Bachmann 2-4-2 Columbia Tips

[ Home ] [ Up ] [ Previous

Page ] [ Next Page ]

The Bachmann 2-4-2 Columbia is a small engine

modeled to look like an old western wood burning engine. There was

another version manufactured that was a coal burner. Actually, neither

follows a real prototype very closely. The closest prototype engine was

a cane field loco that was built by Baldwin and ran in Hawaii.

The Bachmann 2-4-2 Columbia is a small engine

modeled to look like an old western wood burning engine. There was

another version manufactured that was a coal burner. Actually, neither

follows a real prototype very closely. The closest prototype engine was

a cane field loco that was built by Baldwin and ran in Hawaii.

This engine should not be confused with the Bachmann Spectrum Line

2-4-2T which is a much newer and more capable engine.

The 2-4-2 Columbia type got its name because one of the first ones

manufactured was exhibited at the World's Columbian Exposition at

Chicago in 1893. The engine type was generally not very successful and

not many were built. The 4-4-0 American and 4-6-0 Ten Wheeler types

tracked better at speed due to their 4 wheel leading truck and the

2-6-0 Mogul type was generally bigger and provided better traction in

freight service due to more weight and six drivers. The Columbia was

just too small to take advantage of the larger firebox that the

trailing truck allowed. The real advantage of the trailing truck was

realized in the larger Atlantic, Pacific and Mikado class engines.

True to its prototype heritage, the model isn't very successful

either. Of all the large scale engines that I have come across, none

tracks or pulls more poorly that this model. It is my understanding

that this version of the engine is no longer in production.

The engine does have a kind of a "cute" look to it and since it does

actually run, it deserves the attention that it takes to make it

marginally useful.

Contents

Derailments

The engine, especially the leading truck, has a tendency to derail

often, especially over turnouts. There is really little that can be

done besides checking and setting the leading and trailing truck gauge.

There is not enough clearance above the truck to add much weight to the

trucks, but 1 oz of stick on HO type weights does help some.

Shimming the drivers also helps keep the frame in line and helps to

minimize derailments. This also works on the 4-6-0 Big Hauler. The

shimming method can be found in the Big Hauler Tips Page.

[ Top ]

Gearing

The gearing method used in the Columbia is similar to the early

model Big Haulers. However, the gearing is less likely to get mangled

simply because the engine pulls so poorly that little stress gets

applied to the gears. Two or at most three cars is about all this

little engine can handle even on light grades. On a 5% grade, one car

is about it.

When I first got my Columbia many many moons ago, it ran terrible.

It jerked badly and had awful gear noise. I finally got so tired of it

that I sent it back to Bachmann with $20 to get it repaired. Bachmann

was good to their warranty and when the engine came back, it had a new

bottom end. It ran very quietly and smoothly. The difference was

astounding. It still didn't pull worth a hoot, but at least it was

usable.

[ Top ]

Power Pickup

The Columbia suffers from flaky power pickup, just like its bigger

brother, the 4-6-0 Big Hauler, and for all the same reasons.

The spring loaded power contacts crap out, but not as badly as on

the Big Hauler because the engine draws less current and the contacts

don't heat as much. The fixes are the same as for the Big Hauler,

either remove and rebuild the contacts or substitute LGB contacts for

them.

The driver lateral play can allow the drivers to move away from the

contacts enough so that they no longer touch the backs of the drivers.

Shimming the drivers solves this problem.

The wheels get dirty easily and do require cleaning more often that

I would like.

The pony trucks are wired to pick up power but, as with the Big

Hauler, the bearings don't transmit power very well. Besides

lubricating the bearings with conductive oil, there is not much that

can be done with them.

The tender

trucks on the Columbia have pockets molded in them that accept LGB

power pickups. By installing metal wheels and wiring power contacts to

the engine, a significant improvement in power pickup reliability can

be realized. However, this improvement comes at the cost of increased

drag which this little engine can ill afford.

The tender

trucks on the Columbia have pockets molded in them that accept LGB

power pickups. By installing metal wheels and wiring power contacts to

the engine, a significant improvement in power pickup reliability can

be realized. However, this improvement comes at the cost of increased

drag which this little engine can ill afford.

The tender trucks take small wheels. I used Gary Raymond 33"

wheelsets. Dean Lowe also makes wheels that will fit.

With the trucks disassembled, drill out the plastic wall between the

adjacent pockets with a drill a couple of sizes smaller than the

pockets. Then use the same drill to drill through to this new passage

from the outside. Solder small flexible wires to each contact and

thread the wires into the pocket and out the new center hole.

Reassemble the truck and wire the new contacts to the engine. The

trailing truck is a convenient place to connect to the engine by

soldering wires to the existing wheel bearings.

