8 Aug 12

8 Aug 12[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

A speaker is an electro-mechanical device that is intended to convert analog electrical energy into acoustic energy. They are manufactured in a dizzying array of sizes, shapes and capabilities for a variety of applications. For the purposes of this page, I will restrict the discussion to those speakers that are suitable for use with model railroad sound systems. This means that a single speaker usually has to do the whole job unlike many applications were several types of speakers are used together to extend the frequency range of the audio signal.

I won't go too much into the details of speaker design or applications, this information is already all over the internet. A good place to start looking for more information is Wikipedia. The pages at Loudspeakers and Electrical Characteristics of a Dynamic Loudspeaker are good places to start.

However, there are some parts that I feel the need to stress and these are covered by the section below with a specific slant toward model railroad applications.

There are a lot of things to look out for in the selection of a speaker besides it's impedance and power rating. Just by looking at the way a speaker is made and looking at the ratings (hopefully) printed on the back, you can make a good first choice of which speaker to use.

I show this one first

because it has a clear plastic cone so that some of the guts are

easy to see. This one came out of a Vanderbilt tender for an

AristoCraft Pacific. This speaker has pretty much all of the stuff

that you will find in any speaker. The frame, or basket, is a

stamped steel piece. It provides sufficient rigidity for this

application. Stiffer baskets, maybe a heavy cast aluminum part, are

simply not needed for the low audio power that model trains use.

The transparent cone is suspended around its edge and via a

diaphragm (the orange thing) at the center. These two suspensions

allow the cone to move so that it can pump air and to keep it

centered. A "voice coil" is a single layer of wire wrapped around

the tubular section at the center of the cone. The voice coil wires

are brought out to a set of solder terminals on the backside of the

speaker. When an electrical current is passed through the coil, it

creates a magnetic field. That field interacts with a fixed

magnetic field formed by a permanent magnet. One pole of the

permanent magnet is the metal slug that can be seen inside the

voice coil. The other pole is formed by a metal cup attached to the

basket. The magnet itself is behind the voice coil, between the

backside of the slug and the back of the cup.

I show this one first

because it has a clear plastic cone so that some of the guts are

easy to see. This one came out of a Vanderbilt tender for an

AristoCraft Pacific. This speaker has pretty much all of the stuff

that you will find in any speaker. The frame, or basket, is a

stamped steel piece. It provides sufficient rigidity for this

application. Stiffer baskets, maybe a heavy cast aluminum part, are

simply not needed for the low audio power that model trains use.

The transparent cone is suspended around its edge and via a

diaphragm (the orange thing) at the center. These two suspensions

allow the cone to move so that it can pump air and to keep it

centered. A "voice coil" is a single layer of wire wrapped around

the tubular section at the center of the cone. The voice coil wires

are brought out to a set of solder terminals on the backside of the

speaker. When an electrical current is passed through the coil, it

creates a magnetic field. That field interacts with a fixed

magnetic field formed by a permanent magnet. One pole of the

permanent magnet is the metal slug that can be seen inside the

voice coil. The other pole is formed by a metal cup attached to the

basket. The magnet itself is behind the voice coil, between the

backside of the slug and the back of the cup.

This is an inexpensive speaker with only moderate performance. It was replaced for a better one making this one available for this photo.

Speakers don't have to be circular.

These three oval speakers are of the type used in many AristoCraft

locomotives. The field cup can be easily seen on the one on the

left. This one was taken out of an AristoCraft RS3 to be replaced

by another more like the other two. This kind of speaker is very

commonly used in computers and external computer speakers. They fit

really well into large scale locomotives. If you can find parts

like these, they will come in very handy. The center and right

speakers sport a larger magnet housing. A larger magnet can

create a stronger magnetic field. The stronger field allows the use

of more audio power to get more forceful cone movement for louder

sound.

Speakers don't have to be circular.

These three oval speakers are of the type used in many AristoCraft

locomotives. The field cup can be easily seen on the one on the

left. This one was taken out of an AristoCraft RS3 to be replaced

by another more like the other two. This kind of speaker is very

commonly used in computers and external computer speakers. They fit

really well into large scale locomotives. If you can find parts

like these, they will come in very handy. The center and right

speakers sport a larger magnet housing. A larger magnet can

create a stronger magnetic field. The stronger field allows the use

of more audio power to get more forceful cone movement for louder

sound.

This is a pair of cheap

speakers recovered from some low cost clock radio or something like

that. They have a paper cone, but otherwise are similar to the

plastic cone speaker shown above. The cone has a fairly stiff

suspension (the ripples around the edge) that limits cone movement.

