1 Mar 09

1 Mar 09 19 Aug 08

19 Aug 08 19 Aug 08

19 Aug 08 1 Mar 09

1 Mar 09 1 Mar 09

1 Mar 09 19 Aug 08

19 Aug 08 19 Aug 08

19 Aug 08 1 Mar 09

1 Mar 09Large scale smoke units operate by vaporizing a special oil. The oil is especially formulated to evaporate at a fairly low temperature while forming fairly large and visible droplets. The oil is also formulated to evaporate completely leaving no residue behind. Another important characteristic is that the oil has very low viscosity so that it runs along surfaces well. This last characteristic is what controls the rate of smoke production.

Unfortunately, these fluids only come in white "smoke." It sure would be nice to blow out black stuff, but so far there is no oil that will show black. We'll have to settle for white.

All the available smoke units heat a small quantity of fluid to evaporation. The fluid feed rate is controlled by the design of the generator.

One common characteristic of all smoke units is that their lifetime is very strongly influenced by their temperature which is controlled by the evaporation of the fluid. If this source of cooling is removed, for example by running out of fluid, the heater temperature will increase rapidly and the heater will quickly fail.

There are a variety of different implementations of smoke systems and fluids. Their characteristics and differences are the subjects of this page.

[ Top ]

The LGB smoke

unit is a cylindrical unit that sits inside the smokestack. It has

a central heater element which is surrounded by smoke fluid.

Capillary action draws the smoke fluid up along the heater element

where it is evaporated with some considerable force. This causes

the vapor to be ejected at high speed. Sometimes the unit will spit

and sputter and even blow smoke rings.

The LGB smoke

unit is a cylindrical unit that sits inside the smokestack. It has

a central heater element which is surrounded by smoke fluid.

Capillary action draws the smoke fluid up along the heater element

where it is evaporated with some considerable force. This causes

the vapor to be ejected at high speed. Sometimes the unit will spit

and sputter and even blow smoke rings.

It would appear that the LGB smoke unit is manufactured by Seuthe for LGB and others. The Lionel Atlantic uses a Seuthe element. If you can find them, Seuthe units cost somewhat less than LGB units. The LGB units come in 3 different operating voltages, 5 volts, 18 volts and 24 volts. Seuthe units are available at other voltages as well.

The 5 volt units will likely have less of a tendency to burn up simply because their input voltage is usually well controlled to produce an optimum power level of 1.5 watts. For example, the smoke unit in the Lehmann Porter cannot be turned off. It is a 5 volt unit and mine has many hundreds of operating hours with a dry smoke unit and it still works. The higher voltage units are intended to run directly from track power which has a wide voltage range. To get enough smoke at lower track voltages, the unit has to run at much higher power at high track voltages. The dissipation can run to 2.5 watts at the maximum rated voltage and if run dry at high voltage, they are at risk of failing.

The best setup for reliability is to use 5 volt units with a 5 volt regulator from regular track power. With battery power or DCC, where the available voltage is pretty constant, then high voltage units should be used with a resistor in series to limit the dissipation of the unit to about 1.5 watts. At 1.5 watts, the units smoke fairly well and are very reliable. If you want more smoke, then you can run the dissipation up a little and get more smoke at the risk of reduced smoke unit lifetime.

If too much smoke fluid is poured into the unit, the fluid will convectively cool the heater to the point that it'll never get hot enough to smoke. The most common symptom of too much fluid, besides no smoke, is spitting of large droplets of fluid. In this case, you can wait a day or so until the fluid evaporates, or you can run the unit until it spits out enough to start working properly again or you can turn the loco over and pour out the excess.

As the smoke fluid level decreases due to consumption of fluid, more and more of the hot element is exposed and what fluid does get drawn up the heater is heated explosively. The unit tends to generate smoke most violently just before it runs out of fluid. A good load of fluid is about 15 drops +/- 5 drops.

The LGB unit is quite compact so that it is easy to retrofit their replacement units into other locos. For regular track powered locos, I use 5 volt units for replacement because with the addition of a 5 volt regulator and Aristo PWC, smoke production is excellent, even at very low speeds. This combination works much better than the typical LGB constant smoke system, see PWC Tips for more details on voltage regulators. For DCC locos, I use the 24 volt element, sometimes with a 39 ohm 1/2 watt resistor in series with it. This causes the 24 volt unit to run at 16 to 18 volts. It still makes enough smoke and at the lower voltage it smokes longer and is less likely to burn up if run dry. The downside of the LGB unit is that it somewhat expensive, $20 or more depending on where you buy it.

[ Top ]

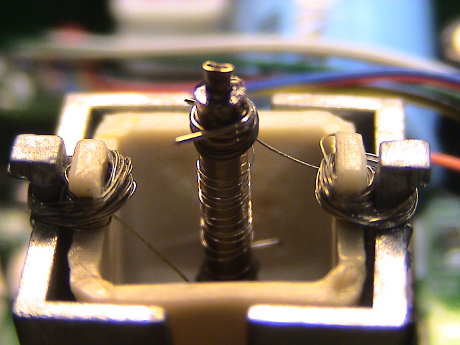

The

Bachmann smoke unit is designed to sit below the smoke stack. A

heater element is supported in a small tub. One of my Shay's had

the same arrangement as a Big Hauler, the heater is supported on

end in the center of the tub. A metal tube is heated by a wire coil

wound around the outside of the tube. Fluid is drawn up the inside

of the tube from the tub and heated. The vapor is ejected straight

upward from the open upper end of the tube. This ejection of the

smoke allows most of the smoke to go up the stack even though the

unit itself sits down in the smokebox. When making good smoke,

parts of the heater often run red hot (above 900 degrees C) which

is why these units often don't last very long.

