Aristo Rogers 2-4-2 Tips

[ Home ] [ Up ] [ Previous

Page ] [ Next Page ]

The 2-4-2 Columbia type got its name because one of the

first ones manufactured was exhibited at the World's Columbian

Exposition at Chicago in 1893. The engine type was generally not very

successful and not many were built. The 4-4-0 American and 4-6-0 Ten

Wheeler types tracked better at speed due to their 4 wheel leading

truck and the 2-6-0 Mogul type was generally bigger and provided better

traction in freight service due to more weight and six drivers. The

Columbia was just too small to take advantage of the larger firebox

that the trailing truck allowed. The real advantage of the trailing

truck was realized later in the larger Atlantic, Pacific and Mikado

class engines.

The 2-4-2 Columbia type got its name because one of the

first ones manufactured was exhibited at the World's Columbian

Exposition at Chicago in 1893. The engine type was generally not very

successful and not many were built. The 4-4-0 American and 4-6-0 Ten

Wheeler types tracked better at speed due to their 4 wheel leading

truck and the 2-6-0 Mogul type was generally bigger and provided better

traction in freight service due to more weight and six drivers. The

Columbia was just too small to take advantage of the larger firebox

that the trailing truck allowed. The real advantage of the trailing

truck was realized later in the larger Atlantic, Pacific and Mikado

class engines.

The Rogers 2-4-2T did find a home in some eastern elevated and

suburban railways. The engines were small but still handled several

wooden coaches. The trailing truck, which did not support an extended

firebox, allowed the engine to track well going in reverse which

allowed the engines to work well in push-pull service. The engines

usually carried their own coal and water to negate the need for a

tender. Since the rail lines were usually short, the engines were never

far enough away from fuel and water to make a tender necessary.

When the major eastern cities eventually outlawed steam engines on

urban lines, the Rogers 2-4-2 engines were put out to pasture and

replaced with electric traction.

The Aristo model of the Rogers 2-4-2 has not been manufactured in

about 8 years. The original model was a 2-4-2T but apparently so many

people added tenders that Aristo decided to forgo the coal bunker and

include a switcher type slope back tender with a very basic chuff only

sound system.

The 2nd generation model has also been mechanically updated. It has two motors, one

for each axle, and two traction tires. The overall detail has been

improved in the retooling process. All the grabs and piping are

unpainted brass wire. The drivers now have metal tires and plastic

centers. Additional weight has been added. Gear and motor noise are

imperceptible.

There is a 3rd generation model which has been updated to accept a DCC decoder or Train Engineer receiver. I have not seen one of these.

The engine runs very well indeed and its pulling power is very good

for an engine this small. See my Tractive Effort Tests Page for the

Rogers pulling performance as compared to several other engines.

I've run some other comparisons against an LGB 0-4-0 with a powered

tender and the Rogers barely outpulls the LGB engine, even with only 4

drivers vs. the LGB's 8 drivers.

Contents

Scale

Aristo has labeled the box that the

Rogers comes in as #1 Gauge, 1/29 scale. However, my eyeballs tell me

that this engine is far from 1/29 scale. I don't have any drawings of a

prototype Rogers 2-4-2, but setting this engine next to a Bachmann

1/20.3 scale Shay looks reasonable. For example the cab door is 3-3/8"

tall, or a little over 8' tall at 1/29 scale. A 1/29 scale Kareem Abdul

Jabbar would have no trouble getting into the Rogers cab.

Aristo has labeled the box that the

Rogers comes in as #1 Gauge, 1/29 scale. However, my eyeballs tell me

that this engine is far from 1/29 scale. I don't have any drawings of a

prototype Rogers 2-4-2, but setting this engine next to a Bachmann

1/20.3 scale Shay looks reasonable. For example the cab door is 3-3/8"

tall, or a little over 8' tall at 1/29 scale. A 1/29 scale Kareem Abdul

Jabbar would have no trouble getting into the Rogers cab.

Putting the Rogers next to a 1/29

scale Pacific really shows the difference. This little engine should

look like a toy next to a heavy Pacific, but it actually taller and

wider. The Rogers would look right at home on a turn-of-the-century

narrow gauge layout, but on a more modern 1/29 scale layout, it

wouldn't fit well.

Putting the Rogers next to a 1/29

scale Pacific really shows the difference. This little engine should

look like a toy next to a heavy Pacific, but it actually taller and

wider. The Rogers would look right at home on a turn-of-the-century

narrow gauge layout, but on a more modern 1/29 scale layout, it

wouldn't fit well.

The Rogers stands 6-3/4" tall from the railheads and is 4-3/4" wide

across the cab roof. The engine and tender are 23-1/2" long from the

rear step to the tip of the pilot.

[ Top ]

Power Pickup

When I first got the Rogers, I dropped it onto my track and ran

pretty well, but it sputtered some. Since it had rained the day before,

the track was covered with splashed grit and the engine didn't like it

one bit. One pass with a track cleaning car, and the engine ran

well.

The Rogers picks up power from all 8 wheels via carbon brushes.

These brushes have lower drag than I usually experience with LGB type

contacts.

Running on the same dirty track, the Rogers didn't do quite as well

as a Bachmann Shay (which has outstanding power pickup reliability) but

it did well enough.

After extended running, the engines wheels got dirty and needed

cleaning. This is a common problem with Aristo steam engines. There is

something about the wheel material that seems to attract dirt and makes

wheel cleaning a common chore. The pony trucks really do pick up

significant power. Just cleaning them and leaving the drivers dirty

will result in a significant improvement.

As of late 2000, Aristo has released replacement drivers for the

Rogers made of a new material. If this is the same stuff that the new

0-4-0 wheels are made of, then there will be an improvement in power

pickup reliability. The improvement that the drivers can provide is

somewhat tempered by the traction tire on the rear set. Since the

crankpins are of different length, a second front set cannot be

substituted for the rear set.

Before I changed out the wheels, I ran the Rogers a bit and it was

showing definite signs of needing the wheels cleaned, even with the

tender wheels being used for power pickup too. After I changed the

wheels, and without cleaning any of the others, the engine ran much

better even with the tender disconnected. I ran it for about half an

hour and the power pickup didn't seem to be degrading. I'll need to put

many more hours on it before I'll really know how much better it is.

With the old wheels, a half hour of running was enough to get it to

start sputtering.

Replacing the drivers is a fairly straightforward task. Remove the

crankpin screws and remove the connecting rod. The wheels may have to

be rotated some to get access to the screws. It is easiest to do the

work if the crankpins are at their lowest point. Then remove the wheel

screws, lockwashers and the indexing washers. Use a flat blade

screwdriver to gently pry off the wheels making sure that you don't

lose the carbon brushes behind the wheels. Then press the new wheels in

place with the crankpins in the same position. The wheel with the

longer crankpin and traction tire goes to the rear. Before you press

the new wheel home, make sure that the carbon brush is in place, it may

have popped out when the old wheel was removed. Note that there two

slots next to the axle hole, these have to line up with the slot in the

axle. The indexing washer has a ridge that goes into these slots and

locks the wheel to the axle. Your new wheels should come with a split

ring lockwasher, use it even if there wasn't one under the old screw

head. As you tighten the axle screws rock the wheel slightly to be sure

that the indexing washer seats properly. The new wheels may also come

with a replacement axle, you won't need it.

The wheel spacing of both the pony trucks and the drivers are such

that several of them can sit on the plastic frogs of cascaded turnouts

or crossings. Add this to some dirt on the remaining wheels that are

sitting on the track and the traction tires on the rear drivers which

limit their effectiveness in picking up power, and the engine can stall

in some places. This seems to only be a problem with tight radius

turnouts.

Since the tender also picks up power on all 8 wheels for the sound

system, I wired it across to the engine following the technique show in

my Power Connector Tips

page. After this was done, much of the power pickup troubles went away.