The magnet is small. Unless your requirements are very restrictive,

you'll want to find better ones. These might be adequate to use

with a Bachmann analog chuff only sound board. If you spend $100 or

more on a good sound system, you'll want a much better speaker than

these.

This is a pair of cheap

speakers recovered from some low cost clock radio or something like

that. They have a paper cone, but otherwise are similar to the

plastic cone speaker shown above. The cone has a fairly stiff

suspension (the ripples around the edge) that limits cone movement.

The magnet is small. Unless your requirements are very restrictive,

you'll want to find better ones. These might be adequate to use

with a Bachmann analog chuff only sound board. If you spend $100 or

more on a good sound system, you'll want a much better speaker than

these.

This is a pair of

speakers with a firm suspension, but a MUCH larger magnet assembly.

The magnet itself is visible on this part, it is the black ring

around the back. We're getting close to what we are looking for

with these parts.

This is a pair of

speakers with a firm suspension, but a MUCH larger magnet assembly.

The magnet itself is visible on this part, it is the black ring

around the back. We're getting close to what we are looking for

with these parts.

These small speakers

have a much softer suspension to allow more cone movement. This

provides better damping, a lower resonant frequency and it allows

the speaker cone to move more so that it can pump more air. This is

important to be able to get any kind of low frequency response at

all from a very small speaker. The one on the left has a half roll

of an impregnated cloth. The one on the right has the ripple like

suspension like the cheaper speakers, but the ripple area is

treated in such a way as to make it soft.

These small speakers

have a much softer suspension to allow more cone movement. This

provides better damping, a lower resonant frequency and it allows

the speaker cone to move more so that it can pump more air. This is

important to be able to get any kind of low frequency response at

all from a very small speaker. The one on the left has a half roll

of an impregnated cloth. The one on the right has the ripple like

suspension like the cheaper speakers, but the ripple area is

treated in such a way as to make it soft.

This is the front

and back of a speaker intended for automotive stereo use. The cone

has a soft half roll suspension and it can really move a lot, so

much so that the mounting surface is recessed behind a thick foam

gasket as the cone can move right out of the front and hit a

mounting surface if the gasket wasn't there. The basket is also

highly sloped to allow the cone to move backwards without striking

the basket. The magnet is fair sized. One of these speakers

replaced the plastic cone speaker in the AristoCraft Vanderbilt

tender.

This is the front

and back of a speaker intended for automotive stereo use. The cone

has a soft half roll suspension and it can really move a lot, so

much so that the mounting surface is recessed behind a thick foam

gasket as the cone can move right out of the front and hit a

mounting surface if the gasket wasn't there. The basket is also

highly sloped to allow the cone to move backwards without striking

the basket. The magnet is fair sized. One of these speakers

replaced the plastic cone speaker in the AristoCraft Vanderbilt

tender.

All of the speakers shown above are about 2 to 2.5" in diameter, a suitable size for mounting inside most large scale rolling stock. There are larger speakers available with these same characteristics. If you can fit a larger speaker into your intended application, do so. In this case, bigger really is better.

In the smaller scales,

there isn't nearly enough room for a 2" speaker. These are a

collection of small speakers that are sized to fit into HO or

smaller equipment. All of these are rated at 0.25 watts or less.

The ones above vary from 0.5 watts to 8 watts.

In the smaller scales,

there isn't nearly enough room for a 2" speaker. These are a

collection of small speakers that are sized to fit into HO or

smaller equipment. All of these are rated at 0.25 watts or less.

The ones above vary from 0.5 watts to 8 watts.

The three across the top are 28 mm 8Ω speakers that are typically supplied with HO type sound systems. The left one has been enclosed in a small homebrew housing, the center one is one that came with a Dallee sound board and the right one came with a Digitrax sound decoder. The little one on the lower left is a 15 mm driver that came with a Digitrax N scale sound decoder. The other two are the front and backside of a 22 mm or so 100Ω speaker that came with LokSound v3.5 sound decoders. These speakers are all low profile so that they have very limited cone movement capability. All have plastic cones and fairly small magnets. However, 250 mW is all an HO sized loco really needs for indoor operation and besides the really poor low frequency response of these speakers, they work well enough. There are "high bass" version of HO sized speakers that look more like small versions of the automotive speakers above. They don't make much more overall sound, but they do work down to lower frequencies. These speakers probably cannot reproduce anything below the speech range of 300 Hz, the "high bass" versions may be able to get down to 200 Hz or so.