The

Bachmann smoke unit is designed to sit below the smoke stack. A

heater element is supported in a small tub. One of my Shay's had

the same arrangement as a Big Hauler, the heater is supported on

end in the center of the tub. A metal tube is heated by a wire coil

wound around the outside of the tube. Fluid is drawn up the inside

of the tube from the tub and heated. The vapor is ejected straight

upward from the open upper end of the tube. This ejection of the

smoke allows most of the smoke to go up the stack even though the

unit itself sits down in the smokebox. When making good smoke,

parts of the heater often run red hot (above 900 degrees C) which

is why these units often don't last very long.

The

other Shay had an arrangement more like this. The heater was

horizontal with the four support wires immersed in the smoke fluid.

Fluid was drawn up the wires and evaporated directly from the

heater coil. I don't think that this was the desired arrangement as

this unit burnt up in a very short time.

The

other Shay had an arrangement more like this. The heater was

horizontal with the four support wires immersed in the smoke fluid.

Fluid was drawn up the wires and evaporated directly from the

heater coil. I don't think that this was the desired arrangement as

this unit burnt up in a very short time.

The Bachmann unit can generate A LOT of smoke, but it also consumes fluid really fast, two or three minutes on a load is typical. Its not a good idea to put more than 5 to 10 drops into the smoke unit. Since the unit sits inside the boiler, any overflow will spill inside the engine. On a Shay, it'll drain out of the boiler and into the front truck. The light smoke oil will then dissolve or dilute the grease in the front truck. If you put enough fluid in to partially immerse the heater element, the fluid will evaporate from the outside of the heater as well. This vapor is not directed up the stack and instead fills the boiler with smoke.

The top of the smoker tube is often partially pinched, probably to increase the velocity of the ejected smoke. However, on SOME units, the restriction seems to be a little excessive, the tube is either completely or almost completely pinched off. The smoke output of a unit that smokes poorly for this reason can be increased by clipping off the very tip of the pinched tube to increase the area of the exit port a little. The unit will consume fluid at a higher rate so be sure to keep track of fluid level and don't let it run dry or you'll be replacing the smoker soon.

On older Bachmann Big Hauler smoke units the wires are wound around lugs on the plastic cup and are pressed against the heat sink castings. These connections can get flaky even of the heater isn't actually burned up. On the Shay, the wires from the smoke unit are wrapped around lugs on the heatsinks themselves so that this problem is avoided.

The best fix for burnt up a Bachmann smoke unit is to either do without smoke or change the Bachmann unit out for an LGB unit. See Bachmann Shay Tips for instructions on changing the smoke unit in a Bachmann Shay. The procedure for a 10 Wheeler is similar.

[ Top ]

The Aristo

smoke unit is a little different than the others. It doesn't run as

hot as the others and doesn't eject smoke as well by itself, so

Aristo provides a method to pump air through it. The Aristo smoke

unit typically doesn't generate the same density of smoke as either

the LGB or Bachmann units, but it will smoke much longer, perhaps

three to four times, on one load of fluid.

The Aristo

smoke unit is a little different than the others. It doesn't run as

hot as the others and doesn't eject smoke as well by itself, so

Aristo provides a method to pump air through it. The Aristo smoke

unit typically doesn't generate the same density of smoke as either

the LGB or Bachmann units, but it will smoke much longer, perhaps

three to four times, on one load of fluid.

In the diesels and the older style Pacific, there is a fan that forces air through the smoke unit. On the older Pacific, 0-4-0 and Rogers, there is a piston type air pump in a cylinder that puffs air through the unit so that you get steadily timed puffs out the stack, although there is only one puff per driver turn instead of the "correct" 4 puffs per driver turn. The C-16 doesn't have any air pump at all. It operates similarly to the LGB unit. The older Pacific will also leak smoke from around the cylinders.

The C-16, 0-4-0, Rogers and Classic Railbus use a differently designed smoke unit. This one is cylindrical and can be unplugged for replacement. The heater and a wick fill the inside of the unit.

The

oil in the diesel Aristo unit is conducted to the heater by a wick

and the capacity of the smoke unit is large so that you have to put

in quite a bit of smoke fluid or it won't smoke well or at all. 25

drops is the recommended load and it may last for half an hour.

Since the wick controls how much fluid gets to the heater, these

units can even hold more fluid without getting slowed down like the

other units. However, the wick must be positioned so that the smoke

fluid can find it. A unit that doesn't make much smoke or smokes

only for a short time probably needs the wick moved. Open the unit

and arrange the wick so that it sits in the lowest part of the

smoke unit floor so that it can soak up any fluid that is in

there.

The

oil in the diesel Aristo unit is conducted to the heater by a wick

and the capacity of the smoke unit is large so that you have to put

in quite a bit of smoke fluid or it won't smoke well or at all. 25

drops is the recommended load and it may last for half an hour.

Since the wick controls how much fluid gets to the heater, these

units can even hold more fluid without getting slowed down like the

other units. However, the wick must be positioned so that the smoke

fluid can find it. A unit that doesn't make much smoke or smokes

only for a short time probably needs the wick moved. Open the unit

and arrange the wick so that it sits in the lowest part of the

smoke unit floor so that it can soak up any fluid that is in

there.

