When I originally planned the GIRR in 1996 I had intended to

illuminate whatever buildings appeared on the layout. Even though the

whole layout can be very well illuminated with halogen outdoor lighting

for nighttime running, this doesn't get close to simulating night. To do

that, one would expect that the layout's inhabitants would have some

lights burning in their homes and businesses.

It was a long time before I actually accumulated enough buildings to

actually go to the trouble of illuminating them. As I have nearly

enough buildings to populated my town, I need to find their "final"

placement so that I can add infrastructure around and under them. This

will include roadways, underground wiring for the lights and

underground drip irrigation lines for the plants. Some of the buildings

will conceal the drip irrigation junction valves. Others already

conceal electrical junctions. That process has started.

My buildings stay out all year around so that the illumination of

the buildings can be a semi-permanent installation. Buildings that come

indoors for the winter may require some extra features to deal with

wiring that may become exposed when the building is removed.

One of the first decisions that you have to make is to select what

kind of lamp that you are going to use. I prefer LEDs in most

applications with GOW (Grain Of Wheat) bulbs second. LEDs are far more

efficient that incandescent bulbs, and lately, their cost isn't much

higher either. You can light a whole building with LEDs on 10 to 50 mA,

a single GOW bulb draws 50 mA or more by itself. There might be lots of

lights on a layout and the current can really add up. It's best to

conserve if you can.

Until

recently, LEDs have been the wrong color for building lighting. The

typical white LED was too

blue. It cast a bright but hard light. This works ok for modern

locomotive high intensity headlights but the color is wrong for

residential lighting. The typical "white" LED has a color temperature of

about 6000°K like the sample on the right. The newer "warm white"

LEDs cost about the same, have nearly the same intensity, but have a

color temperature of about 3000°K, a very close match to

incandescent lighting. Warm white LEDs are available for about $1

each.

Until

recently, LEDs have been the wrong color for building lighting. The

typical white LED was too

blue. It cast a bright but hard light. This works ok for modern

locomotive high intensity headlights but the color is wrong for

residential lighting. The typical "white" LED has a color temperature of

about 6000°K like the sample on the right. The newer "warm white"

LEDs cost about the same, have nearly the same intensity, but have a

color temperature of about 3000°K, a very close match to

incandescent lighting. Warm white LEDs are available for about $1

each.

The GOW bulbs run at reduced intensity have a reddish cast to them. The warm white LEDs, when compared side by side are more yellowish with a very slight hint of green. Both do an acceptable job.

LEDs are also low voltage devices. Then need about 3 volts at 20 mA

to run at full intensity. The LEDs in the photo are running at 5 mA so

that they do get much more intense. They are easy to stack in series so

that the same 20 mA can run several LEDs if sufficient supply voltage

is available. LEDs run on DC so you'll need a DC source to run

them.

White LEDs typically come in two

sizes, 3 and 5 mm. The smaller packages tend to cast a wider beam and

are better for illumination of larger areas, such as the inside of a

building. The beam is not as intense as that cast by a 5 mm LED as the

total beam energy is spread over a larger area.

White LEDs typically come in two

sizes, 3 and 5 mm. The smaller packages tend to cast a wider beam and

are better for illumination of larger areas, such as the inside of a

building. The beam is not as intense as that cast by a 5 mm LED as the

total beam energy is spread over a larger area.

LEDs are polarity sensitive. The longer lead is positive. If you cut

the leads off and then forget which is which, look at the shape of the

electrodes inside. The smaller one is the positive terminal. The leads

themselves are quite stiff and rugged. You shouldn't solder right next

to the lens, solder down below the bump in the lead and then cover the

connections with heat shrink tubing.

This photo compares a warm white 3 mm LED with a similar 5 mm version running at 5 mA. The 3 mm one has a much broader beam, 60°, and is much less intense than the 25° beam of the 5 mm unit although both make the same total light output. The 3 mm version would be better for area lighting in structures.

This photo compares a warm white 3 mm LED with a similar 5 mm version running at 5 mA. The 3 mm one has a much broader beam, 60°, and is much less intense than the 25° beam of the 5 mm unit although both make the same total light output. The 3 mm version would be better for area lighting in structures.

