Thomas and James Tips

[ Home ] [ Up ] [ Previous

Page ] [ Next Page ]

A few years ago, Lionel released a Thomas the

Tank Engine set. Thomas is a British inside cylinder 0-6-0 tank

engine that pulls two coaches, Annie and Clarabel. This set was

based on the Shining Time Station TV series that is probably still

playing on PBS. I would imagine that many large scalers with small

children somehow managed to acquire this set.

A few years ago, Lionel released a Thomas the

Tank Engine set. Thomas is a British inside cylinder 0-6-0 tank

engine that pulls two coaches, Annie and Clarabel. This set was

based on the Shining Time Station TV series that is probably still

playing on PBS. I would imagine that many large scalers with small

children somehow managed to acquire this set.

Later, another set containing James the Red Engine

was released. James is an inside cylinder 2-6-0 tender engine of

British design that pulls two 4 axle freight wagons.

Later, another set containing James the Red Engine

was released. James is an inside cylinder 2-6-0 tender engine of

British design that pulls two 4 axle freight wagons.

Neither of these sets is still manufactured but some may still

be around. At the end of James' production run when Lionel exited

the large scale business, these sets were blown out by a discount

store chain, Pic-N-Save, for $49.95 each.

Contents

Power Pickup

Both Thomas and James have six driven wheels, but only four pick

up power. Considering that the brass wheels get dirty fairly fast,

this combination is sure to cause flaky power pickup. If the engine

runs fine in the turns and sputters on the straights, suspect dirty

wheels more than dirty track.

There is a simple modification that can be done to both engines

that materially improves power pickup. The change is to add

contacts to the center driver set.

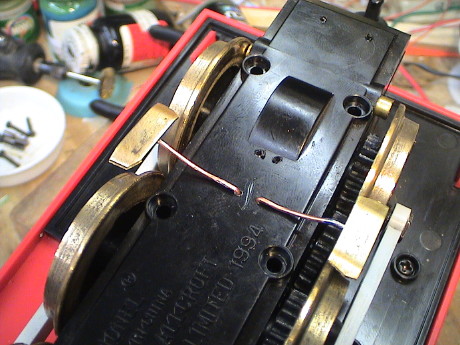

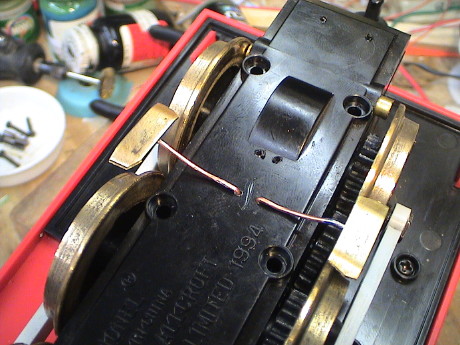

There is no room to add a conventional

power pickup to the center drivers, but it is easy to add a wiper

contact that bears on the center driver tread. On James, it is

straightforward to add a 1/32" thick by 3/32" wide brass contact

strip. The strip is simply clamped between the frame and shell

castings as shown in the photo. A wire is then soldered to the

brass strip and run through a hole drilled in the lower shell and

connected directly to the motor.

There is no room to add a conventional

power pickup to the center drivers, but it is easy to add a wiper

contact that bears on the center driver tread. On James, it is

straightforward to add a 1/32" thick by 3/32" wide brass contact

strip. The strip is simply clamped between the frame and shell

castings as shown in the photo. A wire is then soldered to the

brass strip and run through a hole drilled in the lower shell and

connected directly to the motor.

I attached the same

type of contact to Thomas' frame with plumber's epoxy putty. This

particular epoxy is handy because it sets up really fast so that

you don't have to hold it in place for more than about five

minutes. The epoxy also will not stick to your fingers. I modified

Thomas several years ago. After I took this photo recently, I

realized that I probably could have clamped the contact on Thomas

the same way that I did James.

I attached the same

type of contact to Thomas' frame with plumber's epoxy putty. This

particular epoxy is handy because it sets up really fast so that

you don't have to hold it in place for more than about five

minutes. The epoxy also will not stick to your fingers. I modified

Thomas several years ago. After I took this photo recently, I

realized that I probably could have clamped the contact on Thomas

the same way that I did James.

Even with the center

drivers contributing to power pickup, James was still touchy. I

took a hint from my own Lionel Handcar Tips page

and added a set of sliders. After I got the handcar weighted

sufficiently to deal with the drag of the sliders, they really

improved it's performance such that it would actually run.

Even with the center

drivers contributing to power pickup, James was still touchy. I

took a hint from my own Lionel Handcar Tips page

and added a set of sliders. After I got the handcar weighted

sufficiently to deal with the drag of the sliders, they really

improved it's performance such that it would actually run.

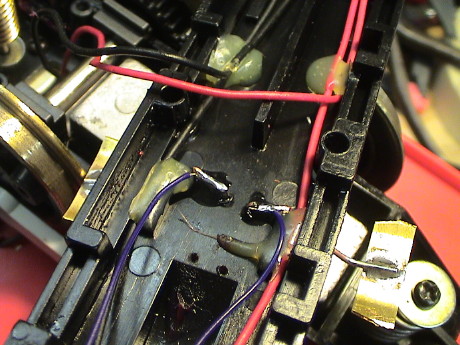

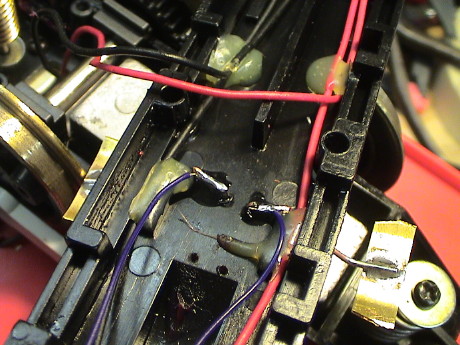

The sliders are simply brass strips soldered to 18 ga copper

wire and secured to the bottom cover of the loco. The copper wire

makes and adequate spring and is easily adjustable.

On the inside, the

wire is just bent over and secured with some Zap-A-Gap CA. A wire,

soldered before the application of the CA, leads back to a brass

strip that connects the rear piston contacts.

On the inside, the

wire is just bent over and secured with some Zap-A-Gap CA. A wire,

soldered before the application of the CA, leads back to a brass

strip that connects the rear piston contacts.

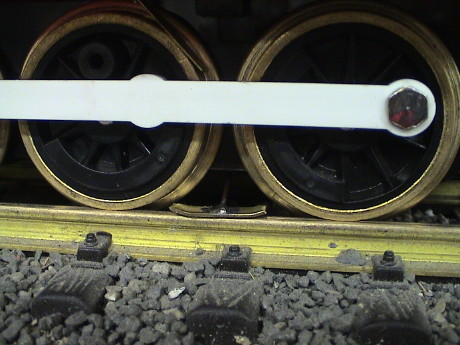

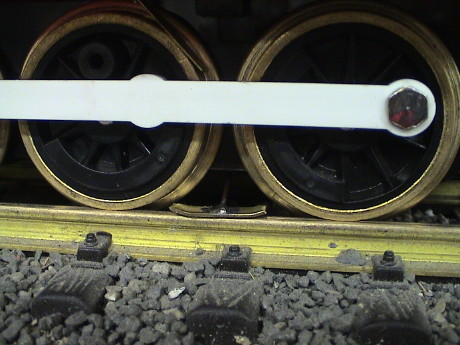

The sliders fit right

between the center and rear drivers and are not too visually

obtrusive. The improvement in power pickup was quite pronounced.

