13 Oct 08

13 Oct 08 7 Nov 08

7 Nov 08[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

13 Oct 08

13 Oct 08 7 Nov 08

7 Nov 08 When Lionel was

making large scale trains, they made a handcar. This car is long out of

production. I got this one long ago, probably on a closeout, but I

really don't remember.

When Lionel was

making large scale trains, they made a handcar. This car is long out of

production. I got this one long ago, probably on a closeout, but I

really don't remember.

The handcar actually came with couplers, but it is so weak that it won't actually pull anything except maybe one light car on dead flat track. I took the couplers off long ago.

The car has brass wheels, all of which are wired to pick up power, but they oxidize rapidly and power pickup is marginal at best. Only one axle is driven, the motor sits vertically hidden by the "barrel" and drives the axle below it via a worm gear.

The handcar handles rock via a crank mechanism driven by an O-ring coupled to the driven axle. The two riders rock with the handles.

When the wheels and track are fairly clean, the car sort of runs and doesn't make a lot of noise. However, it's top speed is just a tad higher than two men could propel the thing. It'll go very fast on the flat but it cannot handle grades at all due to wheel slippage. Overall, the handcar was too unreliable to do much running except on nearly flat track.

The brick is pretty

simple. It attaches to the carbody with 4 screws. There are no

electrical connections outside the brick. During reassembly, one must

be cautious to line up the fork that drives the handle.

The brick is pretty

simple. It attaches to the carbody with 4 screws. There are no

electrical connections outside the brick. During reassembly, one must

be cautious to line up the fork that drives the handle.

The shell has

virtually nothing in it except for the handle assembly. The brown

"barrel" hides the motor.

The shell has

virtually nothing in it except for the handle assembly. The brown

"barrel" hides the motor.

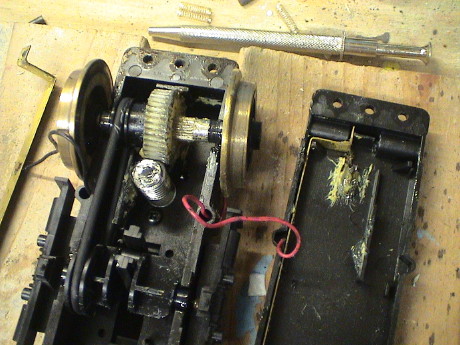

The motor worm

engages a gear on one axle. The rubber O-ring belt spans that axle and

the crank assembly in the middle. The other axle freewheels.

The motor worm

engages a gear on one axle. The rubber O-ring belt spans that axle and

the crank assembly in the middle. The other axle freewheels.

Power pickup is via 4 spring loaded carbon brushes that ride on the backs of the wheels. When the brick is opened, one must be careful not to lose these parts as they will just fall out. The springs rest against brass strips. A single wire on each side connects this strip to the motor.

I am in the process of converting the GIRR Mountain Division to DCC although I will retain the complete cab control system that is there now. The handcar may be a little problematic to convert to DCC, not because of any unusual complexity, which it surely does not have, but because of decoder physical size and cost.

The car has a stall current of over 3 amps which rules out any available HO decoder, inexpensive or not. Running current is low, about 400 mA. I am not about to spend a lot of money on a decoder for this puppy. However, I already have a surplus decoder that I won't be using anywhere else so the price for that one is right.

There isn't a lot of

room to install even a small large scale decoder. There is a space

between the shell and the brick on the side opposite the motor that

might be big enough to fit this MRC AD320 decoder.

There isn't a lot of

room to install even a small large scale decoder. There is a space

between the shell and the brick on the side opposite the motor that

might be big enough to fit this MRC AD320 decoder.

Electrical installation will be as easy as it gets. The two wires from the motor are unsoldered and spiced into the power input wires of the decoder. The motor output wires are wired back to the motor. There is no need to disassemble the brick to do this.

I took the handcar home to the GIRR (because that was where the decoders and DCC equipment were) and I first tested it on the outdoor track which was visibly oxidized but my other stuff ran on it. I put handcar on the track, and as expected, it didn't run at all. It is just too sensitive to dirty track however it was running fine on the indoor track of the GIRR Mtn Division just the day before. I cleaned a section of track with a pole sander and it ran ok.

