5 Sep 10

5 Sep 10 29 Nov 10

29 Nov 10 3 Feb 12

3 Feb 12[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

5 Sep 10

5 Sep 10 29 Nov 10

29 Nov 10 3 Feb 12

3 Feb 12While looking for an integrated sound and motor DCC decoder for a Bachmann Davenport, I had rejected most of the decoders that I knew about because they either didn't have enough sound volume or motor current capability to deal with the Bachmann Davenport and still have a gas mechanical sound file. I deemed an RGS Goose sound to be close enough. I have a Sierra Goose already, it worked well but the Sierra is discontinued. The Soundtraxx Tsunami is not yet released with a Goose sound file and it may never be. The other large scale decoders were too big.

What to do?

I discovered another European company, ESU, that makes DCC sound decoders. They make four versions of decoders, a micro version intended for N scale, a "standard" version intended for HO scale, an XL version for large scale and a version intended for use with the Marklin system.

The motor current and sound capability varies between these versions. The XL version will drive a 8Ω speaker with a couple of watts. This is pretty standard in the large scale world but it is expensive (about $175) and too large for the Davenport. The HO version has barely sufficient current capability for the Davenport and comes with a dinky 100Ω speaker. It is rated at a half watt of audio power, marginal for outdoor large scale purposes, but it good enough for indoor usage. It also comes pre-wired for the 8-pin NMRA DCC socket which the Davenport uses. The LokSound V3.5 decoder is available for about $110, reasonable for a sound and DCC decoder. The physical smaller micro version actually costs more than the HO version. It has the same sound capability, at less power due to the lower voltage typically found in N scale and it also has less motor current capability. It has functions outputs only for headlights.

The LokSound V3.5 (HO version) is big enough for a small loco in large scale but you need to verify the maximum continuos motor current to make sure that it won't exceed 1.1 amps.

I am quite impressed with this decoder. It took a little getting used to and some tweaking on the programming to get it to work right, but after adjustment, it functions very well.

The sound and motion coordination of the ESU LokSound decoder is outstanding. It is virtually impossible to break the synchronization between the sound and motion as shown in this video clip of a LokSound V3.5 HO decoder in a Bachmann Railtruck.

The speaker issues gave me pause. My experience with HO sound systems has not been really good. I had to build an audio power amplifier for a Soundtraxx DSX because there simply was nowhere near enough audio power for outdoors. The Digitrax SFX0416 is marginal for indoors. A high impedance speaker used by the LokSound V3.5 decoder indicated to me that the audio power would be low. However, write ups on the internet indicated that it was adequate so I bit.

The audio power capability of a sound system depends primarily on three factors, the supply voltage available, the impedance of the load and the configuration of the audio power amplifier. For a DCC system running at fairly high track voltage, there would be roughly 20 volts DC available to the decoder. Most sound systems use a single ended complementary symmetry audio power amplifier. This means that the MAXIMUM peak to peak audio output voltage would approach the DC supply voltage AND that an output coupling capacitor would be necessary because otherwise there would be 10 volts DC sitting on the speaker at all times. A coupling capacitor will also result in a pop each time the audio power amp powers up or down as the capacitor either charges or discharges through the speaker.

Such a sound system would be able to produce up to 7 VRMS provided that the audio amp could drive enough current into an 8Ω load. This would be about 6 watts, a very healthy power level and MUCH too much for an HO sized decoder.

ESU solved this problem by using a 100Ω speaker. This would normally limit the available power to about 0.5 watts when running on large scale track voltages and much less on HO voltages. Also, the circuit would still require a fairly large blocking capacitor. I think that ESU is using an double ended audio power amp in an H-bridge configuration because this system DOES NOT pop when powered up or down. This puts 10 volts DC on BOTH ends of the speaker so that a blocking capacitor is not required. Further, an H-bridge doubles the available voltage swing because one end of the speaker can be driven up while the other end is driven down. Without losses, the output voltage could approach 14 VRMS and generate almost 2 watts into 100Ω. The system clearly doesn't make 2 watts so it's output swing is limited by something else, but at least it doesn't need a blocking capacitor.

