Aristo Pacific Tips

[ Home ] [ Up ] [ Previous Page ] [

Next Page ]

The Aristo 4-6-2

Pacific is a fine engine so I've found very little that needs fixing.

It pulls well, it is quiet and smooth and mine tends to traverse

bad track (which I should fix) without derailing. However, I've found

some things that need attention and these are the subject of this

page.

The Aristo 4-6-2

Pacific is a fine engine so I've found very little that needs fixing.

It pulls well, it is quiet and smooth and mine tends to traverse

bad track (which I should fix) without derailing. However, I've found

some things that need attention and these are the subject of this

page.

The Aristo Pacific is apparently modeled after the B&O President

Class. The model matches the size, overall appearance and some of the

detail locations of that class (pops, whistle and dynamo). Pacific's

were predominantly passenger engines, however they could be pressed

into freight service when necessary.

The model is nominally 1:29 scale and scales out pretty close. The

model has fair detail and runs very smoothly and quietly.

Note that this page deals with the OLD Pacific. There is a NEW

model that has a completely different drive train but still with a single motor.

Contents

Performance

The Pacific is a heavy duty engine and can pull quite a load. See my

Tractive Effort Tests

page for comparative data of the Pacific vs. other common large scale

locos. I use the Pacific primarily to pull a string of heavyweights. It

will handle 5 cars with 6 wheel trucks on a 1.6% grade with 5' radius

turns. The heavyweights drag so much on curves that the capability

decreases to 4 cars when the grade has a 4' radius curve.

When overloaded, the Pacific will let you know. It doesn't slip

gracefully. It stutters and hops around badly at the first sign of

wheel slip. However, when the wheels are not slipping, it pulls

smoothly and fairly quietly. The Pacific also tends to lug down under

load just before it slips, much more so than most other large scale

engines. I believe that this is due to the fact that it has only one

motor instead of the more usual two. The motor is larger than most, but

indications are that the larger motor does not produce the same

tractive effort as locos with two smaller motors. This can be a problem

if the engine is weighted to increase adhesion. The loco can load down

so much that the motor starts to stall. This could cause serious

overheating and eventual failure of the motor.

Early production Pacific's had gear drive to all six drivers. In

later production, the gearing to the center driver has been removed so

that the center drivers are driven only through the siderods. The

driven axles are supported by ball bearings that are also used to

transmit electrical power from the wheels.

There have also been at least two versions of the universal joint

between the motor and the drive shaft. The earlier versions with a

metal U-joint (visible between the firebox and the boiler) sometimes

tended to make noise or transmit torque unevenly. My Pacific had a

slight bind in the drive mechanism that occurred once per drive shaft

turn. I thought that it was the U-joint, but after some investigation,

it seemed to be coming from a drive shaft bearing. When I replaced the

bottom cover of the engine, it went away so that I never did figure out

the root cause of the problem.

[ Top ]

Wheel Issues

The main weak point of the Pacific is its wheels. They are some kind

of casting and they behave similarly to the wheels on the 0-4-0, in

other words, they get dirty REAL fast. I don't know

what the specific problem is but they just sweep up crud and power

pickup gets flaky.

One of our compatriots from New Zealand, Grant Alexander, has found

that chrome plating of the wheels makes a world of difference. Aristo

has changed the wheel material for the 0-4-0 which made an astounding

improvement in power pickup reliability. I hope that someday Aristo

will make the Pacific's wheels in the same material.

In the meantime, you can wire the tender across to the loco to add 8

more wheels of power pickup. This helps a lot, but the tender wheels

are made of the same stuff and they get cruddy too.

The other problem with the drive wheels is that the screws that hold

them on get loose and fall out. You may not notice it for awhile as the

siderods tend to hold a loose wheel in place. The axles have drift pins

installed that pick up slots on the backs of the drivers so that even

if a wheel is wobbling on its shaft, it will still be driven. The

Pacific tends to wobble or waddle under load somewhat, but when even

one wheel gets even a little loose, it'll start to wobble much more.

Pay attention to its little dance and if you see it start to get worse,

stop then and there and tighten the driver screws before you actually

loose one of them.

It is a good idea to use a little purple LocTite 222 (the type rated

for SET SCREWS) to hold the screws in place as simple

torque and lock washers don't seem to do the job.

[ Top ]

Details

The Pacific has fair detail, but its not up to the

detail of newer large scale locos. Further, some of the details look

out of place, like the bell on some versions. The ATSF version mounts

the bell harp on top of the boiler, a prototypical location, but it

sticks up way too high and looks odd. Besides, the damn thing keeps

getting broken off. I remounted it on the smokebox cover, also a

prototypical location for some road names. Pull the harp from the

boiler then fill, file and paint the old mounting location. Then drill

a 1/8" hole in the smoke box cover. There are three holes there

already, drill out the center one. Cut off the base of the harp and set

the harp in the new hole with a drop of superglue.

The Pacific has fair detail, but its not up to the

detail of newer large scale locos. Further, some of the details look

out of place, like the bell on some versions. The ATSF version mounts

the bell harp on top of the boiler, a prototypical location, but it

sticks up way too high and looks odd. Besides, the damn thing keeps

getting broken off. I remounted it on the smokebox cover, also a

prototypical location for some road names. Pull the harp from the

boiler then fill, file and paint the old mounting location. Then drill

a 1/8" hole in the smoke box cover. There are three holes there

already, drill out the center one. Cut off the base of the harp and set

the harp in the new hole with a drop of superglue.

The pilot can be removed so that a front coupler can be attached to

the leading truck to allow double headed operation. The coupler mount

is standard and an Aristo or Kadee #831 will go right on.

[ Top ]

Smoke System

The smoke system is run from a fan that pressurizes the smoke unit.

The smoke unit itself sits on the front deck. The smoke that leaves the

unit is conducted up a brass tube to the smoke stack. There are two

plastic tubes leading down from the stack that conduct a part of the

smoke back down to the cylinders to simulate leaking steam. There is

also an air pump in one of the cylinders that causes the smoke to puff

once per driver turn, one quarter of the prototypical rate as shown in this video.

The smoke unit is controlled by a switch on the front deck. Pulling

the switch forward activates the smoke unit. Pressing it back

disconnects the smoke unit.

The fan itself is run from a low voltage motor in series with the

smoke unit. There are two dual diode stacks in parallel with the motor

to limit the voltage that the motor can see. Unlike other Aristo fans,

this one can run in either direction and still pressurize the smoke

unit.

Smoke fluid must be added to the fluid tub on the pilot deck.

