Aristo Classic Rail Bus Tips

[ Home ] [ Up ] [ Previous

Page ] [ Next Page

]

Aristo has recently released their version of a

rail bus. The rail bus evolved to fill a need on narrow gauge,

shortline and branchline railroads. As passenger traffic dropped

off due to competition from automobiles and highway busses, the

railroads could no longer afford to run a regular steam engine

which pulled maybe one coach. To reduce costs an old wooden coach

was often cut up and grafted to an large automobile or truck frame.

The original gasoline engine and manual transmission were

sufficient to haul the rail bus, and on some lines, maybe an

additional coach if the grades were mild. The rail busses kept

these struggling railroads in business for a few extra years, but

eventually most of these roads folded anyway.

Aristo has recently released their version of a

rail bus. The rail bus evolved to fill a need on narrow gauge,

shortline and branchline railroads. As passenger traffic dropped

off due to competition from automobiles and highway busses, the

railroads could no longer afford to run a regular steam engine

which pulled maybe one coach. To reduce costs an old wooden coach

was often cut up and grafted to an large automobile or truck frame.

The original gasoline engine and manual transmission were

sufficient to haul the rail bus, and on some lines, maybe an

additional coach if the grades were mild. The rail busses kept

these struggling railroads in business for a few extra years, but

eventually most of these roads folded anyway.

The model represents a wooden coach body grafted to a Mac

Bulldog truck frame but without the Mac chain drive.

Jeff Saxton writes:

"Actually, about 75% of ALL railbuses were factory-built jobs,

very few, relatively, were home-built, and I know of NO Mack based

home built railbus; all are factory models with steel carbodies on

the "AC" hood version (the famous chain drive Bulldog which Aristo

replicates), although wood carbodies were used on the smaller

(direct transmission) "AB" models. Mack "AC" Bulldogs date from

around 1915 to 1938 -- and Aristo's choice of radiator design dates

it as post 1921 if I recall correctly.

Single drive axle Mack "AC" railbuses are model "ACR", while

double axle versions are "ACX" models, and none were chain drive,

but direct transmission. Mack made the first ACR in 1916, so quite

early overall. Aristo molded an "A" in the hood, I assume for

Aristo, since licensing from "Mack Trucks Inc." went to Hartland

for their forthcoming Mack bus, which will be similar. The real

hoods should have the parent company's "International Motors" with

the "flying I-M" logo on the hood.

Mack also made some "AL" and "AM" based chassis into railbuses

-- these chassis were used in the line of highway buses and fire

engines Mack produced -- more cylinders -- more horsepower."

Contents

Performance and Detail

The Aristo Classic Rail Bus is a very smooth

running model. Power pickup is on all eight wheels and is very

steady. The wheels themselves do not appear to be susceptible to

pitting so that they tend to stay clean. The motor runs very

smoothly. The bus will maintain very slow speeds at about one tie

per second. It'll go slower on straight track, but the additional

load when transitioning to a 2' radius turn will stall it. Like

most direct worm gear drives, the bus has a slight tendency to

lurch at some speeds and loads on some downgrades.

The Aristo Classic Rail Bus is a very smooth

running model. Power pickup is on all eight wheels and is very

steady. The wheels themselves do not appear to be susceptible to

pitting so that they tend to stay clean. The motor runs very

smoothly. The bus will maintain very slow speeds at about one tie

per second. It'll go slower on straight track, but the additional

load when transitioning to a 2' radius turn will stall it. Like

most direct worm gear drives, the bus has a slight tendency to

lurch at some speeds and loads on some downgrades.

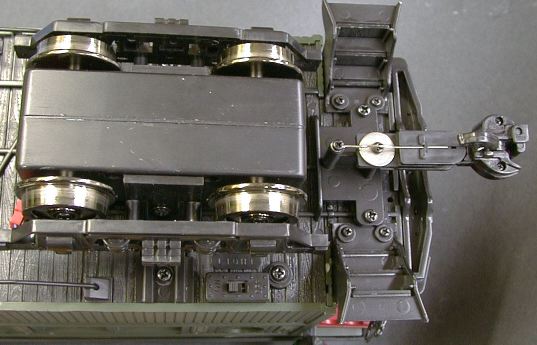

The bus has one dicast motor block similar to the one used in

the Center Cab Industrial Switcher.

The wheels on the rail bus are slightly smaller. The front truck is

an unsprung archbar design with ball bearing wheels and electrical

pickups. The rear truck sideframes represent a typical equalized

coach truck. The motor block also picks up power on all four wheels

through ball bearings.

The bus runs very smoothly and quietly and is tolerant of

moderately dirty track due to the 8 point power pickup. Sometimes

the bus tends to wobble a little, but then again, real rail busses

did that too. The wobble appears to occur when the bus goes through

turnouts. The wheel flanges are a little smaller than the

"standard" large scale flange which allows the wheels to drop into

the frogs.

The model has no extra weighting except for the weight of the

cast motor brick so its traction is fairly weak. It will handle one

additional coach on a 4% grade, more than that and it starts to

slip. However, a real rail bus often struggled just to drag itself

around so this "feature" is prototypical too. One couldn't expect a

4 cylinder flathead gasoline motor to pull a whole train. I did run

my standard Tractive

Effort Tests on the rail bus and it did fairly well, pulling

about as well as other locos with 4 driven wheels.

The bus appears to be very tolerant of out of level or gauge

track and did not derail on its own at all during testing on both

the GIRR or the GIRR Mountain Division layouts. On the first pass

over the Mountain Division, the smokestack whacked an overhead

support quite solidly and the bus derailed then. The stack has

since been lowered so this is no longer a problem. The rail bus is

a little too light in the front to push over the points of an LGB

1200 turnout while going forward, but it will do it in reverse.

I did notice that the power brick wheels didn't seem to be

evenly resting on the track when the bus was going over vertical

track gradients (the GIRR Mountain Division has one spot that needs

fixing). The A-frame that mounts the power brick doesn't have much

play to allow it to rock fore and aft like the A-frames in the

Center Cab Industrial switcher do. Loosening the two brick mounting

screws on the sides of the A-frames a half a turn each allowed the

brick to rock a little more within the A-frame and then the unit

tracked better over the uneven track.