James used to have a tendency to fail to pick up power after it was

stopped and to stutter on turnouts. These tendencies seem to have

gone away.

The sliders fit right

between the center and rear drivers and are not too visually

obtrusive. The improvement in power pickup was quite pronounced.

James used to have a tendency to fail to pick up power after it was

stopped and to stutter on turnouts. These tendencies seem to have

gone away.

[ Top ]

Disassembly

Both Thomas and James are fairly easy to get apart for

lubrication or modification. There are only a couple of

cautions.

The brick covers come off with six screws. The only caution is

to be careful of the spring loaded power pickup contacts. If you

just lift the lower brick cover, they will pop out and are easy to

loose. As you are lifting the cover, place your fingers near each

contact and as the contact moves beyond the wheel face, hold it

with your finger. You can then gently relieve the pressure on the

contacts. Some of them may fall out, but at least the springs won't

eject them across the room. Inspect the springs, they should be

silver colored. If they are brown, they have been overheated and

have lost their strength. Those springs won't work very well and

should be replaced.

Thomas's body shell comes off with seven screws. There are three

on each side and one in front. Note that the front one is shorter

than the others. If you put one of the longer screws back in that

spot, you will break off the mounting post when the screw bottoms

out. The shell may take a little persuasion to release at the

smokebox joint. Just gently lift and wiggle the shell and it will

pop off.

James comes apart in much the same fashion except that the screw

in front is obscured by the pilot truck which must be removed to

gain access to the screw.

[ Top ]

Lubrication

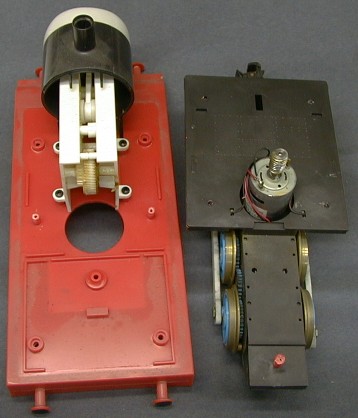

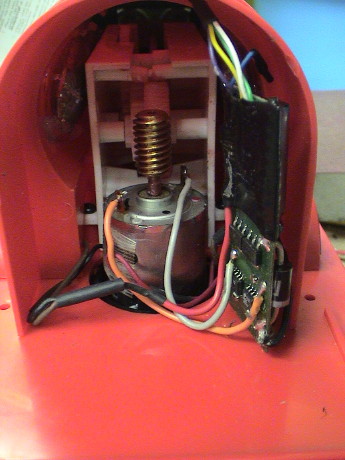

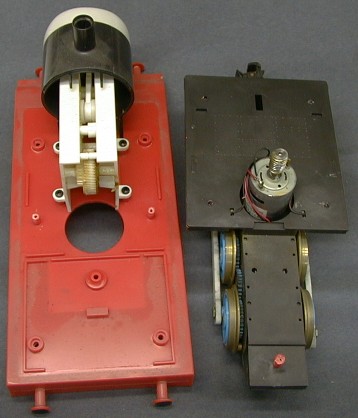

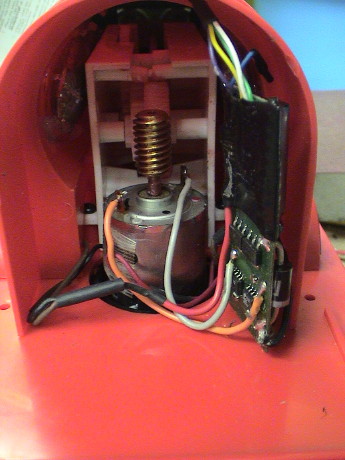

Both Thomas and James use a small vertically mounted can motor

that drives the rear axle through a worm gear. Power is transmitted

to the other two axles by an external spur gear train similar to

that used on many Lionel "O" scale locos. Lubrication of the worm

should be done with heavy gear grease or oil. Lubrication of the

spur gear train is a little more problematic because lubricants

applied there will attract dirt and excessive lubrication will get

on the backs of the wheels and interfere with the power contacts. I

use a very small amount of LGB 50019 oil on the external gearing as

this oil is effective and doesn't seem to foul the electrical

contacts.

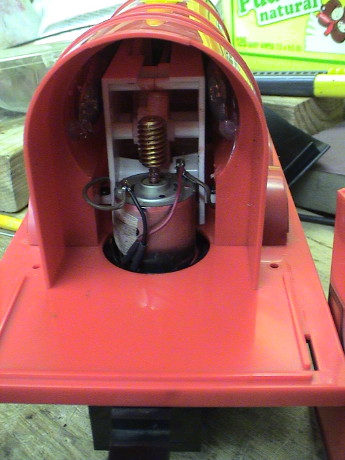

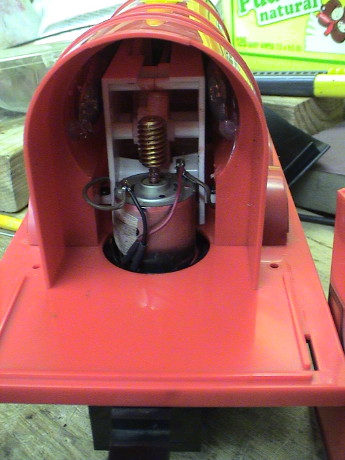

The mechanism that runs the moving eyes on the smoke box cover

can be lubricated, if necessary, with gear grease.

After many years, the grease that Lionel used can dry out and

become hard. If some grease hardens in a gear, it can literally

plug the gear teeth and result in a repeating bind in the

mechanism. This can happen on any gear in the loco. If this

happens, the solution is to pick out the hardened grease from all

the teeth with a small pick or screwdriver and relubricate the

loco.

[ Top ]

Couplers

James resides at the Geologically

Improbable Railroad, Mountain Division and so he needed LGB

knuckle couplers. It turned out to be straightforward to mount them

in place of the supplied hook and loop couplers.

Thomas runs on my outdoor version of the Geologically Improbable Railroad so he

needed Kadee couplers. #831's mount with little difficulty.

[ Top ]

Adding Weight

Both engines are very light. They will pull their assigned two

car consist on level track fine, but add a car or hit a moderate

grade and both will spin their drivers. I added 12 to 16 oz of lead

to the inside of both engines centered above the drivers.

James has a three axle tender that is very light and would

derail under almost any kind of a load beyond his two cars. I glued

4 oz of lead under the tender floor and the tender started to

behave itself.

Neither of these sets have metal wheels yet. I'm not sure why I

haven't changed them.

[ Top ]

Sound Installation in James

Neither Thomas or James come equipped with a sound system, and

considering how little these engines are worth, it doesn't seem

reasonable to spend the money to add one. However, after I added a

Sierra to one of my Shays, its old Bachmann sound board became

available. Since it could run off a battery for a long time, it

seemed reasonable to install in James which still had plastic

wheels.

There is little room

in Thomas for a sound board and speaker, but James has a large

nearly empty tender that is easily big enough. The tender shell is

attached with two screws, one under the rear coupler and the other

also secures the drawbar.

There is little room

in Thomas for a sound board and speaker, but James has a large

nearly empty tender that is easily big enough. The tender shell is

attached with two screws, one under the rear coupler and the other

also secures the drawbar.