On the diesels, smoke fluid is dripped directly down the exhaust stack. On the 0-4-0, Rogers and C-16, fluid is dripped down the smokestack. However on the older Pacific, the smoke fluid is injected into a covered box that is located directly under the smokebox. On the prototype, this box would normally hold train control equipment.

The Rogers, 0-4-0,

Classic Railbus and Long Steel Caboose all use this plug in unit.

I've had several of these fail and replaced them with LGB units

wired to a monaural phone plug so that the replacement assembly

plugs right back in. This works on the locos but it would not work

on the Railbus or caboose.

The Rogers, 0-4-0,

Classic Railbus and Long Steel Caboose all use this plug in unit.

I've had several of these fail and replaced them with LGB units

wired to a monaural phone plug so that the replacement assembly

plugs right back in. This works on the locos but it would not work

on the Railbus or caboose.

All of the older Aristo units are also more easily replaced than the others. In all cases that I am aware of, the smoke unit can simply be pulled out and a new one plugged in. The smoke stack assembly on the older Pacific must be partially pulled out to unlock it's smoke unit.

The older Aristo diesel units are all molded in black plastic for manufacturing logistics reasons. If you want to paint them, they take paint well and don't get hot enough on the top to damage the paint. I've done the ones on my Warbonnet FA's, Floquil Bright Silver matches the Aristo paint almost perfectly. Floquil Santa Fe Blue matches the blue/yellow paint scheme well. If you do paint them, paint the stack too, then clean off some of the paint around the top of the stack with a lacquer thinner coated cotton swab to simulate the soot stains that are part and parcel of Alco diesels.

As of production of the SD45 in

about 2001, AristoCraft has been changing their smoke units to a

new fan driven version. This unit has a similar heating element to

the older ones, but it also has built in electronics that sense

when the unit has run dry and shut it down. More detail on this

unit can be found in my SD45

Tips page. The newer Pacific, Mikado, Mallet, FA, FB, RS3 and

U25 also use this newer self contained unit.

As of production of the SD45 in

about 2001, AristoCraft has been changing their smoke units to a

new fan driven version. This unit has a similar heating element to

the older ones, but it also has built in electronics that sense

when the unit has run dry and shut it down. More detail on this

unit can be found in my SD45

Tips page. The newer Pacific, Mikado, Mallet, FA, FB, RS3 and

U25 also use this newer self contained unit.

All of the newer units contain

a fan, some control electronics along with a heater and wick

similar to the older units. These units can also hold quite bit of

fluid, but it is not so critical to keep them wet. They will sense

when they go dry and shut down to protect themselves.

All of the newer units contain

a fan, some control electronics along with a heater and wick

similar to the older units. These units can also hold quite bit of

fluid, but it is not so critical to keep them wet. They will sense

when they go dry and shut down to protect themselves.

This is a very early version of the newer unit, it was in the original SD45. Note that the heater leads are formed straight away from the heater body and soldered to the board.

In later versions

the heater leads are bent straight down and plug into small sockets

on the board. Greg Elmassian has expressed concerns in his

web page that the stress created by the lead forming produces

strains on the end caps and causes some units to develop flakey

electrical connections in the heater resulting in unreliable

operation of the unit.

In later versions

the heater leads are bent straight down and plug into small sockets

on the board. Greg Elmassian has expressed concerns in his

web page that the stress created by the lead forming produces

strains on the end caps and causes some units to develop flakey

electrical connections in the heater resulting in unreliable

operation of the unit.

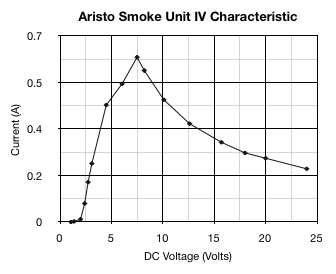

This is

an IV characteristic of a single Aristo smoke unit with DC applied.

Above 8 volts or so it making full smoke. The power stays

relatively constant above 8 volts. It will run to 24 volts but

there are problems at high voltages. The units will shut down

prematurely.

This is

an IV characteristic of a single Aristo smoke unit with DC applied.

Above 8 volts or so it making full smoke. The power stays

relatively constant above 8 volts. It will run to 24 volts but

there are problems at high voltages. The units will shut down

prematurely.

I was testing my RDC with 22 volts of DCC on the track and the unit shut down after 2 minutes and ran only 1 minute each time I restarted it by turning the smoke unit off and on again. I thought that the unit was defective. Then as I was testing my SD45 on the same track voltage, it ran for 15 minutes on a partial load of fluid. At the 15 minute mark, it TRIED to shut down and failed, restarting again by itself. I thought that this was odd. Later, I tested a loose smoke unit on the bench on the same 22 volts of DCC and it shut down after 2 minutes, acting just like the unit in the RDC. Then I retested it on my bench supply at about 18 volts DC and it ran for 15 minutes.

Does it not like DCC? No, it's fine with DCC, it just doesn't like high voltages. I retested the RDC with 16 volts of DCC and the smoke unit ran for 15 minutes. A retest with 22 V of DCC and it shut down.

During the test run to get this IV curve on DC, I ran it all the way to 24 volts. It ran until it got there and then tried shut down after about a minute at 24 volts. A failed shutdown is indicated by the fan slowing for about half a second and then coming back on. I restarted it and tweaked the voltage up a little and it shut down immediately at 24.5 volts. Backing off to 22 VDC allowed it to run for 2 minutes. Backing off further to 20 volts allowed it stay on until it ran out of fluid. This is consistent with the results I got with DCC on the RDC.