These little speakers don't make much volume so that the sound pressure that they generate is not very high. The enclosed speaker uses only 15 mil styrene for it's enclosure, fully stiff enough for the sound pressures involved. It is easy to wrap a styrene strip around a speaker, glue it into a ring and then glue that to the back of the speaker. The rear cover is just another piece of 15 mil sheet glued across the back.

A speaker may be a simple device mechanically, but electrically, they are pretty complex. There are a lot of characteristics that impact a speaker's performance capability in any given application.

Speakers typically come with just two electrical specifications, impedance and power rating.

The power rating is the easiest to deal with. The speaker's power rating should exceed the rating of the sound system used to drive it. Otherwise, the higher power of the sound system can drive the speaker to it's physical stops causing internal mechanical interference, awful distortion and likely permanent physical damage to the speaker.

The impedance is a little less easy. The impedance of a speaker is rated in ohms. In fact, it has this impedance only over a small portion of it's operating range. However, the impedance should be matched to the capability of the sound system used. A typical value is 4, 8, 16, 32 or 100 ohms. If the speaker has too low an impedance, it will try to draw too much current from the sound system. This will either cause the sound system to overheat and shut down or physically burn up. If the speaker impedance is too high, the full power of the sound system cannot be delivered to the speaker, resulting in loss of volume but little chance of damage.

For MOST small speakers, the rated impedance is very close to the DC resistance of the voice coil. If you don't know the impedance rating of a speaker, then simply measure it with DC ohmmeter. The AC impedance of the speaker CAN NEVER be less than the DC value.

At DC, or zero frequency, the impedance of the speaker is the DC resistance. As the frequency rises, the speaker will experience a mechanical resonance. This is basically because the speaker is a mass suspended by a spring. At this mechanical resonant frequency, the impedance of the speaker, as measured in free air (without an enclosure to damp the resonance) will be 1.5 to 2 times the DC resistance. If you apply a low frequency sine wave from an audio oscillator to the speaker leads, you may see the cone start to move quite wildly at this resonant frequency. If the speaker is enclosed, the air pressure generated inside the box will damp this movement. A speaker really cannot reproduce frequencies at or below resonance without problems or distortion. At the lowest frequencies, near DC, the speaker is equivalent to a stalled DC motor, it will draw lots of current (limited by it's DC resistance) and make very little audio power. It can run hotter that normal, but not by a lot. Most speakers are very inefficient, less than 5%, so that even if none of the applied audio power is carried away as acoustic energy, the speaker will not run much hotter than it does in normal operation.

At frequencies about twice the mechanical resonant frequency, the impedance dips back down to near the DC value for maybe a decade in frequency. This is the normal operating frequency range of the speaker. At even higher frequencies, the inductance of the voice coil starts to dominate and the impedance starts to double for every octave increase in frequency. The power that can be delivered to the speaker diminishes due to the higher impedance and the sound volume fades away.

A speaker really cannot be used effectively by itself. It MUST have an enclosure of some kind to operate properly.

When the speaker cone moves, it pushes air on one side and pulls air on the other side. The sound pressure waves created from each side are said to be "out of phase." The wavelength of the acoustic signal in air is long with respect to the size of the small speakers so that the wave generated from the back side can roll around the edge of the speaker and literally cancel the wave from the front. This results in serious cancellation of the total output of the speaker. This cancellation is easily demonstrated by making a poor enclosure from you own hand and listening to the difference as heard in this short QuickTime movie.

The easiest enclosure to understand is also impossible to build, it is called the "infinite baffle." Imagine a solid plane that extends to an infinite distance along a plane is all directions. The speaker is mounted in a hole in the baffle. The sound generated from the backside can never get around or through the baffle to interfere with the sound from the front of the speaker. Half of the available power is thrown away, but at least there is no interference. This is about the best that one can do in theory.

In practice, the infinite baffle is not a real great plan. Instead, the backside of the speaker is enclosed in a box, the bigger the better. The box traps the acoustic energy from the backside and hopefully dissipates it so that it simply goes away as a little bit of heat. This method doesn't work too badly and it is easy to do. The box needs to be stiff enough such that the sound pressure inside the box does not distort the box. At the low sound pressures involved in a model railroad application, the box doesn't have to be very stiff. At small scale sound levels, 15 or 20 mils of styrene is enough. For the higher power levels of large scale sound systems, a typical engine or tender shell is enough provided that it doesn't rattle. Some folks insist that the box must be absolutely airtight but in practice, that doesn't matter much either. All that is necessary is to trap MOST of the sound from the backside. If a little bit gets out, it will detract from the volume a little and may cause some frequency response issues, but those issues will usually not be too severe.