The Aristo model is very well detailed. The grating on the back

of the bus is a metal casting with operating gates and platform

drop panels. The rear and side doors operate, but the driver's

doors do not. The paint and lettering is excellent and there are

curtains simulated in the windows. The panels above the windows are

tinted dark green. There is no driver in the bus, this'll have to

get fixed.

There is a smoke unit that represents smoke from a pot bellied

stove at the rear of the coach. In typical Aristo fashion, the unit

doesn't generate huge volumes of smoke, but the smoke plume is

visible with the bus running at about half speed while using an

Aristo PWC power pack. The smoke unit doesn't make much smoke at

all with a standard DC power pack except at full throttle. The

smoke unit is removable, it just unplugs like many other Aristo

smoke units.

The model has both interior and exterior lighting. There are

four interior lights installed in fixtures on the walls. The rear

markers are illuminated as is the cab. The headlight operates but

is not directional. There are switches underneath near the rear

truck. One controls the smoke unit and the other controls the motor

and lights. It would have been nice to be able to turn just the

motor off so that the bus could sit lighted and smoking. Without

some rewiring, this cannot be done. The wiring is inside the floor

of the unit so that some significant disassembly will be required

to access the wiring.

The truss rods are metal and the metal turnbuckles actually

thread on. However, the turnbuckles are not reverse threaded so

that it is not possible to "adjust" the truss rods with the

turnbuckle.

The Aristo Classic Rail bus represents a

typical combo coach type of bus. The bus was divided into three

parts, a driver's compartment, small baggage, mail and freight

section, and a coach section. These busses typically stopped

anywhere on the line where somebody flagged them to pick up or drop

off passengers, mail and freight. The baggage compartment is easily

big enough to hold a sound system, batteries and a control

receiver.

The Aristo Classic Rail bus represents a

typical combo coach type of bus. The bus was divided into three

parts, a driver's compartment, small baggage, mail and freight

section, and a coach section. These busses typically stopped

anywhere on the line where somebody flagged them to pick up or drop

off passengers, mail and freight. The baggage compartment is easily

big enough to hold a sound system, batteries and a control

receiver.

The roof is attached with four screws. Two are easily accessible

under the rear awning. To access the other two, remove the front

steps and look in the front corners of the roof for the other two

screws. It takes a fairly long #1 Phillips screwdriver to reach

them. Don't pull them all the way out. The flanges on the body are

threaded and the screws will stay in place if pulled out just far

enough to release the roof. This makes getting the roof back on

much easier.

[ Top ]

Scale and Clearance

Aristo built this model around a narrow

gauge 1/24 scale Sierra combo coach but the model is identified as

1/29 scale. However the general proportions of the model are much

larger than other 1/29 scale equipment. It is nearly an inch taller

than a standard heavyweight coach.

Aristo built this model around a narrow

gauge 1/24 scale Sierra combo coach but the model is identified as

1/29 scale. However the general proportions of the model are much

larger than other 1/29 scale equipment. It is nearly an inch taller

than a standard heavyweight coach.

The Rail

bus is even 1/2" taller than a Bachmann coach (the scale of the

Bachmann coach is debatable). The rear door of the rail bus is just

over 6' tall in 1/29 scale so this comes out ok, but the driver's

door is nearly 8' tall in 1/29 scale. Based on the match to other

coaches, the rail bus would look more appropriate on a 1/24 scale

1930's era narrow gauge layout than a more modern standard gauge

one.

The Rail

bus is even 1/2" taller than a Bachmann coach (the scale of the

Bachmann coach is debatable). The rear door of the rail bus is just

over 6' tall in 1/29 scale so this comes out ok, but the driver's

door is nearly 8' tall in 1/29 scale. Based on the match to other

coaches, the rail bus would look more appropriate on a 1/24 scale

1930's era narrow gauge layout than a more modern standard gauge

one.

The front and rear steps are way off the ground, The step down

is over 2' in 1/24 scale, even higher in 1/29 scale. The bus is

just a little too tall. This appears to be a result of the size of

the power brick. It is tucked pretty tightly against the floor of

the bus so it would appear that the only way to lower the bus would

be to recess the brick up into the coach floor, a fairly major hack

job.

The rail bus is 21" long from the tip of the pilot to the rear

coupler. The bus is 4-1/4" wide over the body and 5-3/8" wide over

the marker lamps. This is wider than most other large scale rolling

stock so if you have restricted side clearances there may be some

difficulty. There were a couple of hidden spots on straight track

at the GIRR Mountain Division where the markers dragged against

adjacent layout structures. Nothing else had ever dragged at these

spots, so the rail bus is actually wider than any other stock that

I already had. I was able to adjust the track centerline to split

the difference and the bus barely passed without other structural

work.

The roof line extends 6-1/2" from the railheads. There are four

vents on the roof that are 1/4" taller and the smokestack extends

to 7-1/8" from the railheads.

The worst overhang on a 2' radius curve is the rear step at

2-3/8", just a little less than a Big Hauler, so that the rail bus

will probably fit on most railroads that don't have vertical

clearance problems.

The smokestack didn't clear some rather hard limits on my indoor

layout and it needed some work. I reduced the height of the stack

by a little more than 1/4". I pulled the stack off the metal heater

assembly and cut 1/4" off the stack after removing the smokejack.

The smokejack was then reinstalled as close to the top of the stack

as possible. New screw holes were drilled with a #55 drill using

the smokejack as a template. The heater element now sticks out of

the top of the stack by about 1/16" but is protected from damage by

the smokejack.

The motor brick sits quite low due the small wheels. It will

hang up on LGB automatic uncoupling tracks which lift the drive

wheels barely off the track. If the bus is going to slowly when it

crosses an uncoupler, it will stop dead with the wheels spinning,

high centered on the motor brick. The center cab switcher uses the

same brick, but has larger wheels so that it just clears the

uncoupling ramp.