Pouring it down the stack usually will not work as it has to get down

the very small brass tube. The top cover of the fluid tub must be

replaced or the smoke will just pour out of the tub.

The smoke unit can be removed quite easily. First, pull up on the

ENTIRE smoke stack assembly until it moves upward about 3/8". Do not

try to pull it all the way off. This lifts the brass tube out of the

top of the smoke unit. Then pull the smoke unit itself out forward. If

it does not come right out, then pull up on the stack assembly a little

so that the brass tube clears the top of the smoke unit. This is all

easier to see if you remove the smokebox front cover. Reinstall the

smoke unit the same way, when the unit has seated properly, press the

smoke stack assembly back down to lock the smoke generator in

place.

[ Top ]

Stock Sound System

The Pacific Tender comes with a sound system installed. This system

has been much derided, but under the right conditions it isn't too

bad.

The system chuffs fairly well and rings a sort of a bell sound at

low speed. There is no whistle. However, the sound system relies on the

Aristo PWC system to work. Without PWC, the sound system doesn't get

enough voltage off the track to work properly and it howls, growls, and

screeches terribly at low speed. With PWC, it may make awful sounds but

only at very slow speed.

In either case, the sound can be improved by opening the tender and

installing a RECHARGEABLE 9 volt battery in the clip

provided. The upside is that the sound system will operate at low speed

and sound OK. The downside is that the engine can be stopped with the

chuff blowing constantly as is common on a Bachmann Big Hauler. I use

PWC so I don't use the battery and the sound shuts off when the track

power goes away completely.

The chuff trigger is a Hall effect device mounted above a tender

axle. A doughnut shaped magnet rides on a rubber roller on the axle.

The Hall effect device is mounted next to the magnet. If the chuff

isn't working right, make sure that the rubber roller is clean and that

the Hall effect device is RIGHT NEXT to the magnet.

Even when its working, the chuff rate is about 1/3 of the prototypical

rate of 4 chuffs/turn.

After the rubber roller gets old and hardens up some it doesn't

provide enough friction to turn the magnet reliably. After much fussing

and fiddling, I finally tried to renew the roller surface with a

coating of contact cement, AND IT WORKED! To apply the cement, pull the

wheelset with the roller from the truck by flexing the truck sideframe

slightly and then paint a layer of contact cement on the roller. Rubber

cement would probably work too. Let it dry for about an hour and

reinstall the wheelset. I do not know how long this patch will last,

but even if it fails after awhile, it would be easy enough to do it

again.

There is an adjustment on the sound board for bell sound. Diddling

on it can make the sound a little better or more likely much worse and

getting the best (not good but best) sound requires a fairly touchy

adjustment of this control. You can try to adjust it, but don't expect

miracles.

[ Top ]

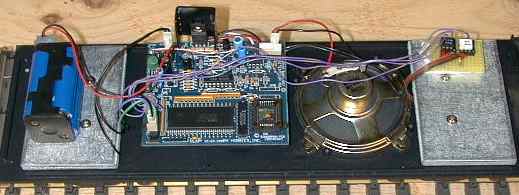

Digital Sound System

I finally got tired enough

of the stock sound system to spend the $110 or so to upgrade the sound

system to Aristo's new ART-29341 digital sound system. This system

isn't really new, its a version of the PH hobbies S3005S that's been

around for several years. The system has a basic chuff, bell and

whistle sounds with blowdown and compressor sounds while the engine is

standing. The board has been modified to fit the mounting posts of the

Pacific tender and to deal with the Hall device chuff sensor. The

system is mostly a plug in installation, no soldering is required.

I finally got tired enough

of the stock sound system to spend the $110 or so to upgrade the sound

system to Aristo's new ART-29341 digital sound system. This system

isn't really new, its a version of the PH hobbies S3005S that's been

around for several years. The system has a basic chuff, bell and

whistle sounds with blowdown and compressor sounds while the engine is

standing. The board has been modified to fit the mounting posts of the

Pacific tender and to deal with the Hall device chuff sensor. The

system is mostly a plug in installation, no soldering is required.

I installed the device per Aristo's typically brief instructions and

I did have some minor difficulties, mostly due to wires that were too

short.

A video demonatrating the sounds that this system makes can be found at my PH Hobbies Sound Systems Tips page.

- The hole for the volume control was too small to accept the new

control. I had to drill it out to 17/64" so that the control would fit.

Even then, the rotation stop tab gets in the way. I bent it out of the

way. Alternatively, a small hole could be drilled to clear the

tab.

- The wires leading to the read switches were just a bit too short to

mount the reed switches as indicated in the instructions. I turned the

connector around from the way that it was installed out of the box so

that the wires would reach. This still works as the connector is not

keyed and it just swaps the bell and whistle reed switches. Eventually,

I installed an ART-5474 to key the bell and whistle so I didn't use the

reed switches. Even later, I installed a DCC decoder and now that is

used to trigger the bell and whistle.

- The battery wire was too short to mount the battery on the front

weight as instructed so that I moved the battery to the rear weight

were there was more room.

- The instructions call for double backed foam tape to mount the

battery. It would have been nice to have a piece included. I had some

anyway so I mounted the battery with foam tape.

- The speaker wire wouldn't reach it's connector until the speaker

was rotated.

- The power lead to the front truck just did reach, but not by much.

Another 1/4" of wire would have made life much easier.

- Step 12 in the instructions says to plug the 3 wire cable from the

chuff sensor to the bottom side of the board. The pins were on the

top.

- The chuff sensor is not keyed so that it could be plugged on either

way. Of course, the first time that I did it, I got it backwards and

the system wouldn't chuff. Turning the connector around fixed

that.

I mounted the 5474 on the back of the speaker with another piece of

foam tape. The lugs were clipped off and the power leads and the leads

were soldered to the circuit board where the leads to the front truck

terminate. I also added a pair of 100 microhenry inductors to isolate

the power leads from the track. An antenna wire extends rearward to

connect to the following car.

Initial results with the 5474 were not so good. While it does

trigger the bell and whistle, the range is not adequate. Sometimes it

doesn't work standing right next to the engine. I tested this

particular 5474 on the bench and I could trigger the whistle from 50'

away which as far as I could hear it when the unit was inside the

garage and I was in the backyard. However, when installed in the tender

and sitting on the track it doesn't work nearly as well.