In an HO environment with about 14 volts on the track, the decoder would have 12 VDC to work with. Assuming a double ended audio power amp and a 100Ω speaker with about 0.5 volt lost in each amplifier transistor, this would work out to a maximum output capability of about 600 mW which agrees with the 600 mW spec for the unit.

If you try to put an 8Ω speaker on this audio power amp, the output current would be so high that it would probably damage the amplifier. Don't even try it. The largest 100Ω speaker provided by ESU is the 40 mm one that I used. It's a perfect fit in the Bachmann Davenport but you have to glue it down.

The newer LokSound Select is rated at 2 watts with a 4Ω speaker. It is clear that something else is going on here. I believe that the LokSound Select uses a PWM configuration for the audio power amp. If the PWM frequency is high enough, then PWM can work fine to drive a speaker. Most personal audio players and cell phones use high efficiency PWM amplifiers, but usually with higher impedance loads such as 32Ω. The motor driver on the LokSound select can run as high as 40 kHz, the audio amp could use the same or similar circuit. CD quality digital audio is encoded at 44.1 kHz so a digital audio power amp clearly has the audio quality necessary. Most motor drivers used in DCC decoders and many radio control receivers are double ended as well, I would suspect that the LokSound Select audio amp is double ended. Be controlling the PWM duty factor, the unit could efficiently drive a low impedance load and not burn up. An HO motor typically draws up to an amp at 12 volts, but the system is designed to provide power at up to a 100% duty factor to provide 12 watts or so of motor drive. This is a 12Ω load. By limiting the duty factor to 33%, the same circuit could drive a 4Ω load, limit the available audio power output and not overload. The DC resistance, or stall impedance, of a typical HO motor runs in the range of 3Ω upwards to more than 10Ω. Speakers usually have a DC resistance that is similar to their impedance ratings or 4Ω upward. This is clearly in the range of an HO motor driver circuit's capability too.

This is

the LokSound V3.5 decoder with the included tiny speaker and an

optional larger 40 mm speaker, both of them are 100Ω. The

decoder has a standard 8 pin NMRA DCC socket.

This is

the LokSound V3.5 decoder with the included tiny speaker and an

optional larger 40 mm speaker, both of them are 100Ω. The

decoder has a standard 8 pin NMRA DCC socket.

This is a full featured decoder with silent motor drive, BEMF motor control, two functions in addition to the lights, sound and compatibility with any DCC system. The motor driver is capable of 1.1 amp of continuos current. The decoder also analog converts well on DC or PWC and the sound and headlights operate properly when analog converted as well.

All the function outputs can be programmed for special effects such as random flicker, strobe and such as can be seen in this video. Also, the lights are dimmable in any of those modes. The lights usually come on and go off slowly so that the turn on surge of an incandescent lamp is avoided. The strobes are pretty quick, but an incandescent bulb is not well suited to a strobe anyway, use an LED. The blink rate of the strobes and blinking lights is adjustable.

The sound is very well coordinated with the motion and there are lots of "extra" sounds that play at random times or under special circumstances. For example, if you come to a controlled stop, the brakes will squeak a little. If you come to a hard stop, the brakes will screech. The bell is crisp and clear and the horn can be played easily. The sound quality is quite good, as good as the best of them.

The LokSound manual does not describe the sound produced by most of the function buttons on a DCC throttle, probably because the assignments would likely vary in the various sound files. Here it is for the Goose system. There may be assignments made for blowers and dynamic brakes on other systems. These sounds don't apply to a gas mechanical railtruck, railbus or Galloping Goose.

| Function Key | Function or Sound | Notes |

|---|---|---|

| F0 | Headlight | Several attributes assignable |

| F1 | Bell | Crisp sounding bell |

| F2 | Horn | Playable Horn |

| F3 | Coupler Clank | Includes air line connection and hiss |

| F4 | None | Configured for smoke in the Davenport using the violet wire. |

| F5 | None | |

| F6 | Cab Chatter | Short radio transmission |

| F7 | None | |

| F8 | Mute/Volume | Press it once, the sound system shuts down Press it twice quickly, the volume increases in four steps and then returns to minimum |

| F9 | Rail Clatter | Rail sound on jointed rail |

| F10 | Brake Line Connection/Air Hiss | Same as the last part of F3 |

| F11 | Short Horn | Plays only on activation of F11, nothing happens on deactivation of F11 |

| F12 | None |

F4, F5, F7, and F12 are available for reassignment to function wires. The LokSound V3.5 has only two spare function wires, the green one is already wired to the 8 pin DCC plug, the violet one is unattached. The LokSound XL has 6 free function wires. The LokSound Micro has no extra functions beyond the headlights.