However, the tender wheels get dirty too and eventually, they all need

cleaning. Maybe someday, Aristo will release replacement wheels for the

tender in the new material, maybe even with ball bearing pickups.

The connector wires are easy to attach to the tender, simply solder

them to the lugs that are behind each journal box. On the engine, its a

little more difficult. The power pickups on the rear pony truck are the

likely places to connect the wires. However, the brass bushings for the

brushes are encased in a plastic holder and soldering directly to the

exposed surfaces of the bushings would surely result in a melted brush

holder. Instead, I cut the wires about 1/2" away from the pickups and

stripped both ends of each wire about 1/16" I then soldered the ends

back together along with the wire leading to the power connector.

[ Top ]

Tracking and Derailments

The leading and trailing trucks are sprung and I initially

experienced no problems with derailments on 4' radius curves. The

drivers initial did not rock with respect to each other. However, they are designed to. The gearboxes for each driver are arranged to rotate slightly but mine were so still that they were effectively fixed. Some working of the mechanism by hand freed them up a little so that the axles could rock to follow wavy track.

When I brought the engine to the GIRR Mountain Division and ran it

on 2' radius curves, it had some minor tracking problems. On curves,

the inside wheel on both the leading and trailing trucks tended to lift

off the rail. The leading truck would lift going forward, the trailing

truck would lift in reverse. Sometimes the springs would fully extended

and sometimes they would bind and not fully extend. The wheel lifting

appears to be a result of the fact that the trucks don't actually guide

the engine through curves. When the body of the engine cocks to the

outside upon entering a curve it puts a lot of pressure on the outside

pony truck wheel. As a result, the inside wheel is lifted a little

until the whole engine settles itself into the turn.

This didn't actually cause any derailments but it is clearly a

precursor to one, especially if the track is not level. The problem is

due to the travel limit of the pony trucks. They are allowed to swing

just far enough to deal with 2' radius curves when the engine body is

lined up on the track centerline. When the engine body is cocked with

respect to the track centerline, the pony trucks can hit their travel

limit stops. This tends to force the engine back into line, but it also

causes the inside wheel to lift.

I've

gouged on my Rogers a little and fixed this problem. The front pony

truck is fairly easy to fix. Remove two screws that hold on the cover

to the truck pivot and lift out the truck a little. Use a fine file or

a small motor tool cutter to remove some plastic at the ends of the

curved slot as shown in the photo. Trim the truck until the truck can

actually touch the cylinder head. You may also have to remove a small

amount of plastic from the frame where the truck edge touches it. This

shows as a white spot on the photo.

I've

gouged on my Rogers a little and fixed this problem. The front pony

truck is fairly easy to fix. Remove two screws that hold on the cover

to the truck pivot and lift out the truck a little. Use a fine file or

a small motor tool cutter to remove some plastic at the ends of the

curved slot as shown in the photo. Trim the truck until the truck can

actually touch the cylinder head. You may also have to remove a small

amount of plastic from the frame where the truck edge touches it. This

shows as a white spot on the photo.

The rear truck is a little more difficult to remove. One of the

cover screws is obscured by the mount for the power pickups. Remove the

screw that holds the pickup assembly in place and carefully remove it.

Be sure to restrain the carbon brushes as the internal spring will push

them out when they get free of the wheel. Then gently pry out the

mounting bracket for the brush assembly. The sides of the mounting

bracket have tabs on them that if pressed inwards from the bottom will

release and the mounting bracket can be pulled out. Then remove the

truck and do the same slot widening as with the front truck. You may

also have to trim some plastic from the upper rear outside corner of

the truck itself so that it can clear the screws that mount the cab

steps.

A different kind of tracking problem occurred because of another

typical Aristo problem. The screws that hold on the drivers got very

loose which allowed the drivers to spin on their axles at times,

especially in those same tight turns. This caused the drivers to on

each side to rotate with respect to one another and the siderods would

bind. The result is that the engine would grind to a halt in tight

turns. After the driver mounting screws were tightened and the driver

quartering rechecked, this problem went away.

The drivers are indexed by a ridge on the back of the washer under

the driver mounting screw. When the screw gets loose, the driver will

no longer be locked in position with respect to the axle. Aristo has

sent me some split ring lock washers to put under the screw head. These

seem to be working in keeping the screws in place. If this doesn't work

in the long run, a little Purple LocTite 222 on the screws will

definitely hold them in place. Don't use anything stronger than 222 or

you will never get the screws back out if you should need to.

The pony truck wheels on my unit seem to be just a bit under gauge.

This didn't seem to cause a problem until they ran through the LGB 1200

turnouts where I had shimmed the

guard rail to solve derailment problems with wheels that were slightly

over gauge. On the turnouts with the thicker shims (40 mils) the under

gauge pony trucks would bind between the shim and the wing rail next to

the frog. This would cause the pony truck to squeeze upward and derail.

Turnouts that had been treated with a thinner shim (20 mil) worked

better so I have been replacing the thicker shims with the thinner

ones.

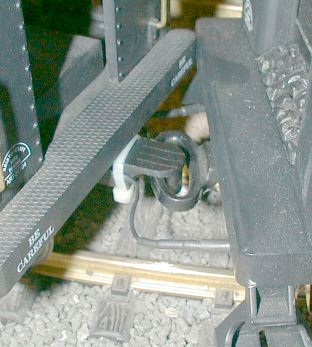

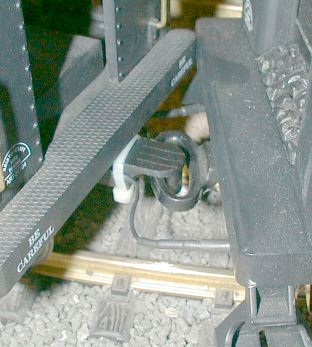

I noticed

another problem with the Rogers. It doesn't like to push heavy loads on

2' radius track. The drawbar in the engine is mounted on the rear pony

truck. When coupled to a slopeback tender, the force applied to the

rear pony truck while pushing a heavy load would tend to derail it on a

curve. This photo shows that the spacing between the tender and the

engine is fairly tight during pushing but the drawbar still takes up

the entire load. However, if the spacing could be reduced just a

little, the frame members on the engine and tender would touch and take

up part of the load. I considered body mounting the drawbar, but after

playing with the drawbar position with the rear truck derailed so that

it could be centered, it became obvious that the width the loop on the

tender was not wide enough and the engine would probably derail the

tender truck. Further, body mounting the drawbar would be a

nonreversible modification and if it didn't work out, I would be stuck

buying a new pony truck.

I noticed

another problem with the Rogers. It doesn't like to push heavy loads on

2' radius track. The drawbar in the engine is mounted on the rear pony

truck. When coupled to a slopeback tender, the force applied to the

rear pony truck while pushing a heavy load would tend to derail it on a

curve. This photo shows that the spacing between the tender and the

engine is fairly tight during pushing but the drawbar still takes up

the entire load. However, if the spacing could be reduced just a

little, the frame members on the engine and tender would touch and take

up part of the load. I considered body mounting the drawbar, but after

playing with the drawbar position with the rear truck derailed so that

it could be centered, it became obvious that the width the loop on the

tender was not wide enough and the engine would probably derail the

tender truck. Further, body mounting the drawbar would be a

nonreversible modification and if it didn't work out, I would be stuck

buying a new pony truck.

Moving the

engine drawbar was quite easy and completely reversible so I decided to

try it to see if it worked. A new screw hole is drilled in front of the

original one and the drawbar is simply attached to the new hole.

Moving the

engine drawbar was quite easy and completely reversible so I decided to

try it to see if it worked. A new screw hole is drilled in front of the

original one and the drawbar is simply attached to the new hole.

