Aristo Power Brick Tune-up

[ Home ] [ Up ] [ Previous

Page ] [ Next Page ]

All the pre-1999 Aristo

diesel products use the same truck assembly which is modeled after

an AAR type B truck that was often used on Alco and early GE

equipment. The information on this page applies equally well to the

U-25B, FA-1, FB-1 and RS-3 manufactured roughly through the end of

1998.

All the pre-1999 Aristo

diesel products use the same truck assembly which is modeled after

an AAR type B truck that was often used on Alco and early GE

equipment. The information on this page applies equally well to the

U-25B, FA-1, FB-1 and RS-3 manufactured roughly through the end of

1998.

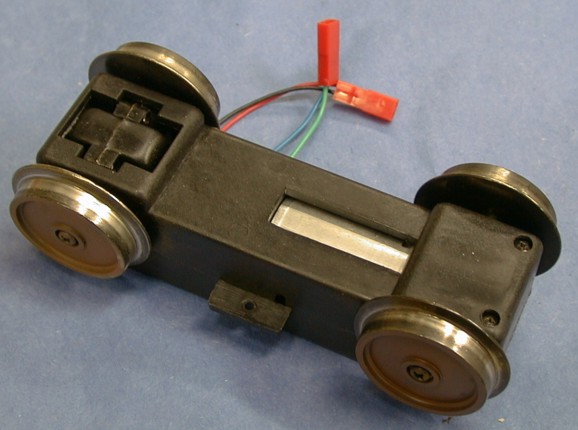

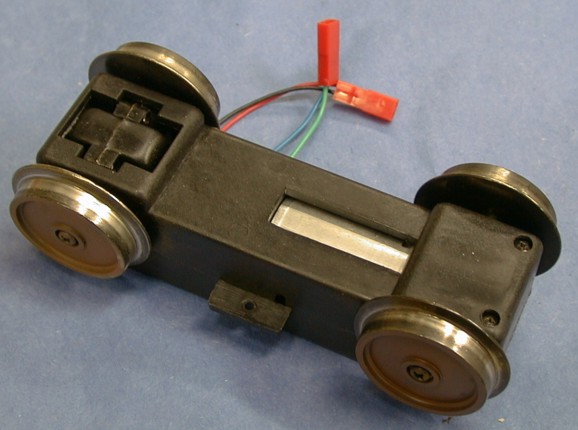

This brick was from one of the latest locos made with the

non-ball bearing brick, a 2nd generation RS-3. There is only one

connector on the brick itself, a blue/green pair for the motor

only. Power was conducted to the frame from wires connected to the

sideframes. The motors on this version used a 3 pin connector that

plugged into the bottom of the frame. The power (usually a

black/white pair) used a similar 2 pin connector that also plugs

into the frame.

One version older bricks (usually black box locos) used red

in-line connectors for both the motor and power. The motor wires

were still blue/green but the power wires could either be black/red

or black/white. These then plugged into a 4 pin connector on the

board inside the loco.

Even older versions (mostly blue box) didn't have the red

in-line connectors. The wiring harness from the brick and

sideframes went directly to a 4 pin connector inside the loco.

The main spotting

features of the old brick are the axle extensions at each wheel.

This is a late version of the "old" brick taken off an RS-3. The

even older versions have lash screws at each end of the brick to

set the axle play as discussed below. Even older versions don't

have the plastic hub on the wheels.

The main spotting

features of the old brick are the axle extensions at each wheel.

This is a late version of the "old" brick taken off an RS-3. The

even older versions have lash screws at each end of the brick to

set the axle play as discussed below. Even older versions don't

have the plastic hub on the wheels.

