Sierra Sound Installation in the Aristo

Slopeback Tender

[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

The slopeback tender was developed to give the

engineer better rearward visibility for switching moves. An engineer

could usually see his own rear coupler. The tender couldn't hold nearly

as much water as a regular tender, but switchers rarely were far from

water anyway so it wasn't a problem.

The slopeback tender was developed to give the

engineer better rearward visibility for switching moves. An engineer

could usually see his own rear coupler. The tender couldn't hold nearly

as much water as a regular tender, but switchers rarely were far from

water anyway so it wasn't a problem.

The Aristo Slopeback tender comes with a basic analog sound system.

The only sound that it makes is a chuff which is not very well

synchronized with the engine speed. It sounded ok until I began to

install digital sound systems in other locos when it paled by

comparison.

I elected to install a Soundtraxx Sierra system in the tender behind

an Aristo Rogers 2-4-2. Since Sierra doesn't have a sound system

customized for this loco, I just listened to the sound samples on the

Soundtraxx web site until I

found one that I liked and didn't have already. I ended up with the

sound for an EBT 2-8-2.

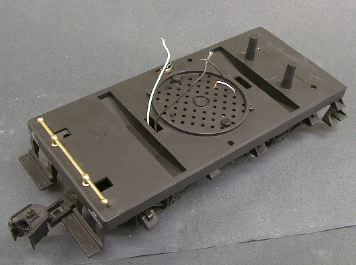

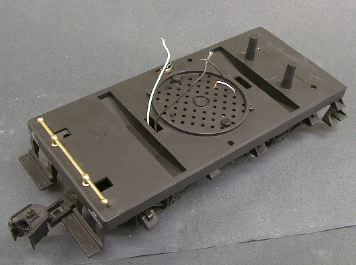

The first thing that I did was strip

everything out of the existing tender. There was nothing there that I

wished to retain except for the power wires from the trucks. The 2"

speaker is a good one for its size, but I wanted a bigger one, and the

stock speaker is not mounted to provide the best sound output. The

sound board itself was scrapped. Even the power switch is not usable

because it has only one pole and I prefer to disconnect both the track

power and the battery when the system is turned off. This takes a dual

pole switch.

The first thing that I did was strip

everything out of the existing tender. There was nothing there that I

wished to retain except for the power wires from the trucks. The 2"

speaker is a good one for its size, but I wanted a bigger one, and the

stock speaker is not mounted to provide the best sound output. The

sound board itself was scrapped. Even the power switch is not usable

because it has only one pole and I prefer to disconnect both the track

power and the battery when the system is turned off. This takes a dual

pole switch.

The 3" speaker supplied with the Sierra can mount over the ring in

the tender floor, but I chose to use a better oval speaker that

typically comes with computer speaker sets. Look for a sale for

"non-amplified" computer speakers and junk the cabinets. The speakers

are fine. I saw a set advertised for $0.99 on sale at Fry's

Electronics.

The oval speaker was too tall to mount in the existing speaker

location, so I choose to mount the speaker toward the front of the

tender and to mount the battery where the old speaker was. This is

especially convenient because the Sierra board itself can be mounted on

the back of the speaker so that it is accessible through the coal load.

The coal load unlatches by pushing the water hatch to the rear. This

makes it unnecessary to mount a remote volume control switch. An array

of holes needs to be drilled under the new speaker location to let the

sound out. The speaker didn't fit until some grinding was done on the

old speaker ring.

The new speaker covers over the hole where the wiring to the front

truck used to go. Since there are now only 2 wires, they were rerouted

up through two of the old speaker holes. The rest of the holes were

plugged with hot glue. The hole for the rear truck wiring is plugged by

covering it with electrical tape.

The rear headlight runs from track power and is non directional. It

used to plug into the sound board to pick up its power. Since I don't

like to hardwire the tender shell to the tender floor, I removed the

two pin connector from the old sound board and soldered wires to the

pins that were in the board and then wired it to track power. A 1N4000

type 1 amp rectifier diode can be added in series with the rear light

to make it directional if desired. If it comes on in the wrong

direction, just reverse the diode.

The Sierra can be set so that its chuff rate is

roughly proportional to the engine speed, but this method really

doesn't work too well. I prefer to use a synchronized chuff by

installing the supplied reed switch and magnets. With 2 magnets on a

tender axle, the chuff rate is about 3 chuffs per turn which is fast

enough. It also changes with engine speed reliably except when the

engine is slipping. It is a lot easier to wire the switch within the

tender instead of running wires to the loco and finding a place to

mount the switch and magnets.