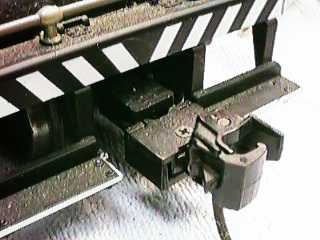

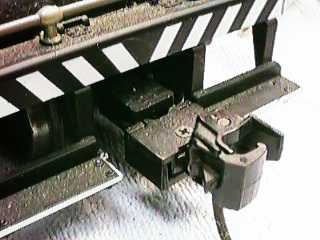

In the

depth of a 2' radius curve where the side forces on the pony truck

would be the highest, the frames of the engine and tender touch and

take up the load. The drawbar actually fully unloads at this point.

This seemed to fix the derailment problem. The forces on the pony truck

are still pretty high when the engine is coming into or out of the

curve and the frames are not touching but it doesn't seem to derail.

Maybe the drawbar could be pulled forward as far as it would go and it

might work even better.

In the

depth of a 2' radius curve where the side forces on the pony truck

would be the highest, the frames of the engine and tender touch and

take up the load. The drawbar actually fully unloads at this point.

This seemed to fix the derailment problem. The forces on the pony truck

are still pretty high when the engine is coming into or out of the

curve and the frames are not touching but it doesn't seem to derail.

Maybe the drawbar could be pulled forward as far as it would go and it

might work even better.

[ Top ]

Sound Tender

The Slope back tender that comes with the Rogers appears to be

identical to the tender that is supplied as an option to the 0-4-0

switcher. The tender comes with a sound system installed. This system

has been much derided, but under the right conditions it isn't too

bad.

The system chuffs fairly well but that's all it does. The sound

system relies on the Aristo PWC system to work properly. Without PWC,

the sound system doesn't get enough voltage off the track to work and

can howl, growl, or screech terribly at low speed. On pulse power packs

(such as MRC packs) it will hum and buzz. With PWC, it may occasionally

make awful sounds but only at very slow speed. Unlike the Pacific's

Long Tender, there is no provision for connection of a battery to allow

the pack to work without PWC.

The volume control for the chuff is accessed by lifting the coal

load from the rear. The water hatch slides back to unlatch the coal

load.

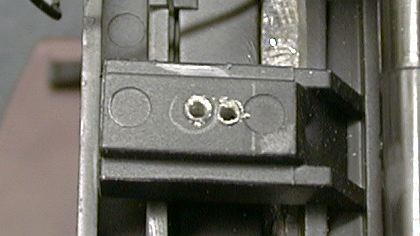

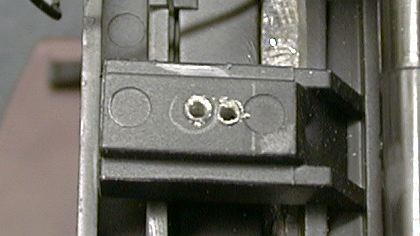

The chuff trigger is a Hall effect device mounted above a tender

axle. A doughnut shaped magnet rides against a rubber roller on the

axle. The Hall effect device is mounted next to the magnet. If the

chuff isn't working right, make sure that the rubber roller is clean

and that the Hall effect device is RIGHT NEXT to the

magnet. Even when it is working, the chuff rate is about half of the

prototypical rate of 4 chuffs/turn.

After the rubber roller gets old and hardens up some it doesn't

provide enough friction to turn the magnet reliably. After much fussing

and fiddling, I finally tried to renew the roller surface with a

coating of contact cement, AND IT WORKED! Pull the wheelset with the

roller from the truck by flexing the truck sideframe slightly and then

paint a layer of contact cement on the roller. Rubber cement would

probably work too. Let it dry for about an hour and reinstall the

wheelset. I do not know how long this patch will last, but even if it

fails after awhile, it would be easy enough to do it again.

I have subsequently done an installation of a Soundtraxx Sierra in this slopeback

tender. This sound quality of the Sierra is much better than the built

in system, but then again, it costs a lot more too.

[ Top ]

Smoke

The Rogers comes with a smoke system. The system is similar to other

Aristo steamer smoke systems in that it puffs smoke in time with the

drivers, but at only one puff per driver turn. As is typical with

Aristo smoke, the system doesn't generate large quantities of smoke,

but it does smoke for quite a while on the 6 to 7 drop recommend

charge.

The smoke switch is behind the smokebox door (like Bachmann engines)

but it is not labeled so it is easy to forget if the switch is in the

on or off position. Also even the though the smoke generator has its

own switch, the smoke won't work unless the motor is on too.

The smoke unit plugs onto the smoke box so replacing a burnt out

generator should take about 3 seconds.

The instructions say to pour smoke fluid in the opening at the top

of the stack. However, the hole is so small, the first drop plugs up

the little hole. The top cap can be easily pulled off to reveal the

smoke element so that it is much easier to load fluid.

The smoke unit in mine eventually shorted out due to a damaged plug

and it was replaced a Seuthe unit. Seuthe makes LGB smoke units which

are identical. A 16 volt unit works well as this engine usually runs

fairly slowly.

The center unit in the photo

is the stock Aristo unit. It can be removed from the stack by pushing

it out of the bottom of the stack. The Seuthe unit is slightly larger

in diameter than the Aristo unit so the stack has to be modified for it

to fit. Run a 3/8" drill bit through the stack to ream it out and the

Seuthe element will just fit. A 3.5 mm mono phono plug can be wired to

the smoke element so that the assembly will still plug into the engine

although a pair of needle nose pliers is necessary to insert the plug

before the stack is pressed home.

The center unit in the photo

is the stock Aristo unit. It can be removed from the stack by pushing

it out of the bottom of the stack. The Seuthe unit is slightly larger

in diameter than the Aristo unit so the stack has to be modified for it

to fit. Run a 3/8" drill bit through the stack to ream it out and the

Seuthe element will just fit. A 3.5 mm mono phono plug can be wired to

the smoke element so that the assembly will still plug into the engine

although a pair of needle nose pliers is necessary to insert the plug

before the stack is pressed home.

The hole in the stack cap also can be opened up. A 1/8" hole seems

to work fine.

[ Top ]

Mounting Other Couplers

A

Kadee #831 coupler can be mounted directly in place of the supplied

Aristo knuckle coupler, however the rear step must be cut to clear the

coupler box. Cutting right next to the step supports will provide

enough clearance for running on 8' diameter curves. To accommodate 4'

diameter curves, more of the step and the inside two step supports

would have to be removed and new step supports fabricated from strip

styrene.

A

Kadee #831 coupler can be mounted directly in place of the supplied

Aristo knuckle coupler, however the rear step must be cut to clear the

coupler box. Cutting right next to the step supports will provide

enough clearance for running on 8' diameter curves. To accommodate 4'

diameter curves, more of the step and the inside two step supports

would have to be removed and new step supports fabricated from strip

styrene.

An LGB knuckle coupler mounts more easily and with no modifications

to the tender required, although some modification to the coupler is

necessary. The mounting groove in the coupler is slightly too narrow to

fit over the coupler mounting tang. I find that a quick pass with a

1/4" motor tool cutter tool will widen the slot in the coupler to allow

it to mount with the original screw in the original hole. The small

cross piece on the coupler shank, the part with the LGB logo on it,

also needs to be ground down to about 1/3 its standard thickness or it

will ride on the rear step and hold the rear wheelset slightly off the

track. After these modifications are made to the coupler, the coupler

height comes out just right.

Mounting a coupler on the engine pilot is not practical. The

overhang on curves would be too large to allow a coupler to work

properly. The pilot does have a drawbar attached.

[ Top ]

Instruction Manuals

Aristo instruction manuals are typically cryptic. The Rogers manual

is better than most, but it could still use improvement. I did find

some problems with the instructions.

Marker Lights. The manual indicates that there are LEDs used

for classification lights. I couldn't find any on the PRR unit that I

had. Lewis Polk informs me that some road names have LED markers and

some do not. The PRR configuration has flag standards instead marker

lamps.