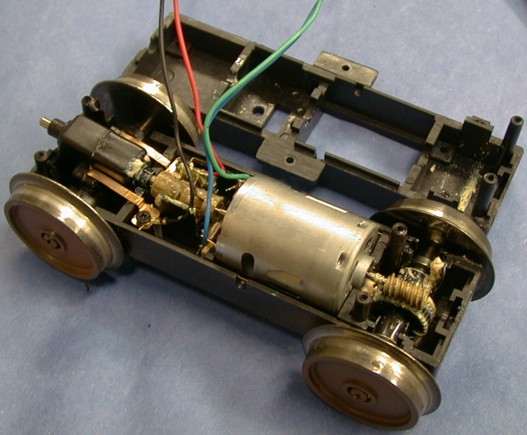

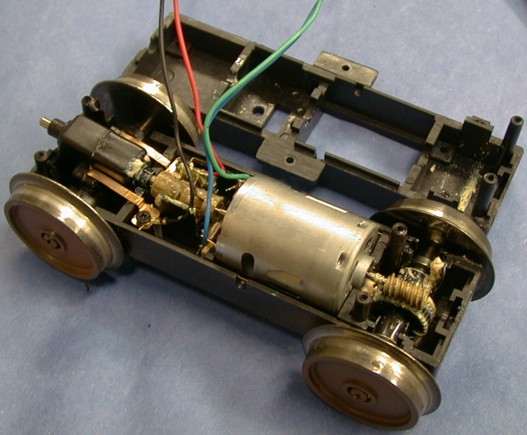

The axle ends fit into brass bushings on the truck sideframes.

The engine is actually suspended from these axles and bushings via

the sideframes and some springs. The axles are also used for power

pickup via the bushings and some wires connected to brass straps on

the sideframes that contact these bushings.

The older bricks may have a brass or plastic universal joint. Be

careful when you take it out, sometimes the metal rods in the

universal fall out.

As of 1999 a new design

appeared that is significantly different. The new design has ball

bearings and the axles do not extend to the sideframes. The wheels

are held on with screws at the center of each wheel. This page is

relevant only to the older design.

As of 1999 a new design

appeared that is significantly different. The new design has ball

bearings and the axles do not extend to the sideframes. The wheels

are held on with screws at the center of each wheel. This page is

relevant only to the older design.

The newer bricks pick up power via the ball bearings inside the

trucks. The engine is suspended via the tabs on the sides of the

bricks and the sideframes are for decoration only.

This brick is taken from a Doodlebug that does not have frame

mounted connectors. There are pigtails hanging out from the bottom

of the Doodlebug to make contact with the red connectors. The

connectors are keyed backwards so that it is not possible to

mis-connect them.

Newer locos with a distribution board and DCC socket inside

usually have the 2 and 3 pin connectors facing downward from the

frame to connect the bricks.

The new

brick differs significantly inside too. This brick has ball

bearings at each wheel and power is picked up through the bearings.

Therefore, there are power contact straps inside and an extra pair

of wires leading from each brick. The motors have a noise

suppression capacitor already installed. This brick doesn't seem to

suffer the same binding issues as the older one so the notes below

have little importance for this design.

The new

brick differs significantly inside too. This brick has ball

bearings at each wheel and power is picked up through the bearings.

Therefore, there are power contact straps inside and an extra pair

of wires leading from each brick. The motors have a noise

suppression capacitor already installed. This brick doesn't seem to

suffer the same binding issues as the older one so the notes below

have little importance for this design.

If you have

a U-25B, FA-1, FB-1 or RS-3 with the older bricks and one or both

are too far gone for remedial work, you can get a replacement ball

bearing brick that will fit your loco. These also fit the RDC and Doodlebug. The ART-29351 is a

brick/sideframe assembly with wiring harness that fit both the

older and newer types of locos. If you loco is really old, it MAY

require some wire splicing but the brick will still fit.

If you have

a U-25B, FA-1, FB-1 or RS-3 with the older bricks and one or both

are too far gone for remedial work, you can get a replacement ball

bearing brick that will fit your loco. These also fit the RDC and Doodlebug. The ART-29351 is a

brick/sideframe assembly with wiring harness that fit both the

older and newer types of locos. If you loco is really old, it MAY

require some wire splicing but the brick will still fit.