There isn't enough room for an adequate antenna for the 5474 inside

the tender. No amount of rearrangement of an antenna wire would work. I

stretched a 3' piece of wire back across the following car (a

heavyweight) and it worked much better. I also found that if the wire

was stretched under the car, it didn't work nearly as well if the wire

was taped to the car roof. I eventually routed the wire just under the

roof and connected it to the tender with an set of DB-25 contact pins

(see my Connector Tips page

for details on the connector. Just as a precaution, I also routed the

end of the wire back down the other end of the car and installed a

connector there too in case I need to further extend the wire across

the NEXT car.

With the antenna wire extending just under the roof of the car, I

can usually trigger the sound system from about 50' although it still

doesn't work every time.

The battery charging of the

digital sound system is similar to other sound systems manufactured by

PH Hobbies. The system will charge better from PWC than from pure DC.

These curves show the battery voltage as a function of average input

voltage. With PWC, the battery will start to charge at lower average

input voltage than with DC. This system is essentially identical to the

old one in my Atlantic and it has never needed a charge since the day

that I installed it. I expect that the Pacific system will work the

same way.

The battery charging of the

digital sound system is similar to other sound systems manufactured by

PH Hobbies. The system will charge better from PWC than from pure DC.

These curves show the battery voltage as a function of average input

voltage. With PWC, the battery will start to charge at lower average

input voltage than with DC. This system is essentially identical to the

old one in my Atlantic and it has never needed a charge since the day

that I installed it. I expect that the Pacific system will work the

same way.

[ Top ]

Installation of DCC in the Pacific

This is the schematic of the Pacific as

built by Aristo. Fortunately all the necessary wiring is readily

accessible with the cab and boiler removed. The cab comes off with 4

screws. The boiler comes off with five more, four underneath and one on

top at the joint between the boiler and the smokebox. Refer to Aristo's

Exploded Diagrams for details on the locations

of these screws. The two brass handrails can be unclipped from the

front two stanchions on each side of the smokebox and the cab and

boiler can be lifted off.

This is the schematic of the Pacific as

built by Aristo. Fortunately all the necessary wiring is readily

accessible with the cab and boiler removed. The cab comes off with 4

screws. The boiler comes off with five more, four underneath and one on

top at the joint between the boiler and the smokebox. Refer to Aristo's

Exploded Diagrams for details on the locations

of these screws. The two brass handrails can be unclipped from the

front two stanchions on each side of the smokebox and the cab and

boiler can be lifted off.

Battery power users will note that the inside of the boiler has a

huge amount of USABLE volume to allow battery

installation. The interior clear space is fully 13" long and slightly

over half round at 2.5" in diameter.

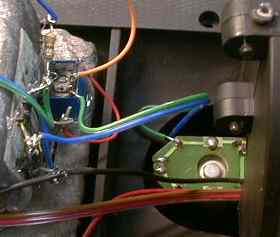

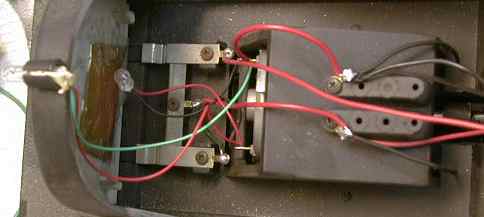

This is a view of the firebox area of

the Pacific. Track power is brought up into the shell and attached to

two lugs seen at the right of the photo. From here, power is routed

back to the two switches in the cab floor. One controls the cab lights,

firebox light and motor. The other controls the headlight and markers.

Smoke unit power is wired from underneath the boiler directly to the

smoke unit. I ended up removing all this wiring and abandoning the

switches altogether. The cab light, firebox light and motor are all

wired separately to the decoder. The only original connections left on

the power lugs are the wires coming up from under the engine that

connect to the power pickups on the drivers and the trailing truck. The

only new connection to these lugs goes to the power input of the

decoder and to the rectifier used to power the smoke unit.

This is a view of the firebox area of

the Pacific. Track power is brought up into the shell and attached to

two lugs seen at the right of the photo. From here, power is routed

back to the two switches in the cab floor. One controls the cab lights,

firebox light and motor. The other controls the headlight and markers.

Smoke unit power is wired from underneath the boiler directly to the

smoke unit. I ended up removing all this wiring and abandoning the

switches altogether. The cab light, firebox light and motor are all

wired separately to the decoder. The only original connections left on

the power lugs are the wires coming up from under the engine that

connect to the power pickups on the drivers and the trailing truck. The

only new connection to these lugs goes to the power input of the

decoder and to the rectifier used to power the smoke unit.

I used a Lenz LE230 back-emf decoder in the Pacific. I chose this

decoder because it was the only high current back-emf decoder that I

could find and it had received good performance reports from other

users. Zimo also makes a good back-emf decoder, but the one that I had

on order was backordered for almost 4 months and I was tired of waiting

for it. The Pacific really needs the motor speed control that back-emf

provides because its speed tends to be quite sensitive to load. Mine

will lug down on upgrades and run away on downgrades. Back-emf can keep

these speed variations under better control. The LE230 is rated at 2.5

amps continuous output. The Pacific draws about 1.6 amps while slipping

so the LE230 ought to be able to handle it.

Pacific Schematic After DCC Installation

DCC installation in the Pacific is a pretty straightforward task,

except for the smoke unit. The only high current (500 mA) function

output of the LE230 is F1 which I prefer to use for the sound system

bell instead. None of the other function outputs have the current

capability to run the smoke unit directly (400 mA cold, 250 mA hot). I

usually prefer to leave my smoke units connected to the track so that

they are controlled by the regular smoke switch instead of the decoder

and therefore don't add load to the decoder. Also, if the smoke

function gets turned on by accident when it is dry, I don't toast the

smoke units. However, the Pacific smoke unit uses a fan to force air

out of the smoke unit and the fan motor will not run on DCC track power

which is AC. Therefore I added a bridge rectifier to the smoke unit to

create the necessary DC power and further I wired it from a relay

(visible in the next photo) so that it could be run from a low current

function output. The switch on the pilot deck will still turn it off.

Unlike other Aristo smoke system fans, this one operates properly with

the fan turning in either direction.

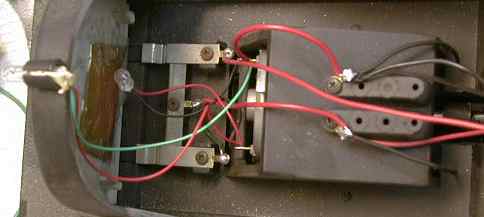

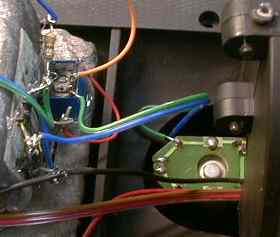

This photo shows the top of the fan

assembly. One power wire is routed up to the left side of the circuit

board, the other is routed to part of the smoke switch underneath. Both

wires must be removed and insulated. They will not be used in the DCC

installation. New wires are soldered to these points and brought up to

the bridge rectifier and relay. The relay and rectifier are glued to

the engine weights with GOOP. Track power for the smoke unit is wired

from the main power lugs in the firebox.

