This page is

dedicated to the details of one particular DCC/Sound decoder, the

QSI Quantum Aristo. QSI

makes some HO sized decoders and just one model of a large scale

decoder, the Quantum Aristo. However it is a really good one that

seems to work just about anywhere. Nominally, it is "Plug-N-Play"

decoder intended to work in the DCC socket of AristoCraft

locomotives. However, it will also work in the sockets of some

Bachmann locomotives as well. It also has an adaptor board that

simulates the socket and converts the decoder to a screw connection

version. When the decoder is plugged into one of these adaptor

boards, it is called a "Quantum Magnum".

This page is

dedicated to the details of one particular DCC/Sound decoder, the

QSI Quantum Aristo. QSI

makes some HO sized decoders and just one model of a large scale

decoder, the Quantum Aristo. However it is a really good one that

seems to work just about anywhere. Nominally, it is "Plug-N-Play"

decoder intended to work in the DCC socket of AristoCraft

locomotives. However, it will also work in the sockets of some

Bachmann locomotives as well. It also has an adaptor board that

simulates the socket and converts the decoder to a screw connection

version. When the decoder is plugged into one of these adaptor

boards, it is called a "Quantum Magnum".

This is a full function DCC decoder with a 3 amp average motor

capability and an excellent integrated sound system. It has been

used on locos as large as an Aristo SD45 and many USA Trains locos

without blowing up. It will also work in much smaller locos where

it will physically fit. It will work on DC as well as DCC although

on track powered DC it will shut down when the track voltage gets

too low however there is a SuperCap kit for it that allows the

sound to continue for a few seconds after loss of track power. QSI

also makes a radio receiver that will plug into the decoder and

accept commands from an Airwire transmitter so that it can also

function under battery power.

There is just one model of this decoder used for both steam and

diesel. Depending on who you order it from, it may come with a

particular sound set pre-installed. The entire sound set and

decoder parameters can be reloaded into the decoder at any time

PROVIDED that the user has the Quantum programmer software and

interface. Firmware upgrades can also be installed via the

programmer. There is much more data in the sound set than just

sound. For SOME locomotives, QSI has determined an optimal set of

operational parameters that is included in the sound set so that

the user doesn't have to tweak these after the fact.

This page will be by nature limited in scope to straight up DCC

issues because I have no experience with it in DC or battery

powered modes. I will also not try to repeat information that is in

the manual except where I found it confusing. As of the creation

date of this page, I have three of these puppies, all steam, one in

a Bachmann Shay, one in a

recent Aristo Pacific and

one in an LGB 22232 0-4-0

switcher. A sample of the sound that the QSI makes can be found in this QuickTime video of the one in the Shay.

I felt that this decoder deserved it's own page just because it

is so different than a more standard DCC decoder. There are many

decoders that can just be described with a few specs, all the

details follow standards. This is good, with most other decoders,

an experienced DCC user doesn't even have to read the manual until

it comes time to tweak some manufacturer specific Configuration

Variable. The QSI decoder will work right out of the box as well

but to get the most out of it, it needs some tweaking.

The decoder comes with minimal instructions for programming. You

should download the ~250 page programming manual from the QSI web

site if you want to make any changes at all.

This decoder is not yet completely bug free, some things don't

seem to work quite right, but it can be made to work quite well

with some simple work arounds or programming adjustments.

Contents

Operational Characteristics

From a DCC throttle, the QSI works pretty much like any other

DCC decoder. It will respond to the throttle in a normal fashion

except that it comes programmed with an acceleration and

deceleration delay that comes along with it's default throttle

mode. It's functions also respond differently depending on if it

standing or moving. There are also some functions that change

depending on what it was doing previously. All this can be a bit

confusing at first blush, but you get used to it.

The 250

page instruction manual has the details of how the system works

and how to best take advantage of the features of the decoder. This link is to the Nov 2010 version, 4.6.1. If they update the manual the link will probably break. A revised link can be found at the QSI by following the Q2 link and looking on the right of the page for the new link.

Sound. The decoder's sound responds in synchronism to

throttle commands although the steam chuff can be controlled by a

cam as well. If the chuff rate doesn't match the loco speed very

well, it can be tweaked. The sound is fully digital and of very

high quality with lots of voices available. For example, the

cylinder cocks can be activated such that the cylinder blowdown

will play, in sync, for 16 chuffs or to 12 smph, whichever comes

first.