These bricks run at the same speed as the older ones so they

don't have to be changed out in pairs. A single assembly as shown

in the photo can be found for about $50 at various online

retailers.

I have this one wired to test as an individual brick. My

intention is to use it to replace the brick under a Bachmann

trolly.

Most Aristo diesels are smooth running engines, but there are

some that are unsteady at low speeds. This is caused by the motor,

which are inside each truck, running at different speeds due to

changes in loads on that brick. One brick wants to run faster than

the other and they fight each other. This does not have to happen

and with a little work, gear grease, heavy gear oil and a few

scraps of thin styrene, EVERY brick can be made to

run very well.

A major problem with some bricks is that the brick case halves

pinch the motor bearings adding unnecessary drag. This can be

prevented by shimming the case halves apart with the aforementioned

styrene scraps, although any small piece of shim material about 20

mils (0.5 mm) thick will do.

Sometimes an Aristo brick will develop a loud squeak. This is

usually caused by a dry joint between a motor shaft and a lash

screw. You should lubricate the brick, but to temporarily solve the

problem, try to determine which truck the squeak is coming from and

turn the lash screw furthest from the rocking gearbox

counterclockwise about 10 degrees. If this doesn't do it, try the

other lash screw.

There is a universal joint inside each brick. Sometimes this

joint comes loose and slips on either the motor shaft or a gearbox

shaft. There were two types of universals used in various

production runs, a metal one and a plastic one. The metal one is

the most likely to slip. Slippage is indicated if the axle in the

rocking gearbox does not turn at all. The universal has two very

small setscrews on it, one or both of them often tends to loosen.

These screws are so small that it is easy to damage them. Before

you go in there and gouge up a setscrew, find a jewelers

screwdriver that fits the full length of the screw slot and is

thick enough to just fill the slot. If you use the wrong

screwdriver, you'll likely damage the screw requiring a replacement

IF you can get the old damaged screw back out.

To do internal work, you'll need to have some lubricants handy.

You can get away with just three types.

General oiling can be done with LGB 50019 Special oil

which works very well for all light oiling applications such as

shaft bearings and bushings.

Gear lubrication requires a heavy gear oil or grease such

as LGB 51020 gear grease or HobeLube HL655 gear oil.

Electrical contact lubrication requires a conductive

lubricant. There are several types available from Bachmann,

AristoCraft and others.

Whatever lubricants that you use MUST be

plastic compatible. Many general lubricants, like 3-in-1 oil, will

eventually attack plastic.

Before you tear into the bricks test your loco to see if you

actually should do anything.

- Testing

- Connect your loco to a power pack which has very

good low voltage control. A Bachmann pack will not do. Nor will a

Train Engineer because the slowest speed step is just a little too

high. A conventional pack like an MRC pack will do fine. The

easiest way to connect power to the engine for testing is to use

two clip leads and clip to the lugs on the inside of the side

frames. Do this with the engine on its side or cradled upside

down.

- Run the engine at very low speed. If all is well,

both trucks will start at the same time and run very slowly without

stalling. If you can run the wheels at 10 RPM (one wheel turn in 6

seconds) or less, you can stop because it doesn't get any better.

If the trucks won't run that slow or run at different speeds, or if

you just want to do some preventive maintenance, then proceed.

- Brick Removal

- Remove ONE brick from the engine. Depending on

the model and the vintage, you may have to remove the shell to

unplug the wires. If you can pull enough wire out of the body so

that you can work with the brick, then you don't have to remove the

shell either.

- Remove the side frames by removing three screws

from each side frame. If the engine is a 1997 model, be careful

when removing the side frames as there is a spring and contact in

each axle bushing. Note the power pickup wire that fits under one

of the top screws. You'll have to get this wire back in the right

place when you reinstall the brick.