Note that for a function, except the headlights, to work, it FIRST must be assigned to a function button. Then any special attributes that are desired can be assigned to the wire. There are several functions and sounds that do not come assigned to any function keys. The manual describes what these are and how to map them to unused buttons.

The BEMF worked right out of the box. I haven't had to tweak it. With Vstart (CV2) set to zero and at speed step 1, the loco crawls along at about 1 tie per 20 seconds. If the coupler is grabbed to stop the loco's motion, the wheels keep right on turning. The control seems good enough with the default values for BEMF. I tried playing with them and, for this loco, the defaults seem to be about right.

Even though this is an HO decoder it is rated to run at 25 volts on the track. I run 22 volts and the decoder had no difficulty with the high track voltage. It also ran fine at 18 volts.

The manual for the ESU LokSound decoders is provided as a .pdf file on the mini CD supplied in the box. To read this CD on a PC or a Mac, you need a CD drive with a tray such that you can load the undersized CD. DO NOT try to insert this disk into a slot loading optical drive on a recent Macintosh. It will probably jam the drive. You'll have to find a computer with a slide out CD tray.

In late 2009, ESU

announced a new HO sized decoder similar to the LokSound v3.5 but

improved in many ways. It has taken them 9 months or so to ship one

to me, a steam version. It took until April 2012 to get a 645

turbo version.

In late 2009, ESU

announced a new HO sized decoder similar to the LokSound v3.5 but

improved in many ways. It has taken them 9 months or so to ship one

to me, a steam version. It took until April 2012 to get a 645

turbo version.

However, it was worth the wait. It works better than the LokSound v3.5, makes more audio and uses 4 to 16Ω speakers. The steam manual was released months after the decoder, but I got it installed and running even with only a diesel manual to go by.

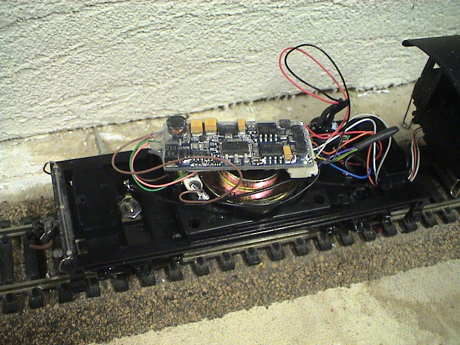

I'll have more to say about this unit later, but it appears to be a very high quality DCC sound decoder for just $80, BYO speaker. It is installed in a Bachmann HO Consolidation. The tender is configured to accept a 28 mm speaker and the PWB in the tender accepts an 8 pin NMRA medium plug. However, the decoder comes as a wired unit so I had to solder my own plug which had been cut off a much older decoder. The decoder itself uses a standard 9 pin JST socket on the decoder body so that it can plug right into locos that already have a 9 pin JST harness. The external capacitor is hard wired to the decoder and does not wire through the connector. In that case, installation mostly involves mounting a speaker and soldering two brown wires to the speaker. ESU sells an optional harness to interface to the NMRA 8 pin medium plug, but any similar harness from Digitrax or TCS will work too. The wires on the ESU harness are pretty small, this may be good in some installations, not so good in others.

Programming appears to be an issue as ESU has used some CV values higher than 255 which cannot be accommodated directly on older Digitrax throttles. However, JMRI 2.10 has some LokSound Select decoder definitions and those CV's are represented. The CV's past 255 are "indexed" by the value in CV32. If CV32=0, 1, 2 or 3, the "indexed" CV's can be accessed but the manual is not at all clear how this is done. Better to use JMRI 2.10 and use the graphical user interface. JMRI will then handle the details.