Tender Instructions. My engine didn't come packed with any

instructions for the tender at all.

[ Top ]

Disassembly of the Rogers

Like

many steam locos, the Rogers isn't extremely easy to take apart, but it

can be done. A good resource for information about the assembly of this

loco can be found on AristoCraft's Exploded Diagrams

page.

Like

many steam locos, the Rogers isn't extremely easy to take apart, but it

can be done. A good resource for information about the assembly of this

loco can be found on AristoCraft's Exploded Diagrams

page.

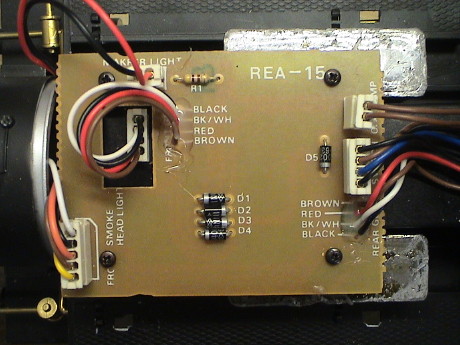

The saddle tank comes off after removal of two screws under the

walkways (not shown at all in the exploded diagrams) and removal of the

cab. The cab comes off via removal of the rear step. Then the saddle

tank can be squeezed to release four clips and pulled off.

The motor bricks come out from the bottom after removal of the

retainers that hold the posts at the front and back of the brick and

the connecting rods. While it is perhaps possible to get the bricks out

and back in without removing the saddle tank, it is a lot easier to

deal with the connectors on the tops of the bricks with the tank

removed.

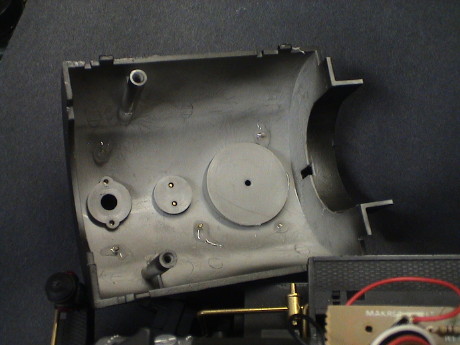

Even with the

exploded diagrams in hand, I had difficulties removing the saddle tank

to obtain access to the printed wiring board where all the electrical

connections are. The tank should have come off easily, but the PWB was

wide enough so that it had actually ground a groove into one of the

screw posts such that the forward left corner of the tank refused to

release easily. I had to pry it pretty hard to get to pop loose. After

that, I filed some small grooves in the PWB where the posts were and

also ground off a little of the posts so that it would fit

properly.

Even with the

exploded diagrams in hand, I had difficulties removing the saddle tank

to obtain access to the printed wiring board where all the electrical

connections are. The tank should have come off easily, but the PWB was

wide enough so that it had actually ground a groove into one of the

screw posts such that the forward left corner of the tank refused to

release easily. I had to pry it pretty hard to get to pop loose. After

that, I filed some small grooves in the PWB where the posts were and

also ground off a little of the posts so that it would fit

properly.

The smokebox can

be removed to access the wiring inside. A single screws, accessible

from the left side under the smokebox can be removed. Then the post it

was screwed into is pushed out to the right side. Then the smokebox can

be lifted and turned. There is a hose from a pump in the left cylinder

that provides a little puff for the smoke unit. It needs to be slid off

the metal tube leading up to the base of the smoke unit.

The smokebox can

be removed to access the wiring inside. A single screws, accessible

from the left side under the smokebox can be removed. Then the post it

was screwed into is pushed out to the right side. Then the smokebox can

be lifted and turned. There is a hose from a pump in the left cylinder

that provides a little puff for the smoke unit. It needs to be slid off

the metal tube leading up to the base of the smoke unit.

[ Top ]

Rogers Wiring

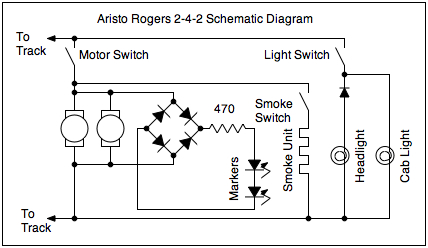

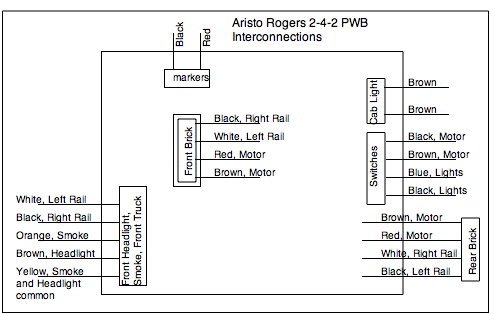

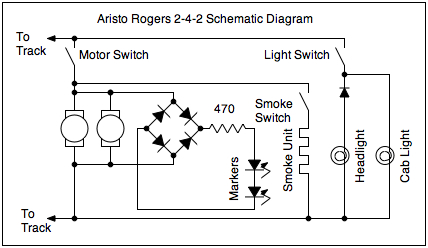

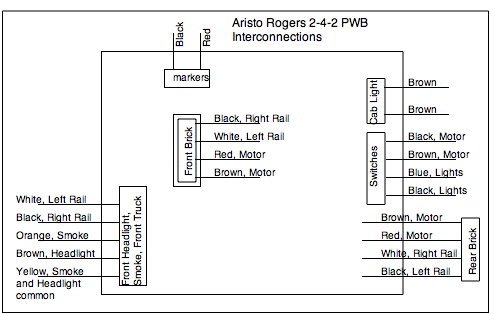

The schematic of the Rogers is pretty

straight forward. The only odd part is that the power for the LED

markers (on units that have them) and for the smoke unit is derived

from the motor terminals so that the markers and smoke will not work if

the motors are not running.

The schematic of the Rogers is pretty

straight forward. The only odd part is that the power for the LED

markers (on units that have them) and for the smoke unit is derived

from the motor terminals so that the markers and smoke will not work if

the motors are not running.

Note that this information is for the "middle age" Rogers. The old

one was a tank engine with a coal bunker in the back of the cab. It may

have similar wiring. I have not seen the "new" one but I have been told

that it has been prewired for battery power so that it's connections

will be different. The spotting feature for that unit would be a square

black connector hanging from under the cab.

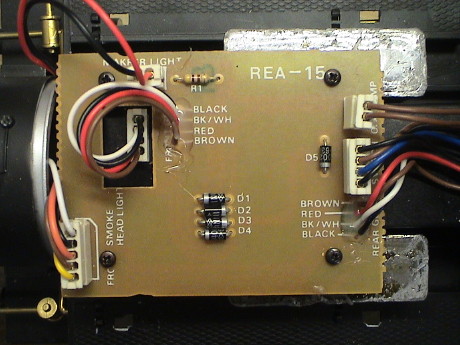

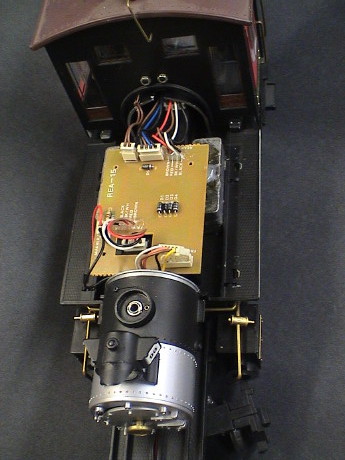

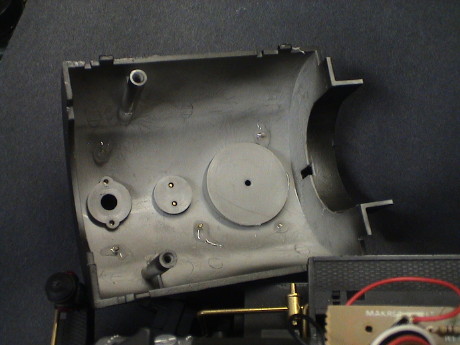

The printed wiring

board itself is a simple one sided assembly. This is the primary

junction point for all of the wiring EXCEPT the rear pony truck power

pickups which appear to connect directly to the rear motor brick. Note

that the black and white wires are the track pickups, but since the two

bricks are reversed with respect to each other, sometimes white and

black join. The motor wires are similarly reversed with respect to each

other.