- Remove only one brick at a time. You'll want the

other one in place to give you a clue as to how to reinstall the

brick. Note that the bricks are apparently reversed from each other

(the motors and gearboxes are on different ends)

AND that the wires leading to the lugs which

contact the brass contract strip on the back of the side frames are

apparently reversed as well. This is the way it is supposed to

be.

- Pull the brick out a little ways. If a set of

connectors comes out of the hole in the body or more than 6" of

wire comes out, you're in luck, you don't have to remove the shell.

If not, take off the shell so that you can disconnect the brick

from the loco.

- Brick Disassembly

- On each brick case, there should be six screws and two more

holes for two screws that are not used. Remove the screws.

Carefully separate the case halves. The motor and the axle in the

rocking gearbox should remain in the piece that has the wires

coming out from it. The axle nearest the motor should remain with

the other case half.

- Motor and Universal Joint Lubrication

- Lubricate the motor bearings with a small amount

of medium weight oil.

- Lubricate the commutator (visible through holes

in the motor can on some motors) with a VERY SMALL

amount of light conductive oil.

- Lubricate the worm on the end of the motor with

heavy gear grease or heavy gear oil.

- Lubricate the universal joint with heavy gear

oil.

- Gearbox Lubrication

- Gently remove and disassemble the gearbox and

lubricate the worm inside and the axle and drive shaft bushings

with heavy gear grease or heavy gear oil. If your brick has a metal

universal joint, be sure not to lose either of the two pins in the

universal. Some units have plastic universals that do not have

metal pins.

- Lubricate the shaft end with a small drop of

heavy gear oil.

- Reassemble the gearbox.

- Gearbox Lash Adjustment

- Adjust the gearbox lash by rotating the input shaft and

tightening on the lash adjustment screw on the end of the gearbox.

Tighten until you feel some drag and then back off just enough so

that the drag goes away. It may be necessary to further loosen the

lash screw in the next step.

- Reinstall the gearbox and the universal joint. Rock the wheel

to see if there is any lash in the universal joint. There should be

just a little. If not, loosen the lash screw further until you can

JUST start to see the universal lash just a

little.

- Intermediate Testing

- Connect the brick in its partially disassembled state back to

the engine and run it. The one wheelset installed should run

REALLY slowly and smoothly. If not, take the

gearbox back out and try to run the motor alone. If it won't run

slow, then the motor may be bad. Due to the magnetic detenting in

the motor, it may seem a little jerky even if it is in good

condition but it should run steadily. The motor by itself won't run

slower than several revolutions per second.

- If you ever want to install radio remote control, you might

want to solder a 0.1 micro farad capacitor across the motor

terminals at this point. If you are going to install DCC, do not

install this capacitor.

- Lubrication of the 2nd Axle

- Lubricate the second set of axle bushings with heavy gear oil

or grease.

- Lubricate the worm gear with a small drop of heavy gear oil or

gear grease.

- Lubricate the end of the shaft with a small drop of heavy gear

oil.

- Final Adjustments

- Reassemble the brick but don't put in the screws. Try running

it again. It should still run real slow. If not, something is

binding. Find the problem and fix it.

- Now install all six screws and tighten them one at a time while

the brick is running slowly. You may find that tightening one or

more of the screws (most likely the center ones) causes the brick

to bind. If you find that the brick doesn't run as well as it did

when it was apart then loosen all 6 screw about one turn and pull

the case halves apart as far as you can. Low speed operation is

probably restored.

- Here is where you will need the shims. Place a shim on each

side of the motor between the case halves, right next to the center

screws and tighten them again. If all is well, the brick still runs

smoothly. Tighten the end screws and check again. If low speed

operation is lost, then another shim between the case halves is

needed. Tighten the screws one at a time to find where the binding

is and shim near that screw.

- When the brick is properly shimmed, tighten the other lash

screw (the one away from the gearbox) with the brick running slowly

until the speed decreases then back it off until it doesn't affect

slow speed performance.