Lights. The lighting follows Rule 17 unless you change

it. The lights will be dim unless the loco is moving in the

direction of the light, when it will switch to bright. There are

parameters for changing how dim the lights are, but the bright

parameter seems to be set at max and does not appear to be user

changeable. The lights ramp from dim to bright slowly so that it

would not appear to be required to add resistors in series with

incandescent bulbs. The decoder gives them time to adjust. The

ramping is also a little easier on the bulbs than just being

slammed on or off. The "dim" setting defaults to 32 (range of 0 to

255). For an incandescent bulb, this can be roughly equal to "off"

but it works fine with LEDs.

BEMF. The decoder has back EMF capability that is enabled

by default. The mode that is active is called RTC, or Regulated

Throttle Control. This mode has loose BEMF coupling so that the

locos used in this mode will consist fairly well without serious

bucking. There are three other throttle modes as well but currently

two of them are disabled due to some patent issue with Mike's Train

House who claims a patent on some forms of BEMF control where there

is clearly prior art. I expect that this issue will be resolved

sometime, but it will take lawyers and courts to change it. The

other available throttle mode is STC, or Standard Throttle Control.

This essentially turns the BEMF off.

When in RTC, there are several BEMF parameters that can be

adjusted to change the performance of the BEMF system. There

appears to be a bug in the BEMF system so that in once case I had

to turn it off, see the Odd Behaviors section below.

Speed Control. The decoder has the capability, by reading

the BEMF signal, to determine the motor speed. If this is

calibrated by measuring the actual locomotive speed, the loco can

report its speed in miles per hour and it can use the actual speed

to trigger some sounds. The speed can also be matched to the

throttle setting such that 50% is also 50 smph.

Audio Feedback. Since this decoder has sound integrated,

it can report, via a recorded voice, what it is doing or the

results of programming. When you change a CV value in OPS mode, the

voice will report the CV being changed and the value that it

changed to. By entering a CV value into CV64, the voice will report

the current value without changing it. This makes programming on a

programming track unnecessary because the decoder can tell you what

it knows by audio feedback.

Function Outputs. The QSI has only two native function

outputs, F0f and F0r (white and yellow wire). These are all that

are implemented in the Aristo PnP interface. There is or will be an

accessory interface that adds more function outputs at extra cost.

Since most of the extra function outputs that I use on other

decoders go to controlling the sound system, the lack of these

extra outputs on the QSI is not all that important because the

sounds are already directly controlled by function keys. I

generally don't like to wire smoke through a decoder anyway and

things like the cab light and markers can be left on all the

time.

If you really need more function outputs, then for $17 you can

get a Digitrax or TCS function only decoder that provides 4

additional 250 mA functions with special effects.

Speed Matching. The QSI decoder has built in momentum, I

think to allow the sound and motion to better coordinate. This

complicates speed matching to other DCC equipped locos with other

kinds of decoders some, but not a lot. The standard speed matching

process applies. You can do this by programming on the main using

whatever OPS mode programming method your DCC system allows. This

method uses the "3 point" speed matching method which will work

just fine for the vast majority of cases. I've never had to use the

full 28 step table to speed match any locos well enough to consist

nicely. If you want to do 28 step speed matching, use Decoder Pro

in JMRI. Don't try to do it on a throttle.

- Place the locos on parallel tracks or one behind the other with

some space between them on the same, preferably level, track.

- Initially set CV's 2 through 6 to zero on both locos.

- CV2=0 sets the minimum starting voltage to zero

- CV3=0 sets the acceleration momentum to zero (on QSI to

minimum)

- CV4=0 does the same for deceleration

- CV5=0 sets the top speed to maximum

- CV6=0 sets the mid speed to the straight line mid point between

CV2 and CV5

- Set CV2 on both locos

- Increase the value of CV2 for each loco until the loco just

starts to move at speed step 1.

- Don't worry if the actual speed at speed step 1 matches unless

one loco is way off from the other one.

- Put the locos in a consist. This makes it easier to control

both their speeds at the same time.

- Run the throttle up to max and see which one is faster. If the

locos are on the same track and the faster one is the rearmost one,

run them in reverse so a gap opens between the locos.

- Set CV5 on the faster one to bring it down in speed to match

the slower one.