A 3"

speaker fits easily on the flat floor. A bunch of holes drilled

through the floor lets the sound out. The Bachmann sound board was

recovered from a defunct R/C Big Hauler. To make the board fit

better in the Shay, it had been literally hacked in half. All the

sound circuitry is on the rear third of the board so all that is

necessary is to cut a trace leading down each side of the board

past the sound circuitry and then to physically cut the rest of the

board off. I left some of the motor control circuit behind just

because it was easier to cut right through the motor controller IC.

The rest of the board is mounted to the back of the speaker magnet

with foam mounting tape. The battery is stuck to the side of the

speaker with foam mounting tape.

A 3"

speaker fits easily on the flat floor. A bunch of holes drilled

through the floor lets the sound out. The Bachmann sound board was

recovered from a defunct R/C Big Hauler. To make the board fit

better in the Shay, it had been literally hacked in half. All the

sound circuitry is on the rear third of the board so all that is

necessary is to cut a trace leading down each side of the board

past the sound circuitry and then to physically cut the rest of the

board off. I left some of the motor control circuit behind just

because it was easier to cut right through the motor controller IC.

The rest of the board is mounted to the back of the speaker magnet

with foam mounting tape. The battery is stuck to the side of the

speaker with foam mounting tape.

The sound

switch is a reed switch left over from a PH Hobbies sound board

installation sometime in the dark distant past. The switch is stuck

to an existing bracket in front of the rear axle. Two small high

energy magnets are attached to the rear axle with Zap CA.

The sound

switch is a reed switch left over from a PH Hobbies sound board

installation sometime in the dark distant past. The switch is stuck

to an existing bracket in front of the rear axle. Two small high

energy magnets are attached to the rear axle with Zap CA.

This cheap and dirty installation didn't cost me a dime out of

pocket as all the parts were already available as left overs from

previous sound system installations. The sound is typically not

great, but then considering the cost, it is acceptable.

[ Top ]

Battery and Radio Control Installation in

Thomas

Thomas is a favorite now of the nephews, but it often tended to

disappoint them because it just didn't run all that well. Even with

the power pickup improvements described above, Thomas was never an

outstanding performer on track power. There just aren't enough

pickup wheels and the brass wheels tend to get dirty quickly. Just

as I have done on several other locos, if they are too small to

pick up power well, they get converted to battery power with radio

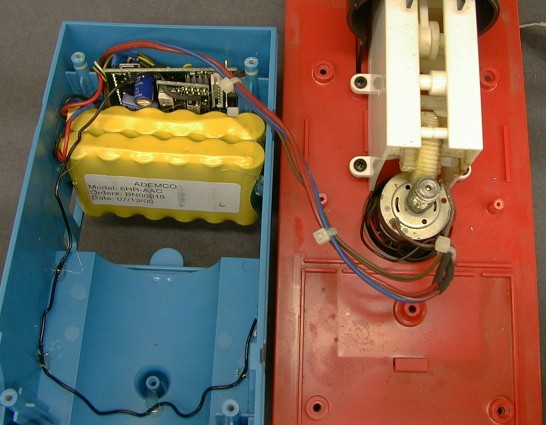

control. Thomas got converted to battery-r/c using the tri-modal

wiring that I have described elsewhere. I choose to

use a 75 MHz CRE-55491 receiver (because I had one handy) and a 12

cell NiCad pack (because I got it for $12 at a local ham radio swap

meet). All the rest of the parts were retrieved from my parts

stock.

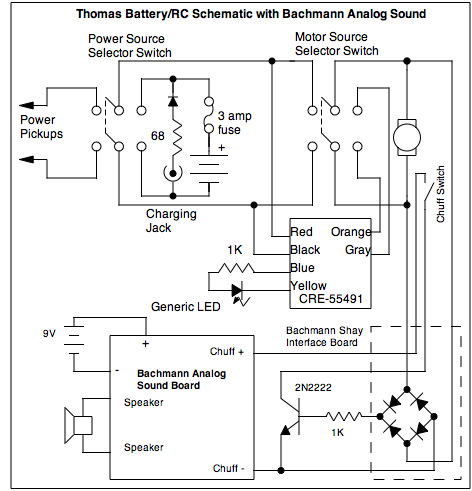

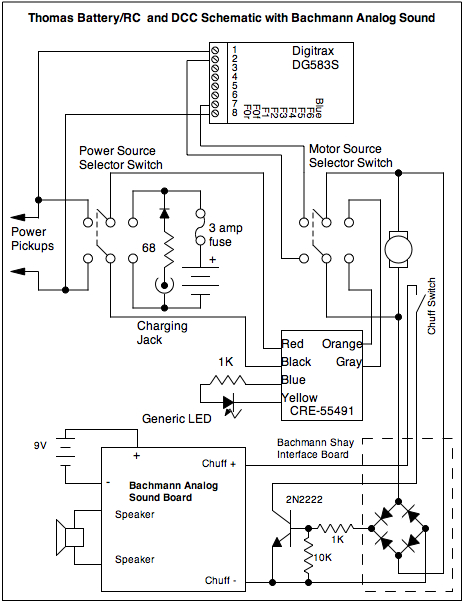

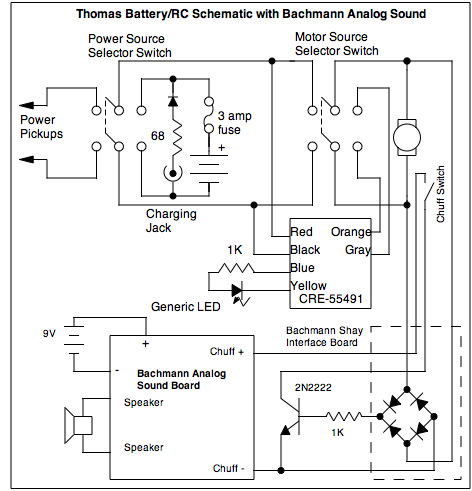

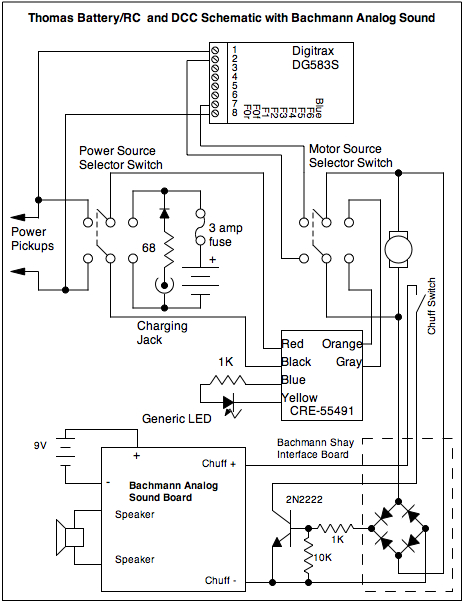

This is the schematic

of I used to wire Thomas. It is my standard "tri-modal" circuit. It

takes just a little more wiring than the dead simple versions, but

depending on how the switches are set, it will still run from

straight track power, or RC with track power, or RC with the

internal battery. The charge jack is arranged to charge properly

from a 24 VDC source.

This is the schematic

of I used to wire Thomas. It is my standard "tri-modal" circuit. It

takes just a little more wiring than the dead simple versions, but

depending on how the switches are set, it will still run from

straight track power, or RC with track power, or RC with the

internal battery. The charge jack is arranged to charge properly

from a 24 VDC source.

