31 May 10

31 May 10[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

31 May 10

31 May 10 A USA Trains Speeder followed

me home from the Big Train Show this afternoon. I managed to get it

on the track for a little testing before actually packing to go on

travel for about 8 weeks. It ran pretty well. The track hadn't been

cleaned in a month and was pretty heavily oxidized but it ran. It

sputtered, but it ran. I ran the pole sander over the main line and

then it ran just fine. I also ran it in analog mode with DCC on the

track and besides for the typical DCC buzz in an analog loco, it

also ran fine. There is a light amount of gear noise but it runs

quite smoothly.

A USA Trains Speeder followed

me home from the Big Train Show this afternoon. I managed to get it

on the track for a little testing before actually packing to go on

travel for about 8 weeks. It ran pretty well. The track hadn't been

cleaned in a month and was pretty heavily oxidized but it ran. It

sputtered, but it ran. I ran the pole sander over the main line and

then it ran just fine. I also ran it in analog mode with DCC on the

track and besides for the typical DCC buzz in an analog loco, it

also ran fine. There is a light amount of gear noise but it runs

quite smoothly.

The speeder is not feature heavy. All it has is a motor and a non-directional headlight. There are no conventional couplers, but there is a drawbar of sorts at the rear.

It tracks well and power pickup is reliable as long as the wheel wipers don't get bent. However, the speeder is small and light so it is intolerant of debris on the track. Hit a leaf or twig and it'll derail immediately.

The speeder picks up power on

four wheels, but only the rear two are powered, similarly to the

Lionel Handcar. The power pickups are metal wipers that ride on the

backs of the wheels. I checked the motor current and it is very

low. At 18 volts running light, it draws between 60 and 70 mA. At

full stall, it draws 700 mA. An HO or even N scale DCC decoder will

do fine in this one provided that I can find the room. However,

this will have to wait for a couple of months as I will be out of

town for most of that time.

The speeder picks up power on

four wheels, but only the rear two are powered, similarly to the

Lionel Handcar. The power pickups are metal wipers that ride on the

backs of the wheels. I checked the motor current and it is very

low. At 18 volts running light, it draws between 60 and 70 mA. At

full stall, it draws 700 mA. An HO or even N scale DCC decoder will

do fine in this one provided that I can find the room. However,

this will have to wait for a couple of months as I will be out of

town for most of that time.

DCC

installation in the Speeder is a piece of cake. The only real issue

is finding room for an HO scale decoder, I used a Digitrax DH163D

(wired) decoder because I had one and I could evaluate how DCC

would work in this loco without spending any money. The plan was

that if it worked, I'd consider buying some HO sound decoder and

return the DH163 to stock.

DCC

installation in the Speeder is a piece of cake. The only real issue

is finding room for an HO scale decoder, I used a Digitrax DH163D

(wired) decoder because I had one and I could evaluate how DCC

would work in this loco without spending any money. The plan was

that if it worked, I'd consider buying some HO sound decoder and

return the DH163 to stock.

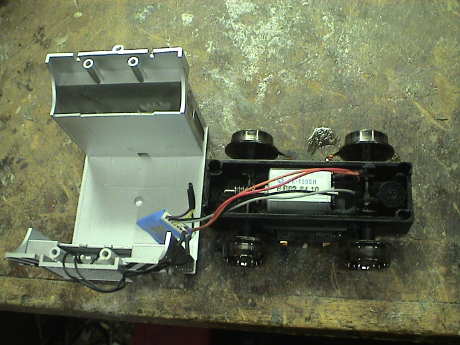

There are four screws in the motor block that release the block

from the body. Then the bottom part of the body will come out by

gently prying on the "lift handles" at either end. There is a cast

resin weight in the rear of the car. This guy completely fills a

cavity that is ideal for stashing the decoder. The obvious solution

is to ditch the 1.4 oz weight and replace it with a similar amount

of something denser, such as lead. This then leaves volume

available to stash the decoder.

I

used two 1 oz fishing weights, held in with a liberal amount of hot

glue. You could also pour lead shot (recovered from a few 12 ga

shotgun shells) and then bind it in with hot glue, silicone sealer

matte medium or diluted wood glue.

