I picked up an LGB loco at the

2008 SoCalGRS annual meeting. It

is an LGB 0-4-0 and Vanderbilt tender carrying an Great Northern logo.

This engine came equipped with sound, smoke, lights and is supposed to

be DCC ready. As soon as I got it home, it went on the track for a test

run. All seemed to be reasonably well. The rest of this page describes

the loco in some finer detail as well as the modifications that were

performed, some of them happened virtually immediately.

I picked up an LGB loco at the

2008 SoCalGRS annual meeting. It

is an LGB 0-4-0 and Vanderbilt tender carrying an Great Northern logo.

This engine came equipped with sound, smoke, lights and is supposed to

be DCC ready. As soon as I got it home, it went on the track for a test

run. All seemed to be reasonably well. The rest of this page describes

the loco in some finer detail as well as the modifications that were

performed, some of them happened virtually immediately.

The loco represents one of the many thousands of 0-4-0 switchers

built over a period of about 100 years. This one is modeled after a

loco made in the latter part of that period as it carries a dynamo. The

overall scale is debatable. To me, it looks kind of squished in the

length dimension.

The loco runs quite well, although there are always improvements

possible.

Contents

The engine and tender carry fair detail. The grabs are all metal but

the siderods are plastic and there is no valve gear. The backhead

detail is cast in place but there are some valve handles attached in a

few spots. The headlights are directional. There is one lonely valve on

the running board on each side, I don't know which of the dozens of

valves that might be found on a real loco that these two valves are

supposed to represent.

There is a 4 position switch on the backhead which can be used to

turn various combinations of motor, lights, smoke and sound on or off,

but if you want sound, you get everything else too. If you want the motor, you get the cab lights and smoke too.

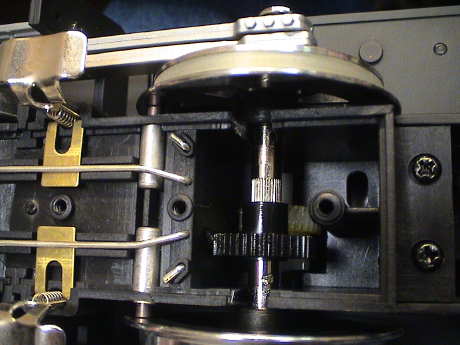

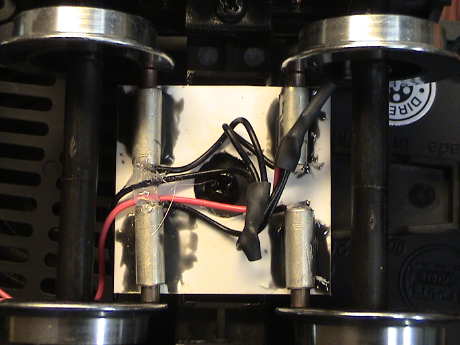

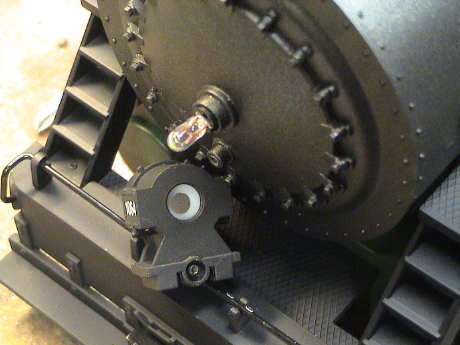

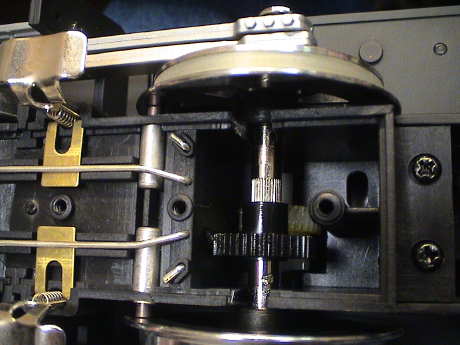

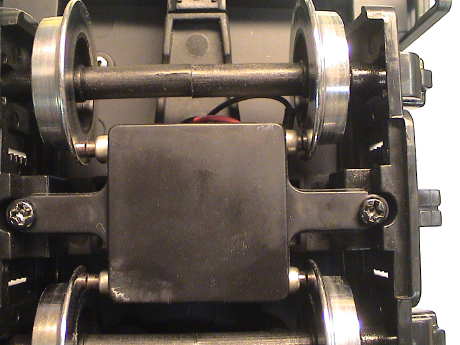

The motor brick has

a dual reduction gearing setup. There are also indications that the

power pickups and the motors are brought up to the inside of the loco

separately.

The motor brick has

a dual reduction gearing setup. There are also indications that the

power pickups and the motors are brought up to the inside of the loco

separately.

There is an electronic sound system built into the tender. It does a

good job at the chuff, bell and whistle. I heard no other sounds. The

bell and whistle are triggered via (supplied) track magnets interacting

with a magnetic pickup on the front truck of the tender. The

instructions indicate that the tender can accept a DCC decoder to

trigger the sounds as well.

The chuff rate control is electronic, at very low speeds, it

produces four chuffs/driver revolution but it doesn't follow changes in

speed very well. At the higher speeds, it's hard to tell if the chuff

rate is correct.

The engine has a standard LGB (Seuthe) smoke unit which is

essentially on all of the time. The instructions indicate that the

smoke unit can be run dry without damage.

The unit smokes stongly BUT if has just been filled, if probably won't smoke at all because the last drop of smoke fluid is plugging the exit hole on the stack. Poke a twig or toothpick in the hole in the top of the stack to break up the droplet so that the smoke can escape.

During the conversion to DCC, some of the functions of the switch have changed. Since the decoder controls most of the action, it doesn't matter what position the switch is in EXCEPT that the leftmost position turns off the cab light and smoke unit.

LGB cautions that the loco should be run ONLY from LGB power packs

or the manufacturer's warranty would be voided. Since LGB went out of

business, I suspect that the "warranty" has already expired. I ran it

from a Train Engineer set both to Linear and PWC modes. There didn't

seem to be a lot of difference, it ran fine on both.

As is typical for LGB locos, it runs very quietly. I detected no

unusual sounds and the mechanism noise is barely perceptible.

The tender had an unnerving tendency to wobble back and forth and

sometimes run "crabbed" across the track. This was due to a large

amount of slop in the tender axles. It took 2 nylon shims on each side

of each axle to control this tendency.

At 20 volts on the track, the loco goes a little faster than a real

0-4-0 would likely be run. I estimate the top speed at about 50 smph

depending on what scale the loco really is. This is not totally

unreasonable.

The loco is NOT a very strong puller, but that is expected of a such

a small loco. It will pull 5 large cars on my 1.6% ruling grade which

makes it one of the weaker pullers in my stable. However, it doesn't

slurp down a lot of juice doing it. Even at full slip, the loco draws

only slightly more than an amp, and that is WITH the smoke unit

running. Full hard stall is 3 amps.

