Aristo Center Cab Switcher Tips

[ Home ] [ Up ] [ Previous Page

] [ Next Page ]

The Aristo Center Cab Switcher is a small

diesel locomotive modeled after a generic design of many small

industrial engines. There was no real prototype for this loco, but

it is credible in size and proportion. Many small switchers were

made with a center cab and a small (150 to 300 hp) engine/generator

set under each hood.

The Aristo Center Cab Switcher is a small

diesel locomotive modeled after a generic design of many small

industrial engines. There was no real prototype for this loco, but

it is credible in size and proportion. Many small switchers were

made with a center cab and a small (150 to 300 hp) engine/generator

set under each hood.

Aristo has apparently taken two short hoods, the cab and battery

boxes from their RS-3 and put them on a new frame with a new die

cast power brick. Unlike the L'il Critter, this locomotive has

engine exhaust ports. There are NO smoke

units.

Contents

Performance and Detail

The Center Cab is a very smooth and quiet engine.

There is some audible gear noise, but the sound of the wheels on

the rails is louder than the mechanism. The engine is moderately

weighted and has good pulling power. It won't pull as well as the

larger heavier diesels, but since the motors are full sized, a

little weight in the body may improve that. I did run my standard

Tractive Effort

Tests on the center cab and it did fairly well, pulling about

as well as other Aristo diesels that haven't had additional weight

installed. Most of the engine weight is in the truck castings,

there are no internal body weights. There are also no traction

tires.

The Center Cab is a very smooth and quiet engine.

There is some audible gear noise, but the sound of the wheels on

the rails is louder than the mechanism. The engine is moderately

weighted and has good pulling power. It won't pull as well as the

larger heavier diesels, but since the motors are full sized, a

little weight in the body may improve that. I did run my standard

Tractive Effort

Tests on the center cab and it did fairly well, pulling about

as well as other Aristo diesels that haven't had additional weight

installed. Most of the engine weight is in the truck castings,

there are no internal body weights. There are also no traction

tires.

The slow speed performance is good, the slowest steady speed is

about 1 tie per second either loaded or running light. The top

speed is lower than other diesels, this locomotive more closely

matches the top speed of a C-16 than the other Aristo Diesels.

Typical industrial diesels could not exceed 40 mph due to their

non-swinging truck design. The truck sideframe models a welded up

truck similar to ones found on many small engines.

There are two switches underneath the loco for the motor and the

non existent smoke. These can be reached while the loco is still on

the track.

The paint job is a little more complete than the older RS-3's.

On this unit, painted in an ATSF style, the ladders and their metal

eyelets are all painted.

The wheel treads are wider than most wheels. This doesn't seem

to harm anything, but the engine looks a little odd from the

bottom. After extended running on my very dirty track, the wheels

picked up a slight haze, but there was no sign of pitting. Power

pickup was good considering the track it was running on which

probably hasn't been cleaned since last year. The engine did

respond to the bad track by speeding and slowing as it gained and

lost power, but it did so smoothly without the jerkiness of some

locos. It never did actually stall.

[ Top ]

Scale and Clearance

This is a very short locomotive so that it will handle tight

turns quite well. It has minimal overhang under any conditions so

that there are likely few railroads it won't fit on. The locomotive

is 12" long over the end steps and 15" long over the coupler faces.

The engine is 4" wide and 5-5/8" tall. The wheelbase of the truck

is 2.343". The trucks are 5.3" on center.

Since there isn't a real prototype for this engine, its "scale"

is open to interpretation. However, the engine size is consistent

with the 1/29 scale of the rest of the Aristo product line.

[ Top ]

Center Cab Power Bricks

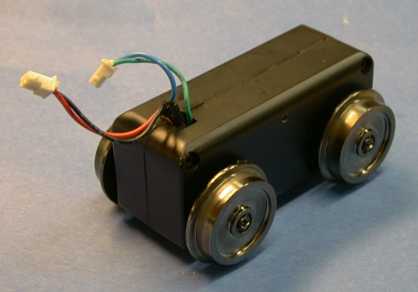

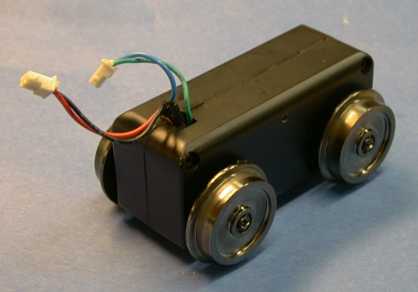

The Center Cab brick is a die cast metal

assembly. It is self contained and is very easy to remove from the

loco. There are two screws in sides of the A-frame that mounts the

truck. Removal of these screws releases the truck. The wiring is

connected to the loco with two plugs. These are differently sized

and keyed so that it is not possible to switch them or plug them in

backwards.

The Center Cab brick is a die cast metal

assembly. It is self contained and is very easy to remove from the

loco. There are two screws in sides of the A-frame that mounts the

truck. Removal of these screws releases the truck. The wiring is

connected to the loco with two plugs. These are differently sized

and keyed so that it is not possible to switch them or plug them in

backwards.

There are four screws on each side that hold the brick halves

together. To disassemble the brick, remove two wheels on one side

by removing the screws in the center of the wheels. The wheels are

centered on the axles with tapers and may bind a little, but a

little prying will pop them off. Then remove the four screws on

that side and pull the halves apart. The screws that hold the case

halves together are anchored in plastic insulating spacers.

The truck

has a conventional can motor and worm gear drive. The motor has a

bypass capacitor and a device that appears to be a surge suppressor

soldered across its terminals. The motor is also wrapped in

electrical tape to insulate the can from the dicast case halves.

The power pickup wires are connected through lugs screwed to each

case half. Note that the wires are just crimped into the lugs and

can come out. This may not be visible due to the sleeving. If you

have a truck apart, it might be reasonable to cut off the sleeving,

remove the wire from the lug, put some more sleeving on the wire,

solder it back to the lug and then heat shrink the sleeving over

the soldered joint.

The truck

has a conventional can motor and worm gear drive. The motor has a

bypass capacitor and a device that appears to be a surge suppressor

soldered across its terminals. The motor is also wrapped in

electrical tape to insulate the can from the dicast case halves.

The power pickup wires are connected through lugs screwed to each

case half. Note that the wires are just crimped into the lugs and

can come out. This may not be visible due to the sleeving. If you

have a truck apart, it might be reasonable to cut off the sleeving,

remove the wire from the lug, put some more sleeving on the wire,

solder it back to the lug and then heat shrink the sleeving over

the soldered joint.

Each axle runs in two ball bearings that are pressed on the

axle. Power is picked up on every wheel and transferred to the case

halves through the bearings. These bearings should provide a long

bearing life, even if the loco is more heavily weighted.

Older Aristo bricks

used screws as thrust bearings and sometimes they would squeak

loudly. Also, if the screws were misadjusted, either the motor

bearings would have to take up the thrust or the lash screws would

add drag as the adjustment was quite critical. This brick uses a

spring loaded thrust bearing instead so that adjustment is not

required. The thrust bearing does not add appreciably to motor

drag.