Thomas consists of three major parts, the motor brick and

sub-frame, the frame and the shell (not shown in this view). The

first order of business in any RC installation is to determine

where to put all the stuff. This takes some thought. I like to

either put everything on the frame or everything in the shell to

minimize the number of wires going between the frame and the shell.

It was pretty clear that in this installation, most of the stuff

would go into the shell. Thomas's eyeball activation mechanism

takes up the entire boiler volume so everything would have to go

into the saddle tanks or the cab.

The saddle tanks

were too small to hold the battery packs that I had, but they would

fit nicely crosswise in the cab with the cab interior view block

removed. The region inside the tender could hold the receiver. The

switches and charge jack were a problem.

The saddle tanks

were too small to hold the battery packs that I had, but they would

fit nicely crosswise in the cab with the cab interior view block

removed. The region inside the tender could hold the receiver. The

switches and charge jack were a problem.

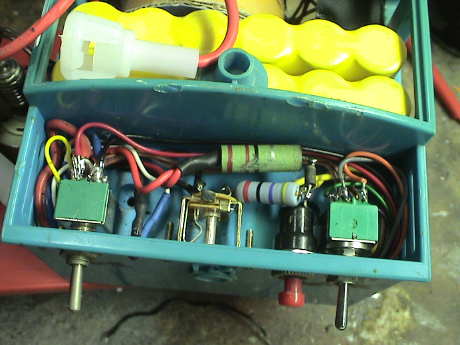

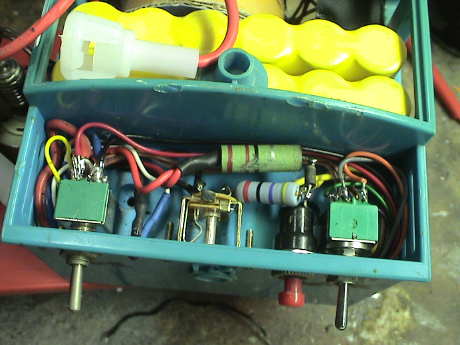

Thomas's coal load

is easily removed and the region under it was just right to hold

the five items that had to fit there, two power control switches,

the code set button, the charge jack and an indicator LED to make

programming the receiver from outside the loco practical. The LED

is wired as the rear headlight. Thomas doesn't have a front

headlight and I choose not to install one.

Thomas's coal load

is easily removed and the region under it was just right to hold

the five items that had to fit there, two power control switches,

the code set button, the charge jack and an indicator LED to make

programming the receiver from outside the loco practical. The LED

is wired as the rear headlight. Thomas doesn't have a front

headlight and I choose not to install one.

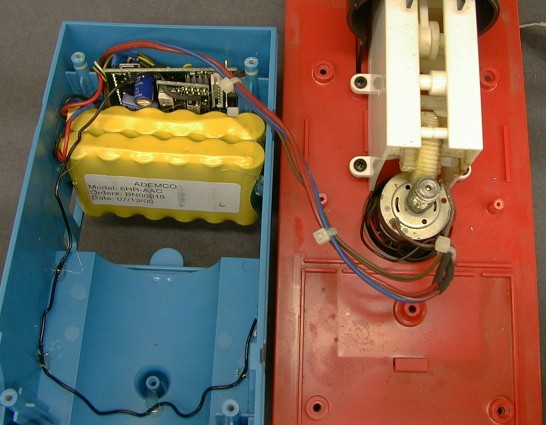

With the batteries installed as shown, Thomas' weight

distribution is wrong. With power abruptly applied, Thomas would do

wheelies. I added 4 oz of lead under the front wheel skirts and

inside the front of the saddle tanks to help balance the weight of

the batteries.

All this hardware hanging off

the back of Thomas isn't particularly attractive, but they were

easy to install and access in that location. The back side of the

coal load and its mounting posts must be gouged off but this can't

seen from the outside and the posts weren't used anyway.

All this hardware hanging off

the back of Thomas isn't particularly attractive, but they were

easy to install and access in that location. The back side of the

coal load and its mounting posts must be gouged off but this can't

seen from the outside and the posts weren't used anyway.

The receiver is simply mashed back in the

tender. I didn't use the adaptor board because there wasn't room.

The shrink tubing over the wires soldered to the pins is sufficient

to hold the receiver in place against the battery.

The receiver is simply mashed back in the

tender. I didn't use the adaptor board because there wasn't room.

The shrink tubing over the wires soldered to the pins is sufficient

to hold the receiver in place against the battery.

Now Thomas runs quite smoothly and it doesn't care what

condition the track or wheels are in. The next time that the

nephews visit, they'll have Thomas to run until the battery goes

down. Then if they want to run it some more, they can switch it to

track power and keep going provided some hesitation doesn't bother

them.

[ Top ]

DCC Installation in James

James resides at the GIRR Mountain Division which has recently

been converted to DCC. James was the last loco to be converted. I

didn't want to spend a lot of money on a decoder so I attempted to

use an HO sized decoder, a Digitrax DH123D which costs only $16. I

knew that James's stall current was a little high for this decoder

but it's running current is well within the DH123's capability. I

have used the DH123 successfully in a 2nd generation Big Hauler and

a Lionel Handcar.

There is enough

room inside James for a small decoder. The cab comes off with just

two screws revealing all that is necessary to install a decoder,

especially considering that there are no accessory functions

used.

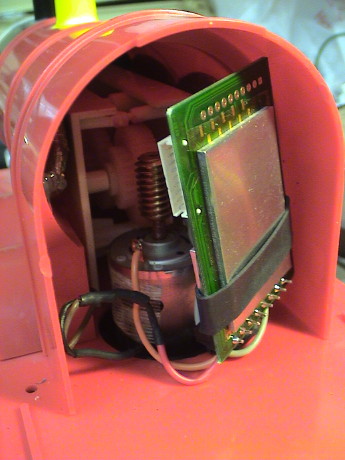

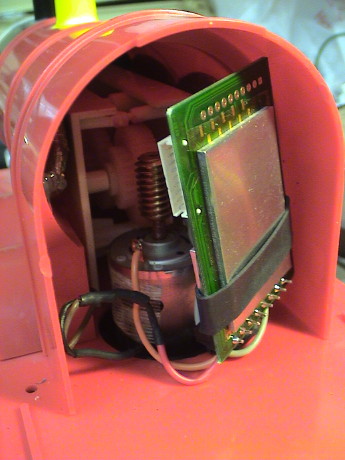

There is enough

room inside James for a small decoder. The cab comes off with just

two screws revealing all that is necessary to install a decoder,

especially considering that there are no accessory functions

used.

The DH123D went in

fine and seemed to run ok for awhile. But after just one lap

around, James stopped inside a tunnel. When I got to it, it was

smoking. James was indeed a little too much for this decoder. It is

clearly burned up.

The DH123D went in

fine and seemed to run ok for awhile. But after just one lap

around, James stopped inside a tunnel. When I got to it, it was

smoking. James was indeed a little too much for this decoder. It is

clearly burned up.

I recovered an

MRC AD320 decoder from an Aristo Classic Railbus which got a

Digitrax DG583S to replace the AD320. The AD320 has just 4

functions and I needed one more so I used the, now surplus, AD320

in James. It just fit next to the motor. As expected, the AD320

makes quite a bit of noise as heard in this H.264 video clip. However it does run.