I then

did the basic DCC installation with the MRC AD320 decoder. It accepted

a new address on the programming track so I thought I was good to go. I

put it on the main track and it didn't run all. Then I remembered that

this is a 28 step decoder so I had to status edit address 87 (my chosen

address for the handcar) for 28 speed step mode and then it ran fine,

but REALLY fast. Here is where I ran into difficulty, the AD320 has

minimal programming capability and the Vmax and Vmid CVs are not

programmable. Since it wouldn't start until about speed step 3 and it

was running too fast at speed step 7, there was little available speed

control. I could program CV2, the start voltage so that it would just

start to run at speed step 1, but this would leave only 6 speed steps

of control, which is unacceptable.

I then

did the basic DCC installation with the MRC AD320 decoder. It accepted

a new address on the programming track so I thought I was good to go. I

put it on the main track and it didn't run all. Then I remembered that

this is a 28 step decoder so I had to status edit address 87 (my chosen

address for the handcar) for 28 speed step mode and then it ran fine,

but REALLY fast. Here is where I ran into difficulty, the AD320 has

minimal programming capability and the Vmax and Vmid CVs are not

programmable. Since it wouldn't start until about speed step 3 and it

was running too fast at speed step 7, there was little available speed

control. I could program CV2, the start voltage so that it would just

start to run at speed step 1, but this would leave only 6 speed steps

of control, which is unacceptable.

One thing that I noticed was that the motor noise was not as severe as on locos that have to work harder. This is one of the reasons that I had replaced the AD320 before.

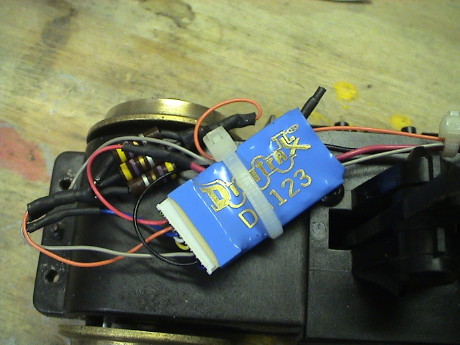

The

relative low motor noise with the AD320 indicated that I maybe could

use an old Digitrax DG580L which had made about as much motor noise as

the AD320. I tested the three surplus DG580L decoders that I had and

found that two of them still actually worked. The third one had clearly

seen some hard times and it didn't run properly. I took the AD320 out

and put one of the "good" DG580L decoders in. This decoder is

programmable every way from Sunday. When run in 28 speed step mode, it

could be programmed for Vstart, Vmid and Vmax. I set Vmax at about 20%,

Vmid at 10% and left Vstart alone. Now the handcar gives me a

reasonable top speed with the rest of the speed steps spread from 0 to

20% of the maximum possible so that all of the 28 speed steps are

actually usable. The motor noise is audible, but it is not

objectionable on this lightly loaded motor. Motors that are more

heavily loaded get hammered harder and make more noise.

The

relative low motor noise with the AD320 indicated that I maybe could

use an old Digitrax DG580L which had made about as much motor noise as

the AD320. I tested the three surplus DG580L decoders that I had and

found that two of them still actually worked. The third one had clearly

seen some hard times and it didn't run properly. I took the AD320 out

and put one of the "good" DG580L decoders in. This decoder is

programmable every way from Sunday. When run in 28 speed step mode, it

could be programmed for Vstart, Vmid and Vmax. I set Vmax at about 20%,

Vmid at 10% and left Vstart alone. Now the handcar gives me a

reasonable top speed with the rest of the speed steps spread from 0 to

20% of the maximum possible so that all of the 28 speed steps are

actually usable. The motor noise is audible, but it is not

objectionable on this lightly loaded motor. Motors that are more

heavily loaded get hammered harder and make more noise.

The decoder is not fastened down. It is captured by the shell so it isn't going anywhere.

I did have one unexpected difficulty with both decoders. The brick by itself is so light that it doesn't have enough traction to climb a 1.6% grade by itself without slipping the one driven wheelset. The car needs the weight of the shell just to run on any kind of a grade.

So the handcar has been converted to DCC for zero out-of-pocket cost, just about as much as it is worth. If I decide that I eventually want a better decoder in this puppy, I'll be able to adapt a Digitrax DH123 decoder with some careful additions of resistors. The stall current of the handcar is about 3.5 amps, about twice too much for even a fairly hardy HO sized decoder like the DH123 (which costs about $16). However, the stall current of the motor can be reduced by adding a resistor in series with the motor. 4 or 5 ohms in series with this motor will bring the total motor stalled resistance to 9 ohms which will result in a net stall current of just 2 amps, the capability of the DH123. A resistor will also drop the power delivered to the motor and normally wouldn't be acceptable, but this handcar is seriously over-motored. Dropping the speed with an external resistance is something that I could have done with the AD320 as well, but that decoder's almost total lack of programmability was just not very appealing.