The Sierra can be set so that its chuff rate is

roughly proportional to the engine speed, but this method really

doesn't work too well. I prefer to use a synchronized chuff by

installing the supplied reed switch and magnets. With 2 magnets on a

tender axle, the chuff rate is about 3 chuffs per turn which is fast

enough. It also changes with engine speed reliably except when the

engine is slipping. It is a lot easier to wire the switch within the

tender instead of running wires to the loco and finding a place to

mount the switch and magnets.

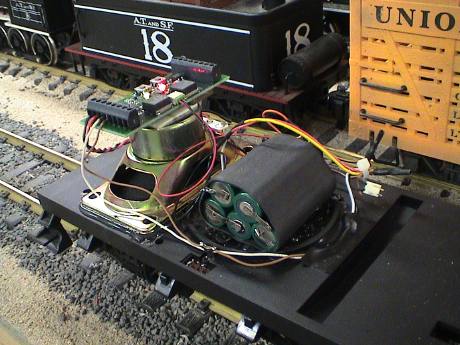

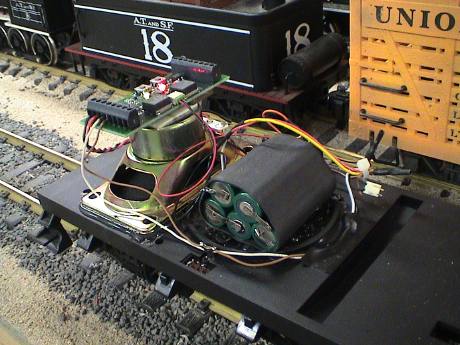

It is now 2006 and after 6 years of intermittent use, the original 500mA-hr gelcell battery has died. I have replaced it with 5 tabbed NiMH

cells to make a new 6 volt battery with 3x the capacity of

the original battery. No modifications to the sound system is

required, the board will charge the new battery at about 150 mA peak, dropping

to less than 100 mA after the battery picks up up a little charge. At

this rate, it will take about 15 hours of sitting on energized track to

full charge these 1650 mA-hr cells. However, the battery still charges while the sound system is in use so that it will eventually fully charge while running. NiMH cells are a better choice than NiCad for this kind of service because NiMH is less sensitive to being continually charged and discharged.

It is now 2006 and after 6 years of intermittent use, the original 500mA-hr gelcell battery has died. I have replaced it with 5 tabbed NiMH

cells to make a new 6 volt battery with 3x the capacity of

the original battery. No modifications to the sound system is

required, the board will charge the new battery at about 150 mA peak, dropping

to less than 100 mA after the battery picks up up a little charge. At

this rate, it will take about 15 hours of sitting on energized track to

full charge these 1650 mA-hr cells. However, the battery still charges while the sound system is in use so that it will eventually fully charge while running. NiMH cells are a better choice than NiCad for this kind of service because NiMH is less sensitive to being continually charged and discharged.

Tabbed cells are much harder to find than regular AA cells. I got

these at Hosfelt for about $2.75

each. The tabs are easy to solder together with the cells arranged plus

to minus. Then the whole works is encapsulated in a piece of shrink

tubing. It is possible to make a battery stack with non-tabbed batteries, but considerable heat needs to be applied to solder to the battery ends and this heat can damage a battery. The welded on tabs on these cells make soldering easy.

While I was in there, I did add a

directionally sensitive headlight circuit. It was easiest to add it to

the wiring leading to the headlight itself, the connector plugs into

straight track power.

While I was in there, I did add a

directionally sensitive headlight circuit. It was easiest to add it to

the wiring leading to the headlight itself, the connector plugs into

straight track power.

The GIRR Mountain division uses the

Aristo Train Engineer system with PWC. Adding a storage capacitor to

the diode allows the light to come on brighter sooner. If straight DC

track power is used, the capacitor won't help at all. All that is

needed then is the diode to make the rear headlight directionally

sensitive.

The GIRR Mountain division uses the

Aristo Train Engineer system with PWC. Adding a storage capacitor to

the diode allows the light to come on brighter sooner. If straight DC

track power is used, the capacitor won't help at all. All that is

needed then is the diode to make the rear headlight directionally

sensitive.

[ Top ] [ Home ] [ Up ] [ Previous Page ] [ Next Page ]

This page has been accessed  times since 11 Mar 00.

times since 11 Mar 00.