This photo shows the top of the fan

assembly. One power wire is routed up to the left side of the circuit

board, the other is routed to part of the smoke switch underneath. Both

wires must be removed and insulated. They will not be used in the DCC

installation. New wires are soldered to these points and brought up to

the bridge rectifier and relay. The relay and rectifier are glued to

the engine weights with GOOP. Track power for the smoke unit is wired

from the main power lugs in the firebox.

The

stock headlight wiring is pretty straightforward. This is the stock

wiring. Two wires coming from the switches in the back bring power to

the markers and to the headlight. The headlight is powered through a

diode to make it directional.

The

stock headlight wiring is pretty straightforward. This is the stock

wiring. Two wires coming from the switches in the back bring power to

the markers and to the headlight. The headlight is powered through a

diode to make it directional.

Headlight and marker wiring

modifications are easy. The headlight wires are removed from their

previous connections and extended with new wire. The original wires run

only the markers and can either be left connected to the original

switch or wired to a decoder function. The headlight is connected

directly to the decoder as shown in the decoder instructions. If you

want to dim the headlight in when running in reverse, cross connect the

forward and reverse headlight decoder function connections with a 150

to 220 ohm resistor.

Headlight and marker wiring

modifications are easy. The headlight wires are removed from their

previous connections and extended with new wire. The original wires run

only the markers and can either be left connected to the original

switch or wired to a decoder function. The headlight is connected

directly to the decoder as shown in the decoder instructions. If you

want to dim the headlight in when running in reverse, cross connect the

forward and reverse headlight decoder function connections with a 150

to 220 ohm resistor.

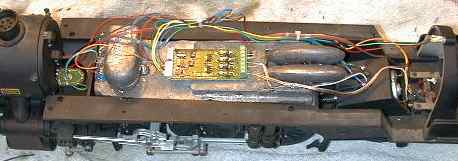

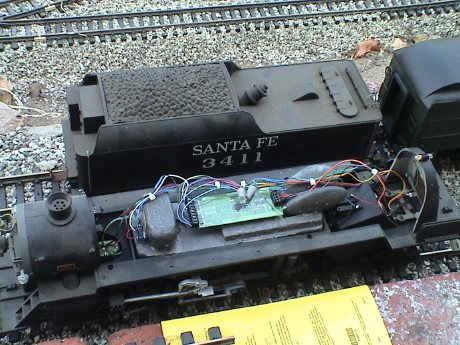

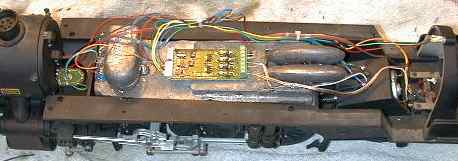

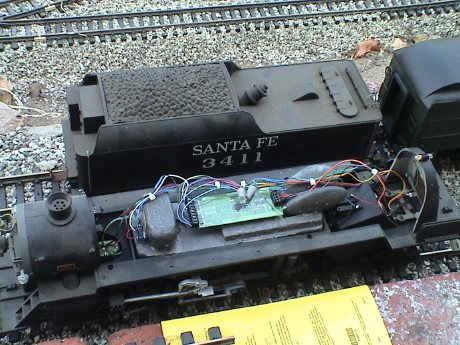

This is the Pacific after

the DCC installation was completed. Virtually all the original wiring

is gone and replaced with wiring to or from the DCC decoder.

This is the Pacific after

the DCC installation was completed. Virtually all the original wiring

is gone and replaced with wiring to or from the DCC decoder.

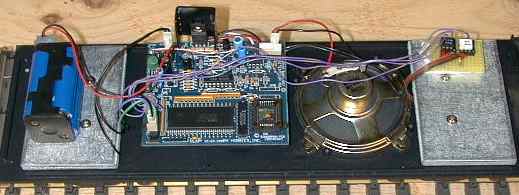

The tender

houses the Aristo Digital Sound system. The bell and whistle used to be

controlled by an ART-5474 accessory receiver, but now they are

controlled through optoisolators from the DCC decoder. I choose to

mount the generic optoisolators in the tender on a small circuit board

seen in the upper right of the photo. Connection to the loco is made

through a 3 pin Molex connector carrying the F1 and F2 function leads

and the blue decoder wire.

The tender

houses the Aristo Digital Sound system. The bell and whistle used to be

controlled by an ART-5474 accessory receiver, but now they are

controlled through optoisolators from the DCC decoder. I choose to

mount the generic optoisolators in the tender on a small circuit board

seen in the upper right of the photo. Connection to the loco is made

through a 3 pin Molex connector carrying the F1 and F2 function leads

and the blue decoder wire.

I eventually destroyed the stock speaker while removing the 5474

which has been foam taped to the back of the speaker (the rear pole

piece came off with the 5474) so I have replaced it. I used a generic

TV replacement speaker. Later I found that a Radio Shack 40-252 speaker

would fit as well.

Some of the DCC signal leaks into the PH sound board causing a high

pitched buzz. It isn't too loud if the batteries are well conditioned.

However, dead batteries or batteries with poor connections in the

holder will allow a fairly loud buzz. Cleaning the battery ends and the

holder contacts may reduce the AC impedance of the battery stack. I

found that a 10 uF capacitor soldered across the battery terminals on

the circuit board also helped to attenuate the noise.

There will still be some residual noise that couples directly to the

board from the rails. The PH board has a lot of audio gain and just

putting a finger near the volume control will couple in more noise.

There probably isn't much that can be done with the residual noise.

When running on constant DCC track voltage, the regulator IC on the

PH sound board will get too hot and eventually thermally shut down to

protect itself. If your batteries are any good, you may not notice it

as the sound system will continue to run on the batteries until the

regulator cools enough to turn itself back on. This will continue to

happen unnoticed while the regulator is getting beat up. A better plan

is to add a heat sink to the regulator so that it doesn't heat so

much.

It all worked pretty well. The decoder F5 (firebox) and F6 (smoke)

functions did not initially work. This turned out to be an

incompatibility between the Lenz LE230 decoder and the Digitrax Chief

command station. I eventually sent the Chief back to Digitrax for

another problem (it literally burned up) and when it came back, F5 and

F6 began to work.