In order to run the

tractive effort and current consumption tests, I need to jettison the

supplied hook and loop couplers and install Kadee couplers. The Kadee

#831 is designed for truck mounting and it fits well at both ends. I

choose to cut the ends of the mounting tangs off both ends to get the

couplers to mount inward a bit. On the engine front coupler, the side

to side travel is about the same mounted either with the stock tang or

a shortened tang as the coupler box interferers with the front step

after only a little rotation in either case. This is now, in effect, a

body mount.

In order to run the

tractive effort and current consumption tests, I need to jettison the

supplied hook and loop couplers and install Kadee couplers. The Kadee

#831 is designed for truck mounting and it fits well at both ends. I

choose to cut the ends of the mounting tangs off both ends to get the

couplers to mount inward a bit. On the engine front coupler, the side

to side travel is about the same mounted either with the stock tang or

a shortened tang as the coupler box interferers with the front step

after only a little rotation in either case. This is now, in effect, a

body mount.

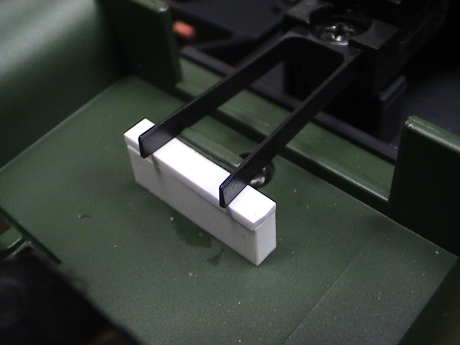

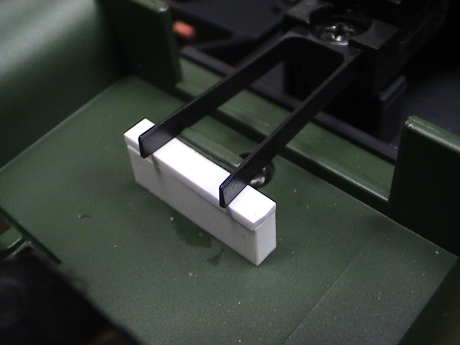

This

mount has a little vertical slop that is not acceptable for a Kadee

coupler. The coupler needs to be held at its highest position for

proper operation. This is easily accomplished with the addition of the

white shims under the ends of the centering springs. I used a total of

0.310" of shim, maybe a little less would do as well. This holds the

springs down and therefore the coupler is held up.

This

mount has a little vertical slop that is not acceptable for a Kadee

coupler. The coupler needs to be held at its highest position for

proper operation. This is easily accomplished with the addition of the

white shims under the ends of the centering springs. I used a total of

0.310" of shim, maybe a little less would do as well. This holds the

springs down and therefore the coupler is held up.

On the tender, it

is a full truck mount. I also cut the tang back so that I could use the

original mounting hole for the original screw. There used to be a dummy

coupler mounted on the rear beam above the hook and loop. It came off

right away.

On the tender, it

is a full truck mount. I also cut the tang back so that I could use the

original mounting hole for the original screw. There used to be a dummy

coupler mounted on the rear beam above the hook and loop. It came off

right away.

Power is picked up on the loco only on 4 wheels and 2 sliders,

however one of the drivers has a traction tire so that limits it's

power pickup pretty significantly.

Although my track is pretty dirty as it has been raining a little

recently, the engine ran on it, but not all too well. It spit and

sputtered in spots and stalled a couple of times. This is about the

same performance as my LGB

2060 which has essentially the same pickup arrangement. Overall,

the limited power pickup is not adequate for use on pretty dirty track.

I ran my track cleaning car around three times to sweep off the loose

stuff and then the engine by itself ran pretty well but the headlight

still flickered in spots and the loco wanted to stall on switch frogs.

But I don't keep my track in pristine condition so that I'll be adding

power pickups to the tender shortly.

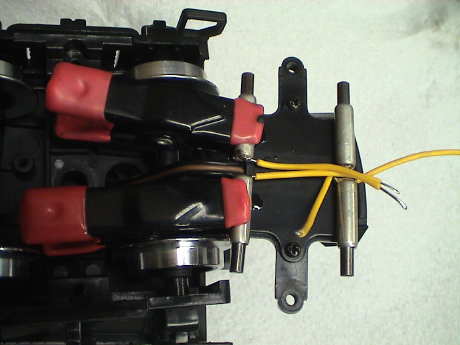

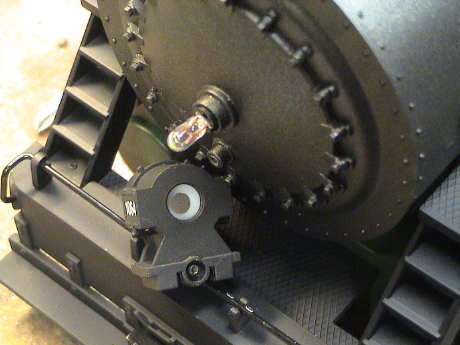

I used

some extra LGB contacts that I had and attached them to the topside of

the reed switch assembly on the front tender truck. In this photo, I

have clamped a pair of contacts while the tack adhesive, Zap-A-Gap,

sets up. Later, I reinforced the joint with two-part filled epoxy.

I used

some extra LGB contacts that I had and attached them to the topside of

the reed switch assembly on the front tender truck. In this photo, I

have clamped a pair of contacts while the tack adhesive, Zap-A-Gap,

sets up. Later, I reinforced the joint with two-part filled epoxy.

After

the epoxy had set and the reed switch assembly was replaced, the

contacts are tucked up out of the way. The wires run up the hole in the

tender floor and run back to the connector at the rear of the tank. The

contact on this connector that is on the engineer's side is also the

one that eventually works it way to the loco, also on the engineer's

side.

After

the epoxy had set and the reed switch assembly was replaced, the

contacts are tucked up out of the way. The wires run up the hole in the

tender floor and run back to the connector at the rear of the tank. The

contact on this connector that is on the engineer's side is also the

one that eventually works it way to the loco, also on the engineer's

side.

A quick test on the layout showed that there was a major

improvement. The headlight flickering was completely gone and there was

no problem with switch frogs. I ran the engine on a section of track

that hadn't been cleaned in a month or so and it also ran well,

although there was a little headlight flickering in a few spots.

Overall, this is a good deal.

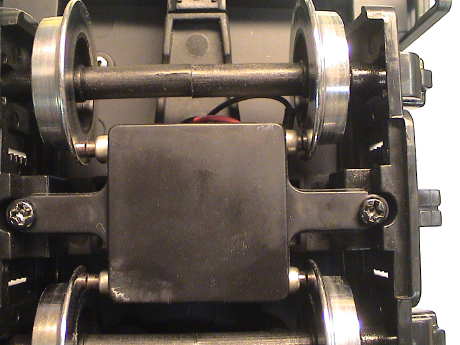

After I bought some more LGB type contacts (from Massoth), I installed a set on the rear tender truck as well. The loco wasn't really hurting for power pickup, but more is better. These were attached to a 1.45" square piece of 0.060" stryene sheet with Zap-A-Gap CA to hold them in place and then reinforced with epoxy. Now the loco picks up power on 12 wheels and 2 sliders.