Older Aristo bricks

used screws as thrust bearings and sometimes they would squeak

loudly. Also, if the screws were misadjusted, either the motor

bearings would have to take up the thrust or the lash screws would

add drag as the adjustment was quite critical. This brick uses a

spring loaded thrust bearing instead so that adjustment is not

required. The thrust bearing does not add appreciably to motor

drag.

[ Top ]

Couplers

The Center Cab comes with standard Aristo knuckle couplers body

mounted and a set of hook and loop couplers in the box. The

existing couplers extend way out from the engine but they do work

with other Aristo rolling stock on 2' radius curves. On S curves,

the couplers get pretty contorted but they still work.

There are probably many ways to install Kadee couplers, but I

choose to use a method similar to one that I used on the RS-3. I

have a box if Kadee #831's so that I was inclined to use this

standard truck mount coupler. The coupler mount is similar to the

RS-3, but it isn't exactly the same. The post on an RS-3 has a

ridge at the right height to position a modified Kadee #831. The

Center Cab post does not have this ridge so that it must be

modified somewhat to mount a Kadee.

The post is

just under 0.25" in diameter and is nearly the right height to hold

a #831 if the mounting hole on the #831 is drilled out to 0.25".

The coupler box then rests on the pilot and the whole assembly

comes out just a tad higher than the optimum height. The coupler

cannot droop because it is supported by the pilot. However, the

coupler can slide up on the post unless something stops it. The

RS-3 had ridges at the right spot, but these ridges are missing on

the Center Cab. I cut a short piece of 0.25" ID brass tubing and

slid it over the post. With the coupler box in place, I pushed the

tube down to the right position with a toothpick and then applied a

drop of Zap-CA to hold it in place. The existing coupler centering

spring must be trimmed shorter so that it will fit in a #70 hole

drilled in the back of the coupler body

The post is

just under 0.25" in diameter and is nearly the right height to hold

a #831 if the mounting hole on the #831 is drilled out to 0.25".

The coupler box then rests on the pilot and the whole assembly

comes out just a tad higher than the optimum height. The coupler

cannot droop because it is supported by the pilot. However, the

coupler can slide up on the post unless something stops it. The

RS-3 had ridges at the right spot, but these ridges are missing on

the Center Cab. I cut a short piece of 0.25" ID brass tubing and

slid it over the post. With the coupler box in place, I pushed the

tube down to the right position with a toothpick and then applied a

drop of Zap-CA to hold it in place. The existing coupler centering

spring must be trimmed shorter so that it will fit in a #70 hole

drilled in the back of the coupler body

When the

Kadee #831 is mounted this way, much of the coupler box is back

inside the pilot and is not visually obtrusive. The coupler is also

mounted much closer to the locomotive than the stock Aristo

coupler.

When the

Kadee #831 is mounted this way, much of the coupler box is back

inside the pilot and is not visually obtrusive. The coupler is also

mounted much closer to the locomotive than the stock Aristo

coupler.

[ Top ]

Lighting and Electrical

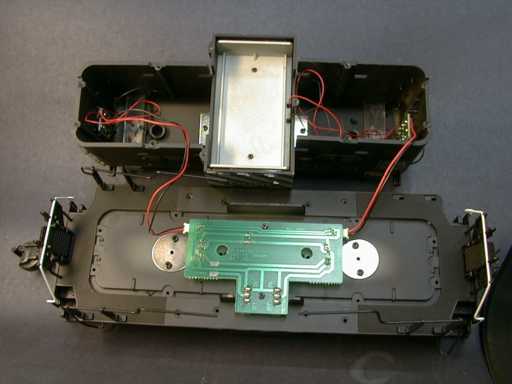

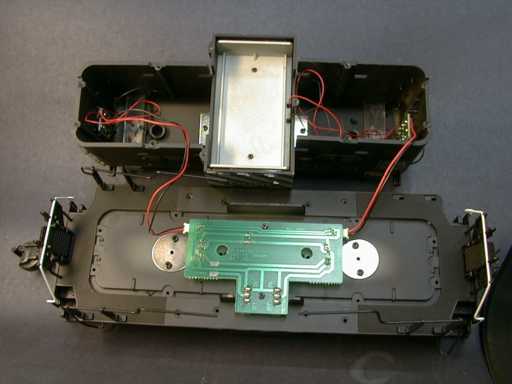

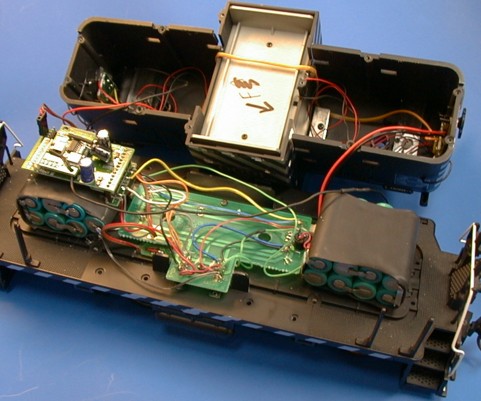

When

splayed open, the Center Cab reveals that there is little inside

the unit. A distribution board is mounted to the frame and the hood

wiring plugs in. There is no overt provision for a DCC decoder or a

command receiver, but since all the necessary wiring is accessible

on the top of the distribution board, it would be an easy job with

a knife to cut the appropriate traces to make the necessary

connections. There is quite a bit of room inside both hoods for

batteries, sound systems, and control receivers or decoders.

When

splayed open, the Center Cab reveals that there is little inside

the unit. A distribution board is mounted to the frame and the hood

wiring plugs in. There is no overt provision for a DCC decoder or a

command receiver, but since all the necessary wiring is accessible

on the top of the distribution board, it would be an easy job with

a knife to cut the appropriate traces to make the necessary

connections. There is quite a bit of room inside both hoods for

batteries, sound systems, and control receivers or decoders.

The

schematic of the Center Cab is dead simple. The main distribution

board on the frame interconnects the motors and power pickups.

Lighting wires are taken off the board to go to each hood. The

lighting is the same as on recent RS-3's but it cannot be turned

off. There are incandescent lights for the cab and the number

boards. The headlights are yellow LED's. These can be seen in the

daylight, but do not cast any form of beam at night. There is a

"smoke" switch but no smoke unit to switch. The switch just

terminates on a pad on the circuit board.

The

schematic of the Center Cab is dead simple. The main distribution

board on the frame interconnects the motors and power pickups.

Lighting wires are taken off the board to go to each hood. The

lighting is the same as on recent RS-3's but it cannot be turned

off. There are incandescent lights for the cab and the number

boards. The headlights are yellow LED's. These can be seen in the

daylight, but do not cast any form of beam at night. There is a

"smoke" switch but no smoke unit to switch. The switch just

terminates on a pad on the circuit board.

The two LEDs on

each end are wired in series with a 470 ohm current limiting

resistor. This sets the diode current at about 20 mA, just right

for a White LED. I have installed

one bright white LED in place of one of the stock LED's in this

picture. The white LED is so bright, that getting this picture was

difficult but it can be seen how much more intense the white LED is

in comparison to the wimpy stock yellow LED. As viewed by eye, the

difference is even greater than the photo indicates.