Some of these units don't like high track voltage and it can make them

misbehave. The affected ones will get a little trigger happy and declare a fluid outage when there is still several minutes of fluid left. In the case where the maximum track voltage is too high

for any given smoke unit, a resistor, like the one in the photo,

can be wired in series with the smoke unit to reduce the applied

voltage. I didn't have exactly the right value so I made one from

two 33 ohm 1 watt resistors in parallel. Selection of the resistor

is not completely straight forward because of the non-linearity of

the IV curve. If the resistor is too large, the unit will try to

draw so much current as it is starting such that the voltage never

climbs high enough to reach the point where the current is highest

at about 8 volts. If the resistor is too small, it won't produce

the desired voltage dropping effect. I found that a 20 ohm resistor

is about the maximum allowable on this particular unit. When the

unit is turned on with 20 ohms in series, the fan comes on slowly

and the unit starts to heat up. After 10 seconds or so, the current

drops a little and the voltage can then increase such that it gets

over the "hump" at 8 volts and the current begins to decrease. Then

the voltage increases rapidly until it settles down at about 15

volts. Resistors less than 10 ohms don't drop enough voltage at the

lower currents drawn at the highest applied voltages. A resistor in

the range of 10 to 15 ohms at 2 watts seems to allow the units to

start immediately and yet still drop the operating voltage enough

such that the units do not shut down until they actually do run out

of fluid.

Some of these units don't like high track voltage and it can make them

misbehave. The affected ones will get a little trigger happy and declare a fluid outage when there is still several minutes of fluid left. In the case where the maximum track voltage is too high

for any given smoke unit, a resistor, like the one in the photo,

can be wired in series with the smoke unit to reduce the applied

voltage. I didn't have exactly the right value so I made one from

two 33 ohm 1 watt resistors in parallel. Selection of the resistor

is not completely straight forward because of the non-linearity of

the IV curve. If the resistor is too large, the unit will try to

draw so much current as it is starting such that the voltage never

climbs high enough to reach the point where the current is highest

at about 8 volts. If the resistor is too small, it won't produce

the desired voltage dropping effect. I found that a 20 ohm resistor

is about the maximum allowable on this particular unit. When the

unit is turned on with 20 ohms in series, the fan comes on slowly

and the unit starts to heat up. After 10 seconds or so, the current

drops a little and the voltage can then increase such that it gets

over the "hump" at 8 volts and the current begins to decrease. Then

the voltage increases rapidly until it settles down at about 15

volts. Resistors less than 10 ohms don't drop enough voltage at the

lower currents drawn at the highest applied voltages. A resistor in

the range of 10 to 15 ohms at 2 watts seems to allow the units to

start immediately and yet still drop the operating voltage enough

such that the units do not shut down until they actually do run out

of fluid.

[ Top ]

More details of specific smoke units and upgrades to smoke units in specific locomotives can be found in the table below.

| Locomotive | Notes |

|---|---|

| Aristo SD45 | Description and test data |

| Bachmann Big Hauler | Electronics upgrade |

| Bachmann Shay | Electronics and smoke unit upgrade |

| Bachmann Climax | Electronics upgrade |

| Aristo RS-3 | Electronics upgrades |

| Aristo Pacific | Description |

| Aristo 0-4-0 | Description |

| Aristo FA-1 | Repairs and upgrades |

| Aristo Rogers 2-4-2 | Upgrade |

| USA Trains GP-9 | Electronics upgrade |

| Aristo 2-8-0 | Upgrade |

[ Top ]

The various smoke units are designed to operate on a wide range of voltage ranging from 5 to 24 volts. Running a smoke unit at 20% or so below its rated voltage will materially improve the unit's life expectancy, especially when run dry, but will also result in some reduction of smoke output.

Some units, such as the LGB 5 volt units, seem to be able to tolerate dry operation well. Others, like Bachmann units, do not tolerate dry running at all. I believe that this is mostly due to the amount of nonlinear resistance that the unit has. As most metals heat, their resistivity increases. With the proper selection of wire for the smoke unit heater, its resistance can substantially increase as it gets hotter, thereby limiting the power delivered to the heater and limiting its temperature increase.

Encased heaters which are not exposed to the oxygen in the air will tend to resist oxidation of the heater wire which will eventually consume the heater. The only encased smoke units that I know of are the LGB units which appear to be manufactured by Seuthe. If you can find Seuthe elements, they will probably cost you a little less than the LGB versions.

The elements have several electrical characteristics which indicate their performance. The cold resistance indicates how much current the unit will draw at turn on. The current will rapidly decrease as the element heats. The smoking current is the normal power consumption of the unit while it is being cooled by evaporation of the smoke fluid. When the unit runs dry and looses its cooling, the heater temperature increases and the current goes down a little more. The larger the decrease in current between smoking and dry, the more the unit will be tolerant of running dry. Note that only the LGB (Seuthe) smoke units show any significant decrease in current when run dry.

Another factor that will significantly impact survival of the smoke unit is whether or not it is driven by a regulator matched to the requirements of the unit. Most newer locos are now including some kind of voltage (or current in USA Trains locos) regulator. If a smoke unit without a regulator is to make reasonable smoke at mid speeds, it will tend to run really hot at higher speeds when the track voltage is higher. This puts the unit under quite a bit of stress. By regulating the voltage to the unit, it can reach full output at mid speed but the voltage on the smoke unit won't increase at higher speeds and overstress the unit.