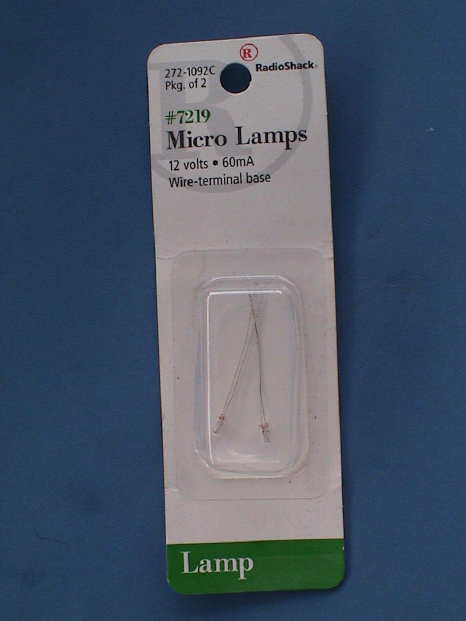

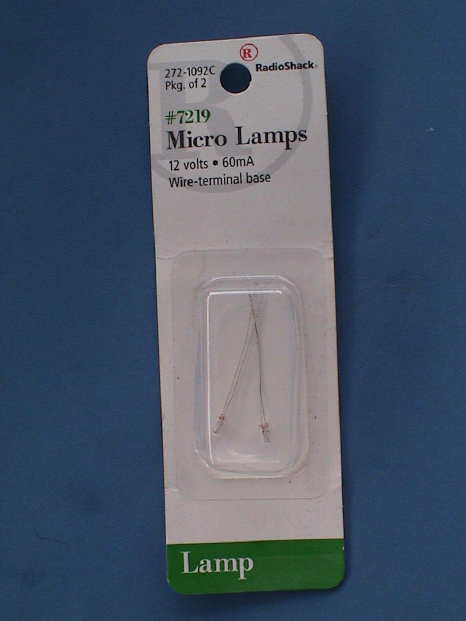

My second favorite for

lighting is the Grain Of Wheat (GOW) bulb. These Radio Shack parts are

inexpensive and particularly useful in applications where I want light

spread all around. LEDs are naturally directional, incandescent bulbs

are non-directional. The bulbs are intended for operation at 12 volts

where they draw 60 mA. I tend to use two in series from a 20 to 22 volt

source so each bulb gets 10 volts or so where it draws 54 mA.

Incandescent bulbs can run happily on either AC or DC power.

My second favorite for

lighting is the Grain Of Wheat (GOW) bulb. These Radio Shack parts are

inexpensive and particularly useful in applications where I want light

spread all around. LEDs are naturally directional, incandescent bulbs

are non-directional. The bulbs are intended for operation at 12 volts

where they draw 60 mA. I tend to use two in series from a 20 to 22 volt

source so each bulb gets 10 volts or so where it draws 54 mA.

Incandescent bulbs can run happily on either AC or DC power.

These particular bulbs are

fairly fragile. The leads are very fine wire and have almost no

strength. Trim them very short and solder 26 ga or smaller insulated

wire to the stubs and then insulate with short pieces 1/16" heat shrink

tubing. Another longer piece of 3/32" tubing should be placed over the

both of the smaller pieces of tubing and then shrunk as well to hold

the leads together. Alternately, if the wires are solid core, they can

be twisted right up to the solder joints to hold them together so that

forces are not applied directly to the fine bulb wires. Then the

assembly is rugged enough to handle.

These particular bulbs are

fairly fragile. The leads are very fine wire and have almost no

strength. Trim them very short and solder 26 ga or smaller insulated

wire to the stubs and then insulate with short pieces 1/16" heat shrink

tubing. Another longer piece of 3/32" tubing should be placed over the

both of the smaller pieces of tubing and then shrunk as well to hold

the leads together. Alternately, if the wires are solid core, they can

be twisted right up to the solder joints to hold them together so that

forces are not applied directly to the fine bulb wires. Then the

assembly is rugged enough to handle.

I built an overhead lamp

for my warehouse. The shade is just a piece of 15 mil styrene cut into

a circular pattern with a wedge cut out. Then the piece was formed into

a cone. The twisted wires leading to the LED were encased in 1/16" heat

shrink tubing. Then the wires were bent to shape to simulate the pipe

that the lamp hangs from. The other bulb is wired in series with the

outdoor lamp to illuminate a nearby window. The pair runs from my

lighting power at 20 VDC.