[ Top ]

Couplers

The rail bus

comes equipped with a body mounted standard Aristo knuckle coupler.

A hook and loop coupler is supplied in the box. The coupler is

mounted so that it can swivel but it still puts quite a bit of

twisting force on a following car in a tight turn. The following

car does not actually derail, but its trying to. The pilot has a

drawbar attached.

The rail bus

comes equipped with a body mounted standard Aristo knuckle coupler.

A hook and loop coupler is supplied in the box. The coupler is

mounted so that it can swivel but it still puts quite a bit of

twisting force on a following car in a tight turn. The following

car does not actually derail, but its trying to. The pilot has a

drawbar attached.

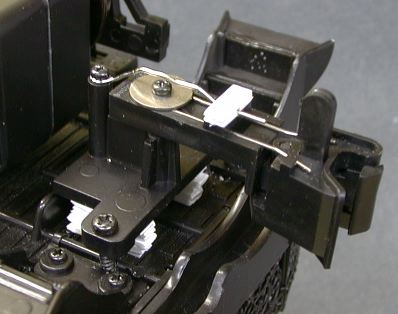

I mounted

an LGB knuckle coupler to the rail bus. The mount required some

modification but the changes were not difficult. The LGB coupler

mounts directly to the existing coupler post. Some small pieces of

styrene are used to fabricate the centering spring capture feature

that was on the original coupler. The centering spring needs to be

formed differently to clear the back of the LGB coupler tang and

mounting screw.

I mounted

an LGB knuckle coupler to the rail bus. The mount required some

modification but the changes were not difficult. The LGB coupler

mounts directly to the existing coupler post. Some small pieces of

styrene are used to fabricate the centering spring capture feature

that was on the original coupler. The centering spring needs to be

formed differently to clear the back of the LGB coupler tang and

mounting screw.

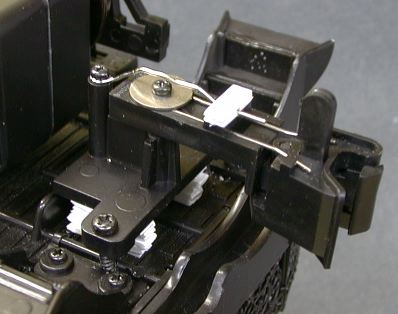

The stock Aristo centering spring as shown in the photo is bent

from 0.035" wire. This turns out to be a little too stiff for use

with the LGB knuckle couplers. The Railbus will often drag the

following car off the track in a turn or a turnout. I hand bent

another spring from 0.025" music wire which seems to have fixed

this problem.

The coupler comes out 3/8" too high so that the entire bracket

was spaced downward with styrene shims to put the coupler at the

right height. It took two stacks of six pieces of 0.062" styrene to

build a shim of the correct height. The screws that hold the

coupler bracket also hold the rear platform in place. The stock

screws are too short to reach with the shim installed so longer

screws were substituted. The mounting screw holes in the bracket

were threaded which is a little unusual. I drilled them out so that

the screws had a clearance fit in the bracket.

It would appear that a Kadee coupler could be mounted in the

same fashion.

[ Top ]

Disassembly of the Railbus

Getting into the Railbus far enough to install passengers, a

driver, sound or RC control isn't too difficult. Getting into it

far enough to get to the printed wiring board inside the floor is

much more difficult. There is an exploded diagram of the Railbus at

the AristoCraft Internet

Depot.

The roof comes off pretty easily. There are two screws under the

rear corners of the roof. These are flat head screws set into the

red awning piece in the rear. The front two screws are way up

inside the front corners. The front steps need to be removed to

access the roof screws. These screws will not come all the way out.

This is good because it would be hard to get them back in. They

will back out far enough to release the roof though and they stay,

captive, in place.

The whole front end assembly with the front frame, front truck,

pilot, cab and engine hood comes off with two screws that are set

into the gas tanks. There are two wires that need to be unsoldered

to completely release the front end. Pull the shrink tubing back

where they wires enter the floor and unsolder the wires at the

posts there.

Once the front end is off, the cab will just pull down and

forward and release. It will still be captive by some wires, but

you can get far enough in to install a driver. There isn't much

room in the cab, most sitting figures will need their legs cut off

to fit.

Taking the rest of it apart is a challenge that I elected not to

attempt as I didn't need to.

[ Top ]

Wiring in the Railbus

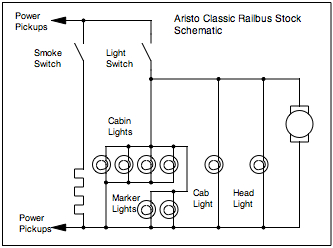

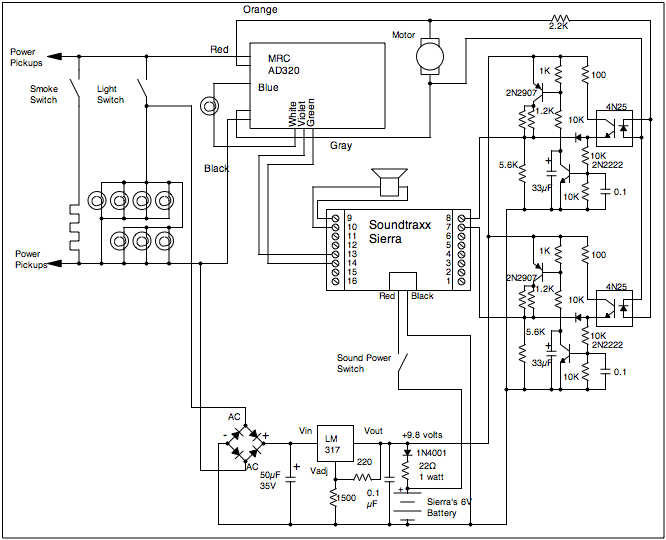

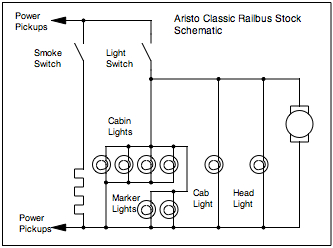

I

have not disassembled the Railbus far enough to visually inspect

the wiring, but it has to be pretty simple and this schematic

describes it's behavior. There are two switches under the body near

the rear truck, one is labeled "Smoke" and the other "Lights." The

only issue is that the motor and lights are switched together. The

headlight is non-directional but that could be easily changed with

the addition of a diode in a headlight wire.