The two LEDs on

each end are wired in series with a 470 ohm current limiting

resistor. This sets the diode current at about 20 mA, just right

for a White LED. I have installed

one bright white LED in place of one of the stock LED's in this

picture. The white LED is so bright, that getting this picture was

difficult but it can be seen how much more intense the white LED is

in comparison to the wimpy stock yellow LED. As viewed by eye, the

difference is even greater than the photo indicates.

With the headlights modified, the Center

Cab will cast a non trivial beam in darkness. The intensity of the

light cannot compete with sunlight but if you run at night, it

makes a considerable improvement.

With the headlights modified, the Center

Cab will cast a non trivial beam in darkness. The intensity of the

light cannot compete with sunlight but if you run at night, it

makes a considerable improvement.

[ Top ]

Smoke

The Center Cab

Switcher DOES NOT have smoke units, but it doesn't

appear that it would be difficult to install LGB smoke units. The

stack is nearly big enough to take one dropped in from the top. A

little work with a 3/8" drill bit and a rattail file can open the

stack sufficiently to allow an LGB or Seuthe smoke unit to fit. I

am not sure that I want to install $40+ worth of smoke units in

this inexpensive locomotive, but it could be done.

The Center Cab

Switcher DOES NOT have smoke units, but it doesn't

appear that it would be difficult to install LGB smoke units. The

stack is nearly big enough to take one dropped in from the top. A

little work with a 3/8" drill bit and a rattail file can open the

stack sufficiently to allow an LGB or Seuthe smoke unit to fit. I

am not sure that I want to install $40+ worth of smoke units in

this inexpensive locomotive, but it could be done.

[ Top ]

Disassembly of the Center Cab

While the Center Cab is not difficult to take apart, there sure

are a lot of screws that need to be removed to do it. Due to

interference between the sideframes and the hood and cab mounting

screws, it is easier overall to just bite the bullet and strip the

whole thing down short of removing the bricks. Remove all four

sideframes (2 screws each). Then remove 14 more screws underneath

to release the battery boxes, hoods and the cab. Both hoods and the

cab come off as a unit.

If you think that you might want to get into this loco more than

once, then when you reassemble it, leave out the hood screws that

are obscured by the truck sideframes. These aren't really necessary

to hold the hoods on because there are tabs in the battery boxes

that also secure the hoods.

[ Top ]

Radio Control Installation in the Center

Cab

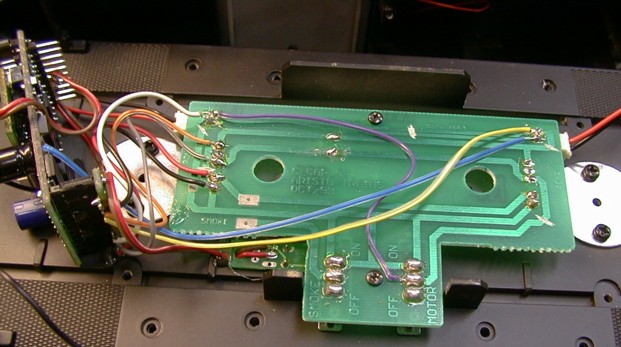

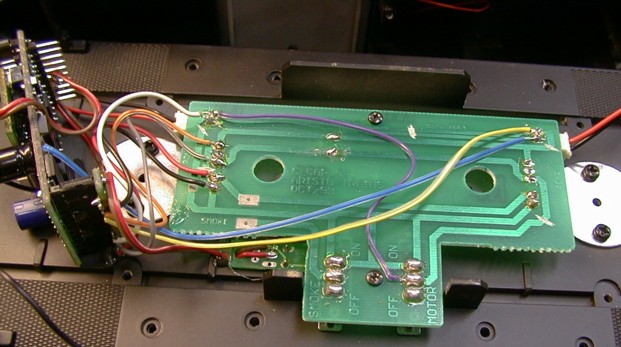

I installed a new

Crest CRE-55491 On Board Train Engineer in the Center Cab. The

installation was pretty easy. Although the rewiring was fairly

extensive from a schematic point of view, it only took 8 circuit

board cuts. Six of the cuts are on the main board and one on each

headlight board. The cuts separate the main circuit board into 4

isolated sections, the power bus, the motor bus and one section

each for the front and rear headlights.

I installed a new

Crest CRE-55491 On Board Train Engineer in the Center Cab. The

installation was pretty easy. Although the rewiring was fairly

extensive from a schematic point of view, it only took 8 circuit

board cuts. Six of the cuts are on the main board and one on each

headlight board. The cuts separate the main circuit board into 4

isolated sections, the power bus, the motor bus and one section

each for the front and rear headlights.

In order to use just the four wires that already go between the

frame and the shell, the functions of the four wires were

reassigned. One brings power up to the shell. The other three

activate one each of the three lighting circuits, the front

headlights, the rear headlights and the cab/number board lights.

The power going to the shell is derived from the internal bus of

the 55491. This bus is available by tapping power from the positive

terminal of the 220 uF capacitor on the 55491.

The cuts can be seen as

light marks on the board, two near each end and one in the upper

center that cuts through BOTH thin traces.

The cuts can be seen as

light marks on the board, two near each end and one in the upper

center that cuts through BOTH thin traces.

The code set switch is mounted to project through the frame

right right next to the switches. The 55491 itself is hot glued

sideways to the frame. The previous motor switch has been

reassigned to control the cab and number board wiring.

[ Top ]

Battery Power Installation in the Center

Cab

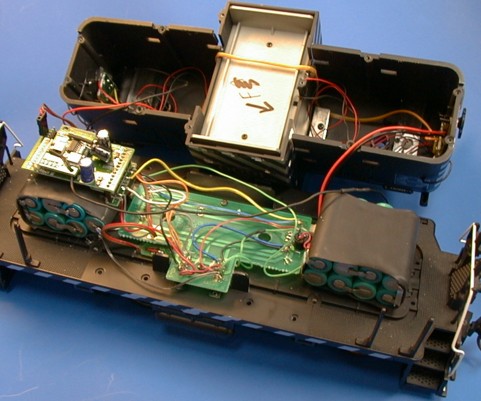

After the track

powered RC installation was in and working, I converted the loco to

track or battery powered operation. For this conversion, I selected

NiMH batteries. 15 AA cells were made into two packs, one of 7

cells and the other 8 cells. The packs were installed in both hoods

with foam mounting tape so that they cleared the truck pivots. The

55491 was mounted with hot glue on top of one of the packs. A

charging jack was mounted on the floor underneath the circuit

board.

After the track

powered RC installation was in and working, I converted the loco to

track or battery powered operation. For this conversion, I selected

NiMH batteries. 15 AA cells were made into two packs, one of 7

cells and the other 8 cells. The packs were installed in both hoods

with foam mounting tape so that they cleared the truck pivots. The

55491 was mounted with hot glue on top of one of the packs. A

charging jack was mounted on the floor underneath the circuit

board.

For this

installation, I elected to use the "tri-modal" configuration. This

allows the loco to run from straight track power, track powered R/C

or battery powered R/C. Since two DPDT switches were already there,

this installation was pretty easy.