After I bought some more LGB type contacts (from Massoth), I installed a set on the rear tender truck as well. The loco wasn't really hurting for power pickup, but more is better. These were attached to a 1.45" square piece of 0.060" stryene sheet with Zap-A-Gap CA to hold them in place and then reinforced with epoxy. Now the loco picks up power on 12 wheels and 2 sliders.

it is possible to get into both the loco and tender without a lot of

difficulty but there are several screws that have to be removed in

either case.

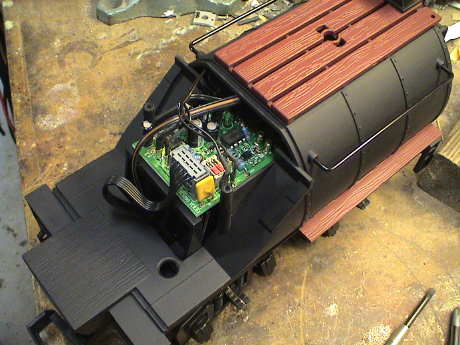

To get

this far, remove the coal load (2 screws on top) and then two more

screws under the 9 volt battery. Then the coal bunker can be removed

exposing the front of the tender's PWB.

To get

this far, remove the coal load (2 screws on top) and then two more

screws under the 9 volt battery. Then the coal bunker can be removed

exposing the front of the tender's PWB.

Removal of

6 more screws under the front part of the tender tank (two of them are

next to the electrical connector to the loco) will allow the coal

bunker and part of the water tank to be removed but this is not really

necessary to access the whole PWB. Just remove four screws under the

rear portion of the water tank to free it. Note that the front half of

the tank must be at least loose to get the back half off. This exposes

the full area of the PWB. The tender board contains the sound

system.

Removal of

6 more screws under the front part of the tender tank (two of them are

next to the electrical connector to the loco) will allow the coal

bunker and part of the water tank to be removed but this is not really

necessary to access the whole PWB. Just remove four screws under the

rear portion of the water tank to free it. Note that the front half of

the tank must be at least loose to get the back half off. This exposes

the full area of the PWB. The tender board contains the sound

system.

The loco is a little

easier to get into. First, remove the handrails along the sides of the

boiler. Then remove 4 screws under the cab and pull it straight up.

Then remove two screws at the sides of the backhead and that will come

off. Then two more screws underneath the front part of the boiler will

free it. Then the whole of the PWB in the loco can be seen.

The loco is a little

easier to get into. First, remove the handrails along the sides of the

boiler. Then remove 4 screws under the cab and pull it straight up.

Then remove two screws at the sides of the backhead and that will come

off. Then two more screws underneath the front part of the boiler will

free it. Then the whole of the PWB in the loco can be seen.

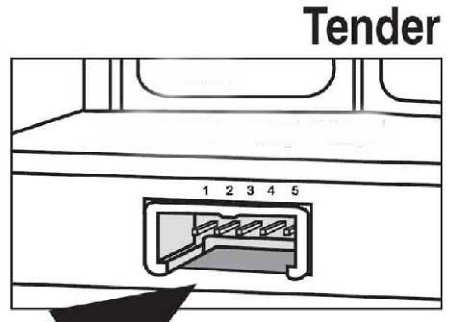

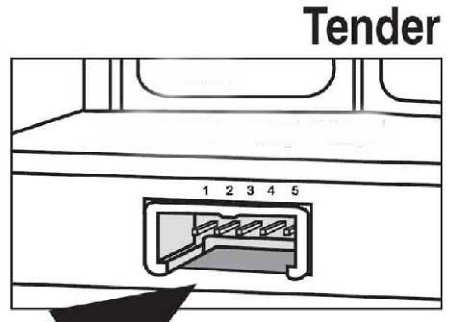

The engine and tender are interconnected with a 5 wire harness.

There is a fairly complex PWB in both units, too complex to trace out

due to all the surface mounted parts and integrated circuits. I did

determine that the outer pins of the loco to tender harness are track

power. These lead all the way to the connector at the rear of the

tender. The loco can be powered via the connector on the back of the

tender.

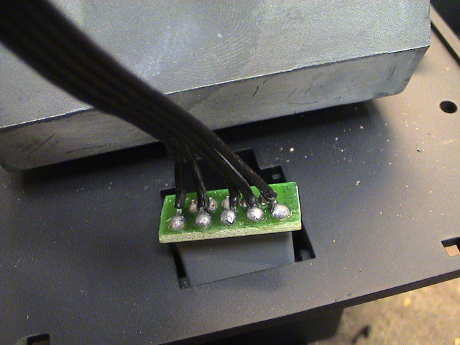

Both PWBs

are supposed to contain connections for a DCC decoder, I assume that

these contacts are the ones but without some installation instructions,

it could be pretty hard to figure out which is which.

Both PWBs

are supposed to contain connections for a DCC decoder, I assume that

these contacts are the ones but without some installation instructions,

it could be pretty hard to figure out which is which.

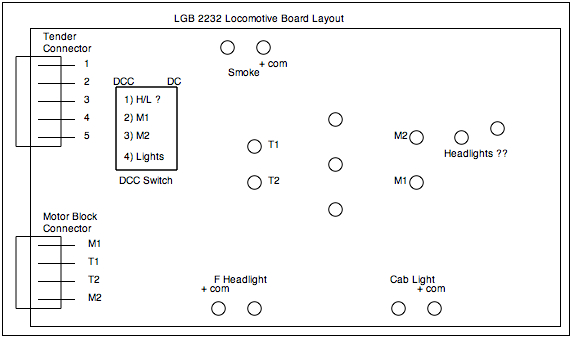

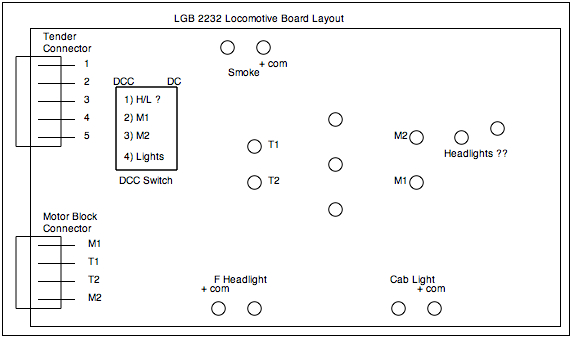

This is a photo of the loco

board. There are 9 contacts on the board that are designed to accept

the mating pins of a DCC decoder designed for this kind of loco. I've

traced the function of the most important ones, but the other 5 have

eluded me.

This is a photo of the loco

board. There are 9 contacts on the board that are designed to accept

the mating pins of a DCC decoder designed for this kind of loco. I've

traced the function of the most important ones, but the other 5 have

eluded me.

At the lower left is the 4 pin connector to the motor block. The

outer pins are for the motor, the inner ones are for the track power

pickups.

The item in the left center is a 4 pole switch. This is there to

allow reconfiguration of the PWB for DCC. All of these switches should

be set to the right (rearward) for regular track power operation. I

think that they should all be set to the left (forward) for DCC. The

functions of these switches is as follows:

Switch 1 has something to do with the headlights

Switch 2 disconnects one motor lead from the rest of the board

Switch 3 disconnects the other motor lead

Switch 4 disconnects the lights

I have not yet determined what controls the lighting when switch 4

is set for DCC. Also, the headlight behavior is funny. If I turn switch

4 to the DCC side, none of the lights work. If I leave switch 4 to the

DC side and move switch 1 to the DCC side, I can make the headlights do

something, but it is odd. If the pin marked "Headlight ??" is grounded

(back to the track via a pair of diodes as a DCC decoder would do it)

then the front headlight comes on. With the pin ungrounded, the rear

headlight comes on. The direction that the motor is running doesn't

have any impact.