I

have not disassembled the Railbus far enough to visually inspect

the wiring, but it has to be pretty simple and this schematic

describes it's behavior. There are two switches under the body near

the rear truck, one is labeled "Smoke" and the other "Lights." The

only issue is that the motor and lights are switched together. The

headlight is non-directional but that could be easily changed with

the addition of a diode in a headlight wire.

[ Top ]

Sierra Sound Installation in the

Railbus

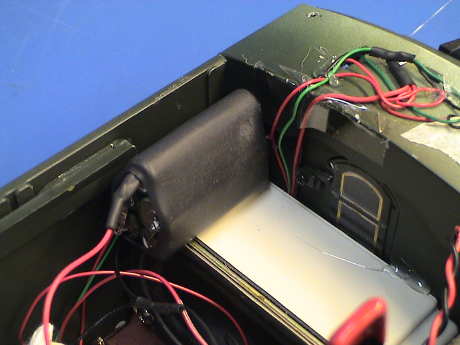

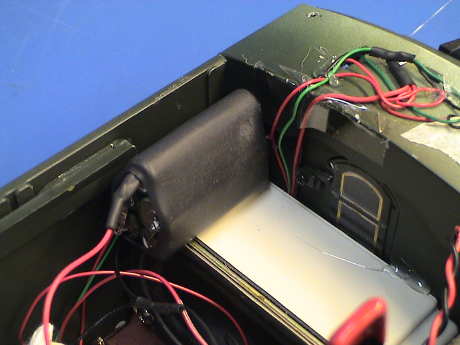

Sound

installation in the Railbus isn't too difficult depending on where

you mount the speaker. I used another of my swap meet computer

speakers in the baggage compartment pointing rearward. These

speakers have their own cabinet so I didn't have to worry about

sealing anything up. The sound comes out the open cargo doors. The

battery is hot glued to the top of the speaker box. The sound card

itself is attached to the floor with double backed foam tape right

behind the speaker so that the programming buttons can be reached

through the doors. I hot glued a couple of bags of coffee to act as

view blocks so that the card cannot be seen looking through the

doors. Power for the installation is tapped from the headlight

wiring above the cab. The power switch (switching both track power

and the battery) is mounted in a hole in the floor. This hole was

drilled about 1/2" in from the edge of the floor, right behind the

unused bolster casting in the floor.

Sound

installation in the Railbus isn't too difficult depending on where

you mount the speaker. I used another of my swap meet computer

speakers in the baggage compartment pointing rearward. These

speakers have their own cabinet so I didn't have to worry about

sealing anything up. The sound comes out the open cargo doors. The

battery is hot glued to the top of the speaker box. The sound card

itself is attached to the floor with double backed foam tape right

behind the speaker so that the programming buttons can be reached

through the doors. I hot glued a couple of bags of coffee to act as

view blocks so that the card cannot be seen looking through the

doors. Power for the installation is tapped from the headlight

wiring above the cab. The power switch (switching both track power

and the battery) is mounted in a hole in the floor. This hole was

drilled about 1/2" in from the edge of the floor, right behind the

unused bolster casting in the floor.

There is a circuit board in the floor somewhere and I didn't

want to drill holes through the floor to let the sound escape. I

probably would have drilled right through something important on

the board. This is why I choose the door method. Since the buttons

on the Sierra can be reached, an external volume/programming switch

is not required.

I choose a Sierra RGS Goose sound system for this install, I

guessed that it would be close. While the Sierra system sounds

good, its speed doesn't match the Railbus speed well unless you

accelerate and decelerate quite slowly. The shifts are distinct,

but the engine sound doesn't "spool" well between shifts. The

system also sounds a dynamic brake and air compressor pop off as

delivered. These should be turned off, there weren't too may

Railbuses with dynamic or air brakes.

As

I was ripping into the Railbus to install DCC, I elected to replace

the Sierra gelcell battery with a 5 AAA cell NiMH pack that I had

assembled for the Bachmann Railtruck. Only after I had made the

pack did I find out that I couldn't get a Sierra for it because the

Sierra has been discontinued. The existing battery was six years

old so I figured that it had lasted well past it's expected

life.

As

I was ripping into the Railbus to install DCC, I elected to replace

the Sierra gelcell battery with a 5 AAA cell NiMH pack that I had

assembled for the Bachmann Railtruck. Only after I had made the

pack did I find out that I couldn't get a Sierra for it because the

Sierra has been discontinued. The existing battery was six years

old so I figured that it had lasted well past it's expected

life.

[ Top ]