For this

installation, I elected to use the "tri-modal" configuration. This

allows the loco to run from straight track power, track powered R/C

or battery powered R/C. Since two DPDT switches were already there,

this installation was pretty easy.

I basically hacked most of the traces on the circuit board to

disconnect everything but the front and rear power pickups and the

motor connectors. All of the traces to the switches were cut and

replaced with wire. Note that the printed wiring board has both

sides of each switch paralleled on the circuit board. It is

necessary to wick all of the solder from the switch terminals and

then carve out the traces between the poles of the switches.

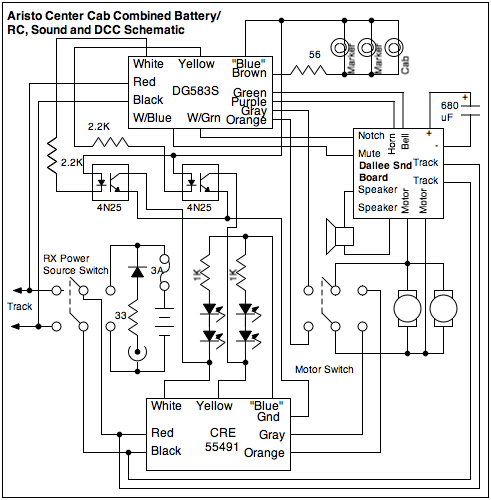

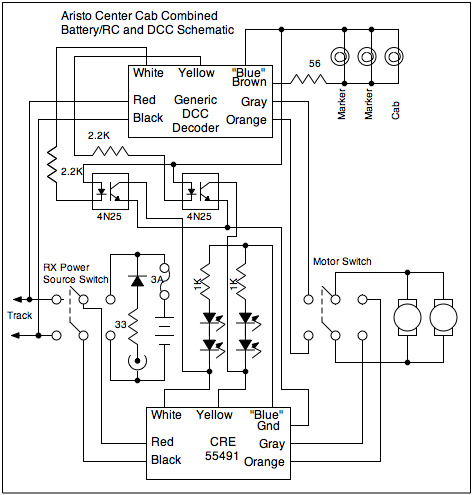

The schematic shows the general wiring of the tri-modal

configuration. One switch controls the source of power, and the

other switch controls where the motors get their power from. The

lighting wiring was left the same as it was in the track powered

R/C configuration. The circuit is designed to charge from 24

VDC.

The headlights are wired the same as the track powered RC

installation but I abandoned the marker and cab lights. These are

incandescent bulbs and draw too much current to run from batteries.

Also, I reused the switch for another purpose so I just left the

incandescent bulbs disconnected.

The antenna of the 75 MHz 55491 is about 18" long. It is routed

around the frame following the shell outline. In this

configuration, the R/C range is 10 to maybe 20 feet.

The range that I got with

the less than ideal antenna arrangement needed improvement. I had

tried other arrangements in the past with the antenna wire wound

around the top of the loco, but these were usually mechanically

unsatisfactory because they complicated disassembly of the loco.

This time I tried a whip antenna made from about 1 foot (30 cm) of

0.020" (0.5 mm) music wire. The wire is so thin that it is nearly

invisible past a few feet especially if it does not contrast with

the background. The wire can be seen coming up from the front deck

just at the nearest corner of the hood. It can also be seen

contrasted against the house in the background.

The range that I got with

the less than ideal antenna arrangement needed improvement. I had

tried other arrangements in the past with the antenna wire wound

around the top of the loco, but these were usually mechanically

unsatisfactory because they complicated disassembly of the loco.

This time I tried a whip antenna made from about 1 foot (30 cm) of

0.020" (0.5 mm) music wire. The wire is so thin that it is nearly

invisible past a few feet especially if it does not contrast with

the background. The wire can be seen coming up from the front deck

just at the nearest corner of the hood. It can also be seen

contrasted against the house in the background.

The wire

antenna was secured to the front pilot assembly with a self tapping

screw. The antenna wire comes through a 0.026" hole in the deck

just outside the cowl and is bent to fit around the screw head. The

antenna wire from the receiver comes though a small hole drilled in

the frame just inside the cowl and is also wrapped around the

screw.

The wire

antenna was secured to the front pilot assembly with a self tapping

screw. The antenna wire comes through a 0.026" hole in the deck

just outside the cowl and is bent to fit around the screw head. The

antenna wire from the receiver comes though a small hole drilled in

the frame just inside the cowl and is also wrapped around the

screw.

This arrangement yielded about triple the former range. There is

reliable control to 30' and some control to 50'. The wire is long

enough so that it will scrape low obstructions some, but it is

flexible enough so that it just slides underneath and pops back to

vertical after clearing the obstruction. Smaller music wire would

work as well, I happened to have the 0.020" diameter wire

handy.

It is somewhat ironic that in the years since I installed

battery/RC into the Center Cab, it get LESS runtime that it did

before. Since it is a 75 MHz RX, it doesn't integrate well with my

27 MHz trackside TE cab control system (except when switched to run

as an analog loco on the track) OR my DCC command control system.

To run it with the DCC stuff, I have to carry around the 75 MHz TX

in addition to the DCC throttle. Before I installed DCC compatible

controls for my interlocking route control system I had to carry

around a 27 MHz TE to control the routes, a DCC throttle to control

the loco and a 75 MHz TE to run the Center Cab. This was too

much.

Once I installed a DCC interface to the route control system, I

only had to carry the DCC throttle and I tended not to run the

Center Cab because it was not DCC capable. Then it occurred to me

that I could have it both ways....

[ Top ]

DCC Installation in the Center Cab

I recently ran the Center Cab at a train show for many hours.

The battery didn't go flat in about 2 hours of running, but I had

difficulty with radio range and also in setting a precision speed

so that the Center Cab stayed in speed sync with another track

powered train running on the same loop. The Train Engineer just

doesn't provide the precision speed control that DCC can provide. I

didn't run it often on the GIRR for the same reason. The loco

itself is very capable and, as demonstrated at the train show,

extremely tolerant of really bad track. All we could run

successfully were the smallest of locos. An FA, which is pretty

tolerant loco in itself, would derail in many places. We didn't

want to stop the show to diddle with the track so anything that had

troubles was simply set aside. The Center Cab ran for hours without

derailing at all.

I've worked out a method to leave virtually all the

functionality that I had with the loco before intact, but I can

still add DCC.

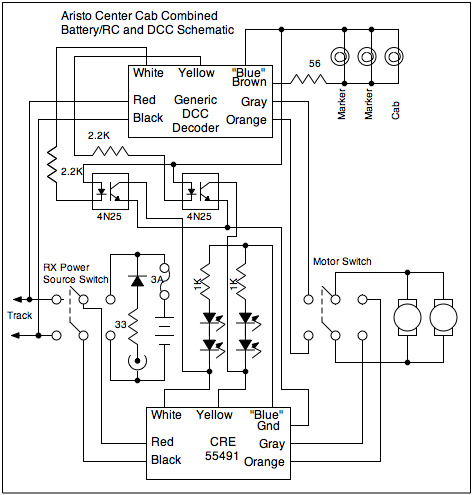

This is the scheme that I have

settled on. It is a slightly modified version of the tri-modal

configuration. The difference is the addition of DCC and the

removal of absolutely straight track power. To run on DC, the loco

depends on the DCC decoder to analog convert. The former "power"

switch now only switches power to the radio receiver so that it

isn't possible to run the motors straight from the battery as

before. The motor switch now selects between the output of the

radio receiver or the DCC decoder. The power selector switch also

serves to disconnect the battery to turn the loco "off" when in

storage or during charging.