The back-emf feature of the decoder interacted with the mechanism

somewhat. This Pacific had a slight bind in the drive line that

occurred once per driveline turn. It was so slight that I never noticed

it when running track power. However, when back-emf is enabled on the

decoder, it does have an effect. The back-emf sensor in the decoder

tries to keep the motor speed constant but it responds a little slowly.

When the driveline binds, the decoder senses it and tries to correct by

adding a little more power. However, by the time that the decoder

corrects, the bind is gone and the power is not necessary. The

locomotive then surges just a little. This only happens when the engine

is running light. When loaded, it does not seem to be a problem. I

worked over the driveline a little this characteristic improved, but it

still needs a little more work.

The Pacific is a little under motored. It has a large motor, but

there is only one and it doesn't have quite enough torque. It tends to

lug down more than most locos under heavy load. I was hoping that

back-emf decoder would help by keeping the average speed up and down

the grades more constant. Since the motor was lugging anyway on the

upgrade, the decoder could not help. It helped some on the downgrade.

It seems that the back-emf implementation in this decoder senses a

short period running average of motor speed. When running down a long

downgrade, the back-emf system sees no short term changes and

eventually allows the engine speed to increase.

Under steady heavy loads, this decoder gets warm but not hot. It

doesn't make nearly as much hammering noise as the Digitrax decoders at

slow speed. However, the feature set of the LE230 is somewhat limited.

It does not operate in 128 speed step mode and has no special effects

on any functions. The decoder converts to analog gracefully although

none of the decoder functions operate when analog converted. I cannot

program the CV's in this decoder using OPS mode on the main line with

my Digitrax Chief. I have to do all programming in PAGE mode on the

programming track.

One of my kids dropped the Pacific and broke a bunch of parts. Since

it was out of service anyway, I removed the LE230 and reinstalled it in

a Bachmann Climax. While I was waiting for the parts (Aristo was moving

their facility and their parts department was out of service also) I

patched it back together and rewired it for track power. I found that

it actually ran stronger under straight track power than with the

LE230. It didn't tend to lug down as much. I then suspected that the

Pacific might be just a little too much of a load for an LE230 as the

decoder was probably going into current limiting.

I also received a repaired and upgraded DG-580L back from Digitrax

so I stuck it in the open engine to see how it worked. It didn't work

too well. Due to some added heatsinking on the decoder, it didn't burn

right up, but it didn't put out enough current to run the Pacific

either. The engine stalled badly in spots where it worked with either

straight track power or the LE230.

After 15 months on backorder, a Zimo

MX65S/N finally showed up. This is a slightly larger (3 amp) back-emf

decoder than the LE230. The Zimo is a really fine unit. It is well heat

sunk so it will probably stand up to abuse well, unlike the Digitrax

units. Its back-emf control is just as effective as the Lenz decoder

and the back-emf effect is programmable from a hard speed lock to a

weak speed lock.

After 15 months on backorder, a Zimo

MX65S/N finally showed up. This is a slightly larger (3 amp) back-emf

decoder than the LE230. The Zimo is a really fine unit. It is well heat

sunk so it will probably stand up to abuse well, unlike the Digitrax

units. Its back-emf control is just as effective as the Lenz decoder

and the back-emf effect is programmable from a hard speed lock to a

weak speed lock.

As delivered, the back-emf feature interacted more strongly with the

gearing bind than the Lenz LE230 did. However, a little messing with

the programming of the back-emf (CV58) and I found that with the CV set

to about 75% I could get a strong enough interaction AND eliminate the

binding at low speeds. The Zimo unit seemed to be able to drive the

Pacific under load better than the Lenz decoder, it doesn't lug as much

as it used to under heavy load. However, this could also be due to the

NCE PB110 booster that I am using now. The PB110's output voltage

doesn't sag nearly as much as the Digitrax Chief's booster.

The Zimo MX65S/N analog converts well with either DC or PWC on the

track. The reversing headlight operates properly, but none of the other

functions operate.

I wired the Zimo

the same as the Lenz with the same functions. However, for some reason,

Zimo starts counting functions at 1 while everybody else starts at 0.

Therefore, the Zimo function numbering on the decoder is offset by one

from the numbering on the DCC throttle. Even though Zimo calls the

headlight function 1, it still responds to the F0 controls on the

throttle. All other functions are offset the same way. The numbering in

the schematic uses Zimo's convention.

I wired the Zimo

the same as the Lenz with the same functions. However, for some reason,

Zimo starts counting functions at 1 while everybody else starts at 0.

Therefore, the Zimo function numbering on the decoder is offset by one

from the numbering on the DCC throttle. Even though Zimo calls the

headlight function 1, it still responds to the F0 controls on the

throttle. All other functions are offset the same way. The numbering in

the schematic uses Zimo's convention.

After running the engine for quite a while with the Zimo decoder I

concluded that it still didn't work as well as when it was running from

straight track power using a Train Engineer as a power source. I

surmised that even the Zimo was current limiting. When then engine

lugged down and started to draw more motor current it would cause the

output voltage of the decoder to drop off and the motor would then lug

worse. The decoder back EMF control would then tried to boost the motor

power by going to full pulse width but there just wasn't enough current

available to cause the motor to pull out of the stall. Both the motor

and the decoder would then overheat. The Train Engineer has enough

current capability to hold up its output voltage so that it could drive

enough current into the motor to keep its torque up and to prevent the

motor from slipping into a stall.

I considered reconverting the loco back to analog control, but I

decided to give it one more shot using a new NCE D408SR decoder. I have

had very good results with an earlier version of this decoder in a pair

of RS-3's. The D408SR is rated at 4 amps average, the Zimo at 3 amps

and the Lenz LE230 at 2.5 amps. Maybe the extra amp would be enough to

keep the motor from sliding down the wrong side of the torque

curve.

The D408SR did indeed work very

well, maybe better than the Train Engineer did. The engine still slows

somewhat at the worst spots on the grades, but it pulls through. More

important after extended running, the motor and decoder are only warm,

not hot like with the smaller decoders.

The D408SR did indeed work very

well, maybe better than the Train Engineer did. The engine still slows

somewhat at the worst spots on the grades, but it pulls through. More

important after extended running, the motor and decoder are only warm,

not hot like with the smaller decoders.