DCC Installation in the Railbus

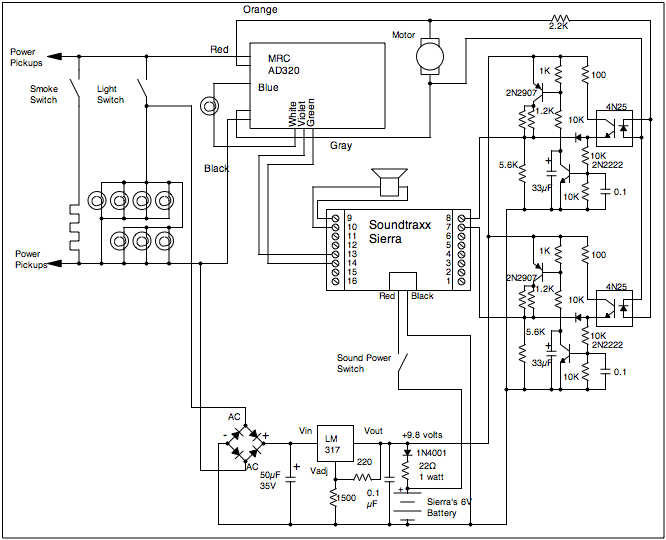

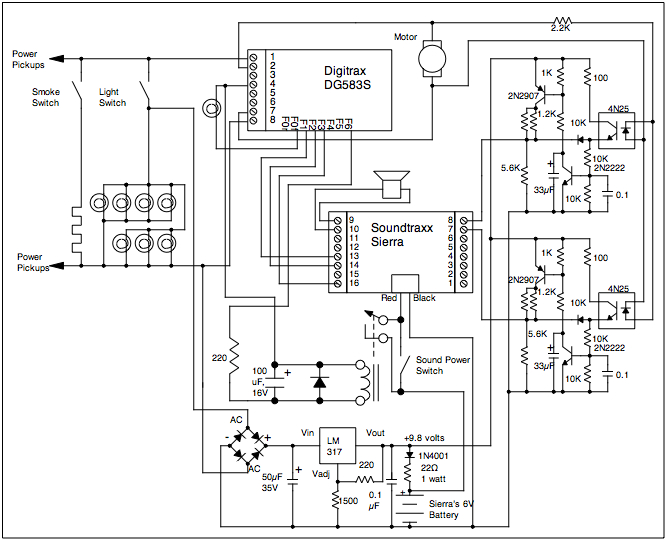

This is the schematic of the DCC

installation in the Railbus. There is a lot of stuff here, but this

is what it takes to get a Sierra to work properly with DCC or most

RC systems. The Railbus uses a "diesel" version of the Sierra, but

programmed with the sounds of a Goose. The diesel systems do not

detect the start and stop events reliably without optical isolators

between the motor and the Sierra. The optical isolators fix the

start and stop sounds, but they screw up the coordination between

the sound of the motor revving up and the actual speed of the

Railbus. This circuit looks a little involved, but it fixes all

that, see my Soundtraxx Sierra

Tips page for more information. The circuit itself is built on

a small piece of perforated board that is mounted above the speaker

on the forward wall.

This is the schematic of the DCC

installation in the Railbus. There is a lot of stuff here, but this

is what it takes to get a Sierra to work properly with DCC or most

RC systems. The Railbus uses a "diesel" version of the Sierra, but

programmed with the sounds of a Goose. The diesel systems do not

detect the start and stop events reliably without optical isolators

between the motor and the Sierra. The optical isolators fix the

start and stop sounds, but they screw up the coordination between

the sound of the motor revving up and the actual speed of the

Railbus. This circuit looks a little involved, but it fixes all

that, see my Soundtraxx Sierra

Tips page for more information. The circuit itself is built on

a small piece of perforated board that is mounted above the speaker

on the forward wall.

The interface circuit was built and tested while the desired

decoder was on backorder. I tested the circuit using an Aristo

ART-5490 as a source of motor drive and it worked fine. However, I

elected to install an MRC AD320 decoder to test the rest of the

installation and I had to make some changes the the circuit. The

AD320 is a low frequency decoder. It was surplus because it had

made too much noise in previous installations but it only made only

a very faint buzzing noise in the Railbus. Otherwise, it worked

fine. However the interface circuit didn't work right because it

had been designed and tested with high frequency pulses. The long,

low frequency pulses made by the AD320 were too long and the

interface circuit wasn't remembering it's state between pulses. I

added a 33µF capacitor at the collector of the 2N2222 to

prevent the collector voltage from rising between pulses. I also

changed the output divider network a little to tease the output

voltage up just a little so that the sound system would start to

ramp up on the first speed step of the 28 step decoder.

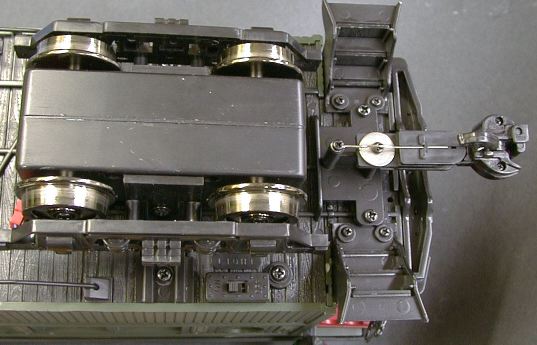

Contrary to the exploded parts diagram on the AristoCraft site,

my motor block has four wires coming out going to two connectors. I

had another set of these connectors so isolating the motor was as

easy as identifying which connector is for the motor and

disconnecting it. I then used one side of a mated pair of spare

connectors that I have to reconnect to the motor. Track power for a

decoder cannot be picked up from the motor leads leading from the

body as the motor is switched along with the lights. Separate

switching of the lights is needed to allow service mode programming

on a programming track.

However, track power contacts can be accessed at these two

terminals near the fuel tanks. These are raw and unswitched track

power.

However, track power contacts can be accessed at these two

terminals near the fuel tanks. These are raw and unswitched track

power.

Getting

the four wires (two for the motor, two for unswitched track power)

back inside is a little more difficult. There is a PWB inside the

floor but it appears to be narrow judging from the exploded parts

diagram. One SHOULD be able to drill up through the floor(s) and

miss it, but it is not necessary to take that risk. Instead, drill

a hole in the front wall behind the engineer. This hole comes

through just above the floor inside without the risk of drilling

through something important. The wires can snake across the bottom

of the loco and go up around a front step. This hole isn't in the

perfect spot, it wants to be nudged inward just a little as the cab

door blocks part of it when the cab is installed.

Getting

the four wires (two for the motor, two for unswitched track power)

back inside is a little more difficult. There is a PWB inside the

floor but it appears to be narrow judging from the exploded parts

diagram. One SHOULD be able to drill up through the floor(s) and

miss it, but it is not necessary to take that risk. Instead, drill

a hole in the front wall behind the engineer. This hole comes

through just above the floor inside without the risk of drilling

through something important. The wires can snake across the bottom

of the loco and go up around a front step. This hole isn't in the

perfect spot, it wants to be nudged inward just a little as the cab

door blocks part of it when the cab is installed.