Simply build an enclosed volume behind the speaker from plastic, wood or even heavy cardboard and seal it up as best as you can. Folks have used premade enclosures, 35 mm film cans, plastic bottle tops, pill bottles or all manner of other things that might be thrown away. The result will be adequate.

Audiophiles may rile at this simple recommendation, but good enough really is good enough.

This is an example of a pre-made enclosure. I bought a bunch of these with speakers many moons ago at a computer swap meet.

This is an example of a pre-made enclosure. I bought a bunch of these with speakers many moons ago at a computer swap meet.

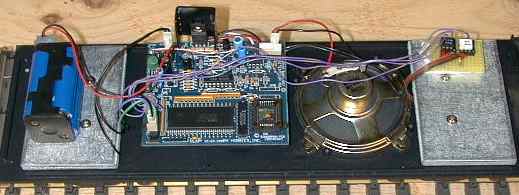

Often a steam tender offers an ideal place to mount a speaker, usually shooting through the tender floor. The tender shell then completes the housing.

Often a steam tender offers an ideal place to mount a speaker, usually shooting through the tender floor. The tender shell then completes the housing.

The fuel tank of a large scale diesel also works well. This is a USAT F3A tank with the speaker simply embedded in a backfill of hot glue.

The fuel tank of a large scale diesel also works well. This is a USAT F3A tank with the speaker simply embedded in a backfill of hot glue.

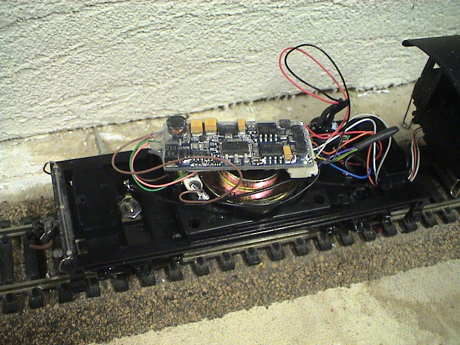

Smaller speakers will even fit in HO steam tenders, usually along with a sound decoder.

Smaller speakers will even fit in HO steam tenders, usually along with a sound decoder.

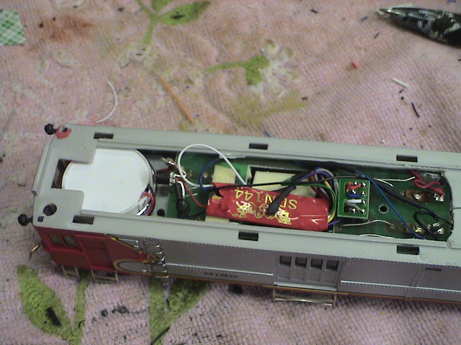

Even the constrained space in an HO doodlebug can hold a speaker made from sheet styrene. This one is facing downward so that the sound escapes around the front truck and gear tower.

Even the constrained space in an HO doodlebug can hold a speaker made from sheet styrene. This one is facing downward so that the sound escapes around the front truck and gear tower.

The large scale Lehman Porter has little room for a speaker, I mounted a small one inside the spark arrestor on the smokestack.

The large scale Lehman Porter has little room for a speaker, I mounted a small one inside the spark arrestor on the smokestack.

When the rest of a loco is filled with batteries or other stuff, sometimes the speaker can be mounted under the cab roof. This one is sealed off on the "front" of the speaker so that the sound radiates off the back and out the windows.

When the rest of a loco is filled with batteries or other stuff, sometimes the speaker can be mounted under the cab roof. This one is sealed off on the "front" of the speaker so that the sound radiates off the back and out the windows.

I mounted a pre-enclosed speaker inside a Doodlebug so that the sound escapes out the open cargo doors. I did the same kind of mount in a railbus.

I mounted a pre-enclosed speaker inside a Doodlebug so that the sound escapes out the open cargo doors. I did the same kind of mount in a railbus.

Sometimes the best place in a steam tender is facing upward. In the LGB powered tender, the path down is blocked by the motor block. I drilled out holes in the coal load and mounted the speaker on the back of the coal load. This trick also works on HO tenders.

Sometimes the best place in a steam tender is facing upward. In the LGB powered tender, the path down is blocked by the motor block. I drilled out holes in the coal load and mounted the speaker on the back of the coal load. This trick also works on HO tenders.

[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

This page has been accessed times since 16 Jan 11.

© 2011-2012 George Schreyer

Created 16 Jan 11

Last Updated August 8, 2012