At the upper left is the connector

for the 5 pin harness that leads to the tender. The definition of these

pins, shown in the following paragraph, was drawn by Stan

Cederleaf.

At the upper left is the connector

for the 5 pin harness that leads to the tender. The definition of these

pins, shown in the following paragraph, was drawn by Stan

Cederleaf.

Pin 1 = Track Power Right (constant to rear outlet)

Pin 2 = Rear Light Common

Pin 3 = Rear Light

Pin 4 = Switched Track Power Right (for soundboard power only)

Pin 5 = Track Power left (to rear outlet and soundboard)

This is a

partial layout diagram for the connections to the board in the loco.

The motor and track connectors were easy to determine. I have not

determined the functions of the other 5 connections. Note that the

lighting and smoke unit are all joined with a + Common trace. The

weight under the board is ALSO + Common, be careful what touches it. +

Common on my loco is about 6.4 volts.

This is a

partial layout diagram for the connections to the board in the loco.

The motor and track connectors were easy to determine. I have not

determined the functions of the other 5 connections. Note that the

lighting and smoke unit are all joined with a + Common trace. The

weight under the board is ALSO + Common, be careful what touches it. +

Common on my loco is about 6.4 volts.

I did not find an obvious system ground (- Common) trace on the PWB

so I synthesized one from two diodes to the track contacts for testing

purposes. I find that if the non-common headlight lead is unplugged and

grounded, it will operate properly UNLESS the switch on the backhead is

set to OFF (position 0). Then the headlight voltage can INCREASE to

track voltage and it gets really bright. This is not good.

The instruction booklet that came with the set indicates that the

loco and tender are DCC ready. I would guess that it is intended to

install a function only decoder in the tender to drive the sound system

and a motor and lights only decoder in the loco body to drive the

motor. There is a 4 pole DIP switch on the board to reconfigure the

wiring to isolate the motor and accept a decoder. LGB made, and Massoth

still makes, a decoder that has pins on it that will plug right into

the sockets on the board. That is why the sockets are unlabeled. There

is no need to label connections that are made in masse by the

connection of a mating assembly.

The LGB and Massoth (and perhaps a Zimo) decoders also understand

the funny serial command string that was originally designed into the

MTS system. To activate functions, F1 was toggled some number of times

to activate a given function. Apparently, the decoders designed for

this loco interpret standard DCC function commands and translate these

into a series of pulses on the F1 pin to emulate "normal" DCC function

operation. I don't think that this loco can actually do anything with

functions past F0. On this loco, the F1 pin appears to just toggle the

direction of the headlight in a non-standard fashion. I don't want to

mess with this.

Some form of documentation would go a long way in making a DCC

installation easier for a DIY guy. LGB did not provide these

instructions because they wanted the user to send the loco in for the

installation of an LGB approved decoder. This is not possible now, but

a DIY installation of a Massoth decoder would be very easy, plug it in

and flip the four switches.

Alternately, I could just jettison the all the internal electronics

an use a QSI sound decoder, perhaps with LED's instead of the

incandescent bulbs. The 5 wire harness to the tender could bring

forward track power from tender pickups and send the speaker signals

back to the tender. The rear headlight could operate off the 5th wire

if a "blue" wire is synthesized in the tender with a couple of diodes.

Alternately, the decoder mounting position could be reversed by putting

it into the tender. Then two wires send track power forward, two more

would send motor power forward and the 5th one would be used for the

front headlight with the "blue" wire synthesized with two diodes in the

loco.

I could also retain the loco board to provide the power for the cab

light and smoke unit. I've found the track and motor terminals on the

board so that I could reassign the 3 center wires on the tender harness

and use wires 2 and 4 for the motor power forward to the loco and wire

3 for the headlight control going back to the tender. I would change

out the headlights to LEDs and wire them directly to the decoder. This

wiring change would be quite easy to do by simply unsoldering the

tender harness on the back of the connector inside the loco and then

tapping off those three wires. New wires would be soldered to those

points to go where they need to go.

Update, Nov 8, 2008. This is the route that I have elected to take.

I'll leave the loco pretty much intact with no changes to the PWB at

all. A QSI DCC sound decoder and screw terminal board that arrived

today will go into the tender and I'll sell the existing LGB sound

board.

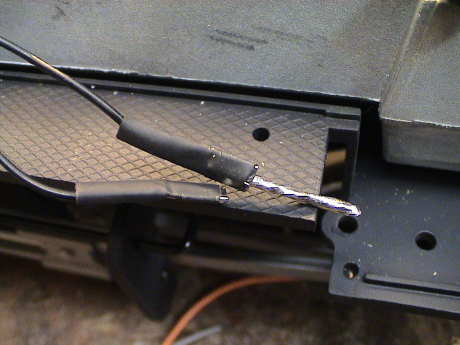

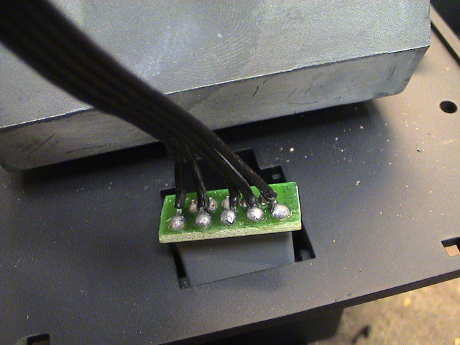

The 5 wire connector

at the rear of the loco comes out of the frame easily. I'll lift the

center 3 wires and insulate them with shrink tube. Different wires will

be soldered to these three pins.

The 5 wire connector

at the rear of the loco comes out of the frame easily. I'll lift the

center 3 wires and insulate them with shrink tube. Different wires will

be soldered to these three pins.

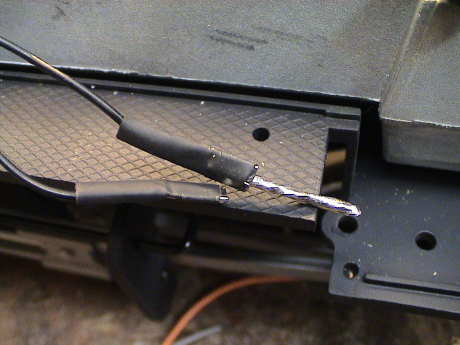

The wires

from pins 2 and 4 will solder to these Molex Series 062 connector pins

that just happen to fit into the sockets on the loco's PWB. The two

pins to the right are the motor pins when switches 2 and 3 on the DIP

switch are pushed forward. DIP switches 1 and 4 will be left in the

rearward, or track power, position. This lets the loco board create

power for the cab light and smoke unit, yet also allows them to be

turned off with the slide switch on the backhead.