- Some decoders, especially Digitrax, behave oddly if BEMF is

enabled. CV5 may not be recognized unless CV6 is set too. In that

case, set CV6 to half of CV5.

- Keep adjusting the faster one to match the slower one at full

throttle

- Then set half throttle and adjust CV6 to match them at half

speed.

- You can either speed up the slower one or slow down the faster

one or both to your satisfaction

- Then set CV3 so that non-QSI equipped loco matches the speed up

characteristic of the QSI equipped loco

- Do the same with CV4 for the slow down characteristic

- At this point, the locos should be matched well enough to run

in a consist.

The QSI can be completely programmed from a full featured DCC

system like a Digitrax Super Chief but it takes the special

programming interface to change the sound file or update firmware.

I don't have the programming interface yet so that there is little

that I can say about it, BUT, there are some things I know.

Progrmming Interface and Software. The QSI software works

in conjunction with a hardware interface. The software can be

downloaded and some of it's functions used without the interface.

The major function is to preview sound files see what you will get

when you order it with a particular sound file. Sound files are

also downloadable free. When a computer is connected via the

programming interface to a decoder, all of the programming of CVs

can be done via the software interface. This makes massive changes

to the CVs much easier.

Macintosh Compatibly. The rub here is that the software

is released ONLY for Windows. This is a problem for me because I

don't have a Windows PC, my household is 100% Macintosh. However,

there are three ways around this issue.

-

Boot Camp is Apple's way of running PC software on an

Intel based Macintosh. Basically, Boot Camp facilitates setting up

a PC partition on the Mac disk. You have to BYO version of XP SP2

or Vista but Boot Camp allows a full up Windows install in a new

partition. Boot Camp creates the new partition (without having to

reformat the disk) and creates an installer CD with all the

necessary drivers to make the Apple hardware work under Windows.

You basically boot your Windows installer disk and do a regular

Windows install, then use the CD to install the drivers. Then you

have a full up PC. When the computer boots, the user gets to select

which OS to boot into. When booted as a Mac, the Windows system is

not accessible. When booted as a PC, Windows takes over and the Mac

partition is not accessible. At this point, you have a PC that

comes with all the liabilities that Windows brings with it. Some

have reported that a Macintosh booted into Windows makes a better

PC that most dedicated PCs. I don't have XP SP2 or Vista so I don't

use Boot Camp.

-

Parallels is a virtualization system that runs in Intel

based Macintoshes. Basically, you launch Parallels under the Mac OS

and it then creates a virtual machine in which to boot Windows or

some other OS. The other OS then runs in a window along side the

other Macintosh windows. Copy/Paste works between OS's. Parallels

will work with Linux, DOS or any version of Windows. I have a copy

of W2K that I use to run the QSI software and it works, at least

the part that allows sound file previews does. The Phoenix

programming interface, which I do have, works fine under Parallels.

There is also a product called VMWare Fusion which does much the

same thing as Parallels and would probably work too. Parallels

costs $80.

-

CrossOver is a entirely different beast. CrossOver is

basically a nice GUI on top of Wine. Wine is an open source project

that emulates Windows APIs (Application Program Interface) on Unix

based systems (which include Linux) such that a PC program can be

executed directly by the Unix system. The Macintosh OS is Unix

underneath a very good GUI. CrossOver intercepts the calls to

Windows services and translates them to Unix calls. Crossover will

not run with all PC applications, only ones that are "clean" and

make all of their calls for system resources through the published

APIs. The QSI software is in this class, and at least as far as the

sound previews go, it works.

I expect that eventually, I'll buy the programming interface

since I now have three of these puppies to support and I am

sufficiently impressed with the QSI decoder to be inclined to buy

more when I need both motor control and sound for a new

installation.

DCC Throttle Programming. DCC decoders are usually

programmed via CVs, or Configuration Variables. A CV is an 8 bit

memory location in the decoder which is non-volatile. Once a CV is

set, it stays that way until it is explicitly changed. The decoder

uses the data stored in the CVs to define many of it's operating

characteristics. Many of them are predefined in the NMRA standard

and the QSI follows the standard.

There is a small range of CVs, 49 through 64, which are defined

to be manufacturer specified. What these do is entirely dependent

on who made the decoder and these are the only ones I'll be dealing

with here.