I recovered an

MRC AD320 decoder from an Aristo Classic Railbus which got a

Digitrax DG583S to replace the AD320. The AD320 has just 4

functions and I needed one more so I used the, now surplus, AD320

in James. It just fit next to the motor. As expected, the AD320

makes quite a bit of noise as heard in this H.264 video clip. However it does run.

Eventually, the AD320

burnt up in James. The heat load was apparently too high as the

circuit board literally came apart. I put analog voltage on the

track for awhile to do some testing on another loco and James was

sitting on powered track. It didn't move, but apparently the AD320

couldn't handle it and it burnt. I smelled the burnt smell but I

didn't know where it came from. It was months later that I tried to

run James again and it just didn't work. I took the decoder out and

it was visually obvious that it was toast.

Eventually, the AD320

burnt up in James. The heat load was apparently too high as the

circuit board literally came apart. I put analog voltage on the

track for awhile to do some testing on another loco and James was

sitting on powered track. It didn't move, but apparently the AD320

couldn't handle it and it burnt. I smelled the burnt smell but I

didn't know where it came from. It was months later that I tried to

run James again and it just didn't work. I took the decoder out and

it was visually obvious that it was toast.

I had a spare Digitrax DG583S so I put it in. It was a simple 4

wire screw terminal installation using the wires that I cut off the

failed AD320. This decoder worked fine and now James runs better

than it ever did.

[ Top ]

Sound Installation in Thomas

A Bachmann Shay at the GIRR Mountain Division surrendered it's

analog sound board when a QSI DCC decoder was installed. The QSI

provides excellent sound and the analog board was no longer needed.

The Shay also surrendered it's "interface board" which has nothing

on it except a bridge rectifier. These parts went in the sound

parts box until I elected to install it in Thomas. This particular

analog sound board had started life in an RC Big Hauler that I

bought from a neighbor kid for parts.

This

is the diagram that I used to do the install in Thomas. The

previous "tri-modal" battery/track/RC wiring was not changed. The

Bachmann analog sound board runs from a 9V battery that will last

for years. The board had also been modified with a circuit to stop

the continuous chuff when it was in the Shay and that circuit was

retained as well.

This

is the diagram that I used to do the install in Thomas. The

previous "tri-modal" battery/track/RC wiring was not changed. The

Bachmann analog sound board runs from a 9V battery that will last

for years. The board had also been modified with a circuit to stop

the continuous chuff when it was in the Shay and that circuit was

retained as well.

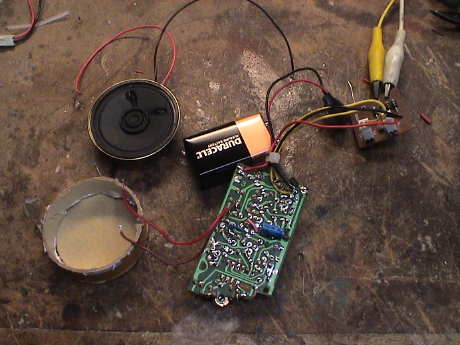

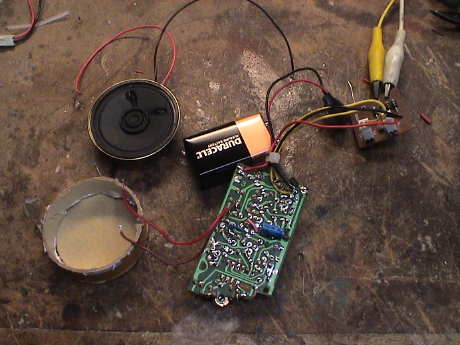

These are most of

the parts needed for the sound installation. The sound board was

later trimmed in size to make if fit better. The speaker was in my

parts box, it was the largest that would easily fit. I made an

enclosure by cutting off the bottom of a caulking gun tube and hot

gluing a piece of cardboard over the end to make a small enclosure.

Not shown is the reed switch and magnets that were used to make the

chuff switch.

These are most of

the parts needed for the sound installation. The sound board was

later trimmed in size to make if fit better. The speaker was in my

parts box, it was the largest that would easily fit. I made an

enclosure by cutting off the bottom of a caulking gun tube and hot

gluing a piece of cardboard over the end to make a small enclosure.

Not shown is the reed switch and magnets that were used to make the

chuff switch.

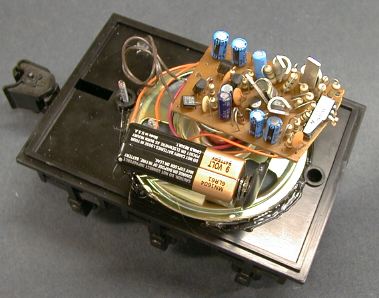

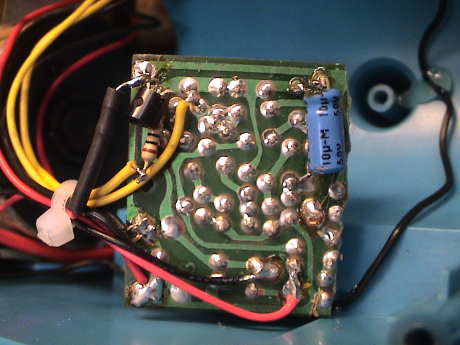

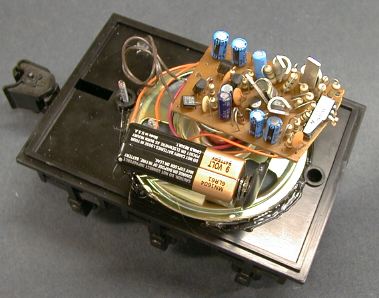

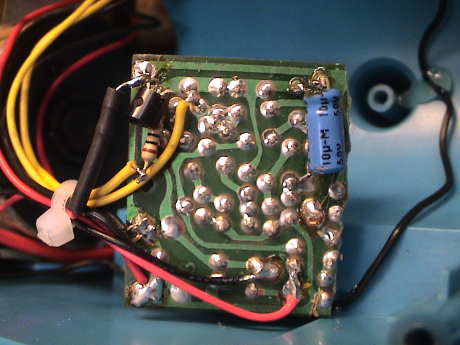

This

is the bottom of the sound board after it was hacked to size. The

very last row of solder pads on the right side are not needed, but

the board was small enough at this point so I didn't trim any

further. The stuff that is gone is all the motor controller

circuitry from the RC Big Hauler. The transistor and resistor in

the upper left is the chuff cutoff switch. The red and black wires

at the lower right are the speaker leads. A diagram of the

connection points to this board can be found at my Better Bachmann Sound for Under a

Buck page.

This

is the bottom of the sound board after it was hacked to size. The

very last row of solder pads on the right side are not needed, but

the board was small enough at this point so I didn't trim any

further. The stuff that is gone is all the motor controller

circuitry from the RC Big Hauler. The transistor and resistor in

the upper left is the chuff cutoff switch. The red and black wires

at the lower right are the speaker leads. A diagram of the

connection points to this board can be found at my Better Bachmann Sound for Under a

Buck page.