I built an overhead lamp

for my warehouse. The shade is just a piece of 15 mil styrene cut into

a circular pattern with a wedge cut out. Then the piece was formed into

a cone. The twisted wires leading to the LED were encased in 1/16" heat

shrink tubing. Then the wires were bent to shape to simulate the pipe

that the lamp hangs from. The other bulb is wired in series with the

outdoor lamp to illuminate a nearby window. The pair runs from my

lighting power at 20 VDC.

This is the overhead

lamp installed on the warehouse.

This is the overhead

lamp installed on the warehouse.

And this is what it looks like at night.

And this is what it looks like at night.

Once the lamps are mounted on pigtails, they can be attached inside and pointed out the windows. The light should shine out a window from above so that the source cannot be seen AND it looks like a ceiling lamp behind the window. These warm white LEDs run at only 1.5 mA each. If the current was any higher, the light would be just too bright at night. However, they cannot be seen at all until dusk. This is the inside of my Mission style station. The whole station building, including the breezeways, runs on just 6 mA from a 20 volt supply. There are a total of 16 LEDs. The total power to illuminate the station is less than 1/4 the power of a SINGLE GOW bulb.

Once the lamps are mounted on pigtails, they can be attached inside and pointed out the windows. The light should shine out a window from above so that the source cannot be seen AND it looks like a ceiling lamp behind the window. These warm white LEDs run at only 1.5 mA each. If the current was any higher, the light would be just too bright at night. However, they cannot be seen at all until dusk. This is the inside of my Mission style station. The whole station building, including the breezeways, runs on just 6 mA from a 20 volt supply. There are a total of 16 LEDs. The total power to illuminate the station is less than 1/4 the power of a SINGLE GOW bulb.

There are two general ways to power lighted buildings, batteries or

a wired power source. There are advantages to both, but for a static

structure, I think that a dedicated power source and conventional

wiring is probably more practical.

Batteries best suited to locations where getting a single pair of

wire to a building is impractical or undesirable for some reason.

Sufficient batteries to power a building can tend to be expensive. Most

rechargeable batteries don't have particularly good charge retention

capability while sitting unused. Gel cell batteries are probably the

most practical type as they can be easily disconnected and moved to an

indoor location to be charged. They also retain their charge while

unused better than other types.

Dedicated wiring allows an AC powered source to be used to

illuminate all the buildings on the layout. All the lights can be run

for as long as needed and all of them can be turned on and off at once

with one switch. Depending on the total load of the building lighting,

the actual source could be an unused power pack set to max output. I

use an Aristo ART-5460

DC power supply, primarily because I had one available. It's 20 volt

output is just right for a series pair of GOW bulbs. 20 volts is also

enough to run a string of 4 or 5 LEDs with a current limiting resistor.

The supply has enough power to run 500 strings or 2500 LEDs, far more

than I'll even need.

If all the lighting on the layout will be incandescent bulbs, then

an AC power source will be fine as well.

The single power supply is also the single control to turn on or off

all the lights.

If a reasonably constant power source is available, as it would be

for either a battery or centralized power supply, then the best way to

control the intensity of the lighting is through the use of voltage

dropping resistors. If a particular light is too bright, it can be

toned down with reduced voltage or current. Incandescent bulbs will

change their color temperature as the intensity is reduced, they will

be come cooler and more red. LEDs will retain the same color

temperature, just with less intensity.

LEDs are current driven devices and want to be run from a current

source. A series resistor with 5 or 6 volts across it makes an

acceptable current source. It's value is calculated by:

R = (Vsource- (N * VLED)) /

ILED

Where:

Vsource = the voltage of your DC power source

N = the number of LEDs in a string

VLED = the voltage drop of a forward biased LED (typically 3

volts per LED)

ILED = the desired LED current, typically 20 mA max, less

for less intensity

For a string of 5 LEDs at 3 volts each and a 20 volt power supply

there will be 15 volts across the LED string and 5 volts across a

series current limiting resistor. To get 20 mA in the LED string, the

resistor needs to be about 250 ohms. The resistor will dissipate only

100 mW. If there are fewer LEDs in the string, the resistor will get

larger and dissipate a little more power.

In a series string, each LED will see the same current and therefore

run at the same intensity. In the instance where one or more of them

needs to be toned down, they can either be run in separate strings with

their own current limiting resistor or a resistor can be placed in

parallel with an LED that needs less intensity. To cut the intensity of

one LED in half a 300 ohm resistor (3 volts / 10 mA) would be wired

across that one LED.