There are only 16 of these CVs so that this tends to constrain

what custom things a decoder can do without some kind of special

tricks. QSI is REALLY tricky here, they have managed to expand

these 16 locations into hundreds of CVs by the definition of two

modifier CVs. CV49 is called the Primary Index or PI. It acts like

a shift key with up to 256 values. CV50 is the Secondary Index or

SI. It can also take on 256 values. With these two modifiers, the

remaining 14 CVs could be expanded into hundreds of thousands of

CVs but QSI has not applied these shift codes to the whole range.

Some of them are defined using only the PI, some are defined with

both the PI and SI, some are reserved for future use and some are

not modified at all by the PI and SI. Still, there are more CVs

available than you can shake a stick at although getting to some of

them may require setting the values of THREE CVs to enter just one

value.

When a CV is listed in the manual as CVxx.yy.zz this means that

to get to it, CV49 must contain the value yy, CV50 must have the

value of zz (if given) and the actual data to be entered goes into

CVxx. This may seem pretty convoluted, but it is necessary to

create spaces for all the data that is needed to customize the QSI

decoder within the constraints of the NMRA specification.

Fortunately, while in OPS programming mode, the address and

value of the CV that you THINK that you are programming is reported

by voice. By entering the address of another CV into CV64, the

decoder will report only the existing value of the CV with the

current PI and SI that are in effect.

If you try to program a CV with an illegal or unimplemented

value then the voice will report the CV number WITHOUT a value or

not report anything at all. Then you know that the programming

attempt didn't "take" and you need to figure out why it didn't

work. In my experience, this usually comes from trying to stuff a

value into the wrong CV or by using an illegal or unimplemented

value to the correct CV.

QSI's programming interface and software make programming these

special CV's much easier than doing it on a throttle. Also, JMRI is aware of the CV

structure of QSI decoders and also makes CV programming of the

manufacturer specific CV's much easier. JMRI will run on a PC, Mac

or Linux.

I've come across a few issues with the QSI, one I think is a

bug, one was just unexpected and one is a drawing error.

BEMF Issue. When I installed a QSI into the LGB 0-4-0, it

didn't work properly. Going forward, the loco would not stop when

commanded to zero speed. It was just crawling along making a mild

buzzing sound. If I interrupted the motion of the loco with my

finger, it would stop until started again. It didn't do the same

thing in reverse. It was clear that the BEMF system was bumping it

along but it SHOULD have been expecting zero back EMF. Maybe it

cannot detect the very low value of BEMF generated by this motor at

that speed and it THOUGHT that the loco was actually stopped. All

manner of playing with the BEMF parameters didn't help. I "fixed"

it by enabling the STC mode where BEMF is turned off. Then the loco

behaved fine. This loco doesn't need BEMF anyway. Someday there

will probably be a firmware update to deal with this.

Headlight Operation. The manual indicated that the

headlights should follow Rule 17 dimming. In this case, they were

programmed to be on bright when moving in the appropriate direction

and dim when standing or going in the other direction. My lights

were "off" when they should have been dim. I didn't think too much

of it until I changed the headlight on the LGB loco to an LED. THEN

it was dim. The rear headlight was still a bulb and it was off,

even in a very dark room, there was no visible light coming off the

"dimmed" bulb. It occurred to me that the "dim" setting was not

bright enough for the filament of the incandescent bulb to reach

about 900°C where it would be hot enough to radiate in the

visible spectrum. A quick check with an IR thermometer indicated

that the bulb was slightly warm, but just not visible. I bumped the

intensity of the rear headlight from the default of 32 to 64 and

now it runs dim, as described in the manual. This is probably why

the incandescent lights in the Pacific and Shay also appear to be

off when they should be dim. The front LED on the LGB loco was

actually brighter than I wanted in the "dim" mode so I turned it

down to half.

Screw Terminal Labels. The optional screw terminal

adaptor board has eight screw terminals that are identified by a

stencil pattern printed on the board. These appear to be correct.

However, as I read the diagram that comes with the decoder, the

location of the blue wire and the headlight identification is

incorrect. If you follow the documentation, the lights won't work

because they will be connected to ground instead of the +common or

blue wire.