Note that the cold current is important if you run your smoke unit from the function output of a DCC decoder or other command receiver. Whatever function output that you use MUST be rated for a load greater than the cold current or you run the risk of burning up the function output.

All the units were tested with a DC power supply connected directly to the smoke element itself so that internal voltage drops within a loco's wiring are not taken into account. Also, the voltages used for testing were somewhat arbitrarily selected. Bachmann units were generally tested at lower voltages just to prevent them from burning up during the test.

| Smoke Unit | Test Voltage | Cold | Smoking Current | Dry Current | Notes | |

|---|---|---|---|---|---|---|

| volts | Resistance ohms |

Current amp |

amp | amp | ||

| LGB 5 volt | 5 | 6.9 | 0.724 | 0.3 | 0.27 | moderate smoke |

| LGB 24 volt | 24 | 91 | 0.264 | 0.10 | 0.09 | heavy smoke |

| LGB 24 volt | 20 | 91 | 0.220 | 0.088 | 0.087 | moderate smoke |

| Seuthe #7 | 16 | 44 | 0.363 | 0.141 | 0.129 | heavy smoke |

| Aristo Rogers | 16 | 27 | 0.59 | 0.26 | 0.25 | light smoke |

| Aristo Rogers | 20 | 27 | 0.74 | 0.30 | 0.27 | moderate smoke |

| Aristo FA | 20 | 14.2 | 1.4 | 0.34 | 0.36 | moderate smoke |

| Aristo RS-3 (old version) |

20 | 8.7 | 2.3 | 0.45 | 0.45 | moderate smoke |

| Aristo RS-3 (2nd version) |

5 | 4.8 | 1.04 | 0.49 | 0.49 | light smoke |

| Bachmann Shay | 16 | 72.5 | 0.22 | 0.23 | 0.23 | heavy smoke |

| Bachmann Big Hauler |

12 | 88 | 0.136 | 0.13 | 0.13 | moderate smoke |

| Bachmann Big Hauler |

16 | 88 | 0.182 | 0.18 | 0.17 | heavy smoke |

| Aristo Long Steel Caboose | 20 | 23 | 0.87 | 0.26 | 0.26 | light smoke |

[ Top ]

Smoke fluid is a light oil that can also be used for cleaning track. Its so light that its almost a solvent. See Track Cleaning Tips for more information on using smoke fluid on your track. I've used five types so I have a little information on the relative performance of these types.

LGB smoke fluid works very well and has considerably less odor than San-Val Magic Smoke so its considerably better than Magic Smoke for use indoors. The Magic Smoke bottle is easier to pour from, I tend to spill less Magic Smoke that LGB fluid. Unfortunately, LGB went into bankruptcy in 2008 so there isn't a continuing supply of this stuff unless whoever bought them out continues the product.

Seuthe makes LGB smoke units and the fluid that comes with Seuthe units appears identical to LGB smoke fluid. Seuthe is still in business and suitable replacement for LGB fluid may be available from them.

Lionel fluid, at least the stuff that came with the Atlantic, may also be Seuthe fluid because the Atlantic uses a Seuthe smoke unit.

San-Val Magic Smoke seems to generate more smoke than LGB fluid, but is has a much stronger odor. The manufacturer claims that it has a pine scent. They must have a really odd idea of the smell of a pine forest as I think that it smells more like the inside of an oil refinery. San-Val itself has mostly gone out of business and they don't sell the fluid anymore. It was made by a "Group Ten" company who also doesn't seem to exist anymore.

Bachmann fluid seems to be a little heavier than either Magic Smoke or LGB fluid and smokes at least as well as LGB fluid in an LGB smoke unit. It has no perceptible odor.

Department 56 "Magic Smoke" should not be confused with the San-Val Magic Smoke described above. This is clearly different stuff. Department 56 manufactures collectable ceramic buildings often found in gift stores. Some of their products have smoke generators and they market their own smoke fluid. I find that Department 56 fluid tends to generate denser smoke than the other fluids and lasts at least as long, in some tests twice as long. This stuff has a distinct odor that is strong but less intense than the other Magic Smoke. I also find that after I use it for awhile indoors, my eyes sting. I am going to continue with this stuff outdoors only. According to the Department 56 web site, their fluid was discontinued in 2000 but it can still be found on the internet. Google for it.

Lamp Oil Some people claim that they use ordinary lamp oil for smoke fluid as it is considerably cheaper than the fluids marketed as smoke fluids. I bought a 22 oz bottle at Cost Plus Imports for $2.99. This stuff is Lamplighter Farms Candle & Lamp Oil and claims to be 99% pure paraffin. Paraffin is a family of particular kind of hydrocarbon. Various forms of the paraffin molecule have different atomic weights and different physical characteristics ranging from a waxy solid to a thin liquid at room temperature. In England, what we call kerosene is called paraffin, don't get these mixed up. Other lamp oils may not be paraffin and may work completely differently. See these Wikipedia articles on Kerosene Lamps, Paraffin, and Mineral Oil for some more information on this stuff. At the very end of the article on Mineral Oil, it says that it can be used in model train smoke units.

This stuff claims to be smokeless and odorless. Maybe so if you burn it, but just evaporating it makes lots of smoke that smells strongly of candle wax. The smoke also dissipates MUCH more slowly than the other fluids so I wouldn't want to use this stuff indoors. The label also claims that the fluid is combustible and harmful or fatal if swallowed. I suppose it is reasonable for lamp oil to be combustible. It smokes for about the same length of time as the other fluids and generates a dense smoke stream. I do not know if it leaves any deposits behind that might degrade a smoke unit but it hasn't hurt any of mine.