The printed wiring

board itself is a simple one sided assembly. This is the primary

junction point for all of the wiring EXCEPT the rear pony truck power

pickups which appear to connect directly to the rear motor brick. Note

that the black and white wires are the track pickups, but since the two

bricks are reversed with respect to each other, sometimes white and

black join. The motor wires are similarly reversed with respect to each

other.

I traced out all the wires. The colors and

functions are shown here.

I traced out all the wires. The colors and

functions are shown here.

[ Top ]

DCC in the Rogers

I went to all the trouble to trace out the wiring because I am going

to install DCC in this Rogers. I have a choice of putting the decoder

in the engine or in the tender. I think that I'll probably put it in

the tender as this will minimize the wiring between the loco and the

tender. Since all the loads in the engine are switched I don't need to

wire them to the decoder to allow programming. Alternately, I could

just put the tender on the programming track.

I will cut the red and brown wires leading to the bricks and connect

the motors together, red to brown. The stubs of wires leading to the

PWB will be insulated and abandoned. This will leave the markers on the

old motor circuit. The motor switch will then become just a marker

switch. The markers will run at constant intensity as they will be

wired directly to the track. I might have to increase the value of the

470 ohm current limiting resistor to about 750 ohms.

With the decoder in the tender I only have to run three more wires

between the engine and tender because the track power pickups are

already wired between the two. Two wires are for the motors. The other

will go to the front headlight (brown) wire. Since the front headlight

is wired to return to a rail along with the smoke unit, I'll have to

cut the red wire inside the smokebox leading from the headlight to the

the smoke unit connector. It will be then reconnected to the positive

terminal of the bridge rectifier (either outside diode toward the

front) that runs the markers to simulate the decoder's "blue" wire. The

headlight will also then be controlled by the old motor switch AND the

DCC decoder. Both will have to be on for the headlight to work.

With the decoder in the tender, connections to the sound triggers to

the Sierra that is already there will be easier. If I put the decoder

in the loco, I'd still have to run two motor wires back to the sound

system, one wire for the rear headlight and four more wires for the

bell, whistle, coupler clank and hiss triggers of the Sierra.

The downside of putting the decoder in the tender is that the loco

will not be able to run by itself. This is common for DCC installations

in steam locos.

The connection to the smoke unit may also require a change. This

loco has a 16 volt Seuthe smoke unit. The DCC track voltage may be a

little high for this unit (depending on what track voltage I end up

with) so I may have to install a small resistor in series with the

smoke unit to drop the voltage to a safe value. I'll determine that

resistor by test after I've done the DCC installation but I expect it

to be in the range of 8 to 24 ohms depending on the track voltage.

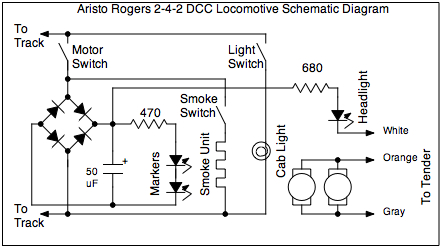

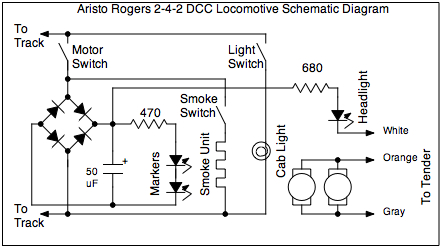

This is a

schematic of the changes that I made to the engine to accommodate DCC.

The actual decoder is installed in the tender. The motors have been cut

loose and wired back to the tender via a 3 wire connector. The third

wire is for the front headlight which was also cut loose from all it's

interconnections and wired back to the tender. I used the bridge

rectifier for the markers to simulate the decoder's blue wire. The

headlight was also changed to a warm white high intensity LED as

described below.

This is a

schematic of the changes that I made to the engine to accommodate DCC.

The actual decoder is installed in the tender. The motors have been cut

loose and wired back to the tender via a 3 wire connector. The third

wire is for the front headlight which was also cut loose from all it's

interconnections and wired back to the tender. I used the bridge

rectifier for the markers to simulate the decoder's blue wire. The

headlight was also changed to a warm white high intensity LED as

described below.

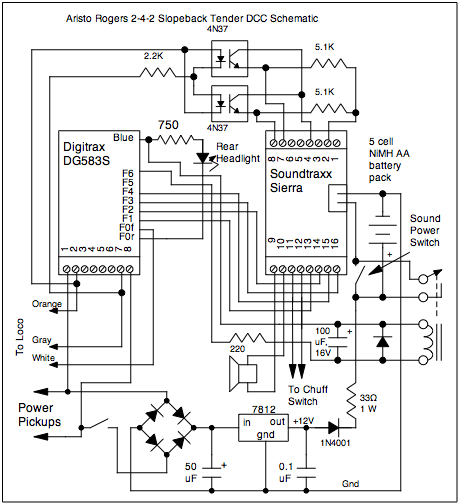

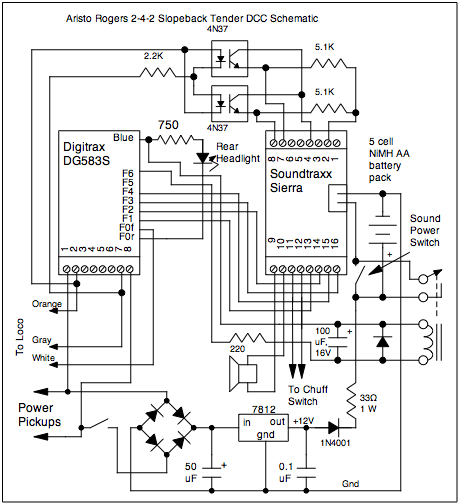

Most of the work was in the tender.

There was already a Soundtraxx Sierra there, it has been retained. The

rear headlight has also been changed out to an LED.

Most of the work was in the tender.

There was already a Soundtraxx Sierra there, it has been retained. The

rear headlight has also been changed out to an LED.

The major additions are the decoder and an interface board which

contains two completely separate circuits. Sierra's have historic

difficulties determining direction when directly connected to a DCC

decoder so I use optical isolators to provide the connection so that

the Sierra can properly blow it's whistle signals. I also use a 12 volt

regulator on this board to act as a battery charger so that whenever

the tender is sitting on powered track, the battery is getting a charge

even if the Sierra isn't turned on. I used the original sound system

slide switch to optionally allow the battery charger to be turned off,

for example during decoder programming. I don't expect to use this

switch much. The bell, whistle, couple clank and blowdown hiss triggers

are wired directly from the Digitrax DG583S decoder.

The relay driven from F6 allows the sound to be turned on remotely.

If the track power goes off, the sound power will go off too. I had a

problem with leaving the manual sound power switch on. If the loco had

been sitting for awhile and the sound system shut itself down, I tended

to forget to turn it off manually before shutting down the layout and

the battery would discharge.

The

three wire connection between the loco and tender is via this swap meet

cable. It had a male connector on one end and a mating female connector

on the other end. I just had to cut the cable and I had both ends. The

business end is securely tied to the drawbar.

The

three wire connection between the loco and tender is via this swap meet

cable. It had a male connector on one end and a mating female connector

on the other end. I just had to cut the cable and I had both ends. The

business end is securely tied to the drawbar.