The Gary Raymond semi-finescale wheels that I had put on the tender

had been causing derailment problems all along. The smaller, more

visually attractive, flange was just not big enough to provide reliable

tracking. I installed a set of Aristo

C-16 tender wheels that I had taken off the C-16 during

investigation of a power pickup problem. These wheels have a typical

large scale (that is way out of scale) flange and they track MUCH

better. The power pickup seems to be good too.

[ Top ]

Sound

The sound system in the Columbia is identical to the Big Hauler

sound system. The Better Bachmann

Sound For About A Buck page describes modifying the sound in a Big

Hauler. All of the modifications described there are entirely

applicable to the Columbia. However, since the drivers on the Columbia

are much smaller than on the Big Hauler, making the 4 chuff

modification may make the engine chuff entirely too fast unless you

like to run fairly slowly.

There is one

complication on the Columbia that doesn't exist on the Big Hauler. The

sound drum is so close to the front mounting post for the bottom cover

that the resistors won't fit without modifications to the drum. I cut

grooves into the drum with a motor tool to recess the resistors and

glued them on with ZapCA.

There is one

complication on the Columbia that doesn't exist on the Big Hauler. The

sound drum is so close to the front mounting post for the bottom cover

that the resistors won't fit without modifications to the drum. I cut

grooves into the drum with a motor tool to recess the resistors and

glued them on with ZapCA.

Like some Big Haulers, the wire that leads between the engine and

tender that connects the sound system gets stiff with age and will

often pull out if its socket. I just replace the wire with a piece of

very small zip cord. Disassembly of the connector can be a challenge,

but it can be done by using a sharp tool to depress the metal clips

that hold the contacts in the connector shell.

[ Top ]

Other Characteristics

Smoke. The Columbia is equipped with a smoke generator but it

cannot be turned off. I was not aware that it had smoke until I pulled

off the stack and looked. It had apparently burned out because it does

not work. The stack (on the wood burner at least) is too small to

accept an LGB smoke unit.

Front Coupler. The front coupler on the Columbia is just a

dummy unit. Even with a functioning coupler it would be fully useless

as the front overhang on curves is too great.

Pilot. The pilot on my wood burner hung too low and caught on

the track often. I've modified the pilot support rods to pull the pilot

up higher so that it will clear normal obstacles.

[ Top ]

A Newer Model?

I've seen reports that Bachmann is still producing an updated

version of the Columbia. From the reports on LSOL, the newer engine has

a completely redesigned gear train. The motor now sits vertically

instead of horizontally behind the rear axle. The reports also indicate

that the engine pulls better than mine and has a smoke unit.

Externally, the model appears to be similar. If you see one cheap, it

might be a deal.

[ Top ]

DCC Installation

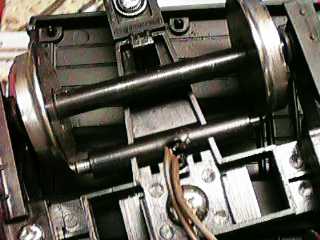

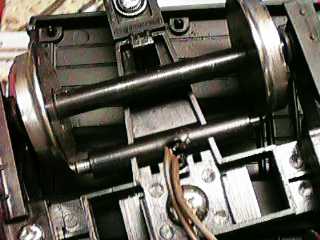

I have elected to convert the GIRR Mountain Division to DCC. This

means installing a DCC decoder in every loco. One of the things that

must be done in a DCC installation is to isolate the motor from all

other wiring. This is a photo of the motor once all the other wiring

has been removed. There is a metal strip down each side of the brick

that brings track power back from the front pony truck and the drivers.

It terminates on a small tab right next to each motor tab. The motor

tabs used to be soldered to these strips. There was also a pair of

wires leading to the rear pony truck and another pair leading up into

the boiler for the (defunct) smoke unit and the headlight. There is no

smoke switch in this loco, the smoke unit runs all the time which is

probably why it died.

I have elected to convert the GIRR Mountain Division to DCC. This

means installing a DCC decoder in every loco. One of the things that

must be done in a DCC installation is to isolate the motor from all

other wiring. This is a photo of the motor once all the other wiring

has been removed. There is a metal strip down each side of the brick

that brings track power back from the front pony truck and the drivers.

It terminates on a small tab right next to each motor tab. The motor

tabs used to be soldered to these strips. There was also a pair of

wires leading to the rear pony truck and another pair leading up into

the boiler for the (defunct) smoke unit and the headlight. There is no

smoke switch in this loco, the smoke unit runs all the time which is

probably why it died.

I have bent the motor tabs inward and the contact tabs outward to

provide clearance between them. The two wires that were soldered to the

tab on each side were later reconnected and insulated with shrink tube.

A new pair was soldered to the motor tabs and also insulated with

shrink tube. All of these connections are accessible from the top of

the brick.