Crest CRE-29601 Smoke and Track Cleaning Fluid is still available. This stuff claims to be petroleum based which may be a different formulation than the others. It has a distinctly different odor than the others.

None of the fluids seem to have any impact on painted surfaces so spills are not a big problem, but they should be wiped up.

In an LGB smoke generator, I found that all the fluids except the Crest fluid worked well with LGB fluid generating the least dense smoke and Department 56 the most dense but there wasn't a really huge difference between all of them. The Crest fluid hardly worked at all in an LGB unit. Indoors, I would use the LGB fluid due to its considerably lighter odor. Outdoors, its pretty much a wash. Smoke 'em if you got 'em.

In an Aristo smoke unit, I found that LGB fluid hardly worked at all and Department 56 fluid generated the most smoke of the highest density and ran for the longest time. Since the Department 56 Magic Smoke is the cheapest of the lot (not counting the lamp oil) and I run mostly Aristo stuff outdoors, I'll probably continue with the Department 56 until it is gone and then move to the paraffin lamp oil outdoors only.

[ Top ]

All of the fluids mentioned above are refined chemical products. The Department 56 Magic Smoke lists its contents, a chemical called propylene glycol. I found a couple of web sites at Propylene Glycol and ToxFAQsTM for Ethylene Glycol and Propylene Glycol that indicate that this is not particularly healthy stuff. Propylene glycol is a somewhat viscous fluid and is shown in the data to be highly flammable, even explosive. I put a drop of this stuff on the sidewalk and tried to ignite it, no dice. Since propylene glycol dissolves in many other fluids, I suspect that Department 56 Magic Smoke is diluted with something to noninflammable levels.

Because we now know something bad about propylene glycol, it begs the question about the characteristics of the other fluids. These might be just as bad or worse. We can't tell because we don't know what is in them.

Bachmann smoke fluid is viscous and smells and works something like Department 56 Magic Smoke so it might be of similar composition.

San-Val's Magic smoke is much less viscous and has a distinctly different odor that propylene glycol. I have no idea what is in it or how bad it is.

LGB's fluid is very light and is clearly different. It has nearly no odor. I have no idea what this stuff is either.

The Crest fluid is claimed to be petroleum based.

The candle oil is paraffin which in itself is not particularly toxic. Solid paraffin is used to seal jars of home canned fruits and vegetables. it is also used, in the Mineral Oil form, as a laxative so that it doesn't seem to cause a problem when ingested. As a vapor, I do not know what impact it has after being inhaled. However, people have been burning paraffin candles for many years and a serious health risk has not emerged. However, the Wikipedia article on Mineral Oil says: "Due to its low density, it is easily aspirated into the lungs, where it cannot be removed by the body and can cause serious complications such as lipoid pneumonia. Based on this warning, I would not use this stuff indoors.

[ Top ]

Toxic or otherwise, another important safety consideration is the flammability of the smoke fluid. This stuff will be in contact with a very hot heater element and if flammable, it could melt down a plastic engine or start a fire. Some smoke units can run red hot. This is greater than 900°C (1650°F) and is easily enough to ignite a flammable liquid or vapor.

Since flaming smoke units have not been a serious problem, I would expect that the most common smoke fluids are flame safe. However, I felt that some kind of test is in order. I elected to use a very simple test method with the three fluids that I had on hand. I have a couple of more types at the GIRR Mountain Division, when I get there next, I'll test them too.

The results of the first three fluids was good, they basically don't burn. I tested San-Val Magic Smoke, Dept 56 Magic Smoke and Paraffin Lamp Oil. The paper burned up to the edge of the wet area and then burned around the wet area while burning very slowly into the wet area. After the paper had burned around the wet spot, the flame went out leaving most of the wet area unburned. I assume that the wet area didn't burn because of the cooling due to evaporation of the fluid. When I tried to reignite the remaining area with the gas match, I could get it to completely burn, but only by holding the gas match on the area and only after completely evaporating the remaining fluid.

As of 2009, a lot of things have changed in the smoke world. LGB is out of business, availability of their fluid is questionable. San-Val no longer sells their Magic Smoke. Dept 56 no longer makes smoke fluid although there is still some to be found on the Internet. AristoCraft has mostly gone over to the integrated smoke units as locomotives get redesigned for their newer electronics. Bachmann is using regulators on most of their smoke units which materially improves their reliability although the smoke units themselves seem to have some significant performance differences from unit to unit. Seuthe (LGB type) units are still available but they are expensive, about $30.

I ran, and are still running, some tests on some units that I have with currently available smoke fluids. There doesn't seem to be much point in evaluating fluids that are no longer available. I believe that Seuthe and LGB fluids are the same stuff, they work the same and smell the same so I did test with LGB fluid because I have only a small sample of Seuthe fluid. I'll be testing LGB and Aristo smoke fluids and 99% paraffin lamp oil.

The testing itself seeks to answer a few questions:

When selecting a fluid to use, the first thing that I want is to actually be able to see the smoke. It doesn't much matter how long it smokes if I can't see the smoke in the first place. Then I want to know how much to load in order to get the best run time and then know how long to expect it to run so that I can either shut if off when dry or reload it.

Since my environment is DCC which supplied a constant and fairly high (22 VRMS) voltage to the track, this is the condition that I tested with. Most modern units are regulated and so that as long as there is enough voltage, they don't care how much. There is an exception in the AristoCraft case as the units don't quite like 22 volts so in their case, I tested at 16 volts or I added a resistor to tame them down a little.