The

cable routes through the rear pony truck and up a hole drilled in the

floor. This brings up up inside the backhead when the backhead assembly

is screwed down to the cab floor. The motor leads (brown and red) were

cut near the old connector and the unused stubs insulated with shrink

tube. The front and rear motor wires were connected to the black and

red conductors of the cable going to the tender. Note that the brown

and red motor wires must be connected brown to red as the motor blocks

are identical, but installed physically reversed.

The

cable routes through the rear pony truck and up a hole drilled in the

floor. This brings up up inside the backhead when the backhead assembly

is screwed down to the cab floor. The motor leads (brown and red) were

cut near the old connector and the unused stubs insulated with shrink

tube. The front and rear motor wires were connected to the black and

red conductors of the cable going to the tender. Note that the brown

and red motor wires must be connected brown to red as the motor blocks

are identical, but installed physically reversed.

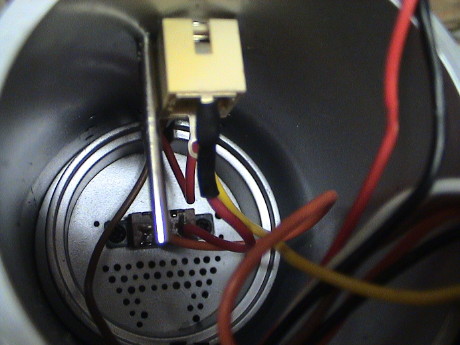

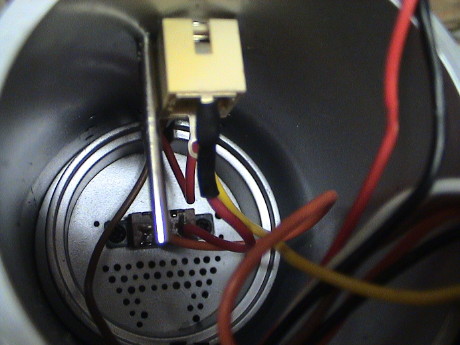

At

the front end, the brown wire leading to the headlight was cut and the

stub insulated. Inside the smokebox, the red wire from the headlight

was cut off at the smoke unit connector terminal. Then the headlight

assembly was pulled out of the smokebox for replacement.

At

the front end, the brown wire leading to the headlight was cut and the

stub insulated. Inside the smokebox, the red wire from the headlight

was cut off at the smoke unit connector terminal. Then the headlight

assembly was pulled out of the smokebox for replacement.

The incandescent headlight was junked and an LED installed in it's

place. The red headlight wire was extended and wired back to the bridge

rectifier at the striped end of diode D4. A 50 uF capacitor was

installed between that point and the other side of the bridge and the

non-striped end of D3. This is not really needed for DCC, but it helps

the headlight intensity a lot when the loco is analog converted when

running on PWC. I didn't have to change the 470 ohm current limiting

resistor on the markers. They draw just 20 mA which is a safe value

even though they are not very bright. These are not particularly good

LEDs.

The

leads on the LED used for the front headlight were formed to allow the

LED to sit inside the headlight housing at the right height. A 680 ohm

current limiting resistor is installed in one lead. The leads were

insulated with shrink tubing and the assembly was attached to the inner

surface of the headlight mounting tube with a small amount of Zap-A-Gap

CA. The headlight housing can then be slipped over the LED and

reattached with it's original screw. The rear headlight was done the

same way but a 750 ohm resistor was used because I couldn't find

another 680.

The

leads on the LED used for the front headlight were formed to allow the

LED to sit inside the headlight housing at the right height. A 680 ohm

current limiting resistor is installed in one lead. The leads were

insulated with shrink tubing and the assembly was attached to the inner

surface of the headlight mounting tube with a small amount of Zap-A-Gap

CA. The headlight housing can then be slipped over the LED and

reattached with it's original screw. The rear headlight was done the

same way but a 750 ohm resistor was used because I couldn't find

another 680.

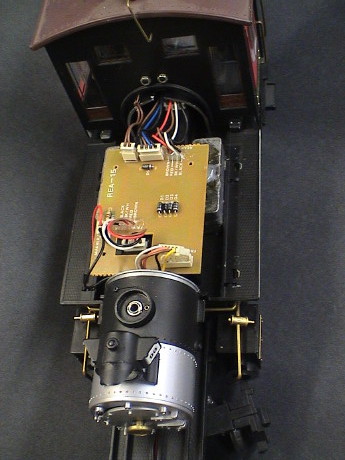

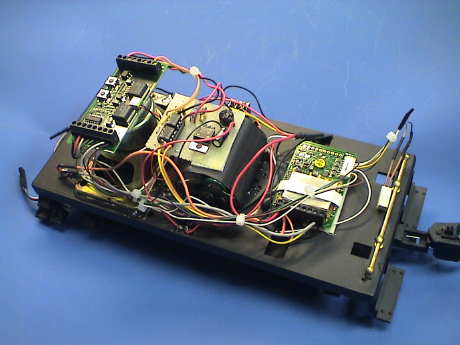

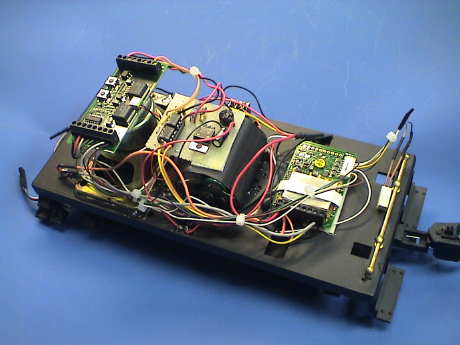

The

tender is the most complex. The sound system sits atop the speaker,

held down with double back foam tape. It is accessible through the open

coal load for programming. A perforated board is mounted with foam tape

on top of the replacement battery for the Sierra. This is a 5 cell AA

NiMH pack and has been completely trouble free for years. The decoder,

a Digitrax DG583S, is mounted with foam tape to the tender floor at the

rear. The existing slide switch about halfway along the fireman's side

is used to control the power to the battery charger. The toggle switch

I originally installed with the Sierra disconnects the Sierra from it's

battery to that the Sierra doesn't flatten the battery during storage.

The battery charger provides about 150 ma of charge rate for the

battery. When the system is running, the battery is about charge

neutral on the average.

The

tender is the most complex. The sound system sits atop the speaker,

held down with double back foam tape. It is accessible through the open

coal load for programming. A perforated board is mounted with foam tape

on top of the replacement battery for the Sierra. This is a 5 cell AA

NiMH pack and has been completely trouble free for years. The decoder,

a Digitrax DG583S, is mounted with foam tape to the tender floor at the

rear. The existing slide switch about halfway along the fireman's side

is used to control the power to the battery charger. The toggle switch

I originally installed with the Sierra disconnects the Sierra from it's

battery to that the Sierra doesn't flatten the battery during storage.

The battery charger provides about 150 ma of charge rate for the

battery. When the system is running, the battery is about charge

neutral on the average.

This all worked out pretty well. I may have some decoder tweaking to

do because the lowest speed is a little higher that I like but overall,

all is well.

[ Top ] [ Home ] [ Up ] [ Previous Page ] [ Next Page ]

This page has been accessed  times since May 5, 1998.

times since May 5, 1998.

©1998-2009 George Schreyer

Created May 5, 1998

Last Updated February 14, 2010

The 2-4-2 Columbia type got its name because one of the

first ones manufactured was exhibited at the World's Columbian

Exposition at Chicago in 1893. The engine type was generally not very

successful and not many were built. The 4-4-0 American and 4-6-0 Ten

Wheeler types tracked better at speed due to their 4 wheel leading

truck and the 2-6-0 Mogul type was generally bigger and provided better

traction in freight service due to more weight and six drivers. The

Columbia was just too small to take advantage of the larger firebox

that the trailing truck allowed. The real advantage of the trailing

truck was realized later in the larger Atlantic, Pacific and Mikado

class engines.