The wires

from pins 2 and 4 will solder to these Molex Series 062 connector pins

that just happen to fit into the sockets on the loco's PWB. The two

pins to the right are the motor pins when switches 2 and 3 on the DIP

switch are pushed forward. DIP switches 1 and 4 will be left in the

rearward, or track power, position. This lets the loco board create

power for the cab light and smoke unit, yet also allows them to be

turned off with the slide switch on the backhead.

The two Molex pins on the left are track power. One diode will be

soldered to each track power pin and then soldered together to make a

"blue" wire that carries full rectified track voltage.

The two

headlight connectors used to fit over pins on the PWB. A 16 ga wire

emulates the pin well enough so that I don't even have to cut off the

connectors. One headlight wire goes to the "blue" wire, the other gets

wired back to the center pin on the loco connector through a 330 (or

maybe 390) ohm resistor. I'll check the headlight voltage when I am

done and adjust the resistor as needed. If I elect to change the

headlight to an LED, the resistor increases to 820 to 1000 ohms.

The two

headlight connectors used to fit over pins on the PWB. A 16 ga wire

emulates the pin well enough so that I don't even have to cut off the

connectors. One headlight wire goes to the "blue" wire, the other gets

wired back to the center pin on the loco connector through a 330 (or

maybe 390) ohm resistor. I'll check the headlight voltage when I am

done and adjust the resistor as needed. If I elect to change the

headlight to an LED, the resistor increases to 820 to 1000 ohms.

The tender will be gutted. I'll retain the rear headlight and treat

it the same as the one in the loco. I'll also change out the speaker

for a better one. I'll retain the 5 wire harness but cut off the end

that goes to the sound board and terminate the 5 wires to the decoder

as needed. Since I'm using the reed switch assembly to support power

pickups, I'll cut it's harness and send it off with the sound

board.

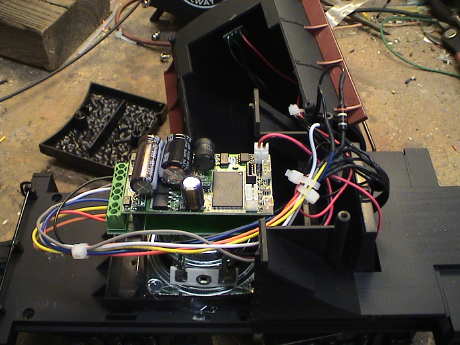

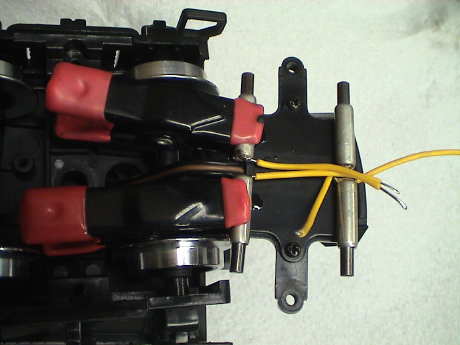

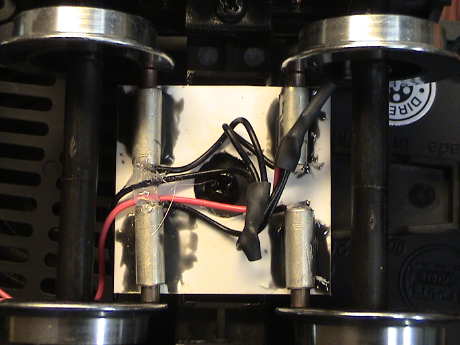

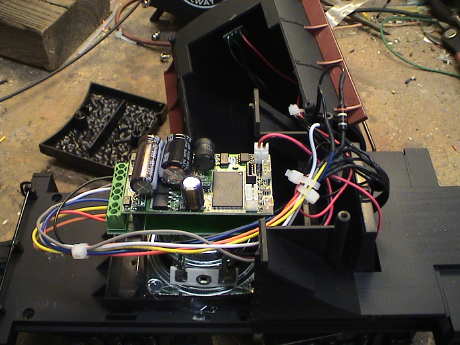

This is the converted loco

after a few minutes work. It is wired as described above and presented

no difficulties.

This is the converted loco

after a few minutes work. It is wired as described above and presented

no difficulties.

The two diodes that synthesize the decoder blue wire are visible in

the contacts plugged into the track power jacks. The orange and gray

wires are the motor wires.

The QSI decoder would not

fit on top of the weight in the tender and my replacement speaker would

not fit under the weight so that weight went overboard. If I need

weight to keep the tender on the track, I'll glue some to the floor

behind the speaker. For the time being, it'll run light.

The QSI decoder would not

fit on top of the weight in the tender and my replacement speaker would

not fit under the weight so that weight went overboard. If I need

weight to keep the tender on the track, I'll glue some to the floor

behind the speaker. For the time being, it'll run light.

These speakers come with an adhesive backed foam seal. It is stuck

to the floor with it's own adhesive and the speaker is hot glued to the

foam seal.

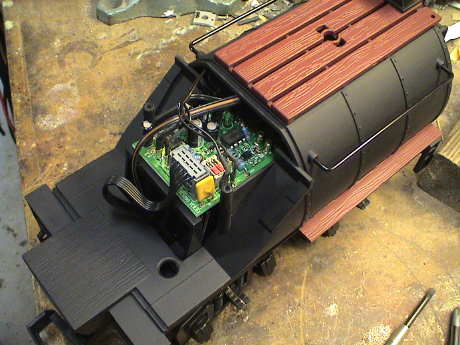

The QSI and it's screw

adaptor board are mounted on the back of the speaker with double backed

foam mounting tape. It clears the inside of the tender shell by about

half an inch. The rear headlight is wired directly to the decoder

through a 390 ohm resistor. The motor and front headlight leads go

forward to the loco.

The QSI and it's screw

adaptor board are mounted on the back of the speaker with double backed

foam mounting tape. It clears the inside of the tender shell by about

half an inch. The rear headlight is wired directly to the decoder

through a 390 ohm resistor. The motor and front headlight leads go

forward to the loco.

The QSI provided documentation and the stencils on the screw adaptor

board don't agree with one another. It could be that I am

misinterpreting the diagram, but I am trained to read engineering

drawings. I followed the stencil on the board and it worked

properly.

It all ran well except that I had a problem with the Regulated

Throttle Control (BEMF) mode. The loco did not want to stop going

forward until it stalled against something. It would stop going in

reverse. It would just creep along with the throttle set at zero. I

tried massaging the BEMF settings but I could not get it to stop

properly. I turned the BEMF off by changing the operating mode to

Standard Throttle Control (STC) and the problem went away.

I had to reset CV56.13 to get the chuff to beat at the correct rate,

it was going about twice too fast.

This QSI decoder has the "500" sound file with a peep-peep standard

whistle. There is also a lower note more standard whistle enabled by

F11. Both of these whistles play manually quite well with the short and

long toots having the same tone. This is unlike the program that came

in the QSI that went into the new Pacific.