The easiest way to wire up the buildings is to run a single pair of

buried wire from building to building. Wire intended for direct burial

is available at any home improvement store for "Malibu" lighting.

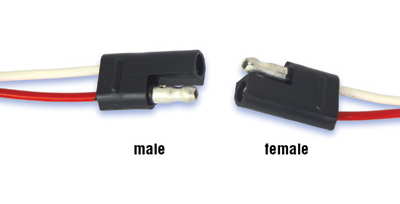

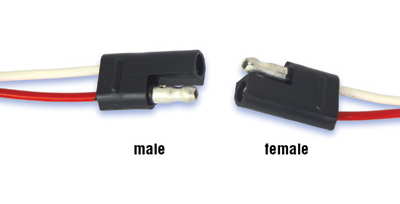

One wire from the

previous building in the chain, another to the next building and the

wires leading to the building can be connected wire nuts. These RV

style polarized connectors are rugged, inexpensive and design to handle

moisture. The connectors are available from most RV stores or some auto parts stores (in the towing section) for about $2

for a mated pair. They typically have 12" leads already attached which

is just about right. This allows a building to be lifted off the layout

and easily disconnected from the bus. When a building is taken in for

over winter storage, some form of protection should be used for the

connections sticking out of the ground. A turned over can with a rock

on top would be sufficient in most cases.

One wire from the

previous building in the chain, another to the next building and the

wires leading to the building can be connected wire nuts. These RV

style polarized connectors are rugged, inexpensive and design to handle

moisture. The connectors are available from most RV stores or some auto parts stores (in the towing section) for about $2

for a mated pair. They typically have 12" leads already attached which

is just about right. This allows a building to be lifted off the layout

and easily disconnected from the bus. When a building is taken in for

over winter storage, some form of protection should be used for the

connections sticking out of the ground. A turned over can with a rock

on top would be sufficient in most cases.

This page has been accessed  times since 2 Sep 08.

times since 2 Sep 08.

© 2008-21010 George Schreyer

Created 2 Sep 08

Last Updated March 22, 2010

Until

recently, LEDs have been the wrong color for building lighting. The

typical white LED was too

blue. It cast a bright but hard light. This works ok for modern

locomotive high intensity headlights but the color is wrong for

residential lighting. The typical "white" LED has a color temperature of

about 6000°K like the sample on the right. The newer "warm white"

LEDs cost about the same, have nearly the same intensity, but have a

color temperature of about 3000°K, a very close match to

incandescent lighting. Warm white LEDs are available for about $1

each.

Until

recently, LEDs have been the wrong color for building lighting. The

typical white LED was too

blue. It cast a bright but hard light. This works ok for modern

locomotive high intensity headlights but the color is wrong for

residential lighting. The typical "white" LED has a color temperature of

about 6000°K like the sample on the right. The newer "warm white"

LEDs cost about the same, have nearly the same intensity, but have a

color temperature of about 3000°K, a very close match to

incandescent lighting. Warm white LEDs are available for about $1

each. White LEDs typically come in two

sizes, 3 and 5 mm. The smaller packages tend to cast a wider beam and

are better for illumination of larger areas, such as the inside of a

building. The beam is not as intense as that cast by a 5 mm LED as the

total beam energy is spread over a larger area.

White LEDs typically come in two

sizes, 3 and 5 mm. The smaller packages tend to cast a wider beam and

are better for illumination of larger areas, such as the inside of a

building. The beam is not as intense as that cast by a 5 mm LED as the

total beam energy is spread over a larger area. This photo compares a warm white 3 mm LED with a similar 5 mm version running at 5 mA. The 3 mm one has a much broader beam, 60°, and is much less intense than the 25° beam of the 5 mm unit although both make the same total light output. The 3 mm version would be better for area lighting in structures.

This photo compares a warm white 3 mm LED with a similar 5 mm version running at 5 mA. The 3 mm one has a much broader beam, 60°, and is much less intense than the 25° beam of the 5 mm unit although both make the same total light output. The 3 mm version would be better for area lighting in structures. My second favorite for

lighting is the Grain Of Wheat (GOW) bulb. These Radio Shack parts are

inexpensive and particularly useful in applications where I want light

spread all around. LEDs are naturally directional, incandescent bulbs

are non-directional. The bulbs are intended for operation at 12 volts

where they draw 60 mA. I tend to use two in series from a 20 to 22 volt

source so each bulb gets 10 volts or so where it draws 54 mA.