This is the scheme that I have

settled on. It is a slightly modified version of the tri-modal

configuration. The difference is the addition of DCC and the

removal of absolutely straight track power. To run on DC, the loco

depends on the DCC decoder to analog convert. The former "power"

switch now only switches power to the radio receiver so that it

isn't possible to run the motors straight from the battery as

before. The motor switch now selects between the output of the

radio receiver or the DCC decoder. The power selector switch also

serves to disconnect the battery to turn the loco "off" when in

storage or during charging.

I had abandoned using the incandescent lighting with battery

power operation due to their current draw, but I will reconnect

those lamps to be controlled via a DCC function and powered only by

the DCC decoder. The CRE-55491 happily accepts DCC track power

although it totally ignores the DCC data on the track. Therefore

the power for the headlights still comes from the RX. It provides

the "Blue" wire function as it is either connected to the battery

or the track and it will see whatever power that is available so

that it can make the + Common voltage that is present on the "Blue"

wire. When the DCC decoder is inactive (because the loco is running

on battery power) the incandescent lights are off. The DCC decoder

can be programmed to enable whatever function is selected for the

cab/marker lights when analog converted so that these lights will

be either controllable with DCC or on if analog converted.

The headlight controls are wired in parallel via optical

isolators to both the DCC decoder and RX. When the loco comes to a

stop, the CRE-55491 turns the headlights off. As long as the

CRE-55491 is remembering that it's last speed command was to stop,

it won't mess with the lights when it isn't being used. Then the

DCC decoder can control the headlights. When switched to battery

power, the DCC decoder is inactive and it leaves the headlights

alone allowing the CRE-55491 to control them. To make this work, I

need to use the "ground" pin on the RX so that the power supplied

by the RX blue wire will return to the RX. There is a grounding

ambiguity without the optical isolators. If the RX is switched to

battery power and the loco is sitting on powered track, there is no

ground return for the headlights to the DCC decoder. Use of the

optical isolators will eliminate that issue.

I tried to fit an available MRC322 in there but it just wouldn't

fit. The MRC322 has a sort of a sound system but it just doesn't

analog convert very well at all. A QSI decoder would fit where the

TE RX is now and it has sound but to buy a new one and make it work

with the battery I'd need a GWire receiver and an Airwire

transmitter as well. This would total about $400 out of pocket, too

much. A DG583S would fit well but it doesn't have sound. A DSX

sound decoder doesn't have the volume for outdoor use. A Phoenix P5

would work, but it's pretty expensive too.

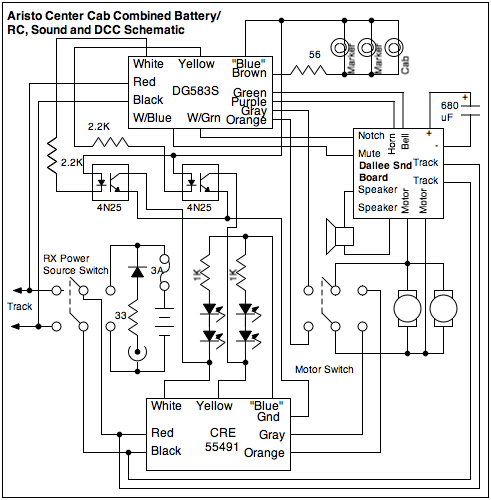

A Dallee system will

barely fit in addition to a DG583S. The Dallee will integrate well

in this configuration and will operate properly when either the DCC

decoder or RX is running the show. So, since I have a DG583S

already and a Dallee board would cost about $94, this looks like

the route I will take. The conversion to DCC costs nothing

additional out of pocket and adding sound costs $94 which I can

optionally do later.

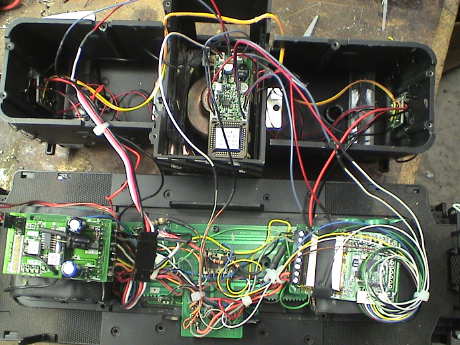

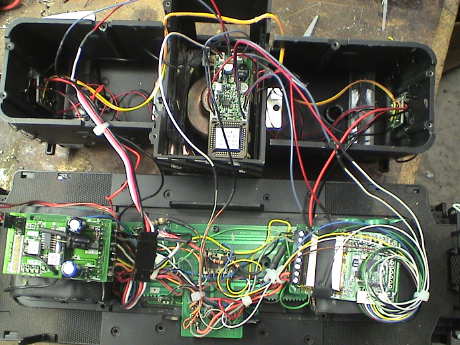

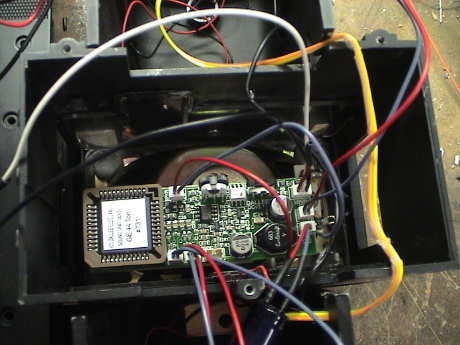

This is the Center Cab with

the DG583S installed. I followed the schematic shown above. Since I

am using the "blue" wires from BOTH the RX and decoder, I had to

add one wire going between the frame and shell. I actually added

three wires because that is what my swap meet special plug/socket

harnesses have and if I ever do add sound, I'll need the other two

wires for the speaker. I did find a place for a small speaker which

can mount in the "rear" hood facing into the cab. I'd have to drill

some holes in the "back" of the cab and take out some cab windows

to let the sound out, but it would work.

This is the Center Cab with

the DG583S installed. I followed the schematic shown above. Since I

am using the "blue" wires from BOTH the RX and decoder, I had to

add one wire going between the frame and shell. I actually added

three wires because that is what my swap meet special plug/socket

harnesses have and if I ever do add sound, I'll need the other two

wires for the speaker. I did find a place for a small speaker which

can mount in the "rear" hood facing into the cab. I'd have to drill

some holes in the "back" of the cab and take out some cab windows

to let the sound out, but it would work.

The two optical isolators are mounted "dead bug" fashion with

foam tape in the middle of the circuit board. They just fit

underneath the cab insert.

There was one ambiguity that I had to work out. This loco

doesn't have an FRA required marking to designate the "front."