Programming the indexed CV's on the LokSound Select can be an issue for Digitrax users. The command station can indeed generate a 10 bit CV address (256-1023) but the DT400 throttle cannot. The newer DT402 version can program the extended CV range that this decoder uses, but I don't have one yet (upgrade hasn't come back in the mail). DecoderPro CAN drive the command station to generate 10 bit addresses so that the indexing works and the indexed CV's can be accessed. I am working with a decoder (still haven't received the 645 turbo version I ordered in January 2010) that has a steam sound file. This is the 73414 version for 8-coupled locos. The indexed CV's that control the relative levels of the various sounds can be programmed directly from a DT402. But the steam system and the diesel system use different CV's for some sounds. The Decoder Pro diesel definition file does not allow access to the steam only CVs so even with DP, I cannot get to them all without a DT402.

The LokSound Select comes with up to 4 prime mover sounds, up to 16 horns or whistles, two bell types and two brake squeal types. The bell rate can be further tweaked from the two rates provided in the sound file. Any of these can be combined by programming CV48. Note that there is an error in the diesel manual where the 4th prime mover is at a value of 48, NOT the value of 64 indicated in the manual. All this programmability makes tweaking the sound set pretty easy PROVIDED that you buy it first with something close to what you want. To actually change the sound set requires a LokProgrammer and the sound downloading software. Most folks will not need to do that, but it is possible to completely change the sound file. This allows a retailer to stock only one piece of hardware and program it before shipment to the version that the customer wants. The customer can then do a final tweak to pick the sounds that he likes by programming CV48 on the main or on a programming track. NOTE that for a change to CV48 to actually be accepted, the power to the decoder has to be cycled so that it starts up from scratch.

However, if a user doesn't like a particular part of the sound file and wants to change that part to something that isn't already there, he is out of luck. The LokProgrammer cannot currently mix and match sounds from other sources, even other Select sound files. The user can change the WHOLE sound set but NOT pieces of the set. This is a software issue and could possibly be changed in the future, but for now, the advanced user is hamstrung.

I now have six of these puppies, two heavy steam systems (in two slightly different Bachmann Consolations), three "diverse" steam versions (one in a Mogul, one in a Pacific and one in a Hudson) and a 645 turbo version.

This is the tender of the Mogul with a rectangular speaker mounted on the floor with the decoder above. This was an entirely wired installation, but since this loco had a DH163 in it before, it was mostly a plug in job. I had to solder two wires to the speaker terminals.

I have recorded the prime mover, whistle and bell sounds that the two steam versions make into a short QuickTime movie. The EMD 645 Turbo sound set has the same horns and bells as any of the diesel sets, but the 3 prime mover sounds are custom to this set.

I've done several ESU LokSound installations. I was sufficiently pleased by the first one that I put another one, also a Goose sound system, in another loco. I then tried the newer, and less expensive, LokSound Select. There is a large scale version, the LokSound XL, but it is pretty expensive. However if it works as well as the HO versions, it might be worth it.

| Locomotive | LokSound Version | Link | Notes |

|---|---|---|---|

| Bachmann Davenport | LokSound V3.5 | DCC Installation in the Bachmann Davenport | This sound and motor controller works well. Although the sound level is still a little weak but large scale standards it is marginally loud enough for use outdoors. |

| Bachmann Railtruck | LokSound V3.5 | DCC Installation in the Bachmann Railtruck | This installation went well too. It worked the same in the Railtruck as it had in the Davenport. |

| Bachmann HO Light 2-8-0 | LokSound Select | The GIRR HO Page | Installed in the tender using the supplied 8 pin NMRA interface. |

| Bachmann HO Heavy 2-8-0 | LokSound Select | The GIRR HO Page | Installed in the tender to a hand wired 9 pin JST socket. |

| Mehano 2-6-0 | LokSound Select | The GIRR HO Page | Installed in the tender to a hand wired 9 pin JST socket. |

| Aristo PCC | LokSound Select | The GIRR HO Page | Installed and then removed from a large scale PCC. The PCC sound file just sounded bad. The decoder was replaced and installed in an HO Mehano 4-6-2. |

| Mehano 4-6-2 | LokSound Select | The AristoCraft PCC | Installed in the tender to a hand wired 9 pin JST socket. |

| Riverossi 4-6-4 | LokSound Select | The GIRR HO Page | Installed in the tender to a hand wired 9 pin JST socket. |

| Bachmann SD45 | LokSound Select 73408 | The GIRR HO Page | Replaced a Bachmann motor decoder. The speaker is mounted under the rear fans but enclosed in a styrene box and mounted to the frame weight. |

I hadn't had this decoder in the Davenport for very long, but it seemed to run quite well. One beef that I have is the relative lack of sound volume but I sort of expected this when I bought the decoder. An example of the sound is in this short h.264 video clip. Another beef is the tendency to stall and restart on insulated frogs. This is partly due to the Davenport's limited power pickup capability, but the decoder's response to power drops was unpleasant until I found the secret setting.