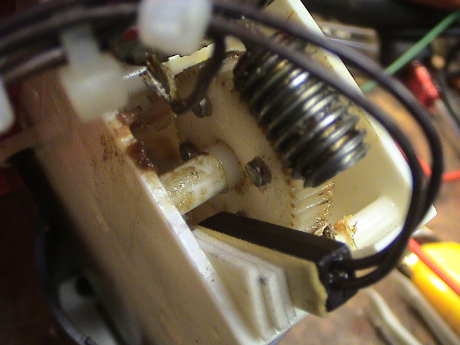

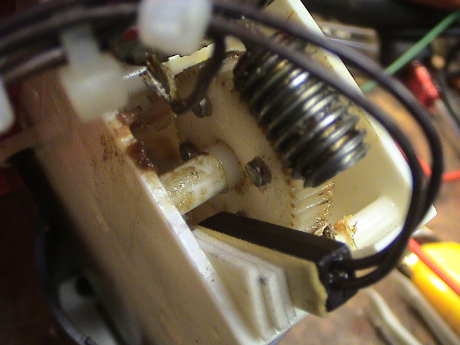

There

wasn't room to put chuff magnets and a reed switch in or on the

brick so I attached them to Thomas's eye movement mechanism

instead. This gear is apparently the same size as the one on the

rear driver because it turns at the same rate as the driving

wheels. I cleaned the side of the gear off with alcohol and

attached four small high energy magnets to the side of the gear

with Zap-A-Gap CA. The chuff reed switch was recovered from my

sound system parts box. I think that it probably came with a PH

Hobbies sound system. The switch is mounted with several layers of

foam mounting tape.

There

wasn't room to put chuff magnets and a reed switch in or on the

brick so I attached them to Thomas's eye movement mechanism

instead. This gear is apparently the same size as the one on the

rear driver because it turns at the same rate as the driving

wheels. I cleaned the side of the gear off with alcohol and

attached four small high energy magnets to the side of the gear

with Zap-A-Gap CA. The chuff reed switch was recovered from my

sound system parts box. I think that it probably came with a PH

Hobbies sound system. The switch is mounted with several layers of

foam mounting tape.

The speaker

in a home made cardboard enclosure is mounted with foam tape

against the traction battery pack. The 9V battery for the sound

system is mounted on the inside of the cab, also with foam tape.

The Shay interface board is mounted to the inside of a side tank

with foam tape. The sound board itself is mounted with hot

glue.

The speaker

in a home made cardboard enclosure is mounted with foam tape

against the traction battery pack. The 9V battery for the sound

system is mounted on the inside of the cab, also with foam tape.

The Shay interface board is mounted to the inside of a side tank

with foam tape. The sound board itself is mounted with hot

glue.

For what it cost me, $zip.zero out of pocket, this installation

worked pretty well.

[ Top ]

DCC Installation in Thomas

Thomas was my very last loco that

hadn't been converted to DCC. It got the battery conversion because

it was unreliable on track power unless the track was reasonably

clean. However, with the newer DCC decoders, locos run a little

better on DCC than they do on straight up track power, especially

ones with variable contact resistance like Thomas has.

Thomas was my very last loco that

hadn't been converted to DCC. It got the battery conversion because

it was unreliable on track power unless the track was reasonably

clean. However, with the newer DCC decoders, locos run a little

better on DCC than they do on straight up track power, especially

ones with variable contact resistance like Thomas has.

There are decoders especially configured to run on backup super

capacitors for a few seconds that pretty much eliminate track power

problems, Lenz makes the best ones now. However, they are expensive

and the super capacitors needed to make it immune to dirty track

are still pretty large. There is simply no room left in Thomas for

that. I used a DG583S because they work very well.

This conversion is less complicated than the other three battery

powered locos to which I have added DCC. Information on these can

be found at my LGB 2060

Tips , FA Tips and Center Cab Tips pages.

The loco already had sound of sorts that I didn't have to touch.

It also already had the DPDT switches installed. There is no

lighting, sound sound triggers or any other need for decoder

accessory functions. The decoder is simply inserted into the track

power path to the motor. The loco will still operate on straight up

DC track power but via the analog conversion capability of the

DG583S decoder which analog converts quite well.

Thomas still has four operating modes.

- Straight up battery/RC

- Track powered (DC, PWC or DCC) RC

- Straight up DCC

- DC track power via analog conversion of the DCC decoder. It

will sometimes work with PWC on the track, but the DCC decoders

sometimes become confused when they see PWC and can't figure out

what to do.

|

The one mode that I lose is with the power switch set to the

battery and the motor switch set to the DCC decoder. This will do

nothing except slowly drain the battery. These switch positions

used to connect the battery directly to the motor. This mode isn't

very useful except as a quick check that the battery has some

charge in it and there are other ways to test that.

The DG583S

decoder is mounted on the bottom of the battery pack and wired up

through an existing hole to the switches on top.

The DG583S

decoder is mounted on the bottom of the battery pack and wired up

through an existing hole to the switches on top.

The only change

on the topside was to remove a pair of wires that went from the

left switch to the right one. This was the pair that connected the

power source switch to the motor selector switch.

The only change

on the topside was to remove a pair of wires that went from the

left switch to the right one. This was the pair that connected the

power source switch to the motor selector switch.

The red and black decoder wires were wired to the power source

switch and the orange and gray motor wires were wired to the motor

selector switch. That was it for the wiring.

The two resistors and a diode that are in this photo and not in

the previous one of this same area are the charge current limiting

resistors that used to to be in the charger cable. The rewiring was

done some time ago so that the loco would charge properly from

straight 24 VDC.

I did add a 10K resistor to the sound switch circuit to fully

drag the base of the control transistor to ground when no motor

drive was present. The switch had a tendency to leak sometimes and

the sound board would crackle softly. That is now fixed.

After the mod, Thomas ran right off. There was a bit more dried

grease on the drive gear for the eyeball assembly that interacted

with the BEMF decoder as a repeating bind. I cleaned the grease

from the gear and that went away. While I was testing Thomas on the

track, it ran quite smoothly until it started making a horrible

racket when running forward. It was quiet in reverse. I knew from

experience that Thomas had eaten another drive gear. Sure enough,

the plastic gear on the rear axle had a worn spot. It quickly got

worse to the point that the gear failed completely.

Lionel is not stocking most parts for obsolete locos. They have

sold their inventory of older parts to North Lima Trainworks. They

did not have the whole axle assembly though, only the drive wheels

with the integrated gear for the gear train to the other driver

axles. It turns out that Lionel thought that they did have the axle

assemblies for $8.50 each. I ordered two but I got a phone call.

They were out of stock and weren't going to get anymore. They did

have one used one in good condition. They gave me the part for free

but I still had to pay shipping. Anyway, it arrived, it was

installed and Thomas lives again.

It ran on track that hadn't been cleaned at all in two or three

weeks although it sputtered some and it derailed a many times on

ivy leaves and stems. I noticed that when it hit a bad spot and

then found power again, it would start up so fast that it would do

wheelies and sometimes derail. The weight of the batteries is

behind the rear driver which upsets Thomas's balance. I had never

noticed this before because the TE RC system has some built in

momentum and I never had abrupt power changes. This jerks were

going to be hard on the gears and may have contributed to the rapid

failure of an already worn out gear. I added a little momentum into

the DCC decoder and that was patched. Some more weight added

forward inside the shell actually fixed that problem.

Now, on reasonably clean track, Thomas runs fine on DCC and it

still has the radio control gear and batteries as well. It ran for

hours on end at the November display layout at the South Coast

Botanic Gardens, both on it's old batteries (got 2.5 hours of run

time) an on DC on the display track. For display layouts, Thomas

sucks the little (and big) kids right in.

[ Top ] [ Home ] [ Up ] [

Previous Page ] [ Next Page ]

This page has been accessed  times since 31 Jan 1998.

times since 31 Jan 1998.