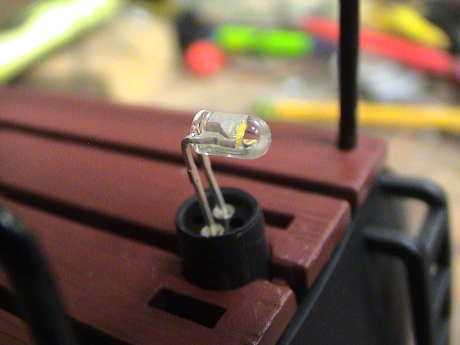

The stock headlight

is a 6 volt incandescent bulb. It fits in a small socket on the front

of the smokebox. The headlight housing simply fits over the bulb. It is

held on with one screw that can be accessed by removing the number

plate. The bulb is fairly bright as bulbs go and it spreads light

around well, it can be seen in daylight, but it doesn't cast much of a

beam.

The stock headlight

is a 6 volt incandescent bulb. It fits in a small socket on the front

of the smokebox. The headlight housing simply fits over the bulb. It is

held on with one screw that can be accessed by removing the number

plate. The bulb is fairly bright as bulbs go and it spreads light

around well, it can be seen in daylight, but it doesn't cast much of a

beam.

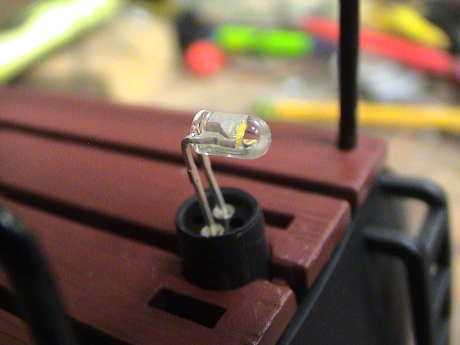

It turns out that a

5 mm LED will fit right in the socket if the leads are clipped short.

The white plastic cup inside the headlight housing is about 4.5 mm in

diameter so it needs to be enlarged just a little to allow the LED

housing to poke into the headlight housing. Since this cup is loose

inside the headlight housing, it a little difficult to drill it, but I

just worked with at an angle with a 0.200" drill bit by hand and

managed to gouge enough plastic off to allow the LED to fit.

It turns out that a

5 mm LED will fit right in the socket if the leads are clipped short.

The white plastic cup inside the headlight housing is about 4.5 mm in

diameter so it needs to be enlarged just a little to allow the LED

housing to poke into the headlight housing. Since this cup is loose

inside the headlight housing, it a little difficult to drill it, but I

just worked with at an angle with a 0.200" drill bit by hand and

managed to gouge enough plastic off to allow the LED to fit.

A white LED wants to

draw 20 mA or so which results in about a 3 volt drop, too small for

the stock loco lighting circuit. If the LED goes in to an unmodified

loco, one of the wires needs to be clipped and a 150 ohm resistor

installed in series with the LED. Normally, the longer lead on an LED

is the positive one, but if you've already clipped them, the positive

lead is the one with the smaller electrode as viewed through the side

of the LED housing.

A white LED wants to

draw 20 mA or so which results in about a 3 volt drop, too small for

the stock loco lighting circuit. If the LED goes in to an unmodified

loco, one of the wires needs to be clipped and a 150 ohm resistor

installed in series with the LED. Normally, the longer lead on an LED

is the positive one, but if you've already clipped them, the positive

lead is the one with the smaller electrode as viewed through the side

of the LED housing.

For a DCC installation where the source voltage is on the order of

18 to 20 volts, a 750 to 1000 ohm resistor is appropriate in series

with the LED.

This is a "warm white" 20 degree high intensity LED and it makes an

excellent headlight. It doesn't have a hint of the blue cast of the

more common "white" LEDs. Because the headlight lens is frosted, the

illumination from the LED can be seen more easily in daylight than the

stock bulb AND it casts much more light in front in the dark.

I had left the

rear headlight as the stock incandescent bulb because a narrow beam 5

mm LED would not easily fit due the geometry of the rear headlight

mounting. However, the beam that it case was pretty dismal. This is a

shot of the illumination to the rear on my test track in the garage

illuminating a roll of paper towels that is used as a bumper on the end

of the test track. I had to use the high sensitivity Night Shot mode of

my camera just to get a picture at all. The camera's IR illuminator is

turned off.

I had left the

rear headlight as the stock incandescent bulb because a narrow beam 5

mm LED would not easily fit due the geometry of the rear headlight

mounting. However, the beam that it case was pretty dismal. This is a

shot of the illumination to the rear on my test track in the garage

illuminating a roll of paper towels that is used as a bumper on the end

of the test track. I had to use the high sensitivity Night Shot mode of

my camera just to get a picture at all. The camera's IR illuminator is

turned off.

The front headlight

conversion went so well that I elected to do the rear one too. However,

I used a 3 mm warm white LED because when the leads are bent

perpendicular to the body, it actually fits up inside the headlight

housing and the lead frame is a perfect fit for the existing

socket.

The front headlight

conversion went so well that I elected to do the rear one too. However,

I used a 3 mm warm white LED because when the leads are bent

perpendicular to the body, it actually fits up inside the headlight

housing and the lead frame is a perfect fit for the existing

socket.

I did have to change the current limiting resistor so I had to open

the tender and cut the old 390 ohm resistor out and add an 820 ohm one

back in. The socket is not polarized as the bulbs didn't need it, but

they way that I originally plugged the LED in was correct, 50/50

chance.

This is the same

test configuration with the same camera with the same settings. The LED

draws half the current as the bulb but is MUCH brighter and because it

is a 60 degree illumination angle LED, it spreads light around pretty

well too, at least as well as the old bulb. It is now too bright in the

"dim" mode so I'll have to reprogram the decoder to tone it down.

This is the same

test configuration with the same camera with the same settings. The LED

draws half the current as the bulb but is MUCH brighter and because it

is a 60 degree illumination angle LED, it spreads light around pretty

well too, at least as well as the old bulb. It is now too bright in the

"dim" mode so I'll have to reprogram the decoder to tone it down.

This page has been accessed  times since 1 Nov 08.

times since 1 Nov 08.

© 2008-2009 George Schreyer

Created 1 Nov 08

Last Updated January 23, 2009

I picked up an LGB loco at the

2008 SoCalGRS annual meeting. It

is an LGB 0-4-0 and Vanderbilt tender carrying an Great Northern logo.

This engine came equipped with sound, smoke, lights and is supposed to

be DCC ready. As soon as I got it home, it went on the track for a test

run. All seemed to be reasonably well. The rest of this page describes

the loco in some finer detail as well as the modifications that were

performed, some of them happened virtually immediately.

I picked up an LGB loco at the

2008 SoCalGRS annual meeting. It

is an LGB 0-4-0 and Vanderbilt tender carrying an Great Northern logo.

This engine came equipped with sound, smoke, lights and is supposed to

be DCC ready. As soon as I got it home, it went on the track for a test

run. All seemed to be reasonably well. The rest of this page describes

the loco in some finer detail as well as the modifications that were

performed, some of them happened virtually immediately. The motor brick has

a dual reduction gearing setup. There are also indications that the

power pickups and the motors are brought up to the inside of the loco

separately.

The motor brick has

a dual reduction gearing setup. There are also indications that the

power pickups and the motors are brought up to the inside of the loco

separately. In order to run the

tractive effort and current consumption tests, I need to jettison the

supplied hook and loop couplers and install Kadee couplers. The Kadee

#831 is designed for truck mounting and it fits well at both ends. I

choose to cut the ends of the mounting tangs off both ends to get the

couplers to mount inward a bit. On the engine front coupler, the side

to side travel is about the same mounted either with the stock tang or

a shortened tang as the coupler box interferers with the front step

after only a little rotation in either case. This is now, in effect, a

body mount.