There just wasn't room in the loco to install a DG583S decoder. The

boiler would have been marginally big enough, except it is nearly full

of cast iron and what space was left, I had filled with lead sometime

in the deep dark distant past. If the smoke unit was removed, the smoke

box would have been long enough but not quite wide enough. A NCE D08SR

might have fit in the smoke box, but I didn't have one handy as I had

just used the last one I had in a Lehmann Porter.

The only place left for the decoder was in the tender so I wired the

motor leads back to a connector to the tender.

My

standard connector has only 3 conductors, two were for the motor and

one for the headlight white wire. However, there weren't enough pins

for the blue wire to power the headlight so I synthesized a blue wire

with half of a bridge rectifier in the form of two diodes soldered to

the tabs of the now dead smoke unit.

My

standard connector has only 3 conductors, two were for the motor and

one for the headlight white wire. However, there weren't enough pins

for the blue wire to power the headlight so I synthesized a blue wire

with half of a bridge rectifier in the form of two diodes soldered to

the tabs of the now dead smoke unit.

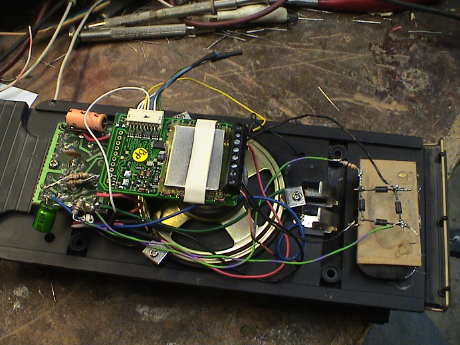

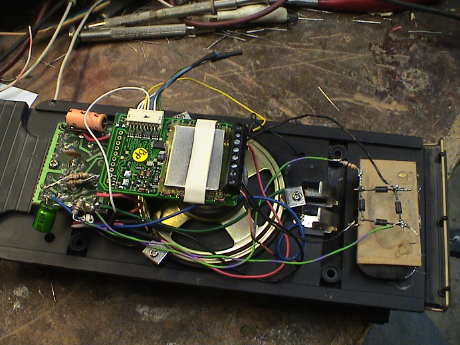

This

is what the tender looked like before I started. The circuit at the

left is a "battery eliminator" for the sound system. It runs from

analog track power to provide 9 volts. When the track power goes away,

so does the power to the sound system so that the chuff would not sit

there blowing continuously when the loco was stopped with the chuff

switch closed. This would not work with DCC because there is track

power all the time. I tried powering this circuit from the motor output

of the decoder, but there was just too much decoder noise getting

through the regulator. Instead, I used my more normal chuff cutoff

circuit as shown in Better Bachmann

Sound For About A Buck. However, in this installation it didn't

work quite right, I had to make it less sensitive by adding a 200 ohm

resistor between the base and emitter of the transistor.

This

is what the tender looked like before I started. The circuit at the

left is a "battery eliminator" for the sound system. It runs from

analog track power to provide 9 volts. When the track power goes away,

so does the power to the sound system so that the chuff would not sit

there blowing continuously when the loco was stopped with the chuff

switch closed. This would not work with DCC because there is track

power all the time. I tried powering this circuit from the motor output

of the decoder, but there was just too much decoder noise getting

through the regulator. Instead, I used my more normal chuff cutoff

circuit as shown in Better Bachmann

Sound For About A Buck. However, in this installation it didn't

work quite right, I had to make it less sensitive by adding a 200 ohm

resistor between the base and emitter of the transistor.

This

is the installation in the tender as completed. The little regulator

circuit has degenerated into a bridge rectifier. The transistor is

mounted next to the sound board. The decoder sits atop the speaker and

pokes up through the hole in the tender shell under the wood load. The

tender will again use a 9V battery to power the sound system but these

last for years.

This

is the installation in the tender as completed. The little regulator

circuit has degenerated into a bridge rectifier. The transistor is

mounted next to the sound board. The decoder sits atop the speaker and

pokes up through the hole in the tender shell under the wood load. The

tender will again use a 9V battery to power the sound system but these

last for years.

The Columbia runs quite well with DCC installed. It seems

uncharacteristically smooth and quiet.

[ Top ] [ Home ] [ Up ] [ Previous Page ] [ Next Page ]

This page has been accessed  times since May 3, 1998.

times since May 3, 1998.

©1998-2008 George Schreyer

Created May 3, 1998

Last Updated December 18, 2008

The Bachmann 2-4-2 Columbia is a small engine

modeled to look like an old western wood burning engine. There was

another version manufactured that was a coal burner. Actually, neither

follows a real prototype very closely. The closest prototype engine was

a cane field loco that was built by Baldwin and ran in Hawaii.

