BEMF.

This loco was tested at LAMRS tonight and passed. It will get the test decoder pulled and a TCS T4X decoder installed as soon as the new decoders arrive.

I didn't put a T4X decoder in this one as I used them elsewhere. I did change out my DH123 that was in it to a DH121 club decoder. The loco buzzes some now but it makes less noise than some other locos with the low frequency decoders in them. It could use a better decoder but this one may be good enough.

While I had done some more testing at the club while the track had not been recently cleaned and I noticed that this loco tended to sputter and stall at spots where other locos had only minor difficulties. It needed some more work.

I brought it home again with the intent of changing out the wheelsets for some that were in better condition. I didn't do that because this loco has different wheelsets that most others. This guy doesn't use the axle bushings for power pickup, but instead it has metal sideframes and uses brass bushings in the sideframes. I also discovered that the forward right wheel on the rear truck wasn't providing power pickup at all. After some poking around with an ohmmeter, I found that the actual bushing wasn't making contact to the frame that it was pressed in to. I managed to actually rotate the bushing just a little with a screwdriver and scrub it in a little and it started to work.

The wheels themselves were covered with a gray haze that did not come off in an alcohol clean. I assume that this was either a micropit haze or some adherent oxide coating. I gently abraded it off each wheel with a Bright Boy. As each wheel turned, I could feel the wheel tugging on the Bright Boy for a few turns until the surface smoothed out and the tugging stopped. Then the loco ran without the headlight flickering. We'll see how it does in regular service.

SP 3343 got a new decoder. It was an easy matter to pop off the shell, unplug the test DH121 and plug in a DH163. The loco ran fine right off the bat.

I ran 3343 at the club last night for a long time. At the end of the evening, it was showing evidence of dirty wheels. I brought it home and found the wheels packed with hard non-conductive crud. I abrasively cleaned and polished the wheels. We'll see how it holds up.

GE demonstrator 808 was one of three locos I picked up at the club that had been converted by somebody else with a club supplied Wangrow decoder. These locos could not be read on the club's programming track so I brought them home for test.

This one ran well enough and it would respond to the SPROG for programming. I programmed a club standard address of 8908 for this loco and it appears good to go.

Since the club is scrapping the Wangrow decoders, this one never got road tested. I pulled it back to wait for a new TCS decoder.

The club had 3 TCS drop in decoders in stock. One fit this loco so I installed it. It ran fine.

GE 808 was certified and ran well for quite a while, then it started to run slowly. A quick bench test at the club indicated a mechanical issue with something dragging inside. I took it home and track tested it, it still made dragging noises. I removed the shell and did a visual inspection for dragging wires, none found. Then I rotated a flywheel a little and one of the push on clips on the drop in decoder for the rear headlight wire fell out. It did not fit back on properly. I soldered the wire in place and track tested it again, problem gone. The wire clip had fallen off and jammed under the rear flywheel. Those little plastic caps often don't fit properly on a replacement drop in decoder, on a couple of installs I had to solder every wire. Anyway, this one goes back to the club next week.

BNSF 8630 is a little puzzling. It responds to the SPROG programming track in the expected fashion but it does not run. Occasionally, it would just run away on the programming track which means that it is trying to analog convert even though analog conversion shows to be off. I suspect a bad decoder in this one.

I put another Wangrow decoder in this loco and it still would not run although it acted like it was working on the SPROG programming track. I put in a jumper plug and the loco ran on DC. I plugged in a Bachmann EZ-Command decoder and it worked. I plugged in a DH123 and it worked. I put the new Wangrow decoder back in and it doesn't work. The Wangrow decoder does work on my test rig. The original Wangrow decoder does NOT work in the test rig. There is something about this loco that the Wangrow decoder does not like.

It is waiting for a new decoder.

I put a TCS T4X in this Atlas loco and it ran fine. The TCS decoder has very good BEMF.

This one came back with a minor cosmetic problem. A chain that connects the front truck to the frame broke off. I glued it back in place and the loco was fine.

The loco has apparently seen some miles since it was converted to DCC about 20 months ago. The wheels are showing signs of wear. They aren't completely worn out yet and they still work but it will need new wheels sometime in the future.

BN 9615 also has a Wangrow decoder and runs well. The loco has some physical damage. It had been dropped. The front coupler is broken, one cab visor is missing and some handrails need a little attention.

I reinstalled the loose handrails and replaced the front coupler and spring. I found the visor and reattached it. Now it is good to go.

Since the club is scrapping the Wangrow decoders, this one never got road tested. I pulled it back to wait for a new TCS decoder.

This loco takes an 8 pin medium plug, but the decoders were delivered with wires. I spliced on the plug from a dead Wangrow and plugged it in, no problems.

It's been nearly 3 years since I last saw this loco. It came back because it was making dry bearing noises. I heard it run that way at the club. Of course, when I took it apart, there was no bearing noise. I lubed all 6 high speed bearings and applied some grease to the worms. It seems fine. It'll go back to the club for more testing.

After all of the first batch and most of the second batch were complete, I picked up two more boxes of locos, 18 in total. We are getting to the bottom of the barrel here and many of these, especially the steamers, are pretty sad. These are listed here in more or less the order that I initially evaluated them.

This is almost a new loco, but it runs badly. It makes very loud gear noise from the front truck. I haven't had it apart yet to figure out what the trouble is, but this will be the first one to work on when I get to it. Otherwise, it's in excellent condition.

After I got into it, I found the problem. The wire clearance under the cab is very tight and the headlight and ditch light wiring gets pinched and pressed down into the front universal joint. When the time comes to put a decoder into this loco, I am going to attach the wires to the shell with CA to keep them where they belong. With the wires out of the way, it runs fine.

This loco can take a multifunction decoder such as a TX4 or DH163 via a 9 pin JST connector.

The headlight wires that were fouling the front U-joint have been glued to the cab floor, that's fixed. The handrails refused to stay on so they have been reattached with very small dabs of CA. This one just needs a decoder and it's ready to go. However, it does not run on 18" radius track, it will derail every time.

This one was simple, it already had a JST plug so I just pulled the jumper plug and plugged in the TCS T4X decoder. It is ready to go.