The D408SR does not have back EMF motor control. This is good and

bad. The good part is that the decoder doesn't try to ram more power

into the motor when it lugs. The bad part is that the engine tries to

run away downgrade. However, by setting the Vmax CV on the decoder to

limit the maximum running speed, I can limit the downgrade speed to

safe values and still have enough power to pull the grades going

up.

The schematic of the installation is similar to the one used in the

Zimo configuration, except the 150 ohm resistor on the reversing

headlight is not needed. The D408SR can dim its own headlight. The

smoke unit is wired to the output normally used for the reversing

headlight. This output has been remapped so that it is disconnected

from the headlight function and operates in both directions.

I had gone through three very

capable DCC decoders and one not-so-capable one in the Pacific, now

it's had a fifth one. The Pacific never did seem to pull as well under

DCC as it had wired for track power. It clearly overwhelmed the Lenz

LE230, Digitrax DG580L, and the Zimo MX65. After many years, with the

NCE D408SR decoder, I also suspected that even that decoder was current

limiting which was allowing the motor to stall under heavy loads. I

decided to make one more try, this time with the biggest brute decoder

out there, the NCE D808SR. This is an 8 amp average, 30 amp peak

decoder. The Pacific shouldn't draw nearly that much, but it may try to

draw more than 4 amps. The D808 is a large and expensive decoder at

$109.95 MSRP. It can be found for $10 or $15 cheaper if you look

around. However, if you need a truly heavy duty decoder, this is the

only one.

I had gone through three very

capable DCC decoders and one not-so-capable one in the Pacific, now

it's had a fifth one. The Pacific never did seem to pull as well under

DCC as it had wired for track power. It clearly overwhelmed the Lenz

LE230, Digitrax DG580L, and the Zimo MX65. After many years, with the

NCE D408SR decoder, I also suspected that even that decoder was current

limiting which was allowing the motor to stall under heavy loads. I

decided to make one more try, this time with the biggest brute decoder

out there, the NCE D808SR. This is an 8 amp average, 30 amp peak

decoder. The Pacific shouldn't draw nearly that much, but it may try to

draw more than 4 amps. The D808 is a large and expensive decoder at

$109.95 MSRP. It can be found for $10 or $15 cheaper if you look

around. However, if you need a truly heavy duty decoder, this is the

only one.

I pulled the Pacific out for yet another test with four heavyweights

in tow. It tended to lug down on the grades and if I held the train

back manually, the engine would just barely slip it's drivers even at

full throttle. This indicates that either the loco is undermotored,

overweight or was being starved for current.

I removed the power and motor wiring from the D408SR and reconnected

the engine for track power and ran the same test with the 10 amp TE

trackside receiver. Now it would not lug as much and it would produce a

healthy driver slip when the train was manually held back. At this

point it was clear that even the D408SR wasn't up the the task.

I then wired in the D808SR and there was an amazing difference. The

Pacific behaved like a whole different locomotive. First, the engine

didn't seem to lug at all. Second, when the train was held back, the

engine would slip at full speed, spinning like mad. Train control was

MUCH more responsive so I added a 5th heavyweight to the consist and it

didn't seem to matter much. Then I added two more for a total of seven

heavyweight cars. Then the loco started to show the strain, it would

slow somewhat when the train was on a grade or a curve, but it didn't

slow very much. While pulling the grade, it would occasionally break

free and slip for a wheel turn or two but it would gain its feet again

and pull. This loco has NEVER pulled seven heavyweight coaches

before.

Further, since the engine doesn't tend to lug hardly at all going

uphill, there is no particular need to cut the speed back going

downhill.

From all of this I have to conclude that the Pacific needs to be

able to draw very high currents when loaded or it will lug down and

stall. If a motor controller limits the current available, the motor

doesn't have a chance. When it stalls, then it really draws current and

will overheat and eventually burn up.

After a lot of running, I started to notice that the thing was lugging down again under a 5 heavyweight load. I parked it for a couple of hours and tried it again. It was better, but after about a half hour, it started to lug again. The motor was really hot. As the temperature goes up, the magnets weaken a little and the winding resistance increases. Both tend to result in less torque and result in the tendency to lug. I have loaded this engine up past it's capability. so now I run with only four heavyweights AND I let it rest after periods of hard work.

The

diagram and table of the D808SR installation are primarily for my

benefit. I didn't draw one when I took out the Zimo and put in the

D408SR. There were some differences that I had to figure out so I don't

want to have to do that again so I'm documenting it in real time.

The

diagram and table of the D808SR installation are primarily for my

benefit. I didn't draw one when I took out the Zimo and put in the

D408SR. There were some differences that I had to figure out so I don't

want to have to do that again so I'm documenting it in real time.

The smoke unit draws too much current to place directly on a

function output so it runs from the track but is controlled by both the

manual smoke switch on the front pilot and a function output from the

decoder. This way, it can't be turned on by accident but it can be

turned off remotely.

Pacific D808SR Wiring

| Function Code |

Function |

D808SR Output |

Wire Color |

Function Attributes |

Notes |

| F0f |

Forward Headlight |

1 |

brown |

CV120=44 |

Dims in reverse |

| F0r |

Rear Headlight |

2 |

n/a |

n/a |

not used |

| F1 |

Bell |

3 |

green |

none |

bell trigger |

| F2 |

Whistle |

4 |

violet |

none |

whistle trigger |

| F3 |

Cab light |

5 |

brown |

none |

on or off |

| F4 |

Markers |

6 |

black |

none |

on or off |

| F5 |

Firebox |

7 |

white w/green |

CV126=4 |

Flickers |

| F6 |

Smoke |

8 |

white |

none |

on or off, in series with manual switch |

| n/a |

Common |

n/a |

blue |

n/a |

+20 volts |

| n/a |

Common |

n/a |

blue |

n/a |

+20 volts |

[ Top ]

Exploded Diagrams

Aristo Craft has posted exploded diagrams of the Pacific at Exploded

Diagrams. They are .PDF files so that you need Adobe Acrobat Reader

to read them, but there is also a link on the exploded diagrams page to

get a free copy of Acrobat Reader. These diagrams are extremely useful

and I would recommend that you download the diagram, print a hard copy

and study it before you take your Pacific apart for the first time.

The cab and boiler can be easily removed to expose most of the

wiring. Four screws under the frame release the cab. Four more screws

under the walkways and a fifth screws on the top at the joint between

the boiler and the smokebox release the boiler. You also have to unclip

the handrails from four clips on the smokebox.

The drive train is accessed by removing eight screws on the bottom

cover. The gearing on the front axle is not directly accessible as the

gear assembly is inside its own gearbox. The gearbox can be removed and

disassembled to lubricate or adjust the quartering of the drivers.