© 1998-2009 George Schreyer

Created Jan 31, 1998

Last Updated November 13, 2009

A few years ago, Lionel released a Thomas the

Tank Engine set. Thomas is a British inside cylinder 0-6-0 tank

engine that pulls two coaches, Annie and Clarabel. This set was

based on the Shining Time Station TV series that is probably still

playing on PBS. I would imagine that many large scalers with small

children somehow managed to acquire this set.

A few years ago, Lionel released a Thomas the

Tank Engine set. Thomas is a British inside cylinder 0-6-0 tank

engine that pulls two coaches, Annie and Clarabel. This set was

based on the Shining Time Station TV series that is probably still

playing on PBS. I would imagine that many large scalers with small

children somehow managed to acquire this set. Later, another set containing James the Red Engine

was released. James is an inside cylinder 2-6-0 tender engine of

British design that pulls two 4 axle freight wagons.

Later, another set containing James the Red Engine

was released. James is an inside cylinder 2-6-0 tender engine of

British design that pulls two 4 axle freight wagons. 24 May 09

24 May 09 22 Dec 08

22 Dec 08 There is no room to add a conventional

power pickup to the center drivers, but it is easy to add a wiper

contact that bears on the center driver tread. On James, it is

straightforward to add a 1/32" thick by 3/32" wide brass contact

strip. The strip is simply clamped between the frame and shell

castings as shown in the photo. A wire is then soldered to the

brass strip and run through a hole drilled in the lower shell and

connected directly to the motor.

There is no room to add a conventional

power pickup to the center drivers, but it is easy to add a wiper

contact that bears on the center driver tread. On James, it is

straightforward to add a 1/32" thick by 3/32" wide brass contact

strip. The strip is simply clamped between the frame and shell

castings as shown in the photo. A wire is then soldered to the

brass strip and run through a hole drilled in the lower shell and

connected directly to the motor. I attached the same

type of contact to Thomas' frame with plumber's epoxy putty. This

particular epoxy is handy because it sets up really fast so that

you don't have to hold it in place for more than about five

minutes. The epoxy also will not stick to your fingers. I modified

Thomas several years ago. After I took this photo recently, I

realized that I probably could have clamped the contact on Thomas

the same way that I did James.

I attached the same

type of contact to Thomas' frame with plumber's epoxy putty. This

particular epoxy is handy because it sets up really fast so that

you don't have to hold it in place for more than about five

minutes. The epoxy also will not stick to your fingers. I modified

Thomas several years ago. After I took this photo recently, I

realized that I probably could have clamped the contact on Thomas

the same way that I did James. Even with the center

drivers contributing to power pickup, James was still touchy. I

took a hint from my own

Even with the center

drivers contributing to power pickup, James was still touchy. I

took a hint from my own  On the inside, the

wire is just bent over and secured with some Zap-A-Gap CA. A wire,

soldered before the application of the CA, leads back to a brass

strip that connects the rear piston contacts.

On the inside, the

wire is just bent over and secured with some Zap-A-Gap CA. A wire,

soldered before the application of the CA, leads back to a brass

strip that connects the rear piston contacts. The sliders fit right

between the center and rear drivers and are not too visually

obtrusive. The improvement in power pickup was quite pronounced.

James used to have a tendency to fail to pick up power after it was

stopped and to stutter on turnouts. These tendencies seem to have

gone away.

The sliders fit right

between the center and rear drivers and are not too visually

obtrusive. The improvement in power pickup was quite pronounced.

James used to have a tendency to fail to pick up power after it was

stopped and to stutter on turnouts. These tendencies seem to have

gone away. There is little room

in Thomas for a sound board and speaker, but James has a large

nearly empty tender that is easily big enough. The tender shell is

attached with two screws, one under the rear coupler and the other

also secures the drawbar.

There is little room

in Thomas for a sound board and speaker, but James has a large

nearly empty tender that is easily big enough. The tender shell is

attached with two screws, one under the rear coupler and the other

also secures the drawbar. A 3"

speaker fits easily on the flat floor. A bunch of holes drilled

through the floor lets the sound out. The Bachmann sound board was

recovered from a defunct R/C Big Hauler. To make the board fit

better in the Shay, it had been literally hacked in half. All the

sound circuitry is on the rear third of the board so all that is

necessary is to cut a trace leading down each side of the board

past the sound circuitry and then to physically cut the rest of the

board off. I left some of the motor control circuit behind just

because it was easier to cut right through the motor controller IC.

The rest of the board is mounted to the back of the speaker magnet

with foam mounting tape. The battery is stuck to the side of the

speaker with foam mounting tape.

A 3"

speaker fits easily on the flat floor. A bunch of holes drilled

through the floor lets the sound out. The Bachmann sound board was

recovered from a defunct R/C Big Hauler. To make the board fit

better in the Shay, it had been literally hacked in half. All the

sound circuitry is on the rear third of the board so all that is

necessary is to cut a trace leading down each side of the board

past the sound circuitry and then to physically cut the rest of the

board off. I left some of the motor control circuit behind just

because it was easier to cut right through the motor controller IC.

The rest of the board is mounted to the back of the speaker magnet

with foam mounting tape. The battery is stuck to the side of the

speaker with foam mounting tape. The sound

switch is a reed switch left over from a PH Hobbies sound board

installation sometime in the dark distant past. The switch is stuck

to an existing bracket in front of the rear axle. Two small high

energy magnets are attached to the rear axle with Zap CA.

The sound

switch is a reed switch left over from a PH Hobbies sound board

installation sometime in the dark distant past. The switch is stuck

to an existing bracket in front of the rear axle. Two small high

energy magnets are attached to the rear axle with Zap CA. This is the schematic

of I used to wire Thomas. It is my standard "tri-modal" circuit. It

takes just a little more wiring than the dead simple versions, but

depending on how the switches are set, it will still run from

straight track power, or RC with track power, or RC with the

internal battery. The charge jack is arranged to charge properly

from a 24 VDC source.

This is the schematic

of I used to wire Thomas. It is my standard "tri-modal" circuit. It

takes just a little more wiring than the dead simple versions, but

depending on how the switches are set, it will still run from

straight track power, or RC with track power, or RC with the

internal battery. The charge jack is arranged to charge properly

from a 24 VDC source.

The saddle tanks

were too small to hold the battery packs that I had, but they would

fit nicely crosswise in the cab with the cab interior view block

removed. The region inside the tender could hold the receiver. The

switches and charge jack were a problem.

The saddle tanks

were too small to hold the battery packs that I had, but they would

fit nicely crosswise in the cab with the cab interior view block

removed. The region inside the tender could hold the receiver. The

switches and charge jack were a problem. Thomas's coal load

is easily removed and the region under it was just right to hold

the five items that had to fit there, two power control switches,

the code set button, the charge jack and an indicator LED to make

programming the receiver from outside the loco practical. The LED

is wired as the rear headlight. Thomas doesn't have a front

headlight and I choose not to install one.

Thomas's coal load

is easily removed and the region under it was just right to hold

the five items that had to fit there, two power control switches,

the code set button, the charge jack and an indicator LED to make

programming the receiver from outside the loco practical. The LED

is wired as the rear headlight. Thomas doesn't have a front

headlight and I choose not to install one. All this hardware hanging off

the back of Thomas isn't particularly attractive, but they were

easy to install and access in that location. The back side of the

coal load and its mounting posts must be gouged off but this can't

seen from the outside and the posts weren't used anyway.