© 2000-2006 George Schreyer

Created Mar 11, 2000

Last Updated August 19, 2006

The slopeback tender was developed to give the

engineer better rearward visibility for switching moves. An engineer

could usually see his own rear coupler. The tender couldn't hold nearly

as much water as a regular tender, but switchers rarely were far from

water anyway so it wasn't a problem.

The slopeback tender was developed to give the

engineer better rearward visibility for switching moves. An engineer

could usually see his own rear coupler. The tender couldn't hold nearly

as much water as a regular tender, but switchers rarely were far from

water anyway so it wasn't a problem. The first thing that I did was strip

everything out of the existing tender. There was nothing there that I

wished to retain except for the power wires from the trucks. The 2"

speaker is a good one for its size, but I wanted a bigger one, and the

stock speaker is not mounted to provide the best sound output. The

sound board itself was scrapped. Even the power switch is not usable

because it has only one pole and I prefer to disconnect both the track

power and the battery when the system is turned off. This takes a dual

pole switch.

The first thing that I did was strip

everything out of the existing tender. There was nothing there that I

wished to retain except for the power wires from the trucks. The 2"

speaker is a good one for its size, but I wanted a bigger one, and the

stock speaker is not mounted to provide the best sound output. The

sound board itself was scrapped. Even the power switch is not usable

because it has only one pole and I prefer to disconnect both the track

power and the battery when the system is turned off. This takes a dual

pole switch.

The Sierra can be set so that its chuff rate is

roughly proportional to the engine speed, but this method really

doesn't work too well. I prefer to use a synchronized chuff by

installing the supplied reed switch and magnets. With 2 magnets on a

tender axle, the chuff rate is about 3 chuffs per turn which is fast

enough. It also changes with engine speed reliably except when the

engine is slipping. It is a lot easier to wire the switch within the

tender instead of running wires to the loco and finding a place to

mount the switch and magnets.

The Sierra can be set so that its chuff rate is

roughly proportional to the engine speed, but this method really

doesn't work too well. I prefer to use a synchronized chuff by

installing the supplied reed switch and magnets. With 2 magnets on a

tender axle, the chuff rate is about 3 chuffs per turn which is fast

enough. It also changes with engine speed reliably except when the

engine is slipping. It is a lot easier to wire the switch within the

tender instead of running wires to the loco and finding a place to

mount the switch and magnets. It is now 2006 and after 6 years of intermittent use, the original 500mA-hr gelcell battery has died. I have replaced it with 5 tabbed NiMH

cells to make a new 6 volt battery with 3x the capacity of

the original battery. No modifications to the sound system is

required, the board will charge the new battery at about 150 mA peak, dropping

to less than 100 mA after the battery picks up up a little charge. At

this rate, it will take about 15 hours of sitting on energized track to

full charge these 1650 mA-hr cells. However, the battery still charges while the sound system is in use so that it will eventually fully charge while running. NiMH cells are a better choice than NiCad for this kind of service because NiMH is less sensitive to being continually charged and discharged.

It is now 2006 and after 6 years of intermittent use, the original 500mA-hr gelcell battery has died. I have replaced it with 5 tabbed NiMH

cells to make a new 6 volt battery with 3x the capacity of

the original battery. No modifications to the sound system is

required, the board will charge the new battery at about 150 mA peak, dropping

to less than 100 mA after the battery picks up up a little charge. At

this rate, it will take about 15 hours of sitting on energized track to

full charge these 1650 mA-hr cells. However, the battery still charges while the sound system is in use so that it will eventually fully charge while running. NiMH cells are a better choice than NiCad for this kind of service because NiMH is less sensitive to being continually charged and discharged. While I was in there, I did add a

directionally sensitive headlight circuit. It was easiest to add it to

the wiring leading to the headlight itself, the connector plugs into

straight track power.

While I was in there, I did add a

directionally sensitive headlight circuit. It was easiest to add it to

the wiring leading to the headlight itself, the connector plugs into

straight track power. The GIRR Mountain division uses the

Aristo Train Engineer system with PWC. Adding a storage capacitor to

the diode allows the light to come on brighter sooner. If straight DC

track power is used, the capacitor won't help at all. All that is

needed then is the diode to make the rear headlight directionally

sensitive.

The GIRR Mountain division uses the

Aristo Train Engineer system with PWC. Adding a storage capacitor to

the diode allows the light to come on brighter sooner. If straight DC

track power is used, the capacitor won't help at all. All that is

needed then is the diode to make the rear headlight directionally

sensitive.