Since the overall volume is a little weak, it takes some tweaking on the various sound volumes to get the optimal results without a lot of distortion. CV63 sets the overall sound volume and CV121 sets the horn volume. Since the horn tends to be louder and distort more, it is important to turn CV121 down to mute the horn a little and then turn CV63 up as high as possible to get a reasonable level of engine sound. With the proper balance, there is JUST enough volume for outdoor use provided that the speaker is dealt with properly. The included speaker would not cut it, count in buying a bigger one and make sure that it is mounted properly.

The decoder analog converts well and is also fairly tolerant of dirty track, the sound doesn't reset often but when it does it gets really annoying. I had a problem with the Davenport with power pickup after running for awhile and the decoder essentially stopped working. It would start up, move a little, stall and then go through it's startup sequence again and then stall again. This was caused by a solvable power pickup problem that degraded over time on the Davenport.

However, there was still a problem on turnout frogs. The Davenport is a 4 wheel rigid frame loco so that on EVERY insulated frog, one wheel will lose power. It then depends on the other wheel on that side to pick up power. If the turnout is dirty or the rails are not completely level, the loco MAY lose power for a short time while passing over the frog when the other wheel lifts from the track or hits a dirty spot. On DC, the Davenport can loose power for a bit but there seems to be enough rotating inertia in the drive train to allow it to glide over an insulated frog without a hiccup. The ESU decoder actually degraded this capability as it shuts down completely when a power interruption gets too long. If it then finds power on the track, the decoder goes through a start up sequence for a few seconds and then trundles off. This sequence can be seen in this h.264 video clip of a stall on an LGB 1600 turnout. The decoder also causes stalls on LGB 1200 and Aristo tight radius turnouts. The impact of an Aristo turnout can be seen here. The stalls occur on this rigid frame 4 wheel loco if the rails leading to the frog are not completely level with the frog. Track leveling issues are obvious if the loco rocks at the point where it stalls. This can be seen in the videos too.

There was no obvious way to reprogram the decoder to change this behavior but while playing with the start voltage, acceleration and deceleration CVs (CV2, CV3 and CV4) I found that there was an unexpected impact. When the value of CV2=0 (default=3), then the loco avoids the complete shutdown and restart if the speed is non-zero AND the acceleration (CV3 default=8) is 3 or less. CV4 doesn't seem to matter. If CV3=4, then the restart is avoided most of the time but it will still do it on occasion. Then when power is found again, even after a long delay, the loco picks up where it left off without going through the restart sequence. If the speed is set to zero, the loco assumes that it is being initially turned on and it goes through it's start up sequence. If CV3 and CV4 are set to zero, then the loco won't play the brake screech sound on stopping or reversing.

If the power dropout is long enough, the sound may be interrupted, but at least it doesn't pop when it powers down or up. This modified behavior can be seen in this video. With CV2 set to zero and CV3<4, the sound isn't as quite as nicely coordinated with the movement, but at least it can get by an insulated frog and some other problem without a 5 second delay. Note that the Davenport doesn't stall on EVERY frog, most of them are fine. There are some particular turnouts, most likely where the rails are not completely level, that induce this behavior.