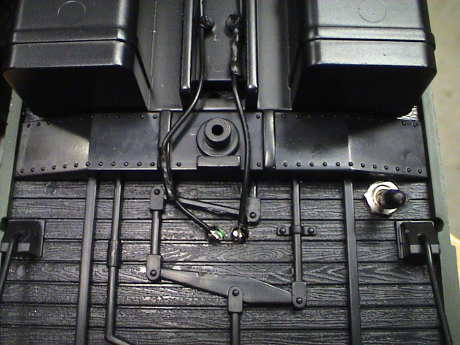

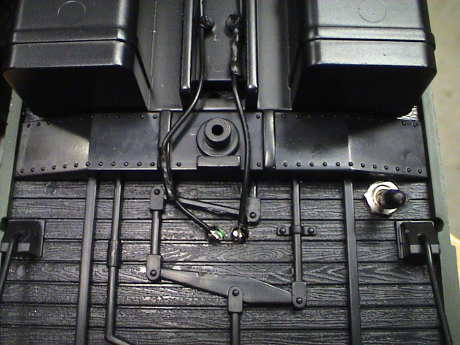

This is

the final installation with the AD320. This old decoder is working

well enough that it might just stay in there. Power for the

interface circuit is picked off the lighting wires above the cab.

The battery charges via the interface circuit board and these two

wires all the time that the lights are on and the Railbus is

sitting on powered track. The AD320 gets it's track power from the

two terminals underneath the floor right behind the fuel tank. The

motor leads are also snaked across the bottom of the Railbus to a

connector that plugs into the motor brick. The AD320 has two

function outputs besides the headlights. These are wired to the

Sierra to manually trigger the bell and horn.

This is

the final installation with the AD320. This old decoder is working

well enough that it might just stay in there. Power for the

interface circuit is picked off the lighting wires above the cab.

The battery charges via the interface circuit board and these two

wires all the time that the lights are on and the Railbus is

sitting on powered track. The AD320 gets it's track power from the

two terminals underneath the floor right behind the fuel tank. The

motor leads are also snaked across the bottom of the Railbus to a

connector that plugs into the motor brick. The AD320 has two

function outputs besides the headlights. These are wired to the

Sierra to manually trigger the bell and horn.

The AD320, the interface board, the battery and the Sierra are

all held in place with pieces of foam mounting tape.

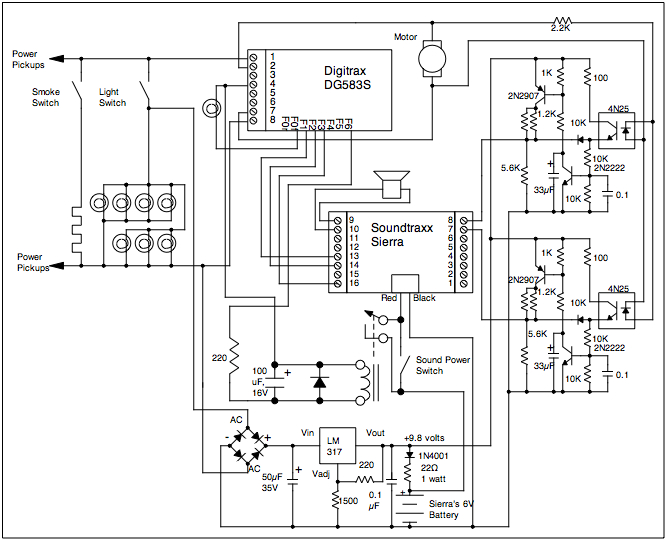

The AD320 did not

stay in the Railbus. It was working fine but I needed it elsewhere

because it was just small enough to fit in James. I also wanted an extra

function output to drive a sound enable relay. It's getting pretty

busy in there now with the speaker, Sierra, battery for the Sierra,

interface circuit for the Sierra, DCC decoder and sound enable

relay. The relay is down on the floor between the sacks. This all

works and I didn't have to change anything on the Sierra interface

circuit to accommodate the high switching frequency of the Digitrax

DG583S decoder.

The AD320 did not

stay in the Railbus. It was working fine but I needed it elsewhere

because it was just small enough to fit in James. I also wanted an extra

function output to drive a sound enable relay. It's getting pretty

busy in there now with the speaker, Sierra, battery for the Sierra,

interface circuit for the Sierra, DCC decoder and sound enable

relay. The relay is down on the floor between the sacks. This all

works and I didn't have to change anything on the Sierra interface

circuit to accommodate the high switching frequency of the Digitrax

DG583S decoder.

This is the revised schematic of

the "final" DCC installation in the Classic Railbus. The relay

allows the decoder to activate the sound system in parallel with

the manual switch. When the decoder controls the sound system, the

sound system will shut down when the decoder commands it or track

power shuts off. This allows me to "forget" to turn it off, it'll

go off by itself and not discharge the battery.

This is the revised schematic of

the "final" DCC installation in the Classic Railbus. The relay

allows the decoder to activate the sound system in parallel with

the manual switch. When the decoder controls the sound system, the

sound system will shut down when the decoder commands it or track

power shuts off. This allows me to "forget" to turn it off, it'll

go off by itself and not discharge the battery.

[ Top ] [ Home ] [ Up ] [

Previous Page ] [ Next Page ]

This page has been accessed  times since 22 July 00.

times since 22 July 00.

© 2000-2009 George Schreyer

Created July 22, 2000

Last Updated February 3, 2009

Aristo has recently released their version of a

rail bus. The rail bus evolved to fill a need on narrow gauge,

shortline and branchline railroads. As passenger traffic dropped

off due to competition from automobiles and highway busses, the

railroads could no longer afford to run a regular steam engine

which pulled maybe one coach. To reduce costs an old wooden coach

was often cut up and grafted to an large automobile or truck frame.

The original gasoline engine and manual transmission were

sufficient to haul the rail bus, and on some lines, maybe an

additional coach if the grades were mild. The rail busses kept

these struggling railroads in business for a few extra years, but

eventually most of these roads folded anyway.