I

used two 1 oz fishing weights, held in with a liberal amount of hot

glue. You could also pour lead shot (recovered from a few 12 ga

shotgun shells) and then bind it in with hot glue, silicone sealer

matte medium or diluted wood glue.

The

Speeder uses a black and red wire to connect the track directly to

the motor. These wires are reversed in position as compared to HO

standards, but large scale also reverses the track polarity. If you

are interested in having the Speeder analog convert properly, then

just follow the HO color guidelines and ignore the left and right

stuff. Then it will work fine. I cut the headlight wires off right

next to the motor and then cut the red and black wires at the

highest portion of their loop when they are pulled out as far as

they will go. The red and black decoder leads go to the red and

black power pickup wires. The gray decoder wire goes to the black

motor wire, the orange decoder wire goes to the red motor wire. I

wired up the headlight to be on in the forward direction only using

the blue and white decoder wires. The lamp is incandescent so it

doesn't care about polarity. It also draws only 23 mA at 20 volts

so it doesn't need a current limiting resistor either.

The

Speeder uses a black and red wire to connect the track directly to

the motor. These wires are reversed in position as compared to HO

standards, but large scale also reverses the track polarity. If you

are interested in having the Speeder analog convert properly, then

just follow the HO color guidelines and ignore the left and right

stuff. Then it will work fine. I cut the headlight wires off right

next to the motor and then cut the red and black wires at the

highest portion of their loop when they are pulled out as far as

they will go. The red and black decoder leads go to the red and

black power pickup wires. The gray decoder wire goes to the black

motor wire, the orange decoder wire goes to the red motor wire. I

wired up the headlight to be on in the forward direction only using

the blue and white decoder wires. The lamp is incandescent so it

doesn't care about polarity. It also draws only 23 mA at 20 volts

so it doesn't need a current limiting resistor either.

The decoder is then stuffed up into the body and the floor is reinstalled. Then the motor brick is reattached with the original screws and it's done. It worked right off, no problems.

The DH163D

was working fine in the Speeder but it doesn't provide sound. The

Speeder is one of the last locos that I have that ran in stealth

mode. So the DH163D came out and a Soundtraxx Tsunami went it. The TSU-1000

sound decoder isn't very suitable for large scale because it is

rated for 1 amp stall current, a spec that few large scale locos

can meet. However, the Speeder draws only 700 mA at full stall so

the Tsunami could handle it. It also just barely fit.

The DH163D

was working fine in the Speeder but it doesn't provide sound. The

Speeder is one of the last locos that I have that ran in stealth

mode. So the DH163D came out and a Soundtraxx Tsunami went it. The TSU-1000

sound decoder isn't very suitable for large scale because it is

rated for 1 amp stall current, a spec that few large scale locos

can meet. However, the Speeder draws only 700 mA at full stall so

the Tsunami could handle it. It also just barely fit.

The wiring was very simple, all the wire colors matched those of the DH163 except for the two purple speaker wires. The Tsunami uses an 8 ohm speaker and makes pretty good volume as compared to other HO sized decoders. I originally tested it with a much better speaker, this one cannot reproduce the bass but it does well enough.

The Tsunami produces a wide range of sounds and the decoder supports BEMF, this is a good decoder for small locos that can handle it.

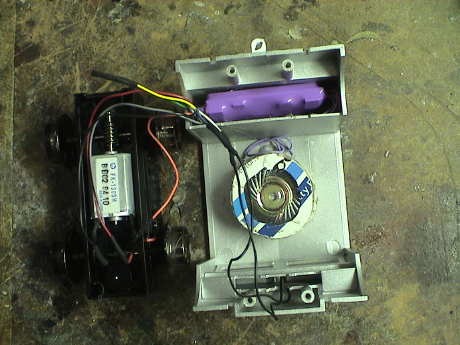

After filling

up the back completely with weight and the decoder, the speaker had

to go somewhere. This is a 1" 8Ω speaker that came with a

Dallee system. I made an enclosure out of a cardboard tube and hot

glue. The enclosure will have to get painted, probably silver to

match the rest of the unit.