The 2-4-2 Columbia type got its name because one of the

first ones manufactured was exhibited at the World's Columbian

Exposition at Chicago in 1893. The engine type was generally not very

successful and not many were built. The 4-4-0 American and 4-6-0 Ten

Wheeler types tracked better at speed due to their 4 wheel leading

truck and the 2-6-0 Mogul type was generally bigger and provided better

traction in freight service due to more weight and six drivers. The

Columbia was just too small to take advantage of the larger firebox

that the trailing truck allowed. The real advantage of the trailing

truck was realized later in the larger Atlantic, Pacific and Mikado

class engines. 22 Sep 08

22 Sep 08 26 Sep 08

26 Sep 08 Aristo has labeled the box that the

Rogers comes in as #1 Gauge, 1/29 scale. However, my eyeballs tell me

that this engine is far from 1/29 scale. I don't have any drawings of a

prototype Rogers 2-4-2, but setting this engine next to a Bachmann

1/20.3 scale Shay looks reasonable. For example the cab door is 3-3/8"

tall, or a little over 8' tall at 1/29 scale. A 1/29 scale Kareem Abdul

Jabbar would have no trouble getting into the Rogers cab.

Aristo has labeled the box that the

Rogers comes in as #1 Gauge, 1/29 scale. However, my eyeballs tell me

that this engine is far from 1/29 scale. I don't have any drawings of a

prototype Rogers 2-4-2, but setting this engine next to a Bachmann

1/20.3 scale Shay looks reasonable. For example the cab door is 3-3/8"

tall, or a little over 8' tall at 1/29 scale. A 1/29 scale Kareem Abdul

Jabbar would have no trouble getting into the Rogers cab. Putting the Rogers next to a 1/29

scale Pacific really shows the difference. This little engine should

look like a toy next to a heavy Pacific, but it actually taller and

wider. The Rogers would look right at home on a turn-of-the-century

narrow gauge layout, but on a more modern 1/29 scale layout, it

wouldn't fit well.

Putting the Rogers next to a 1/29

scale Pacific really shows the difference. This little engine should

look like a toy next to a heavy Pacific, but it actually taller and

wider. The Rogers would look right at home on a turn-of-the-century

narrow gauge layout, but on a more modern 1/29 scale layout, it

wouldn't fit well. I've

gouged on my Rogers a little and fixed this problem. The front pony

truck is fairly easy to fix. Remove two screws that hold on the cover

to the truck pivot and lift out the truck a little. Use a fine file or

a small motor tool cutter to remove some plastic at the ends of the

curved slot as shown in the photo. Trim the truck until the truck can

actually touch the cylinder head. You may also have to remove a small

amount of plastic from the frame where the truck edge touches it. This

shows as a white spot on the photo.

I've

gouged on my Rogers a little and fixed this problem. The front pony

truck is fairly easy to fix. Remove two screws that hold on the cover

to the truck pivot and lift out the truck a little. Use a fine file or

a small motor tool cutter to remove some plastic at the ends of the

curved slot as shown in the photo. Trim the truck until the truck can

actually touch the cylinder head. You may also have to remove a small

amount of plastic from the frame where the truck edge touches it. This

shows as a white spot on the photo. I noticed

another problem with the Rogers. It doesn't like to push heavy loads on

2' radius track. The drawbar in the engine is mounted on the rear pony

truck. When coupled to a slopeback tender, the force applied to the

rear pony truck while pushing a heavy load would tend to derail it on a

curve. This photo shows that the spacing between the tender and the

engine is fairly tight during pushing but the drawbar still takes up

the entire load. However, if the spacing could be reduced just a

little, the frame members on the engine and tender would touch and take

up part of the load. I considered body mounting the drawbar, but after

playing with the drawbar position with the rear truck derailed so that

it could be centered, it became obvious that the width the loop on the

tender was not wide enough and the engine would probably derail the

tender truck. Further, body mounting the drawbar would be a

nonreversible modification and if it didn't work out, I would be stuck

buying a new pony truck.

I noticed

another problem with the Rogers. It doesn't like to push heavy loads on

2' radius track. The drawbar in the engine is mounted on the rear pony

truck. When coupled to a slopeback tender, the force applied to the

rear pony truck while pushing a heavy load would tend to derail it on a

curve. This photo shows that the spacing between the tender and the

engine is fairly tight during pushing but the drawbar still takes up

the entire load. However, if the spacing could be reduced just a

little, the frame members on the engine and tender would touch and take

up part of the load. I considered body mounting the drawbar, but after

playing with the drawbar position with the rear truck derailed so that

it could be centered, it became obvious that the width the loop on the

tender was not wide enough and the engine would probably derail the

tender truck. Further, body mounting the drawbar would be a

nonreversible modification and if it didn't work out, I would be stuck

buying a new pony truck. Moving the

engine drawbar was quite easy and completely reversible so I decided to

try it to see if it worked. A new screw hole is drilled in front of the

original one and the drawbar is simply attached to the new hole.

Moving the

engine drawbar was quite easy and completely reversible so I decided to

try it to see if it worked. A new screw hole is drilled in front of the

original one and the drawbar is simply attached to the new hole. In the

depth of a 2' radius curve where the side forces on the pony truck

would be the highest, the frames of the engine and tender touch and

take up the load. The drawbar actually fully unloads at this point.

This seemed to fix the derailment problem. The forces on the pony truck

are still pretty high when the engine is coming into or out of the

curve and the frames are not touching but it doesn't seem to derail.

Maybe the drawbar could be pulled forward as far as it would go and it

might work even better.

In the

depth of a 2' radius curve where the side forces on the pony truck

would be the highest, the frames of the engine and tender touch and

take up the load. The drawbar actually fully unloads at this point.

This seemed to fix the derailment problem. The forces on the pony truck

are still pretty high when the engine is coming into or out of the

curve and the frames are not touching but it doesn't seem to derail.

Maybe the drawbar could be pulled forward as far as it would go and it

might work even better. The center unit in the photo

is the stock Aristo unit. It can be removed from the stack by pushing

it out of the bottom of the stack. The Seuthe unit is slightly larger

in diameter than the Aristo unit so the stack has to be modified for it

to fit. Run a 3/8" drill bit through the stack to ream it out and the

Seuthe element will just fit. A 3.5 mm mono phono plug can be wired to

the smoke element so that the assembly will still plug into the engine

although a pair of needle nose pliers is necessary to insert the plug

before the stack is pressed home.

The center unit in the photo

is the stock Aristo unit. It can be removed from the stack by pushing

it out of the bottom of the stack. The Seuthe unit is slightly larger

in diameter than the Aristo unit so the stack has to be modified for it

to fit. Run a 3/8" drill bit through the stack to ream it out and the

Seuthe element will just fit. A 3.5 mm mono phono plug can be wired to

the smoke element so that the assembly will still plug into the engine

although a pair of needle nose pliers is necessary to insert the plug

before the stack is pressed home. A

Kadee #831 coupler can be mounted directly in place of the supplied

Aristo knuckle coupler, however the rear step must be cut to clear the

coupler box. Cutting right next to the step supports will provide

enough clearance for running on 8' diameter curves. To accommodate 4'

diameter curves, more of the step and the inside two step supports

would have to be removed and new step supports fabricated from strip

styrene.

A

Kadee #831 coupler can be mounted directly in place of the supplied

Aristo knuckle coupler, however the rear step must be cut to clear the

coupler box. Cutting right next to the step supports will provide

enough clearance for running on 8' diameter curves. To accommodate 4'

diameter curves, more of the step and the inside two step supports

would have to be removed and new step supports fabricated from strip

styrene. Like

many steam locos, the Rogers isn't extremely easy to take apart, but it

can be done. A good resource for information about the assembly of this

loco can be found on

Like

many steam locos, the Rogers isn't extremely easy to take apart, but it

can be done. A good resource for information about the assembly of this

loco can be found on  Even with the

exploded diagrams in hand, I had difficulties removing the saddle tank

to obtain access to the printed wiring board where all the electrical

connections are. The tank should have come off easily, but the PWB was

wide enough so that it had actually ground a groove into one of the

screw posts such that the forward left corner of the tank refused to

release easily. I had to pry it pretty hard to get to pop loose. After

that, I filed some small grooves in the PWB where the posts were and

also ground off a little of the posts so that it would fit

properly.