Normally, there would be an "F" painted on the side of the frame at

the front of a loco. Diesels run happily either direction so that

the "front" is usually determined by the position of the control

stand. In the Center Cab, the only thing that isn't symmetrical is

the control stand in the cab. It's orientation determines the

front. In this installation, the RX is at the rear, the decoder at

the front. I have set the headlights to conform to these

conventions for both the decoder and the RX.

The analog conversion capability of this decoder is quite good

when running on straight DC track power. One would hardly know that

a DCC decoder is in the loop. However, the decoder doesn't like PWC

on the track at all. It will run, but it's throttle response is

poor and the loco is jerky at some speeds. This decoder can also

activate one set of functions to be on when analog converted. This

is done by programming CV13 as per the decoder programming

instruction book. I've set it to run the headlights directionally

and to turn on the cab lights.

[ Top ]

Sound Installation in the Center Cab

If I elect to install a

Dallee sound board, I would wire it like this. The Dallee board

needs an independent source of track power, it gets that from the

input to the RX which is powered one way or another. The motor

inputs to the Dallee are optically isolated on the Dallee board.

The trigger inputs won't have a ground return when the RX is

running on battery power, but the RX cannot command them anyway and

the decoder will be inactive so that it cannot command them either.

However the motor sound will run when the RX is running on battery

power.

If I elect to install a

Dallee sound board, I would wire it like this. The Dallee board

needs an independent source of track power, it gets that from the

input to the RX which is powered one way or another. The motor

inputs to the Dallee are optically isolated on the Dallee board.

The trigger inputs won't have a ground return when the RX is

running on battery power, but the RX cannot command them anyway and

the decoder will be inactive so that it cannot command them either.

However the motor sound will run when the RX is running on battery

power.

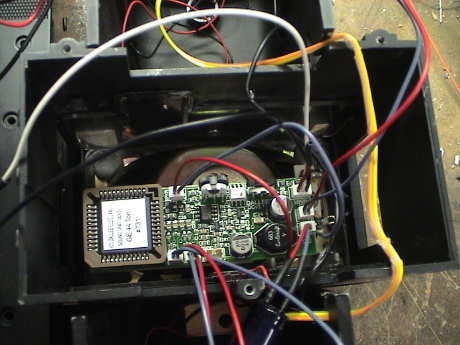

It took me awhile, but I eventually did install a Dallee #731

(44 ton) sound system in the Center Cab. I choose this particular

system because:

- It was fairly inexpensive ($95)

- Would integrate well in the dual motor controller system

- Sounds pretty good, much better than older Dallee systems

- The motor sound is good

- The single chime horn is excellent

- The bell is good

However, the installation didn't go as easily as I had hoped.

With all the other crap that was already there (battery, TE RX and

a DCC decoder) there wasn't room for the sound board under the

hoods or cab.

While

testing the board on the bench, I also realized that it really

could use a good speaker and the speaker that I had planned to use

wasn't going to cut it. There was no place to install a better

speaker and no room for the board. Something had to give.

While

testing the board on the bench, I also realized that it really

could use a good speaker and the speaker that I had planned to use

wasn't going to cut it. There was no place to install a better

speaker and no room for the board. Something had to give.

I elected to rip the cab interior out of the loco and use the

cab volume for the sound installation. The speaker is mounted

against the roof with epoxy putty sealing it in place. The

"enclosure" is now in front of the speaker and the sound is emitted

from the back of the speaker.

I

removed the side windows (which I would have to have done anyway)

to let the sound out of the loco. Now the board can be easily seen

through the window openings, I'll probably jam some black paper in

there to hide the board a little. However, I can get to the volume

and speed controls on the board by working through the cab side

windows.

I

removed the side windows (which I would have to have done anyway)

to let the sound out of the loco. Now the board can be easily seen

through the window openings, I'll probably jam some black paper in

there to hide the board a little. However, I can get to the volume

and speed controls on the board by working through the cab side

windows.

There

are a total of 12 wires that go to the Dallee board. There are two

track power wires, two motor wires (optically isolated on the

board), two wires going to a storage capacitor, two speaker wires

and four function wires. All these wires plug into the Dallee board

so that I didn't install a separate multipin connector. I can still

remove the shell entirely if I want.

There

are a total of 12 wires that go to the Dallee board. There are two

track power wires, two motor wires (optically isolated on the

board), two wires going to a storage capacitor, two speaker wires

and four function wires. All these wires plug into the Dallee board

so that I didn't install a separate multipin connector. I can still

remove the shell entirely if I want.

[ Top ] [ Home ] [ Up ] [

Previous Page ] [ Next Page ]

This page has been accessed  times since 12 July 00.

times since 12 July 00.

© 2000-2009 George Schreyer

Created July 12, 2000

Last Updated August 13, 2009

The Aristo Center Cab Switcher is a small

diesel locomotive modeled after a generic design of many small

industrial engines. There was no real prototype for this loco, but

it is credible in size and proportion. Many small switchers were

made with a center cab and a small (150 to 300 hp) engine/generator

set under each hood.

The Aristo Center Cab Switcher is a small

diesel locomotive modeled after a generic design of many small

industrial engines. There was no real prototype for this loco, but

it is credible in size and proportion. Many small switchers were

made with a center cab and a small (150 to 300 hp) engine/generator

set under each hood. 25 Aug

08

25 Aug

08 The Center Cab is a very smooth and quiet engine.

There is some audible gear noise, but the sound of the wheels on

the rails is louder than the mechanism. The engine is moderately

weighted and has good pulling power. It won't pull as well as the

larger heavier diesels, but since the motors are full sized, a

little weight in the body may improve that. I did run my standard

The Center Cab is a very smooth and quiet engine.

There is some audible gear noise, but the sound of the wheels on

the rails is louder than the mechanism. The engine is moderately

weighted and has good pulling power. It won't pull as well as the

larger heavier diesels, but since the motors are full sized, a

little weight in the body may improve that. I did run my standard

The Center Cab brick is a die cast metal

assembly. It is self contained and is very easy to remove from the

loco. There are two screws in sides of the A-frame that mounts the

truck. Removal of these screws releases the truck. The wiring is

connected to the loco with two plugs. These are differently sized

and keyed so that it is not possible to switch them or plug them in

backwards.

The Center Cab brick is a die cast metal

assembly. It is self contained and is very easy to remove from the

loco. There are two screws in sides of the A-frame that mounts the

truck. Removal of these screws releases the truck. The wiring is

connected to the loco with two plugs. These are differently sized

and keyed so that it is not possible to switch them or plug them in

backwards. The truck

has a conventional can motor and worm gear drive. The motor has a

bypass capacitor and a device that appears to be a surge suppressor

soldered across its terminals. The motor is also wrapped in

electrical tape to insulate the can from the dicast case halves.

The power pickup wires are connected through lugs screwed to each

case half. Note that the wires are just crimped into the lugs and

can come out. This may not be visible due to the sleeving. If you

have a truck apart, it might be reasonable to cut off the sleeving,

remove the wire from the lug, put some more sleeving on the wire,

solder it back to the lug and then heat shrink the sleeving over

the soldered joint.

The truck

has a conventional can motor and worm gear drive. The motor has a

bypass capacitor and a device that appears to be a surge suppressor

soldered across its terminals. The motor is also wrapped in

electrical tape to insulate the can from the dicast case halves.