- Brick reinstallation on the Loco

- After the brick is running right, reinstall it. Note that the

orientation of the brick and the power pickup wires are opposite

the other brick.

- Be sure you get the lugs on the wires still hanging out of the

engine under two of the side frame mounting screws so that they

touch the brass strip on the back of the side frame.

- If your side frames have springs and contacts in the bushings,

be sure to reinstall them. Its a little harder to get the newer

side frames back on, but it can be done with a little

practice.

- Place a small drop of conductive oil on each axle bushing where

the axle extends into the sideframe.

Do the same to the other brick if it needs it.

When you are all done, the engine should run with no hint of

hesitation or jerky operation.

[ Home ] [ Up ] [ Previous

Page ] [ Next Page ]

This page has been accessed  times since 17 Dec 1997.

times since 17 Dec 1997.

© 1997-2009 George Schreyer

Created before Sep 18, 1997

Last Updated May 23, 2009

All the pre-1999 Aristo

diesel products use the same truck assembly which is modeled after

an AAR type B truck that was often used on Alco and early GE

equipment. The information on this page applies equally well to the

U-25B, FA-1, FB-1 and RS-3 manufactured roughly through the end of

1998.

All the pre-1999 Aristo

diesel products use the same truck assembly which is modeled after

an AAR type B truck that was often used on Alco and early GE

equipment. The information on this page applies equally well to the

U-25B, FA-1, FB-1 and RS-3 manufactured roughly through the end of

1998. The main spotting

features of the old brick are the axle extensions at each wheel.

This is a late version of the "old" brick taken off an RS-3. The

even older versions have lash screws at each end of the brick to

set the axle play as discussed below. Even older versions don't

have the plastic hub on the wheels.

The main spotting

features of the old brick are the axle extensions at each wheel.

This is a late version of the "old" brick taken off an RS-3. The

even older versions have lash screws at each end of the brick to

set the axle play as discussed below. Even older versions don't

have the plastic hub on the wheels. As of 1999 a new design

appeared that is significantly different. The new design has ball

bearings and the axles do not extend to the sideframes. The wheels

are held on with screws at the center of each wheel. This page is

relevant only to the older design.

As of 1999 a new design

appeared that is significantly different. The new design has ball

bearings and the axles do not extend to the sideframes. The wheels

are held on with screws at the center of each wheel. This page is

relevant only to the older design. The new

brick differs significantly inside too. This brick has ball

bearings at each wheel and power is picked up through the bearings.

Therefore, there are power contact straps inside and an extra pair

of wires leading from each brick. The motors have a noise

suppression capacitor already installed. This brick doesn't seem to

suffer the same binding issues as the older one so the notes below

have little importance for this design.

The new

brick differs significantly inside too. This brick has ball

bearings at each wheel and power is picked up through the bearings.

Therefore, there are power contact straps inside and an extra pair

of wires leading from each brick. The motors have a noise

suppression capacitor already installed. This brick doesn't seem to

suffer the same binding issues as the older one so the notes below

have little importance for this design. If you have

a U-25B, FA-1, FB-1 or RS-3 with the older bricks and one or both

are too far gone for remedial work, you can get a replacement ball

bearing brick that will fit your loco. These also fit the RDC and Doodlebug. The ART-29351 is a

brick/sideframe assembly with wiring harness that fit both the

older and newer types of locos. If you loco is really old, it MAY

require some wire splicing but the brick will still fit.

If you have

a U-25B, FA-1, FB-1 or RS-3 with the older bricks and one or both

are too far gone for remedial work, you can get a replacement ball

bearing brick that will fit your loco. These also fit the RDC and Doodlebug. The ART-29351 is a

brick/sideframe assembly with wiring harness that fit both the

older and newer types of locos. If you loco is really old, it MAY

require some wire splicing but the brick will still fit.