The DH123 may have some difficulty on track voltages that are out of the normal HO range. It will handle 22 volts on the track but it likely wants to see a lower voltage. This can be fixed with a 20 ohm resistor in the track lead to absorb about 6 volts of track voltage.

Reduction in track voltage to the HO standard of 16 volts may be practical for the GIRR Mtn Division. Speeds are not very high there and there would be a lot less stress on the components. As a test, I switched the GIRR booster to HO mode and retested the handcar. It ran too slow. I had to bump the Vmax setting from 20% to 40% to get a reasonable speed. This is probably a better way to go.

I eventually did put a

Digitrax DH123 into the handcar. It runs better than with the DG580L

and doesn't make all that grumbling sound. However, the handcar just

stops sometimes with power applied, I think because too many DCC

packets have been garbled as the handcar will start right up at the

first change of the throttle. I turned off analog conversion and set a

fairly long deceleration rate so that when it does loose packets, it

gradually slows toward a stop. This makes it act like a hit a braking

section. However, it usually hears a good packet again and then

accelerates back to speed at a programmed acceleration rate. This

tended to make the problem where it just stopped dead on live track go

away.

I eventually did put a

Digitrax DH123 into the handcar. It runs better than with the DG580L

and doesn't make all that grumbling sound. However, the handcar just

stops sometimes with power applied, I think because too many DCC

packets have been garbled as the handcar will start right up at the

first change of the throttle. I turned off analog conversion and set a

fairly long deceleration rate so that when it does loose packets, it

gradually slows toward a stop. This makes it act like a hit a braking

section. However, it usually hears a good packet again and then

accelerates back to speed at a programmed acceleration rate. This

tended to make the problem where it just stopped dead on live track go

away.

The average current of the handcar is well within the DH123 limits, but the stall current is a little more than 2 amps so I added about 2 ohms in series with the motor to limit the hard stall current to just a shade over 2 amps. The resistor is made from 3 4.7 ohm resistors in parallel. The resistors are all on the high side, a little over 5 ohms each.

This handcar typically has had marginal power pickup. Since only the four brass wheels pick up power, the handcar has a tendency to stall on plastic frogs and dirty track. Installation of DCC seems to have helped matters somewhat but I am not sure why. Perhaps the constantly high track voltage makes it less sensitive to variable resistance in the pickups. However, the switch frog issues were still there.

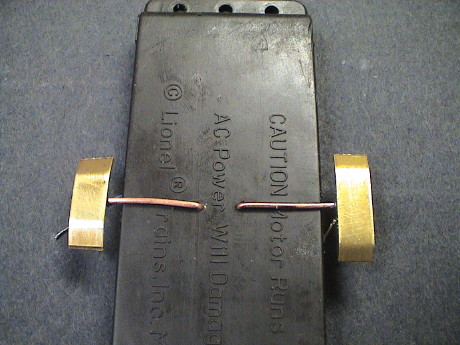

Somewhere on one of the

large scale forums, I saw that somebody had hacked on a set of sliders

on to a loco. I did a similar thing to the handcar. I used some brass

strip for the sliders and 18 ga copper bell wire for the spring. This

stuff is pretty stiff. I wanted to mount it closer to the center of the

handcar but there was mechanism there that I didn't want to interfere

with so I moved it nearer to the non-powered axle. The wire is 0.040"

in diameter so I drilled two 0.040" holes and bent the wire to poke up

through the holes. The wire was then bent over to secure it in the

up/down direction. A drop of Zap-A-Gap CA prevents it from

rotating.

Somewhere on one of the

large scale forums, I saw that somebody had hacked on a set of sliders

on to a loco. I did a similar thing to the handcar. I used some brass

strip for the sliders and 18 ga copper bell wire for the spring. This

stuff is pretty stiff. I wanted to mount it closer to the center of the

handcar but there was mechanism there that I didn't want to interfere

with so I moved it nearer to the non-powered axle. The wire is 0.040"

in diameter so I drilled two 0.040" holes and bent the wire to poke up

through the holes. The wire was then bent over to secure it in the

up/down direction. A drop of Zap-A-Gap CA prevents it from

rotating.