Incandescent bulbs can run happily on either AC or DC power.

My second favorite for

lighting is the Grain Of Wheat (GOW) bulb. These Radio Shack parts are

inexpensive and particularly useful in applications where I want light

spread all around. LEDs are naturally directional, incandescent bulbs

are non-directional. The bulbs are intended for operation at 12 volts

where they draw 60 mA. I tend to use two in series from a 20 to 22 volt

source so each bulb gets 10 volts or so where it draws 54 mA.

Incandescent bulbs can run happily on either AC or DC power. These particular bulbs are

fairly fragile. The leads are very fine wire and have almost no

strength. Trim them very short and solder 26 ga or smaller insulated

wire to the stubs and then insulate with short pieces 1/16" heat shrink

tubing. Another longer piece of 3/32" tubing should be placed over the

both of the smaller pieces of tubing and then shrunk as well to hold

the leads together. Alternately, if the wires are solid core, they can

be twisted right up to the solder joints to hold them together so that

forces are not applied directly to the fine bulb wires. Then the

assembly is rugged enough to handle.

These particular bulbs are

fairly fragile. The leads are very fine wire and have almost no

strength. Trim them very short and solder 26 ga or smaller insulated

wire to the stubs and then insulate with short pieces 1/16" heat shrink

tubing. Another longer piece of 3/32" tubing should be placed over the

both of the smaller pieces of tubing and then shrunk as well to hold

the leads together. Alternately, if the wires are solid core, they can

be twisted right up to the solder joints to hold them together so that

forces are not applied directly to the fine bulb wires. Then the

assembly is rugged enough to handle. I built an overhead lamp

for my warehouse. The shade is just a piece of 15 mil styrene cut into

a circular pattern with a wedge cut out. Then the piece was formed into

a cone. The twisted wires leading to the LED were encased in 1/16" heat

shrink tubing. Then the wires were bent to shape to simulate the pipe

that the lamp hangs from. The other bulb is wired in series with the

outdoor lamp to illuminate a nearby window. The pair runs from my

lighting power at 20 VDC.

I built an overhead lamp

for my warehouse. The shade is just a piece of 15 mil styrene cut into

a circular pattern with a wedge cut out. Then the piece was formed into

a cone. The twisted wires leading to the LED were encased in 1/16" heat

shrink tubing. Then the wires were bent to shape to simulate the pipe

that the lamp hangs from. The other bulb is wired in series with the

outdoor lamp to illuminate a nearby window. The pair runs from my

lighting power at 20 VDC. This is the overhead

lamp installed on the warehouse.

This is the overhead

lamp installed on the warehouse. And this is what it looks like at night.

And this is what it looks like at night. Once the lamps are mounted on pigtails, they can be attached inside and pointed out the windows. The light should shine out a window from above so that the source cannot be seen AND it looks like a ceiling lamp behind the window. These warm white LEDs run at only 1.5 mA each. If the current was any higher, the light would be just too bright at night. However, they cannot be seen at all until dusk. This is the inside of my

Once the lamps are mounted on pigtails, they can be attached inside and pointed out the windows. The light should shine out a window from above so that the source cannot be seen AND it looks like a ceiling lamp behind the window. These warm white LEDs run at only 1.5 mA each. If the current was any higher, the light would be just too bright at night. However, they cannot be seen at all until dusk. This is the inside of my  One wire from the

previous building in the chain, another to the next building and the

wires leading to the building can be connected wire nuts. These RV

style polarized connectors are rugged, inexpensive and design to handle

moisture. The connectors are available from most RV stores or some auto parts stores (in the towing section) for about $2

for a mated pair. They typically have 12" leads already attached which

is just about right. This allows a building to be lifted off the layout

and easily disconnected from the bus. When a building is taken in for

over winter storage, some form of protection should be used for the

connections sticking out of the ground. A turned over can with a rock

on top would be sufficient in most cases.

One wire from the

previous building in the chain, another to the next building and the

wires leading to the building can be connected wire nuts. These RV

style polarized connectors are rugged, inexpensive and design to handle

moisture. The connectors are available from most RV stores or some auto parts stores (in the towing section) for about $2

for a mated pair. They typically have 12" leads already attached which

is just about right. This allows a building to be lifted off the layout

and easily disconnected from the bus. When a building is taken in for

over winter storage, some form of protection should be used for the

connections sticking out of the ground. A turned over can with a rock

on top would be sufficient in most cases.