I did my testing in my garage with the doors open for ventilation. This allowed me to photograph each unit in a controlled environment with more or less constant lighting conditions so that I could use the photos to judge which made denser smoke. There was an issue of wind, but I could pick times where wind was not a big deal and it did allow me to run these tests while it was raining and I couldn't run trains anyway.

I used a 3 ml syringe to measure the fluid load applied because I found that counting drops was unreliable. The different fluids with different viscosities and surface tensions tended to have different droplet sizes so that 10 drops of one fluid is not the same as 10 drops of another.

The testing is partially done and some of it I will have to redo as I learn what works and what doesn't. I started by just adding enough fluid to get the units to smoke and then photographing the result. As I learned how much each kind of unit could tolerate, I reran some of the tests.

The eventual duration tests will be done with a full load of smoke fluid, not at some constant quantity. The idea is not to conserve fluid but to find out how much I need to add to get the maximum duration of the fluid that works the best in any given loco.

The first series of tests tries to answer the first question, which fluid works in which loco without much regard to how long that loco will smoke. Initially, these tests were done at the GIRR, my outdoor layout at my home. Later, I may do the locos at the GIRR Mountain Division but I have 39 locos in total, 27 of which have working smoke units of various kinds, so I'm not going to do them all at once. There are also duplicates of any given design that all seem to work pretty much the same so I am going to do quick test to determine which is the best smoker of the lot and throughly test that one. The idea is to pare the matrix of possible combinations of smoke unit, smoke fluid and fluid load down so that I only have to test a reasonable number of combinations. If a particular fluid smokes poorly in a particular kind of smoke unit, no more testing of that combination is required.

Note that in the photos below, the image of the smoke density isn't as pronounced as what I see with my eyes. I estimate that the visual smoke density is about twice as dense as the photo indicates.

| Locomotive Details | LGB Fluid | Crest Fluid | 99% Paraffin Lamp Oil | Notes |

|---|---|---|---|---|

| AristoCraft

SD45 with integrated smoke unit |

|

|

|

LGB fluid doesn't work at all. Aristo units run at lower temperatures that LGB units and the LGB fluid hardly shows up at all. The lamp oil appeared to do a little better than the Aristo fluid. The smoke density is unspectacular at best. |

| LGB

22232 0-4-0 with 5 volt LGB unit running at 6.4 volts per the LGB design |

|

|

|

LGB fluid worked the best, Aristo only fair.

The lamp oil didn't work very well at all, the vapor is too heavy

to eject through the small opening in the stack. All the fluids tended to "stick" in the top of the stack when dropped in from the bottle. Sometimes, when running, the opening in the stack would "plug up" with a drop of condensed smoke fluid until the droplet released back into the smoke unit. |

| Bachmann

Climax first run, with 12 volt regulated smoke unit. Regulator modified to work properly, see link. |

|

|

The poor Climax smokes so poorly that I didn't even test it with the Crest fluid. | |

| AristoCraft

RDC with integrated smoke unit running at 16 volts instead of 22 volts |

|

Tested only with Crest fluid, since it worked about the same as the SD45 and it's the same smoke unit, didn't bother with the other fluids, they'd be the same too. | ||

| Bachmann

Shay with an LGB 24 volt smoke unit and a 33 ohm resistor |

|

|

|

All three fluids worked about the same, poorly. This unit is obviously running too cool as it doesn't spit, sputter or blow smoke rings. An IR temperature measurement indicated 220°F (only a relative measurement) and the unit ran without any sound. It did run for a long time, for 45 minutes on 10 drops of Crest fluid, 20 minutes on a small squirt of LGB fluid and 20 minutes on 5 drops of lamp oil. |

| Bachmann

Shay with an LGB 24 volt smoke unit 33 ohm resistor removed |

|

|

With the resistor removed, it puts out more

smoke. It also sputters some and the IR temperature reading was

100°F hotter. It also runs for about half the time because it

is consuming fluid faster. In this case, the lamp oil works well in an LGB unit as the exit path for the smoke is not impeded a small exit port. |

|

| USA Trains

GP9 with Bachmann-like elements and some wiring changes |

|

|

|

The smoke units in USAT locos appear to be identical to Bachmann units. The Crest fluid and Lamp Oil work better than LGB fluid. The front element typically smokes more than the rear one and also runs dry sooner. |

| Lionel

Atlantic with a 24 volt Seuthe (stock) smoke unit |

|

Based on the smoke density compared to the Shay above, this probably a 24 volt Seuthe smoke unit. I didn't test it with the other fluids. | ||

| AristoCraft

FA1 with stock smoke unit |

|

|

|

As is typical with Aristo smoke units, it doesn't work well with LGB fluid. This particular works better with Crest Fluid and Lamp Oil, but it is not impressive with any of them. |

| AristoCraft

FB1 with stock smoke unit |

|

|

|

This FB does better than the FA all around even though it is the same vintage of loco. |

| AristoCraft

FA1 with stock smoke unit |

|

I only tested the Warbonnet FA and FB to determine if they worked like the other ones. They work about the same as the freight FB. | ||

| AristoCraft

FB1 with stock smoke unit |

|

|||

| Bachmann Davenport with stock 12 regulated smoke unit |

|

|

|

The Davenport seems to prefer the lower temperature fluids, Crest and Lamp Oil. |