The power pickup wires are connected through lugs screwed to each

case half. Note that the wires are just crimped into the lugs and

can come out. This may not be visible due to the sleeving. If you

have a truck apart, it might be reasonable to cut off the sleeving,

remove the wire from the lug, put some more sleeving on the wire,

solder it back to the lug and then heat shrink the sleeving over

the soldered joint. Older Aristo bricks

used screws as thrust bearings and sometimes they would squeak

loudly. Also, if the screws were misadjusted, either the motor

bearings would have to take up the thrust or the lash screws would

add drag as the adjustment was quite critical. This brick uses a

spring loaded thrust bearing instead so that adjustment is not

required. The thrust bearing does not add appreciably to motor

drag.

Older Aristo bricks

used screws as thrust bearings and sometimes they would squeak

loudly. Also, if the screws were misadjusted, either the motor

bearings would have to take up the thrust or the lash screws would

add drag as the adjustment was quite critical. This brick uses a

spring loaded thrust bearing instead so that adjustment is not

required. The thrust bearing does not add appreciably to motor

drag. The post is

just under 0.25" in diameter and is nearly the right height to hold

a #831 if the mounting hole on the #831 is drilled out to 0.25".

The coupler box then rests on the pilot and the whole assembly

comes out just a tad higher than the optimum height. The coupler

cannot droop because it is supported by the pilot. However, the

coupler can slide up on the post unless something stops it. The

RS-3 had ridges at the right spot, but these ridges are missing on

the Center Cab. I cut a short piece of 0.25" ID brass tubing and

slid it over the post. With the coupler box in place, I pushed the

tube down to the right position with a toothpick and then applied a

drop of Zap-CA to hold it in place. The existing coupler centering

spring must be trimmed shorter so that it will fit in a #70 hole

drilled in the back of the coupler body

The post is

just under 0.25" in diameter and is nearly the right height to hold

a #831 if the mounting hole on the #831 is drilled out to 0.25".

The coupler box then rests on the pilot and the whole assembly

comes out just a tad higher than the optimum height. The coupler

cannot droop because it is supported by the pilot. However, the

coupler can slide up on the post unless something stops it. The

RS-3 had ridges at the right spot, but these ridges are missing on

the Center Cab. I cut a short piece of 0.25" ID brass tubing and

slid it over the post. With the coupler box in place, I pushed the

tube down to the right position with a toothpick and then applied a

drop of Zap-CA to hold it in place. The existing coupler centering

spring must be trimmed shorter so that it will fit in a #70 hole

drilled in the back of the coupler body When the

Kadee #831 is mounted this way, much of the coupler box is back

inside the pilot and is not visually obtrusive. The coupler is also

mounted much closer to the locomotive than the stock Aristo

coupler.

When the

Kadee #831 is mounted this way, much of the coupler box is back

inside the pilot and is not visually obtrusive. The coupler is also

mounted much closer to the locomotive than the stock Aristo

coupler. When

splayed open, the Center Cab reveals that there is little inside

the unit. A distribution board is mounted to the frame and the hood

wiring plugs in. There is no overt provision for a DCC decoder or a

command receiver, but since all the necessary wiring is accessible

on the top of the distribution board, it would be an easy job with

a knife to cut the appropriate traces to make the necessary

connections. There is quite a bit of room inside both hoods for

batteries, sound systems, and control receivers or decoders.

When

splayed open, the Center Cab reveals that there is little inside

the unit. A distribution board is mounted to the frame and the hood

wiring plugs in. There is no overt provision for a DCC decoder or a

command receiver, but since all the necessary wiring is accessible

on the top of the distribution board, it would be an easy job with

a knife to cut the appropriate traces to make the necessary

connections. There is quite a bit of room inside both hoods for

batteries, sound systems, and control receivers or decoders. The

schematic of the Center Cab is dead simple. The main distribution

board on the frame interconnects the motors and power pickups.

Lighting wires are taken off the board to go to each hood. The

lighting is the same as on recent RS-3's but it cannot be turned

off. There are incandescent lights for the cab and the number

boards. The headlights are yellow LED's. These can be seen in the

daylight, but do not cast any form of beam at night. There is a

"smoke" switch but no smoke unit to switch. The switch just

terminates on a pad on the circuit board.

The

schematic of the Center Cab is dead simple. The main distribution

board on the frame interconnects the motors and power pickups.

Lighting wires are taken off the board to go to each hood. The

lighting is the same as on recent RS-3's but it cannot be turned

off. There are incandescent lights for the cab and the number

boards. The headlights are yellow LED's. These can be seen in the

daylight, but do not cast any form of beam at night. There is a

"smoke" switch but no smoke unit to switch. The switch just

terminates on a pad on the circuit board. The two LEDs on

each end are wired in series with a 470 ohm current limiting

resistor. This sets the diode current at about 20 mA, just right

for a

The two LEDs on

each end are wired in series with a 470 ohm current limiting

resistor. This sets the diode current at about 20 mA, just right

for a  With the headlights modified, the Center

Cab will cast a non trivial beam in darkness. The intensity of the

light cannot compete with sunlight but if you run at night, it

makes a considerable improvement.

With the headlights modified, the Center

Cab will cast a non trivial beam in darkness. The intensity of the

light cannot compete with sunlight but if you run at night, it

makes a considerable improvement. The Center Cab

Switcher DOES NOT have smoke units, but it doesn't

appear that it would be difficult to install LGB smoke units. The

stack is nearly big enough to take one dropped in from the top. A

little work with a 3/8" drill bit and a rattail file can open the

stack sufficiently to allow an LGB or Seuthe smoke unit to fit. I

am not sure that I want to install $40+ worth of smoke units in

this inexpensive locomotive, but it could be done.

The Center Cab

Switcher DOES NOT have smoke units, but it doesn't

appear that it would be difficult to install LGB smoke units. The

stack is nearly big enough to take one dropped in from the top. A

little work with a 3/8" drill bit and a rattail file can open the

stack sufficiently to allow an LGB or Seuthe smoke unit to fit. I

am not sure that I want to install $40+ worth of smoke units in

this inexpensive locomotive, but it could be done. I installed a new

Crest CRE-55491 On Board Train Engineer in the Center Cab. The

installation was pretty easy. Although the rewiring was fairly

extensive from a schematic point of view, it only took 8 circuit

board cuts. Six of the cuts are on the main board and one on each

headlight board. The cuts separate the main circuit board into 4

isolated sections, the power bus, the motor bus and one section

each for the front and rear headlights.

I installed a new

Crest CRE-55491 On Board Train Engineer in the Center Cab. The

installation was pretty easy. Although the rewiring was fairly

extensive from a schematic point of view, it only took 8 circuit

board cuts. Six of the cuts are on the main board and one on each

headlight board. The cuts separate the main circuit board into 4

isolated sections, the power bus, the motor bus and one section

each for the front and rear headlights. The cuts can be seen as

light marks on the board, two near each end and one in the upper

center that cuts through BOTH thin traces.