After filling

up the back completely with weight and the decoder, the speaker had

to go somewhere. This is a 1" 8Ω speaker that came with a

Dallee system. I made an enclosure out of a cardboard tube and hot

glue. The enclosure will have to get painted, probably silver to

match the rest of the unit.

Eventually, I

built a whole new speaker enclosure with a "high bass" speaker. The

enclosure is still made from cardboard (model rocket body tube and

some scrap cardboard) but this time I assembled it with Zap-A-Gap

CA and it came out a little neater. It sounds better too as can be

heard in this Quicktime

movie.

Eventually, I

built a whole new speaker enclosure with a "high bass" speaker. The

enclosure is still made from cardboard (model rocket body tube and

some scrap cardboard) but this time I assembled it with Zap-A-Gap

CA and it came out a little neater. It sounds better too as can be

heard in this Quicktime

movie.

The Tsunami sound decoder never really liked the high track voltage, 22 VRMS, at the GIRR very much. It would complain by blinking it's headlight fairly often. This indicates an error condition. I finally elected to do something about it after Greg Elmassian commented about the poor reliability his Tsunami exhibited on his higher track voltage of 24 volts. The Tsunami is rated at 22 volts, but it is an HO decoder and would have not been extensively used or tested by Soundtraxx at 22 volts.

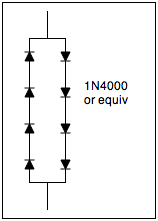

One way to drop the input voltage

is with a resistor, but then the voltage drop depends on load

current as well. Another way to do it is with a simple

bidirectional diode stack. The four diodes in this stack produce a

drop of 2.8 volts total, enough to get the voltage down near 19

volts which provides some margain against the specification. I used

1N4005 diodes for this stack, but virtually any 1 amp silicon

rectifier will work since the Tusnami is rated at only 1 amp

anyway.

One way to drop the input voltage

is with a resistor, but then the voltage drop depends on load

current as well. Another way to do it is with a simple

bidirectional diode stack. The four diodes in this stack produce a

drop of 2.8 volts total, enough to get the voltage down near 19

volts which provides some margain against the specification. I used

1N4005 diodes for this stack, but virtually any 1 amp silicon

rectifier will work since the Tusnami is rated at only 1 amp

anyway.

A

somewhat easier way to wire a diode stack is to use a bridge

rectifier. The diagram shows an application with a high current

bridge, but any cheap 1 amp bridge will work with the Tsunami. Use one bridge rectifier for each 1.4 volts of desired drop.

A

somewhat easier way to wire a diode stack is to use a bridge

rectifier. The diagram shows an application with a high current

bridge, but any cheap 1 amp bridge will work with the Tsunami. Use one bridge rectifier for each 1.4 volts of desired drop.

My parts box yielded

some 1N4005 (400 volt) diodes that I got as surplus somewhere for

about a penny each. The leads were cleaned and bent and the diodes

soldered together in a compact stack. The soldering looks pretty

bad because these diodes probably failed a solderability test, they

didn't wet well even after being scraped clean.

My parts box yielded

some 1N4005 (400 volt) diodes that I got as surplus somewhere for

about a penny each. The leads were cleaned and bent and the diodes

soldered together in a compact stack. The soldering looks pretty

bad because these diodes probably failed a solderability test, they

didn't wet well even after being scraped clean.

The stack was

enclosed in a piece of shrink tube and inserted in series with a

track lead.

The stack was

enclosed in a piece of shrink tube and inserted in series with a

track lead.

The tendency of the decoder to issue an error did not go completely away, but it happened much less often. I saw it only once during my testing, I would have expected it to be doing about half the time like it used to. It is probably telling me that it want's lower voltage yet.

I discovered by accident (a broken solder joint) that this decoder, and probably most others, will actually run from a half wave rectified DCC signal, albiet slowly. If you want to cut your voltage in half, then a single diode will do the job.

[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

This page has been accessed times since 6 Jun 09.

© 2009-2010 George Schreyer

Created 6 Jun 09

Last Updated May 3, 2010