In order to run the

tractive effort and current consumption tests, I need to jettison the

supplied hook and loop couplers and install Kadee couplers. The Kadee

#831 is designed for truck mounting and it fits well at both ends. I

choose to cut the ends of the mounting tangs off both ends to get the

couplers to mount inward a bit. On the engine front coupler, the side

to side travel is about the same mounted either with the stock tang or

a shortened tang as the coupler box interferers with the front step

after only a little rotation in either case. This is now, in effect, a

body mount. This

mount has a little vertical slop that is not acceptable for a Kadee

coupler. The coupler needs to be held at its highest position for

proper operation. This is easily accomplished with the addition of the

white shims under the ends of the centering springs. I used a total of

0.310" of shim, maybe a little less would do as well. This holds the

springs down and therefore the coupler is held up.

This

mount has a little vertical slop that is not acceptable for a Kadee

coupler. The coupler needs to be held at its highest position for

proper operation. This is easily accomplished with the addition of the

white shims under the ends of the centering springs. I used a total of

0.310" of shim, maybe a little less would do as well. This holds the

springs down and therefore the coupler is held up. On the tender, it

is a full truck mount. I also cut the tang back so that I could use the

original mounting hole for the original screw. There used to be a dummy

coupler mounted on the rear beam above the hook and loop. It came off

right away.

On the tender, it

is a full truck mount. I also cut the tang back so that I could use the

original mounting hole for the original screw. There used to be a dummy

coupler mounted on the rear beam above the hook and loop. It came off

right away. I used

some extra LGB contacts that I had and attached them to the topside of

the reed switch assembly on the front tender truck. In this photo, I

have clamped a pair of contacts while the tack adhesive, Zap-A-Gap,

sets up. Later, I reinforced the joint with two-part filled epoxy.

I used

some extra LGB contacts that I had and attached them to the topside of

the reed switch assembly on the front tender truck. In this photo, I

have clamped a pair of contacts while the tack adhesive, Zap-A-Gap,

sets up. Later, I reinforced the joint with two-part filled epoxy. After

the epoxy had set and the reed switch assembly was replaced, the

contacts are tucked up out of the way. The wires run up the hole in the

tender floor and run back to the connector at the rear of the tank. The

contact on this connector that is on the engineer's side is also the

one that eventually works it way to the loco, also on the engineer's

side.

After

the epoxy had set and the reed switch assembly was replaced, the

contacts are tucked up out of the way. The wires run up the hole in the

tender floor and run back to the connector at the rear of the tank. The

contact on this connector that is on the engineer's side is also the

one that eventually works it way to the loco, also on the engineer's

side. After I bought some more LGB type contacts (from Massoth), I installed a set on the rear tender truck as well. The loco wasn't really hurting for power pickup, but more is better. These were attached to a 1.45" square piece of 0.060" stryene sheet with Zap-A-Gap CA to hold them in place and then reinforced with epoxy. Now the loco picks up power on 12 wheels and 2 sliders.

After I bought some more LGB type contacts (from Massoth), I installed a set on the rear tender truck as well. The loco wasn't really hurting for power pickup, but more is better. These were attached to a 1.45" square piece of 0.060" stryene sheet with Zap-A-Gap CA to hold them in place and then reinforced with epoxy. Now the loco picks up power on 12 wheels and 2 sliders. To get

this far, remove the coal load (2 screws on top) and then two more

screws under the 9 volt battery. Then the coal bunker can be removed

exposing the front of the tender's PWB.

To get

this far, remove the coal load (2 screws on top) and then two more

screws under the 9 volt battery. Then the coal bunker can be removed

exposing the front of the tender's PWB. Removal of

6 more screws under the front part of the tender tank (two of them are

next to the electrical connector to the loco) will allow the coal

bunker and part of the water tank to be removed but this is not really

necessary to access the whole PWB. Just remove four screws under the

rear portion of the water tank to free it. Note that the front half of

the tank must be at least loose to get the back half off. This exposes

the full area of the PWB. The tender board contains the sound

system.

Removal of

6 more screws under the front part of the tender tank (two of them are

next to the electrical connector to the loco) will allow the coal

bunker and part of the water tank to be removed but this is not really

necessary to access the whole PWB. Just remove four screws under the

rear portion of the water tank to free it. Note that the front half of

the tank must be at least loose to get the back half off. This exposes

the full area of the PWB. The tender board contains the sound

system. The loco is a little

easier to get into. First, remove the handrails along the sides of the

boiler. Then remove 4 screws under the cab and pull it straight up.

Then remove two screws at the sides of the backhead and that will come

off. Then two more screws underneath the front part of the boiler will

free it. Then the whole of the PWB in the loco can be seen.

The loco is a little

easier to get into. First, remove the handrails along the sides of the

boiler. Then remove 4 screws under the cab and pull it straight up.

Then remove two screws at the sides of the backhead and that will come

off. Then two more screws underneath the front part of the boiler will

free it. Then the whole of the PWB in the loco can be seen. Both PWBs

are supposed to contain connections for a DCC decoder, I assume that

these contacts are the ones but without some installation instructions,

it could be pretty hard to figure out which is which.

Both PWBs

are supposed to contain connections for a DCC decoder, I assume that

these contacts are the ones but without some installation instructions,

it could be pretty hard to figure out which is which. This is a photo of the loco

board. There are 9 contacts on the board that are designed to accept

the mating pins of a DCC decoder designed for this kind of loco. I've

traced the function of the most important ones, but the other 5 have

eluded me.

This is a photo of the loco

board. There are 9 contacts on the board that are designed to accept

the mating pins of a DCC decoder designed for this kind of loco. I've

traced the function of the most important ones, but the other 5 have

eluded me. At the upper left is the connector

for the 5 pin harness that leads to the tender. The definition of these

pins, shown in the following paragraph, was drawn by Stan

Cederleaf.

At the upper left is the connector

for the 5 pin harness that leads to the tender. The definition of these

pins, shown in the following paragraph, was drawn by Stan

Cederleaf. This is a

partial layout diagram for the connections to the board in the loco.

The motor and track connectors were easy to determine. I have not

determined the functions of the other 5 connections. Note that the

lighting and smoke unit are all joined with a + Common trace. The

weight under the board is ALSO + Common, be careful what touches it. +

Common on my loco is about 6.4 volts.

This is a

partial layout diagram for the connections to the board in the loco.

The motor and track connectors were easy to determine. I have not

determined the functions of the other 5 connections. Note that the

lighting and smoke unit are all joined with a + Common trace. The

weight under the board is ALSO + Common, be careful what touches it. +

Common on my loco is about 6.4 volts. The 5 wire connector

at the rear of the loco comes out of the frame easily. I'll lift the

center 3 wires and insulate them with shrink tube. Different wires will

be soldered to these three pins.