The cuts can be seen as

light marks on the board, two near each end and one in the upper

center that cuts through BOTH thin traces. After the track

powered RC installation was in and working, I converted the loco to

track or battery powered operation. For this conversion, I selected

NiMH batteries. 15 AA cells were made into two packs, one of 7

cells and the other 8 cells. The packs were installed in both hoods

with foam mounting tape so that they cleared the truck pivots. The

55491 was mounted with hot glue on top of one of the packs. A

charging jack was mounted on the floor underneath the circuit

board.

After the track

powered RC installation was in and working, I converted the loco to

track or battery powered operation. For this conversion, I selected

NiMH batteries. 15 AA cells were made into two packs, one of 7

cells and the other 8 cells. The packs were installed in both hoods

with foam mounting tape so that they cleared the truck pivots. The

55491 was mounted with hot glue on top of one of the packs. A

charging jack was mounted on the floor underneath the circuit

board. For this

installation, I elected to use the "tri-modal" configuration. This

allows the loco to run from straight track power, track powered R/C

or battery powered R/C. Since two DPDT switches were already there,

this installation was pretty easy.

For this

installation, I elected to use the "tri-modal" configuration. This

allows the loco to run from straight track power, track powered R/C

or battery powered R/C. Since two DPDT switches were already there,

this installation was pretty easy. The range that I got with

the less than ideal antenna arrangement needed improvement. I had

tried other arrangements in the past with the antenna wire wound

around the top of the loco, but these were usually mechanically

unsatisfactory because they complicated disassembly of the loco.

This time I tried a whip antenna made from about 1 foot (30 cm) of

0.020" (0.5 mm) music wire. The wire is so thin that it is nearly

invisible past a few feet especially if it does not contrast with

the background. The wire can be seen coming up from the front deck

just at the nearest corner of the hood. It can also be seen

contrasted against the house in the background.

The range that I got with

the less than ideal antenna arrangement needed improvement. I had

tried other arrangements in the past with the antenna wire wound

around the top of the loco, but these were usually mechanically

unsatisfactory because they complicated disassembly of the loco.

This time I tried a whip antenna made from about 1 foot (30 cm) of

0.020" (0.5 mm) music wire. The wire is so thin that it is nearly

invisible past a few feet especially if it does not contrast with

the background. The wire can be seen coming up from the front deck

just at the nearest corner of the hood. It can also be seen

contrasted against the house in the background. The wire

antenna was secured to the front pilot assembly with a self tapping

screw. The antenna wire comes through a 0.026" hole in the deck

just outside the cowl and is bent to fit around the screw head. The

antenna wire from the receiver comes though a small hole drilled in

the frame just inside the cowl and is also wrapped around the

screw.

The wire

antenna was secured to the front pilot assembly with a self tapping

screw. The antenna wire comes through a 0.026" hole in the deck

just outside the cowl and is bent to fit around the screw head. The

antenna wire from the receiver comes though a small hole drilled in

the frame just inside the cowl and is also wrapped around the

screw. This is the scheme that I have

settled on. It is a slightly modified version of the tri-modal

configuration. The difference is the addition of DCC and the

removal of absolutely straight track power. To run on DC, the loco

depends on the DCC decoder to analog convert. The former "power"

switch now only switches power to the radio receiver so that it

isn't possible to run the motors straight from the battery as

before. The motor switch now selects between the output of the

radio receiver or the DCC decoder. The power selector switch also

serves to disconnect the battery to turn the loco "off" when in

storage or during charging.

This is the scheme that I have

settled on. It is a slightly modified version of the tri-modal

configuration. The difference is the addition of DCC and the

removal of absolutely straight track power. To run on DC, the loco

depends on the DCC decoder to analog convert. The former "power"

switch now only switches power to the radio receiver so that it

isn't possible to run the motors straight from the battery as

before. The motor switch now selects between the output of the

radio receiver or the DCC decoder. The power selector switch also

serves to disconnect the battery to turn the loco "off" when in

storage or during charging. This is the Center Cab with

the DG583S installed. I followed the schematic shown above. Since I

am using the "blue" wires from BOTH the RX and decoder, I had to

add one wire going between the frame and shell. I actually added

three wires because that is what my swap meet special plug/socket

harnesses have and if I ever do add sound, I'll need the other two

wires for the speaker. I did find a place for a small speaker which

can mount in the "rear" hood facing into the cab. I'd have to drill

some holes in the "back" of the cab and take out some cab windows

to let the sound out, but it would work.

This is the Center Cab with

the DG583S installed. I followed the schematic shown above. Since I

am using the "blue" wires from BOTH the RX and decoder, I had to

add one wire going between the frame and shell. I actually added

three wires because that is what my swap meet special plug/socket

harnesses have and if I ever do add sound, I'll need the other two

wires for the speaker. I did find a place for a small speaker which

can mount in the "rear" hood facing into the cab. I'd have to drill

some holes in the "back" of the cab and take out some cab windows

to let the sound out, but it would work. If I elect to install a

Dallee sound board, I would wire it like this. The Dallee board

needs an independent source of track power, it gets that from the

input to the RX which is powered one way or another. The motor

inputs to the Dallee are optically isolated on the Dallee board.

The trigger inputs won't have a ground return when the RX is

running on battery power, but the RX cannot command them anyway and

the decoder will be inactive so that it cannot command them either.

However the motor sound will run when the RX is running on battery

power.

If I elect to install a

Dallee sound board, I would wire it like this. The Dallee board

needs an independent source of track power, it gets that from the

input to the RX which is powered one way or another. The motor

inputs to the Dallee are optically isolated on the Dallee board.

The trigger inputs won't have a ground return when the RX is

running on battery power, but the RX cannot command them anyway and

the decoder will be inactive so that it cannot command them either.

However the motor sound will run when the RX is running on battery

power. While

testing the board on the bench, I also realized that it really

could use a good speaker and the speaker that I had planned to use

wasn't going to cut it. There was no place to install a better

speaker and no room for the board. Something had to give.

While

testing the board on the bench, I also realized that it really

could use a good speaker and the speaker that I had planned to use

wasn't going to cut it. There was no place to install a better

speaker and no room for the board. Something had to give. I

removed the side windows (which I would have to have done anyway)

to let the sound out of the loco. Now the board can be easily seen

through the window openings, I'll probably jam some black paper in

there to hide the board a little. However, I can get to the volume

and speed controls on the board by working through the cab side

windows.

I

removed the side windows (which I would have to have done anyway)

to let the sound out of the loco. Now the board can be easily seen

through the window openings, I'll probably jam some black paper in

there to hide the board a little. However, I can get to the volume

and speed controls on the board by working through the cab side

windows. There

are a total of 12 wires that go to the Dallee board. There are two

track power wires, two motor wires (optically isolated on the

board), two wires going to a storage capacitor, two speaker wires

and four function wires. All these wires plug into the Dallee board

so that I didn't install a separate multipin connector. I can still

remove the shell entirely if I want.

There

are a total of 12 wires that go to the Dallee board. There are two

track power wires, two motor wires (optically isolated on the

board), two wires going to a storage capacitor, two speaker wires

and four function wires. All these wires plug into the Dallee board

so that I didn't install a separate multipin connector. I can still

remove the shell entirely if I want.