Aristo has recently released their version of a

rail bus. The rail bus evolved to fill a need on narrow gauge,

shortline and branchline railroads. As passenger traffic dropped

off due to competition from automobiles and highway busses, the

railroads could no longer afford to run a regular steam engine

which pulled maybe one coach. To reduce costs an old wooden coach

was often cut up and grafted to an large automobile or truck frame.

The original gasoline engine and manual transmission were

sufficient to haul the rail bus, and on some lines, maybe an

additional coach if the grades were mild. The rail busses kept

these struggling railroads in business for a few extra years, but

eventually most of these roads folded anyway. 26 May 02

26 May 02 8 Oct 08

8 Oct 08 The Aristo Classic Rail Bus is a very smooth

running model. Power pickup is on all eight wheels and is very

steady. The wheels themselves do not appear to be susceptible to

pitting so that they tend to stay clean. The motor runs very

smoothly. The bus will maintain very slow speeds at about one tie

per second. It'll go slower on straight track, but the additional

load when transitioning to a 2' radius turn will stall it. Like

most direct worm gear drives, the bus has a slight tendency to

lurch at some speeds and loads on some downgrades.

The Aristo Classic Rail Bus is a very smooth

running model. Power pickup is on all eight wheels and is very

steady. The wheels themselves do not appear to be susceptible to

pitting so that they tend to stay clean. The motor runs very

smoothly. The bus will maintain very slow speeds at about one tie

per second. It'll go slower on straight track, but the additional

load when transitioning to a 2' radius turn will stall it. Like

most direct worm gear drives, the bus has a slight tendency to

lurch at some speeds and loads on some downgrades. The Aristo Classic Rail bus represents a

typical combo coach type of bus. The bus was divided into three

parts, a driver's compartment, small baggage, mail and freight

section, and a coach section. These busses typically stopped

anywhere on the line where somebody flagged them to pick up or drop

off passengers, mail and freight. The baggage compartment is easily

big enough to hold a sound system, batteries and a control

receiver.

The Aristo Classic Rail bus represents a

typical combo coach type of bus. The bus was divided into three

parts, a driver's compartment, small baggage, mail and freight

section, and a coach section. These busses typically stopped

anywhere on the line where somebody flagged them to pick up or drop

off passengers, mail and freight. The baggage compartment is easily

big enough to hold a sound system, batteries and a control

receiver. Aristo built this model around a narrow

gauge 1/24 scale Sierra combo coach but the model is identified as

1/29 scale. However the general proportions of the model are much

larger than other 1/29 scale equipment. It is nearly an inch taller

than a standard heavyweight coach.

Aristo built this model around a narrow

gauge 1/24 scale Sierra combo coach but the model is identified as

1/29 scale. However the general proportions of the model are much

larger than other 1/29 scale equipment. It is nearly an inch taller

than a standard heavyweight coach. The Rail

bus is even 1/2" taller than a Bachmann coach (the scale of the

Bachmann coach is debatable). The rear door of the rail bus is just

over 6' tall in 1/29 scale so this comes out ok, but the driver's

door is nearly 8' tall in 1/29 scale. Based on the match to other

coaches, the rail bus would look more appropriate on a 1/24 scale

1930's era narrow gauge layout than a more modern standard gauge

one.

The Rail

bus is even 1/2" taller than a Bachmann coach (the scale of the

Bachmann coach is debatable). The rear door of the rail bus is just

over 6' tall in 1/29 scale so this comes out ok, but the driver's

door is nearly 8' tall in 1/29 scale. Based on the match to other

coaches, the rail bus would look more appropriate on a 1/24 scale

1930's era narrow gauge layout than a more modern standard gauge

one. The rail bus

comes equipped with a body mounted standard Aristo knuckle coupler.

A hook and loop coupler is supplied in the box. The coupler is

mounted so that it can swivel but it still puts quite a bit of

twisting force on a following car in a tight turn. The following

car does not actually derail, but its trying to. The pilot has a

drawbar attached.

The rail bus

comes equipped with a body mounted standard Aristo knuckle coupler.

A hook and loop coupler is supplied in the box. The coupler is

mounted so that it can swivel but it still puts quite a bit of

twisting force on a following car in a tight turn. The following

car does not actually derail, but its trying to. The pilot has a

drawbar attached. I mounted

an LGB knuckle coupler to the rail bus. The mount required some

modification but the changes were not difficult. The LGB coupler

mounts directly to the existing coupler post. Some small pieces of

styrene are used to fabricate the centering spring capture feature

that was on the original coupler. The centering spring needs to be

formed differently to clear the back of the LGB coupler tang and

mounting screw.

I mounted

an LGB knuckle coupler to the rail bus. The mount required some

modification but the changes were not difficult. The LGB coupler

mounts directly to the existing coupler post. Some small pieces of

styrene are used to fabricate the centering spring capture feature

that was on the original coupler. The centering spring needs to be

formed differently to clear the back of the LGB coupler tang and

mounting screw. I

have not disassembled the Railbus far enough to visually inspect

the wiring, but it has to be pretty simple and this schematic

describes it's behavior. There are two switches under the body near

the rear truck, one is labeled "Smoke" and the other "Lights." The

only issue is that the motor and lights are switched together. The

headlight is non-directional but that could be easily changed with

the addition of a diode in a headlight wire.

I

have not disassembled the Railbus far enough to visually inspect

the wiring, but it has to be pretty simple and this schematic

describes it's behavior. There are two switches under the body near

the rear truck, one is labeled "Smoke" and the other "Lights." The

only issue is that the motor and lights are switched together. The

headlight is non-directional but that could be easily changed with

the addition of a diode in a headlight wire. Sound

installation in the Railbus isn't too difficult depending on where

you mount the speaker. I used another of my swap meet computer

speakers in the baggage compartment pointing rearward. These

speakers have their own cabinet so I didn't have to worry about

sealing anything up. The sound comes out the open cargo doors. The

battery is hot glued to the top of the speaker box. The sound card

itself is attached to the floor with double backed foam tape right

behind the speaker so that the programming buttons can be reached

through the doors. I hot glued a couple of bags of coffee to act as

view blocks so that the card cannot be seen looking through the

doors. Power for the installation is tapped from the headlight

wiring above the cab. The power switch (switching both track power

and the battery) is mounted in a hole in the floor. This hole was

drilled about 1/2" in from the edge of the floor, right behind the

unused bolster casting in the floor.