The Bachmann 2-4-2 Columbia is a small engine

modeled to look like an old western wood burning engine. There was

another version manufactured that was a coal burner. Actually, neither

follows a real prototype very closely. The closest prototype engine was

a cane field loco that was built by Baldwin and ran in Hawaii. 18 Dec 08

18 Dec 08 1 Oct 08

1 Oct 08 The tender

trucks on the Columbia have pockets molded in them that accept LGB

power pickups. By installing metal wheels and wiring power contacts to

the engine, a significant improvement in power pickup reliability can

be realized. However, this improvement comes at the cost of increased

drag which this little engine can ill afford.

The tender

trucks on the Columbia have pockets molded in them that accept LGB

power pickups. By installing metal wheels and wiring power contacts to

the engine, a significant improvement in power pickup reliability can

be realized. However, this improvement comes at the cost of increased

drag which this little engine can ill afford. There is one

complication on the Columbia that doesn't exist on the Big Hauler. The

sound drum is so close to the front mounting post for the bottom cover

that the resistors won't fit without modifications to the drum. I cut

grooves into the drum with a motor tool to recess the resistors and

glued them on with ZapCA.

There is one

complication on the Columbia that doesn't exist on the Big Hauler. The

sound drum is so close to the front mounting post for the bottom cover

that the resistors won't fit without modifications to the drum. I cut

grooves into the drum with a motor tool to recess the resistors and

glued them on with ZapCA. I have elected to convert the GIRR Mountain Division to DCC. This

means installing a DCC decoder in every loco. One of the things that

must be done in a DCC installation is to isolate the motor from all

other wiring. This is a photo of the motor once all the other wiring

has been removed. There is a metal strip down each side of the brick

that brings track power back from the front pony truck and the drivers.

It terminates on a small tab right next to each motor tab. The motor

tabs used to be soldered to these strips. There was also a pair of

wires leading to the rear pony truck and another pair leading up into

the boiler for the (defunct) smoke unit and the headlight. There is no

smoke switch in this loco, the smoke unit runs all the time which is

probably why it died.

I have elected to convert the GIRR Mountain Division to DCC. This

means installing a DCC decoder in every loco. One of the things that

must be done in a DCC installation is to isolate the motor from all

other wiring. This is a photo of the motor once all the other wiring

has been removed. There is a metal strip down each side of the brick

that brings track power back from the front pony truck and the drivers.

It terminates on a small tab right next to each motor tab. The motor

tabs used to be soldered to these strips. There was also a pair of

wires leading to the rear pony truck and another pair leading up into

the boiler for the (defunct) smoke unit and the headlight. There is no

smoke switch in this loco, the smoke unit runs all the time which is

probably why it died. My

standard connector has only 3 conductors, two were for the motor and

one for the headlight white wire. However, there weren't enough pins

for the blue wire to power the headlight so I synthesized a blue wire

with half of a bridge rectifier in the form of two diodes soldered to

the tabs of the now dead smoke unit.

My

standard connector has only 3 conductors, two were for the motor and

one for the headlight white wire. However, there weren't enough pins

for the blue wire to power the headlight so I synthesized a blue wire

with half of a bridge rectifier in the form of two diodes soldered to

the tabs of the now dead smoke unit. This

is what the tender looked like before I started. The circuit at the

left is a "battery eliminator" for the sound system. It runs from

analog track power to provide 9 volts. When the track power goes away,

so does the power to the sound system so that the chuff would not sit

there blowing continuously when the loco was stopped with the chuff

switch closed. This would not work with DCC because there is track

power all the time. I tried powering this circuit from the motor output

of the decoder, but there was just too much decoder noise getting

through the regulator. Instead, I used my more normal chuff cutoff

circuit as shown in

This

is what the tender looked like before I started. The circuit at the

left is a "battery eliminator" for the sound system. It runs from

analog track power to provide 9 volts. When the track power goes away,

so does the power to the sound system so that the chuff would not sit

there blowing continuously when the loco was stopped with the chuff

switch closed. This would not work with DCC because there is track

power all the time. I tried powering this circuit from the motor output

of the decoder, but there was just too much decoder noise getting

through the regulator. Instead, I used my more normal chuff cutoff

circuit as shown in  This

is the installation in the tender as completed. The little regulator

circuit has degenerated into a bridge rectifier. The transistor is

mounted next to the sound board. The decoder sits atop the speaker and

pokes up through the hole in the tender shell under the wood load. The

tender will again use a 9V battery to power the sound system but these

last for years.

This

is the installation in the tender as completed. The little regulator

circuit has degenerated into a bridge rectifier. The transistor is

mounted next to the sound board. The decoder sits atop the speaker and

pokes up through the hole in the tender shell under the wood load. The

tender will again use a 9V battery to power the sound system but these

last for years.