The motor and U-joint can be removed by removing the rear truck and

then removing three screws under the firebox that hold on the bottom

motor cover.

The fan assembly is especially difficult to remove. It looks like

much of the engine would have to be taken apart to remove it.

[ Top ] [ Home ] [ Up ] [ Previous Page ] [ Next

Page ]

This page has been accessed  times since 12 Dec 1997.

times since 12 Dec 1997.

© 1997-2009 George Schreyer

Created Oct 12, 1997

Last Updated September 3, 2009

The Aristo 4-6-2

Pacific is a fine engine so I've found very little that needs fixing.

It pulls well, it is quiet and smooth and mine tends to traverse

bad track (which I should fix) without derailing. However, I've found

some things that need attention and these are the subject of this

page.

The Aristo 4-6-2

Pacific is a fine engine so I've found very little that needs fixing.

It pulls well, it is quiet and smooth and mine tends to traverse

bad track (which I should fix) without derailing. However, I've found

some things that need attention and these are the subject of this

page. 24 Jun 08

24 Jun 08 The Pacific has fair detail, but its not up to the

detail of newer large scale locos. Further, some of the details look

out of place, like the bell on some versions. The ATSF version mounts

the bell harp on top of the boiler, a prototypical location, but it

sticks up way too high and looks odd. Besides, the damn thing keeps

getting broken off. I remounted it on the smokebox cover, also a

prototypical location for some road names. Pull the harp from the

boiler then fill, file and paint the old mounting location. Then drill

a 1/8" hole in the smoke box cover. There are three holes there

already, drill out the center one. Cut off the base of the harp and set

the harp in the new hole with a drop of superglue.

The Pacific has fair detail, but its not up to the

detail of newer large scale locos. Further, some of the details look

out of place, like the bell on some versions. The ATSF version mounts

the bell harp on top of the boiler, a prototypical location, but it

sticks up way too high and looks odd. Besides, the damn thing keeps

getting broken off. I remounted it on the smokebox cover, also a

prototypical location for some road names. Pull the harp from the

boiler then fill, file and paint the old mounting location. Then drill

a 1/8" hole in the smoke box cover. There are three holes there

already, drill out the center one. Cut off the base of the harp and set

the harp in the new hole with a drop of superglue. I finally got tired enough

of the stock sound system to spend the $110 or so to upgrade the sound

system to Aristo's new ART-29341 digital sound system. This system

isn't really new, its a version of the PH hobbies S3005S that's been

around for several years. The system has a basic chuff, bell and

whistle sounds with blowdown and compressor sounds while the engine is

standing. The board has been modified to fit the mounting posts of the

Pacific tender and to deal with the Hall device chuff sensor. The

system is mostly a plug in installation, no soldering is required.

I finally got tired enough

of the stock sound system to spend the $110 or so to upgrade the sound

system to Aristo's new ART-29341 digital sound system. This system

isn't really new, its a version of the PH hobbies S3005S that's been

around for several years. The system has a basic chuff, bell and

whistle sounds with blowdown and compressor sounds while the engine is

standing. The board has been modified to fit the mounting posts of the

Pacific tender and to deal with the Hall device chuff sensor. The

system is mostly a plug in installation, no soldering is required. The battery charging of the

digital sound system is similar to other sound systems manufactured by

PH Hobbies. The system will charge better from PWC than from pure DC.

These curves show the battery voltage as a function of average input

voltage. With PWC, the battery will start to charge at lower average

input voltage than with DC. This system is essentially identical to the

old one in my Atlantic and it has never needed a charge since the day

that I installed it. I expect that the Pacific system will work the

same way.

The battery charging of the

digital sound system is similar to other sound systems manufactured by

PH Hobbies. The system will charge better from PWC than from pure DC.

These curves show the battery voltage as a function of average input

voltage. With PWC, the battery will start to charge at lower average

input voltage than with DC. This system is essentially identical to the

old one in my Atlantic and it has never needed a charge since the day

that I installed it. I expect that the Pacific system will work the

same way. This is the schematic of the Pacific as

built by Aristo. Fortunately all the necessary wiring is readily

accessible with the cab and boiler removed. The cab comes off with 4

screws. The boiler comes off with five more, four underneath and one on

top at the joint between the boiler and the smokebox. Refer to Aristo's

This is the schematic of the Pacific as

built by Aristo. Fortunately all the necessary wiring is readily

accessible with the cab and boiler removed. The cab comes off with 4

screws. The boiler comes off with five more, four underneath and one on

top at the joint between the boiler and the smokebox. Refer to Aristo's

This is a view of the firebox area of

the Pacific. Track power is brought up into the shell and attached to

two lugs seen at the right of the photo. From here, power is routed

back to the two switches in the cab floor. One controls the cab lights,

firebox light and motor. The other controls the headlight and markers.

Smoke unit power is wired from underneath the boiler directly to the

smoke unit. I ended up removing all this wiring and abandoning the

switches altogether. The cab light, firebox light and motor are all

wired separately to the decoder. The only original connections left on

the power lugs are the wires coming up from under the engine that

connect to the power pickups on the drivers and the trailing truck. The

only new connection to these lugs goes to the power input of the

decoder and to the rectifier used to power the smoke unit.

This is a view of the firebox area of

the Pacific. Track power is brought up into the shell and attached to

two lugs seen at the right of the photo. From here, power is routed

back to the two switches in the cab floor. One controls the cab lights,

firebox light and motor. The other controls the headlight and markers.

Smoke unit power is wired from underneath the boiler directly to the

smoke unit. I ended up removing all this wiring and abandoning the

switches altogether. The cab light, firebox light and motor are all

wired separately to the decoder. The only original connections left on

the power lugs are the wires coming up from under the engine that

connect to the power pickups on the drivers and the trailing truck. The

only new connection to these lugs goes to the power input of the

decoder and to the rectifier used to power the smoke unit.

This photo shows the top of the fan

assembly. One power wire is routed up to the left side of the circuit

board, the other is routed to part of the smoke switch underneath. Both

wires must be removed and insulated. They will not be used in the DCC

installation. New wires are soldered to these points and brought up to

the bridge rectifier and relay. The relay and rectifier are glued to

the engine weights with GOOP. Track power for the smoke unit is wired

from the main power lugs in the firebox.