The 5 wire connector

at the rear of the loco comes out of the frame easily. I'll lift the

center 3 wires and insulate them with shrink tube. Different wires will

be soldered to these three pins. The wires

from pins 2 and 4 will solder to these Molex Series 062 connector pins

that just happen to fit into the sockets on the loco's PWB. The two

pins to the right are the motor pins when switches 2 and 3 on the DIP

switch are pushed forward. DIP switches 1 and 4 will be left in the

rearward, or track power, position. This lets the loco board create

power for the cab light and smoke unit, yet also allows them to be

turned off with the slide switch on the backhead.

The wires

from pins 2 and 4 will solder to these Molex Series 062 connector pins

that just happen to fit into the sockets on the loco's PWB. The two

pins to the right are the motor pins when switches 2 and 3 on the DIP

switch are pushed forward. DIP switches 1 and 4 will be left in the

rearward, or track power, position. This lets the loco board create

power for the cab light and smoke unit, yet also allows them to be

turned off with the slide switch on the backhead. The two

headlight connectors used to fit over pins on the PWB. A 16 ga wire

emulates the pin well enough so that I don't even have to cut off the

connectors. One headlight wire goes to the "blue" wire, the other gets

wired back to the center pin on the loco connector through a 330 (or

maybe 390) ohm resistor. I'll check the headlight voltage when I am

done and adjust the resistor as needed. If I elect to change the

headlight to an LED, the resistor increases to 820 to 1000 ohms.

The two

headlight connectors used to fit over pins on the PWB. A 16 ga wire

emulates the pin well enough so that I don't even have to cut off the

connectors. One headlight wire goes to the "blue" wire, the other gets

wired back to the center pin on the loco connector through a 330 (or

maybe 390) ohm resistor. I'll check the headlight voltage when I am

done and adjust the resistor as needed. If I elect to change the

headlight to an LED, the resistor increases to 820 to 1000 ohms. This is the converted loco

after a few minutes work. It is wired as described above and presented

no difficulties.

This is the converted loco

after a few minutes work. It is wired as described above and presented

no difficulties. The QSI decoder would not

fit on top of the weight in the tender and my replacement speaker would

not fit under the weight so that weight went overboard. If I need

weight to keep the tender on the track, I'll glue some to the floor

behind the speaker. For the time being, it'll run light.

The QSI decoder would not

fit on top of the weight in the tender and my replacement speaker would

not fit under the weight so that weight went overboard. If I need

weight to keep the tender on the track, I'll glue some to the floor

behind the speaker. For the time being, it'll run light. The QSI and it's screw

adaptor board are mounted on the back of the speaker with double backed

foam mounting tape. It clears the inside of the tender shell by about

half an inch. The rear headlight is wired directly to the decoder

through a 390 ohm resistor. The motor and front headlight leads go

forward to the loco.

The QSI and it's screw

adaptor board are mounted on the back of the speaker with double backed

foam mounting tape. It clears the inside of the tender shell by about

half an inch. The rear headlight is wired directly to the decoder

through a 390 ohm resistor. The motor and front headlight leads go

forward to the loco. The stock headlight

is a 6 volt incandescent bulb. It fits in a small socket on the front

of the smokebox. The headlight housing simply fits over the bulb. It is

held on with one screw that can be accessed by removing the number

plate. The bulb is fairly bright as bulbs go and it spreads light

around well, it can be seen in daylight, but it doesn't cast much of a

beam.

The stock headlight

is a 6 volt incandescent bulb. It fits in a small socket on the front

of the smokebox. The headlight housing simply fits over the bulb. It is

held on with one screw that can be accessed by removing the number

plate. The bulb is fairly bright as bulbs go and it spreads light

around well, it can be seen in daylight, but it doesn't cast much of a

beam. It turns out that a

5 mm LED will fit right in the socket if the leads are clipped short.

The white plastic cup inside the headlight housing is about 4.5 mm in

diameter so it needs to be enlarged just a little to allow the LED

housing to poke into the headlight housing. Since this cup is loose

inside the headlight housing, it a little difficult to drill it, but I

just worked with at an angle with a 0.200" drill bit by hand and

managed to gouge enough plastic off to allow the LED to fit.

It turns out that a

5 mm LED will fit right in the socket if the leads are clipped short.

The white plastic cup inside the headlight housing is about 4.5 mm in

diameter so it needs to be enlarged just a little to allow the LED

housing to poke into the headlight housing. Since this cup is loose

inside the headlight housing, it a little difficult to drill it, but I

just worked with at an angle with a 0.200" drill bit by hand and

managed to gouge enough plastic off to allow the LED to fit. A white LED wants to

draw 20 mA or so which results in about a 3 volt drop, too small for

the stock loco lighting circuit. If the LED goes in to an unmodified

loco, one of the wires needs to be clipped and a 150 ohm resistor

installed in series with the LED. Normally, the longer lead on an LED

is the positive one, but if you've already clipped them, the positive

lead is the one with the smaller electrode as viewed through the side

of the LED housing.

A white LED wants to

draw 20 mA or so which results in about a 3 volt drop, too small for

the stock loco lighting circuit. If the LED goes in to an unmodified

loco, one of the wires needs to be clipped and a 150 ohm resistor

installed in series with the LED. Normally, the longer lead on an LED

is the positive one, but if you've already clipped them, the positive

lead is the one with the smaller electrode as viewed through the side

of the LED housing. I had left the

rear headlight as the stock incandescent bulb because a narrow beam 5

mm LED would not easily fit due the geometry of the rear headlight

mounting. However, the beam that it case was pretty dismal. This is a

shot of the illumination to the rear on my test track in the garage

illuminating a roll of paper towels that is used as a bumper on the end

of the test track. I had to use the high sensitivity Night Shot mode of

my camera just to get a picture at all. The camera's IR illuminator is

turned off.

I had left the

rear headlight as the stock incandescent bulb because a narrow beam 5

mm LED would not easily fit due the geometry of the rear headlight

mounting. However, the beam that it case was pretty dismal. This is a

shot of the illumination to the rear on my test track in the garage

illuminating a roll of paper towels that is used as a bumper on the end

of the test track. I had to use the high sensitivity Night Shot mode of

my camera just to get a picture at all. The camera's IR illuminator is

turned off. The front headlight

conversion went so well that I elected to do the rear one too. However,

I used a 3 mm warm white LED because when the leads are bent

perpendicular to the body, it actually fits up inside the headlight

housing and the lead frame is a perfect fit for the existing

socket.

The front headlight

conversion went so well that I elected to do the rear one too. However,

I used a 3 mm warm white LED because when the leads are bent

perpendicular to the body, it actually fits up inside the headlight

housing and the lead frame is a perfect fit for the existing

socket. This is the same

test configuration with the same camera with the same settings. The LED

draws half the current as the bulb but is MUCH brighter and because it

is a 60 degree illumination angle LED, it spreads light around pretty

well too, at least as well as the old bulb. It is now too bright in the

"dim" mode so I'll have to reprogram the decoder to tone it down.

This is the same

test configuration with the same camera with the same settings. The LED

draws half the current as the bulb but is MUCH brighter and because it

is a 60 degree illumination angle LED, it spreads light around pretty

well too, at least as well as the old bulb. It is now too bright in the

"dim" mode so I'll have to reprogram the decoder to tone it down.