Sound

installation in the Railbus isn't too difficult depending on where

you mount the speaker. I used another of my swap meet computer

speakers in the baggage compartment pointing rearward. These

speakers have their own cabinet so I didn't have to worry about

sealing anything up. The sound comes out the open cargo doors. The

battery is hot glued to the top of the speaker box. The sound card

itself is attached to the floor with double backed foam tape right

behind the speaker so that the programming buttons can be reached

through the doors. I hot glued a couple of bags of coffee to act as

view blocks so that the card cannot be seen looking through the

doors. Power for the installation is tapped from the headlight

wiring above the cab. The power switch (switching both track power

and the battery) is mounted in a hole in the floor. This hole was

drilled about 1/2" in from the edge of the floor, right behind the

unused bolster casting in the floor. As

I was ripping into the Railbus to install DCC, I elected to replace

the Sierra gelcell battery with a 5 AAA cell NiMH pack that I had

assembled for the Bachmann Railtruck. Only after I had made the

pack did I find out that I couldn't get a Sierra for it because the

Sierra has been discontinued. The existing battery was six years

old so I figured that it had lasted well past it's expected

life.

As

I was ripping into the Railbus to install DCC, I elected to replace

the Sierra gelcell battery with a 5 AAA cell NiMH pack that I had

assembled for the Bachmann Railtruck. Only after I had made the

pack did I find out that I couldn't get a Sierra for it because the

Sierra has been discontinued. The existing battery was six years

old so I figured that it had lasted well past it's expected

life. This is the schematic of the DCC

installation in the Railbus. There is a lot of stuff here, but this

is what it takes to get a Sierra to work properly with DCC or most

RC systems. The Railbus uses a "diesel" version of the Sierra, but

programmed with the sounds of a Goose. The diesel systems do not

detect the start and stop events reliably without optical isolators

between the motor and the Sierra. The optical isolators fix the

start and stop sounds, but they screw up the coordination between

the sound of the motor revving up and the actual speed of the

Railbus. This circuit looks a little involved, but it fixes all

that, see my

This is the schematic of the DCC

installation in the Railbus. There is a lot of stuff here, but this

is what it takes to get a Sierra to work properly with DCC or most

RC systems. The Railbus uses a "diesel" version of the Sierra, but

programmed with the sounds of a Goose. The diesel systems do not

detect the start and stop events reliably without optical isolators

between the motor and the Sierra. The optical isolators fix the

start and stop sounds, but they screw up the coordination between

the sound of the motor revving up and the actual speed of the

Railbus. This circuit looks a little involved, but it fixes all

that, see my  However, track power contacts can be accessed at these two

terminals near the fuel tanks. These are raw and unswitched track

power.

However, track power contacts can be accessed at these two

terminals near the fuel tanks. These are raw and unswitched track

power. Getting

the four wires (two for the motor, two for unswitched track power)

back inside is a little more difficult. There is a PWB inside the

floor but it appears to be narrow judging from the exploded parts

diagram. One SHOULD be able to drill up through the floor(s) and

miss it, but it is not necessary to take that risk. Instead, drill

a hole in the front wall behind the engineer. This hole comes

through just above the floor inside without the risk of drilling

through something important. The wires can snake across the bottom

of the loco and go up around a front step. This hole isn't in the

perfect spot, it wants to be nudged inward just a little as the cab

door blocks part of it when the cab is installed.

Getting

the four wires (two for the motor, two for unswitched track power)

back inside is a little more difficult. There is a PWB inside the

floor but it appears to be narrow judging from the exploded parts

diagram. One SHOULD be able to drill up through the floor(s) and

miss it, but it is not necessary to take that risk. Instead, drill

a hole in the front wall behind the engineer. This hole comes

through just above the floor inside without the risk of drilling

through something important. The wires can snake across the bottom

of the loco and go up around a front step. This hole isn't in the

perfect spot, it wants to be nudged inward just a little as the cab

door blocks part of it when the cab is installed. This is

the final installation with the AD320. This old decoder is working

well enough that it might just stay in there. Power for the

interface circuit is picked off the lighting wires above the cab.

The battery charges via the interface circuit board and these two

wires all the time that the lights are on and the Railbus is

sitting on powered track. The AD320 gets it's track power from the

two terminals underneath the floor right behind the fuel tank. The

motor leads are also snaked across the bottom of the Railbus to a

connector that plugs into the motor brick. The AD320 has two

function outputs besides the headlights. These are wired to the

Sierra to manually trigger the bell and horn.

This is

the final installation with the AD320. This old decoder is working

well enough that it might just stay in there. Power for the

interface circuit is picked off the lighting wires above the cab.

The battery charges via the interface circuit board and these two

wires all the time that the lights are on and the Railbus is

sitting on powered track. The AD320 gets it's track power from the

two terminals underneath the floor right behind the fuel tank. The

motor leads are also snaked across the bottom of the Railbus to a

connector that plugs into the motor brick. The AD320 has two

function outputs besides the headlights. These are wired to the

Sierra to manually trigger the bell and horn. The AD320 did not

stay in the Railbus. It was working fine but I needed it elsewhere

because it was just small enough to fit in

The AD320 did not

stay in the Railbus. It was working fine but I needed it elsewhere

because it was just small enough to fit in  This is the revised schematic of

the "final" DCC installation in the Classic Railbus. The relay

allows the decoder to activate the sound system in parallel with

the manual switch. When the decoder controls the sound system, the

sound system will shut down when the decoder commands it or track

power shuts off. This allows me to "forget" to turn it off, it'll

go off by itself and not discharge the battery.

This is the revised schematic of

the "final" DCC installation in the Classic Railbus. The relay

allows the decoder to activate the sound system in parallel with

the manual switch. When the decoder controls the sound system, the

sound system will shut down when the decoder commands it or track

power shuts off. This allows me to "forget" to turn it off, it'll

go off by itself and not discharge the battery.