This photo shows the top of the fan

assembly. One power wire is routed up to the left side of the circuit

board, the other is routed to part of the smoke switch underneath. Both

wires must be removed and insulated. They will not be used in the DCC

installation. New wires are soldered to these points and brought up to

the bridge rectifier and relay. The relay and rectifier are glued to

the engine weights with GOOP. Track power for the smoke unit is wired

from the main power lugs in the firebox. The

stock headlight wiring is pretty straightforward. This is the stock

wiring. Two wires coming from the switches in the back bring power to

the markers and to the headlight. The headlight is powered through a

diode to make it directional.

The

stock headlight wiring is pretty straightforward. This is the stock

wiring. Two wires coming from the switches in the back bring power to

the markers and to the headlight. The headlight is powered through a

diode to make it directional. Headlight and marker wiring

modifications are easy. The headlight wires are removed from their

previous connections and extended with new wire. The original wires run

only the markers and can either be left connected to the original

switch or wired to a decoder function. The headlight is connected

directly to the decoder as shown in the decoder instructions. If you

want to dim the headlight in when running in reverse, cross connect the

forward and reverse headlight decoder function connections with a 150

to 220 ohm resistor.

Headlight and marker wiring

modifications are easy. The headlight wires are removed from their

previous connections and extended with new wire. The original wires run

only the markers and can either be left connected to the original

switch or wired to a decoder function. The headlight is connected

directly to the decoder as shown in the decoder instructions. If you

want to dim the headlight in when running in reverse, cross connect the

forward and reverse headlight decoder function connections with a 150

to 220 ohm resistor. This is the Pacific after

the DCC installation was completed. Virtually all the original wiring

is gone and replaced with wiring to or from the DCC decoder.

This is the Pacific after

the DCC installation was completed. Virtually all the original wiring

is gone and replaced with wiring to or from the DCC decoder. The tender

houses the Aristo Digital Sound system. The bell and whistle used to be

controlled by an ART-5474 accessory receiver, but now they are

controlled through optoisolators from the DCC decoder. I choose to

mount the generic optoisolators in the tender on a small circuit board

seen in the upper right of the photo. Connection to the loco is made

through a 3 pin Molex connector carrying the F1 and F2 function leads

and the blue decoder wire.

The tender

houses the Aristo Digital Sound system. The bell and whistle used to be

controlled by an ART-5474 accessory receiver, but now they are

controlled through optoisolators from the DCC decoder. I choose to

mount the generic optoisolators in the tender on a small circuit board

seen in the upper right of the photo. Connection to the loco is made

through a 3 pin Molex connector carrying the F1 and F2 function leads

and the blue decoder wire. After 15 months on backorder, a Zimo

MX65S/N finally showed up. This is a slightly larger (3 amp) back-emf

decoder than the LE230. The Zimo is a really fine unit. It is well heat

sunk so it will probably stand up to abuse well, unlike the Digitrax

units. Its back-emf control is just as effective as the Lenz decoder

and the back-emf effect is programmable from a hard speed lock to a

weak speed lock.

After 15 months on backorder, a Zimo

MX65S/N finally showed up. This is a slightly larger (3 amp) back-emf

decoder than the LE230. The Zimo is a really fine unit. It is well heat

sunk so it will probably stand up to abuse well, unlike the Digitrax

units. Its back-emf control is just as effective as the Lenz decoder

and the back-emf effect is programmable from a hard speed lock to a

weak speed lock. I wired the Zimo

the same as the Lenz with the same functions. However, for some reason,

Zimo starts counting functions at 1 while everybody else starts at 0.

Therefore, the Zimo function numbering on the decoder is offset by one

from the numbering on the DCC throttle. Even though Zimo calls the

headlight function 1, it still responds to the F0 controls on the

throttle. All other functions are offset the same way. The numbering in

the schematic uses Zimo's convention.

I wired the Zimo

the same as the Lenz with the same functions. However, for some reason,

Zimo starts counting functions at 1 while everybody else starts at 0.

Therefore, the Zimo function numbering on the decoder is offset by one

from the numbering on the DCC throttle. Even though Zimo calls the

headlight function 1, it still responds to the F0 controls on the

throttle. All other functions are offset the same way. The numbering in

the schematic uses Zimo's convention. The D408SR did indeed work very

well, maybe better than the Train Engineer did. The engine still slows

somewhat at the worst spots on the grades, but it pulls through. More

important after extended running, the motor and decoder are only warm,

not hot like with the smaller decoders.

The D408SR did indeed work very

well, maybe better than the Train Engineer did. The engine still slows

somewhat at the worst spots on the grades, but it pulls through. More

important after extended running, the motor and decoder are only warm,

not hot like with the smaller decoders. I had gone through three very

capable DCC decoders and one not-so-capable one in the Pacific, now

it's had a fifth one. The Pacific never did seem to pull as well under

DCC as it had wired for track power. It clearly overwhelmed the Lenz

LE230, Digitrax DG580L, and the Zimo MX65. After many years, with the

NCE D408SR decoder, I also suspected that even that decoder was current

limiting which was allowing the motor to stall under heavy loads. I

decided to make one more try, this time with the biggest brute decoder

out there, the NCE D808SR. This is an 8 amp average, 30 amp peak

decoder. The Pacific shouldn't draw nearly that much, but it may try to

draw more than 4 amps. The D808 is a large and expensive decoder at

$109.95 MSRP. It can be found for $10 or $15 cheaper if you look

around. However, if you need a truly heavy duty decoder, this is the

only one.

I had gone through three very

capable DCC decoders and one not-so-capable one in the Pacific, now

it's had a fifth one. The Pacific never did seem to pull as well under

DCC as it had wired for track power. It clearly overwhelmed the Lenz

LE230, Digitrax DG580L, and the Zimo MX65. After many years, with the

NCE D408SR decoder, I also suspected that even that decoder was current

limiting which was allowing the motor to stall under heavy loads. I

decided to make one more try, this time with the biggest brute decoder

out there, the NCE D808SR. This is an 8 amp average, 30 amp peak

decoder. The Pacific shouldn't draw nearly that much, but it may try to

draw more than 4 amps. The D808 is a large and expensive decoder at

$109.95 MSRP. It can be found for $10 or $15 cheaper if you look

around. However, if you need a truly heavy duty decoder, this is the

only one. The

diagram and table of the D808SR installation are primarily for my

benefit. I didn't draw one when I took out the Zimo and put in the

D408SR. There were some differences that I had to figure out so I don't

want to have to do that again so I'm documenting it in real time.

The

diagram and table of the D808SR installation are primarily for my

benefit. I didn't draw one when I took out the Zimo and put in the

D408SR. There were some differences that I had to figure out so I don't

want to have to do that again so I'm documenting it in real time.