All this hardware hanging off

the back of Thomas isn't particularly attractive, but they were

easy to install and access in that location. The back side of the

coal load and its mounting posts must be gouged off but this can't

seen from the outside and the posts weren't used anyway. The receiver is simply mashed back in the

tender. I didn't use the adaptor board because there wasn't room.

The shrink tubing over the wires soldered to the pins is sufficient

to hold the receiver in place against the battery.

The receiver is simply mashed back in the

tender. I didn't use the adaptor board because there wasn't room.

The shrink tubing over the wires soldered to the pins is sufficient

to hold the receiver in place against the battery. There is enough

room inside James for a small decoder. The cab comes off with just

two screws revealing all that is necessary to install a decoder,

especially considering that there are no accessory functions

used.

There is enough

room inside James for a small decoder. The cab comes off with just

two screws revealing all that is necessary to install a decoder,

especially considering that there are no accessory functions

used. The DH123D went in

fine and seemed to run ok for awhile. But after just one lap

around, James stopped inside a tunnel. When I got to it, it was

smoking. James was indeed a little too much for this decoder. It is

clearly burned up.

The DH123D went in

fine and seemed to run ok for awhile. But after just one lap

around, James stopped inside a tunnel. When I got to it, it was

smoking. James was indeed a little too much for this decoder. It is

clearly burned up. I recovered an

MRC AD320 decoder from an Aristo Classic Railbus which got a

Digitrax DG583S to replace the AD320. The AD320 has just 4

functions and I needed one more so I used the, now surplus, AD320

in James. It just fit next to the motor. As expected, the AD320

makes quite a bit of noise as heard in this

I recovered an

MRC AD320 decoder from an Aristo Classic Railbus which got a

Digitrax DG583S to replace the AD320. The AD320 has just 4

functions and I needed one more so I used the, now surplus, AD320

in James. It just fit next to the motor. As expected, the AD320

makes quite a bit of noise as heard in this  Eventually, the AD320

burnt up in James. The heat load was apparently too high as the

circuit board literally came apart. I put analog voltage on the

track for awhile to do some testing on another loco and James was

sitting on powered track. It didn't move, but apparently the AD320

couldn't handle it and it burnt. I smelled the burnt smell but I

didn't know where it came from. It was months later that I tried to

run James again and it just didn't work. I took the decoder out and

it was visually obvious that it was toast.

Eventually, the AD320

burnt up in James. The heat load was apparently too high as the

circuit board literally came apart. I put analog voltage on the

track for awhile to do some testing on another loco and James was

sitting on powered track. It didn't move, but apparently the AD320

couldn't handle it and it burnt. I smelled the burnt smell but I

didn't know where it came from. It was months later that I tried to

run James again and it just didn't work. I took the decoder out and

it was visually obvious that it was toast. This

is the diagram that I used to do the install in Thomas. The

previous "tri-modal" battery/track/RC wiring was not changed. The

Bachmann analog sound board runs from a 9V battery that will last

for years. The board had also been modified with a circuit to stop

the continuous chuff when it was in the Shay and that circuit was

retained as well.

This

is the diagram that I used to do the install in Thomas. The

previous "tri-modal" battery/track/RC wiring was not changed. The

Bachmann analog sound board runs from a 9V battery that will last

for years. The board had also been modified with a circuit to stop

the continuous chuff when it was in the Shay and that circuit was

retained as well. These are most of

the parts needed for the sound installation. The sound board was

later trimmed in size to make if fit better. The speaker was in my

parts box, it was the largest that would easily fit. I made an

enclosure by cutting off the bottom of a caulking gun tube and hot

gluing a piece of cardboard over the end to make a small enclosure.

Not shown is the reed switch and magnets that were used to make the

chuff switch.

These are most of

the parts needed for the sound installation. The sound board was

later trimmed in size to make if fit better. The speaker was in my

parts box, it was the largest that would easily fit. I made an

enclosure by cutting off the bottom of a caulking gun tube and hot

gluing a piece of cardboard over the end to make a small enclosure.

Not shown is the reed switch and magnets that were used to make the

chuff switch. This

is the bottom of the sound board after it was hacked to size. The

very last row of solder pads on the right side are not needed, but

the board was small enough at this point so I didn't trim any

further. The stuff that is gone is all the motor controller

circuitry from the RC Big Hauler. The transistor and resistor in

the upper left is the chuff cutoff switch. The red and black wires

at the lower right are the speaker leads. A diagram of the

connection points to this board can be found at my

This

is the bottom of the sound board after it was hacked to size. The

very last row of solder pads on the right side are not needed, but

the board was small enough at this point so I didn't trim any

further. The stuff that is gone is all the motor controller

circuitry from the RC Big Hauler. The transistor and resistor in

the upper left is the chuff cutoff switch. The red and black wires

at the lower right are the speaker leads. A diagram of the

connection points to this board can be found at my  There

wasn't room to put chuff magnets and a reed switch in or on the

brick so I attached them to Thomas's eye movement mechanism

instead. This gear is apparently the same size as the one on the

rear driver because it turns at the same rate as the driving

wheels. I cleaned the side of the gear off with alcohol and

attached four small high energy magnets to the side of the gear

with Zap-A-Gap CA. The chuff reed switch was recovered from my

sound system parts box. I think that it probably came with a PH

Hobbies sound system. The switch is mounted with several layers of

foam mounting tape.

There

wasn't room to put chuff magnets and a reed switch in or on the

brick so I attached them to Thomas's eye movement mechanism

instead. This gear is apparently the same size as the one on the

rear driver because it turns at the same rate as the driving

wheels. I cleaned the side of the gear off with alcohol and

attached four small high energy magnets to the side of the gear

with Zap-A-Gap CA. The chuff reed switch was recovered from my

sound system parts box. I think that it probably came with a PH

Hobbies sound system. The switch is mounted with several layers of

foam mounting tape. The speaker

in a home made cardboard enclosure is mounted with foam tape

against the traction battery pack. The 9V battery for the sound

system is mounted on the inside of the cab, also with foam tape.

The Shay interface board is mounted to the inside of a side tank

with foam tape. The sound board itself is mounted with hot

glue.

The speaker

in a home made cardboard enclosure is mounted with foam tape

against the traction battery pack. The 9V battery for the sound

system is mounted on the inside of the cab, also with foam tape.

The Shay interface board is mounted to the inside of a side tank

with foam tape. The sound board itself is mounted with hot

glue. Thomas was my very last loco that

hadn't been converted to DCC. It got the battery conversion because

it was unreliable on track power unless the track was reasonably

clean. However, with the newer DCC decoders, locos run a little

better on DCC than they do on straight up track power, especially

ones with variable contact resistance like Thomas has.

Thomas was my very last loco that

hadn't been converted to DCC. It got the battery conversion because

it was unreliable on track power unless the track was reasonably

clean. However, with the newer DCC decoders, locos run a little

better on DCC than they do on straight up track power, especially

ones with variable contact resistance like Thomas has. The DG583S

decoder is mounted on the bottom of the battery pack and wired up

through an existing hole to the switches on top.

The DG583S

decoder is mounted on the bottom of the battery pack and wired up

through an existing hole to the switches on top. The only change

on the topside was to remove a pair of wires that went from the

left switch to the right one. This was the pair that connected the

power source switch to the motor selector switch.

The only change

on the topside was to remove a pair of wires that went from the

left switch to the right one. This was the pair that connected the

power source switch to the motor selector switch.