Even with the

exploded diagrams in hand, I had difficulties removing the saddle tank

to obtain access to the printed wiring board where all the electrical

connections are. The tank should have come off easily, but the PWB was

wide enough so that it had actually ground a groove into one of the

screw posts such that the forward left corner of the tank refused to

release easily. I had to pry it pretty hard to get to pop loose. After

that, I filed some small grooves in the PWB where the posts were and

also ground off a little of the posts so that it would fit

properly. The smokebox can

be removed to access the wiring inside. A single screws, accessible

from the left side under the smokebox can be removed. Then the post it

was screwed into is pushed out to the right side. Then the smokebox can

be lifted and turned. There is a hose from a pump in the left cylinder

that provides a little puff for the smoke unit. It needs to be slid off

the metal tube leading up to the base of the smoke unit.

The smokebox can

be removed to access the wiring inside. A single screws, accessible

from the left side under the smokebox can be removed. Then the post it

was screwed into is pushed out to the right side. Then the smokebox can

be lifted and turned. There is a hose from a pump in the left cylinder

that provides a little puff for the smoke unit. It needs to be slid off

the metal tube leading up to the base of the smoke unit. The schematic of the Rogers is pretty

straight forward. The only odd part is that the power for the LED

markers (on units that have them) and for the smoke unit is derived

from the motor terminals so that the markers and smoke will not work if

the motors are not running.

The schematic of the Rogers is pretty

straight forward. The only odd part is that the power for the LED

markers (on units that have them) and for the smoke unit is derived

from the motor terminals so that the markers and smoke will not work if

the motors are not running. The printed wiring

board itself is a simple one sided assembly. This is the primary

junction point for all of the wiring EXCEPT the rear pony truck power

pickups which appear to connect directly to the rear motor brick. Note

that the black and white wires are the track pickups, but since the two

bricks are reversed with respect to each other, sometimes white and

black join. The motor wires are similarly reversed with respect to each

other.

The printed wiring

board itself is a simple one sided assembly. This is the primary

junction point for all of the wiring EXCEPT the rear pony truck power

pickups which appear to connect directly to the rear motor brick. Note

that the black and white wires are the track pickups, but since the two

bricks are reversed with respect to each other, sometimes white and

black join. The motor wires are similarly reversed with respect to each

other. I traced out all the wires. The colors and

functions are shown here.

I traced out all the wires. The colors and

functions are shown here. This is a

schematic of the changes that I made to the engine to accommodate DCC.

The actual decoder is installed in the tender. The motors have been cut

loose and wired back to the tender via a 3 wire connector. The third

wire is for the front headlight which was also cut loose from all it's

interconnections and wired back to the tender. I used the bridge

rectifier for the markers to simulate the decoder's blue wire. The

headlight was also changed to a warm white high intensity LED as

described below.

This is a

schematic of the changes that I made to the engine to accommodate DCC.

The actual decoder is installed in the tender. The motors have been cut

loose and wired back to the tender via a 3 wire connector. The third

wire is for the front headlight which was also cut loose from all it's

interconnections and wired back to the tender. I used the bridge

rectifier for the markers to simulate the decoder's blue wire. The

headlight was also changed to a warm white high intensity LED as

described below. Most of the work was in the tender.

There was already a Soundtraxx Sierra there, it has been retained. The

rear headlight has also been changed out to an LED.

Most of the work was in the tender.

There was already a Soundtraxx Sierra there, it has been retained. The

rear headlight has also been changed out to an LED. The

three wire connection between the loco and tender is via this swap meet

cable. It had a male connector on one end and a mating female connector

on the other end. I just had to cut the cable and I had both ends. The

business end is securely tied to the drawbar.

The

three wire connection between the loco and tender is via this swap meet

cable. It had a male connector on one end and a mating female connector

on the other end. I just had to cut the cable and I had both ends. The

business end is securely tied to the drawbar. The

cable routes through the rear pony truck and up a hole drilled in the

floor. This brings up up inside the backhead when the backhead assembly

is screwed down to the cab floor. The motor leads (brown and red) were

cut near the old connector and the unused stubs insulated with shrink

tube. The front and rear motor wires were connected to the black and

red conductors of the cable going to the tender. Note that the brown

and red motor wires must be connected brown to red as the motor blocks

are identical, but installed physically reversed.

The

cable routes through the rear pony truck and up a hole drilled in the

floor. This brings up up inside the backhead when the backhead assembly

is screwed down to the cab floor. The motor leads (brown and red) were

cut near the old connector and the unused stubs insulated with shrink

tube. The front and rear motor wires were connected to the black and

red conductors of the cable going to the tender. Note that the brown

and red motor wires must be connected brown to red as the motor blocks

are identical, but installed physically reversed. At

the front end, the brown wire leading to the headlight was cut and the

stub insulated. Inside the smokebox, the red wire from the headlight

was cut off at the smoke unit connector terminal. Then the headlight

assembly was pulled out of the smokebox for replacement.

At

the front end, the brown wire leading to the headlight was cut and the

stub insulated. Inside the smokebox, the red wire from the headlight

was cut off at the smoke unit connector terminal. Then the headlight

assembly was pulled out of the smokebox for replacement. The

leads on the LED used for the front headlight were formed to allow the

LED to sit inside the headlight housing at the right height. A 680 ohm

current limiting resistor is installed in one lead. The leads were

insulated with shrink tubing and the assembly was attached to the inner

surface of the headlight mounting tube with a small amount of Zap-A-Gap

CA. The headlight housing can then be slipped over the LED and

reattached with it's original screw. The rear headlight was done the

same way but a 750 ohm resistor was used because I couldn't find

another 680.

The

leads on the LED used for the front headlight were formed to allow the

LED to sit inside the headlight housing at the right height. A 680 ohm

current limiting resistor is installed in one lead. The leads were

insulated with shrink tubing and the assembly was attached to the inner

surface of the headlight mounting tube with a small amount of Zap-A-Gap

CA. The headlight housing can then be slipped over the LED and

reattached with it's original screw. The rear headlight was done the

same way but a 750 ohm resistor was used because I couldn't find

another 680. The

tender is the most complex. The sound system sits atop the speaker,

held down with double back foam tape. It is accessible through the open

coal load for programming. A perforated board is mounted with foam tape

on top of the replacement battery for the Sierra. This is a 5 cell AA

NiMH pack and has been completely trouble free for years. The decoder,

a Digitrax DG583S, is mounted with foam tape to the tender floor at the

rear. The existing slide switch about halfway along the fireman's side

is used to control the power to the battery charger. The toggle switch

I originally installed with the Sierra disconnects the Sierra from it's

battery to that the Sierra doesn't flatten the battery during storage.

The battery charger provides about 150 ma of charge rate for the

battery. When the system is running, the battery is about charge

neutral on the average.

The

tender is the most complex. The sound system sits atop the speaker,

held down with double back foam tape. It is accessible through the open

coal load for programming. A perforated board is mounted with foam tape

on top of the replacement battery for the Sierra. This is a 5 cell AA

NiMH pack and has been completely trouble free for years. The decoder,

a Digitrax DG583S, is mounted with foam tape to the tender floor at the

rear. The existing slide switch about halfway along the fireman's side

is used to control the power to the battery charger. The toggle switch

I originally installed with the Sierra disconnects the Sierra from it's

battery to that the Sierra doesn't flatten the battery during storage.

The battery charger provides about 150 ma of charge rate for the

battery. When the system is running, the battery is about charge

neutral on the average.