On the bottom side,

the whole length of the wire can act as the spring The sliders are

simply soldered to the wire.

On the bottom side,

the whole length of the wire can act as the spring The sliders are

simply soldered to the wire.

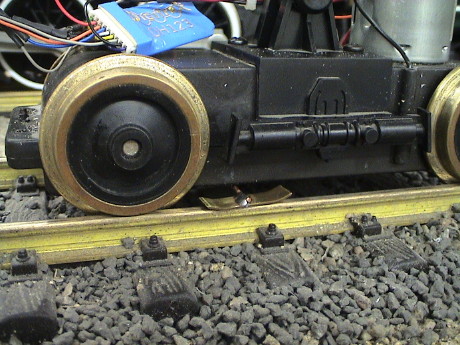

The sliders do work. I have a lot less trouble with flakey power. But they are still a little close to the axle and so that a wheel and slider can still rest on a plastic frog but at least it is easier for the handcar to drift across.

The sliders are

not too visually obtrusive on the track. However, some issues came up.

The handcar is really light so that if the sliders have enough downward

pressure to work, they lifted the whole wheelset off the track. This

wasn't any good so I had to add 4 ounces of weight above and around

that end of the car. Two ounces are up inside at the end, two more are

up in the "saddlebags." This holds the end of the car down so that the

sliders and wheels both bear against the track.

The sliders are

not too visually obtrusive on the track. However, some issues came up.

The handcar is really light so that if the sliders have enough downward

pressure to work, they lifted the whole wheelset off the track. This

wasn't any good so I had to add 4 ounces of weight above and around

that end of the car. Two ounces are up inside at the end, two more are

up in the "saddlebags." This holds the end of the car down so that the

sliders and wheels both bear against the track.

Then the extra drag of the sliders and the extra weight started to cause problems. The handcar didn't have enough traction and would spin it's one driven axle on the grades. There wasn't room underneath for more weight of the same kind of weights I had hand as I had already added 2 ounces above the driven axle long ago so that it would make it up the grades at all. I added 2 more ounces on top and that is marginally enough. I'll have to open a couple of 12 ga shotgun shells and recover the shot so that I can add more weight in the smaller places underneath. My 1 ounce weights are about the right size and shape to represent a bag of cement so I might paint some and pile them on top as cargo. The handcar seems to have enough power to drag the extra weight around just as long as there is enough weight on the driven end to keep the wheels from spinning.

I found some more of the

one ounce weights so I painted them to make them look like something

different than a fishing weight. It took five of the things to stop

most of the wheel spins but now it runs like in never did before. I

also took the opportunity to paint and weather it just a little.

I found some more of the

one ounce weights so I painted them to make them look like something

different than a fishing weight. It took five of the things to stop

most of the wheel spins but now it runs like in never did before. I

also took the opportunity to paint and weather it just a little.

After awhile, it was clear that even the 5 ounces on top and 4 more inside weren't enough. I added 4 more ounces on top in the form of more painted fishing weights at the end with the driven axle and now that appears to be enough. The thing is pretty heavy now.

After awhile, it was clear that even the 5 ounces on top and 4 more inside weren't enough. I added 4 more ounces on top in the form of more painted fishing weights at the end with the driven axle and now that appears to be enough. The thing is pretty heavy now.

I brought the Lionel Handcar back to the outdoor GIRR to see how it would run there. Since I got the Bachmann Handcar I thought I might swap them since the figures on the Lionel Handcar are smaller and more like 1:29 scale. The ones on the Bachmann Handcar are much larger, more like 1:24 or maybe even 1:20.3 scale. However, the Lionel Handcar ran like crap on "clean" track. I define clean track as clean enough to run the USAT Speeder without serious difficulty. The Speeder ran, the Lionel Handcar sputtered and quit. It looks like the Lionel Handcar will stay at the GIRR Mountain Division where it runs well enough and the Bachmann Handcar will remain at the GIRR where, with 8 wheel power pickup, it also runs well enough. The scale of the figures pales in comparison to running reliability.

[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

This page has been accessed times since 21 Sep 08.

© 2008-2010 George Schreyer

Created 21 Sep 08

Last Updated May 31, 2010