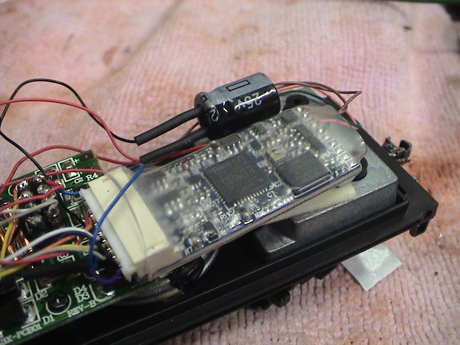

The

LokSound V3.5 is one of the few modern DCC decoders without the

internal ground of the decoder brought out to the outside. The

second one that I got had clear shrinkwrap instead of black so that

the parts can be seen. It is likely that the large tan part in the

lower right is a tantalum storage capacitor. It may be either on

the rectified bus or on a lower voltage internal bus. It might be

possible to trace out the wiring and determine where the + and -

terminals of the bridge rectifier are. The blue wire is probably

already connected to the + side. If the - side were brought out,

external storage could be added, with an appropriate inrush current

limiting resistor and a diode to beef up the decoder's capability

to handle power outages.

The

LokSound V3.5 is one of the few modern DCC decoders without the

internal ground of the decoder brought out to the outside. The

second one that I got had clear shrinkwrap instead of black so that

the parts can be seen. It is likely that the large tan part in the

lower right is a tantalum storage capacitor. It may be either on

the rectified bus or on a lower voltage internal bus. It might be

possible to trace out the wiring and determine where the + and -

terminals of the bridge rectifier are. The blue wire is probably

already connected to the + side. If the - side were brought out,

external storage could be added, with an appropriate inrush current

limiting resistor and a diode to beef up the decoder's capability

to handle power outages.

It appears that the rectifiers and the motor switches are on this side of the board.

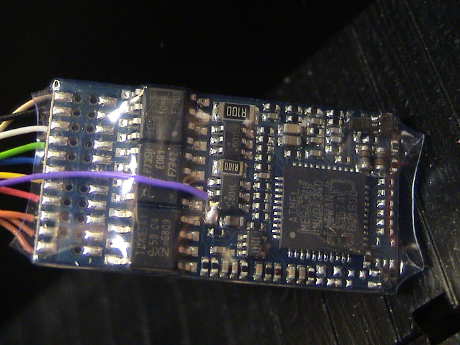

The

backside of the decoder is loaded with what appears to be the

processor, the function switches and maybe the audio power amp.

The

backside of the decoder is loaded with what appears to be the

processor, the function switches and maybe the audio power amp.

Even under the light loads of the Davenport and the Railtruck, the LokSound decoders run pretty warm. The one in the Davenport actually failed once and was replaced under warranty. The one in the Railtruck is even more lightly loaded and it runs quite warm just pushing the Railtruck around. Neither loco gets close to the 1.1 amp rating for this decoder. I am a little concerned that the decoder may have an "optimistic" motor current rating.

It turns out that the problem with this decoder is that it doesn't like high track voltage. It behaves much better at 18 volts than it does at 22 volts. At 22 volts, even with just the sound running at idle, the decoder gets hot enough to shut down when subjected to just a little warm air. I installed a 5.1 ohm 5 watt resistor in series with the track leads to drop the voltage to the decoder under load. I lose top speed at high loads, but this loco isn't supposed to go fast anyway. This should keep this one from burning up. See my Davenport Tips page for more details.

Overall, it appears that the decoder is the right size to handle the Railtruck but undersized for the Davenport.

I had an open house yesterday and I ran the Davenport pushing the video car for maybe an hour. It started to show the signs of thermal trouble again, but not as badly as in the past. The sound would shut down at the slightest power interruption and restart again when the decoder was "rebooted" by doing a track power cycle. I removed the 5.1Ω sandstone resistor and substituted a 10Ω resistor. It still ran fine light.

This morning, I ran it under the same load for well more than an hour and it didn't seem to be having any problems. It still pushed the car at acceptable speeds.

The issue is that the decoder will run at up to 27 volts and it will drive a motor at 1.1 amps, but just not at the same time. It would appear that it will handle a 700 mA load at 15 volts. The sound part seems to have issues first. With the heat produced by the motor driver added to the heat produced by a voltage regulator driving the sound system, the sound regulator appears to shut down when the input voltage is too high and the decoder is hot anyway.

A LokSound Select would be a better choice in this application than the LokSound v3.5. It's sound system uses a Class D amp and is not subject to regulator overheating.

[ Home ] [ Up ] [ Previous Page ] [ Next Page ]

This page has been accessed times since 14 Jan 09.

© 2008-2012 George Schreyer

Created 14 Jan 09

Last Updated April 3, 2012