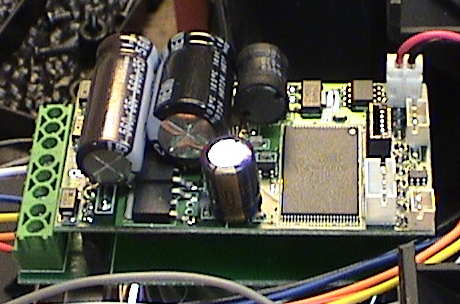

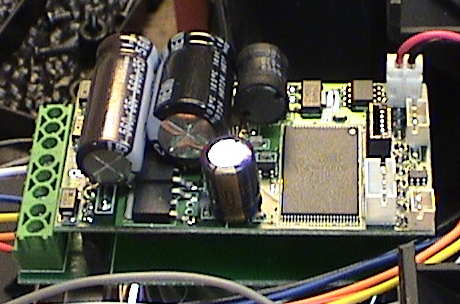

Physical Size. This is physically a large decoder,

primarily in the thickness dimension when the adaptor board is

added. This is due to the length of the pins for the PnP socket and

to the size of some of the components on the board itself. While

the adaptor board can be cut off right next to the 12 pin header

row to make it a little smaller, it is still pretty big. It can be

a challenge to find room for this puppy in some constrained

spaces.

The QSI is a well featured decoder, but it still doesn't allow

some of the customization that other decoders and sound systems

do.

Bell Ring Rate. I'd like to be able to adjust the ring

rate of the bell, there doesn't seem to be a way to do that now.

The bell simulates a fairly fast automatic ringer. I'd like to slow

it down AND to optionally make the ring rate somewhat random as if

a bored fireman was pulling on the bell rope. With the aid of the

programmer, it is possible to upload different bell sounds with

different ring rates. Some sound profiles have multiple bell

sounds. However, if a bell provided isn't what you want and you

don't have a programmer, then you are SOL.

Automatic Start and Stop Signals. The Soundtraxx Sierra

sound system can be configured to make some automatic whistle, bell

and air release sounds when it starts and stops. The Phoenix P5

does similar automatic signals. The QSI has automatic modes for

many of it's sounds, but not these. I'd like the option of setting

it up similarly to the Sierra where it blows two toots when

starting forward, three toots when starting in reverse, plays the

bell up to a preset speed and then blows one toot at stop with an

air release.

Whistle Sounds. If F2 is pressed momentarily, the system

will play a short whistle toot. If F2 is held down longer, it will

play an extended blast for as long as the button is held down. This

works pretty well, but you have to be quick to get the short toot.

The problem is that in some sound sets, the short toot sounds like

it is coming from a different whistle than the longer ones, the 505

set is an example. In the 500 sound set, the short and long toots

at least sound the same except for duration. This should be

fixed.

RDC Sound files. The Budd RDC used a hydraulic torque

converter transmission and a 225 hp diesel engine driving each

truck. They sounded much different than a "regular" diesel

locomotive because they don't "notch" like most diesel electric

engines do. The engine speed ramps up, but not as fast at the RDC

speed changes.

Goose Sound files. There isn't a gas-mechanical sound

file available for the QSI, at least not yet.

This page has been accessed  times since 11 Nov 08.

times since 11 Nov 08.

© 2009 George Schreyer

Created 11 Nov 08

Last Updated October 14, 2009

This page is

dedicated to the details of one particular DCC/Sound decoder, the

QSI Quantum Aristo. QSI

makes some HO sized decoders and just one model of a large scale

decoder, the Quantum Aristo. However it is a really good one that

seems to work just about anywhere. Nominally, it is "Plug-N-Play"

decoder intended to work in the DCC socket of AristoCraft

locomotives. However, it will also work in the sockets of some

Bachmann locomotives as well. It also has an adaptor board that

simulates the socket and converts the decoder to a screw connection

version. When the decoder is plugged into one of these adaptor

boards, it is called a "Quantum Magnum".

This page is

dedicated to the details of one particular DCC/Sound decoder, the

QSI Quantum Aristo. QSI

makes some HO sized decoders and just one model of a large scale

decoder, the Quantum Aristo. However it is a really good one that

seems to work just about anywhere. Nominally, it is "Plug-N-Play"

decoder intended to work in the DCC socket of AristoCraft

locomotives. However, it will also work in the sockets of some

Bachmann locomotives as well. It also has an adaptor board that

simulates the socket and converts the decoder to a screw connection

version. When the decoder is plugged into one of these adaptor

boards, it is called a "Quantum Magnum". 10 Oct 09

10 Oct 09