| AristoCraft

0-4-0 with a Seuthe 18 volt smoke unit set to run at 18 volts |

|

|

|

This guy is probably the best smoker of the bunch. It works like an LGB unit should, with some popping and crackling, bursts of smoke and smoke rings. It did about the same on all three fluids. |

| AristoCraft Pacific new version with integrated smoke unit |

|

|

|

The new Pacific worked pretty much the same as the RDC and SD45 with the same design smoke unit except in this one the LGB fluid worked pretty well. The volume of smoke is large but it doesn't look dense because it is pre-mixed with air before it is ejected. This unit had troubles with premature shut downs until I added a resistor in series with the unit. |

| Original

AristoCraft Pacific with stock smoke unit |

|

|

|

The original Pacific had a smoke generator different from any other. It fills at the bottom and smokes out of many places around the cylinders, it also chuffs in time with the drivers at 1/4 the prototypical rate. It seems to work ok on all the fluids. The LGB sample may have been contaminated with some left over Dept 56 Magic Smoke as it smelled like Magic Smoke. |

As I was in the process of filling out this table, it became clear that some previous observations that I had made about the compatibility of smoke units and smoke fluids was playing out. LGB smoke units run at higher temperature than the others and do not require a fan to eject fluid. They work best with the fluid designed for higher temperature operation, the LGB/Seuthe fluid. AristoCraft fan forced smoke units run at lower temperatures and do not forcefully eject smoke on their own which is why 1) the units need a fan or air pump and 2) the Aristo units that don't have a fan or air pump (Long Steel Caboose and Railbus) don't smoke well with any fluid. Bachmann smoke units use the pressure of the evaporating fluid within the smoke generator tube to eject the smoke, but if these are not set up right, there isn't enough force to push the heavier smoke produced by the heavier fluids up the stack.

Now I have a good idea of what fluids I should bother to test in what smoke units, I can continue to determine the capacity of each kind of smoke unit before the unit becomes overloaded. But before that, I needed a way to, at least approximately, determine what the capacity actually is a method to apply a known quantity of fluid. For this I used a syringe that came with a Seuthe smoke unit. This is a 3 ml plastic syringe with a metal needle. I used to to draw and indicated 1 ml of fluid up from a cup and then drop the fluid back into the cup and count the drops. I found that drop counting was difficult, tedious and not particularly accurate. I was taught in some chemistry class that about 20 drops of water is about a ml. From this syringe, that wasn't even close and the fluids acted differently.

The syringe is good at getting a known quantity of fluid, but it is not so handy for drawing that fluid up from a larger bottle to then transfer to a smoke unit. The dispensers are usually drip bottles and are not calibrated except by counting drops and it is apparent that the drop sizes from the syringe needle and the drip bottles are different. I dripped about a ml into a small cup and counted the drops. I then drew the liquid back from the cup and "measured" how much was dispensed and then calculated the number of bottle drops per ml. This method isn't particularly accurate because some of the fluid, maybe a couple of drops worth was left in the cup, but is is close enough. The actual amount of fluid in any give drop is impacted by BOTH the characteristics of the fluid and the geometry of the drip source.

| Fluid | Drops per ml | |

|---|---|---|

| Syringe | Bottle | |

| Water | ~63 | n/a |

| LGB Smoke Fluid | ~130 | ~58 |

| Crest Smoke Fluid | ~94 | ~37 |

| 99% Paraffin Lamp Oil | ~95 | ~25 |

If I need to, I can eventually count drops from the dispenser bottle, but it would be better to find a syringe with a very long needle and draw up a measured amount of fluid to load up a smoke generator with it's maximum practical load. Now the task is to determine what that load actually is.

The method used to determine the maximum practical load varies by smoke unit design. Each unit is sensitive to the amount of fluid loaded because it needs some exposed heater element to evaporate fluid. With the heater actually submerged, it drowns as the heater does nothing but heat the liquid which keeps the whole assembly cool enough so that it cannot smoke.

LGB. I started with a loose LGB 5 volt unit that I could test on the bench. A loose one is easier to work with because if I overload it, I can simply pour it out into 1 oz plastic measuring cup and start over. I found that the unit takes about 1.2 ml to completely fill it to the top of the element. Of course it would not work with that much fluid in it. At 5 volts on the smoke unit, I could only fill it less than half way, about 0.5 ml before it would get very weak. After some fluid was consumed, it picked up a little. I drew the remaining fluid out of the unit and found that it contained about 0.4 ml, or about 20 to 25 drops. This is consistent with my past experience. This is about all it can hold when running at 5 volts.

I noticed that on an LGB 22232 (a GN 0-4-0) that the circuitry in the loco actually applied 6.4 volts to the smoke unit, which by wire color was indicated to be a 5 volt unit (black and white leads). I assume that this was intended and that LGB had done some tests to determine that this was a safe level for a 5 volt unit. It also smokes about the same as a Seuthe 18 volt unit running at 18 volts. I turned up the voltage on this 5 volt unit and found that it not only smoked much better, but it could handle more fluid as well. At about 3/4 full (0.9 ml), it smoked weakly and spit some. This indicated that there was too much fluid. I waited until it consumed and spit out enough fluid to start working well and turned it off. Drawing out the remaining fluid indicated that it worked with as much as 0.7 ml (40 drops from the LGB bottle). Another test after emptying the unit and refilling it with 40 drops confirmed that this is about the right load from this particular bottle.

AristoCraft Integrated Smoke Unit. The AristoCraft unit was first used in the SD45. As other locos have been first released or redesigned in some redesigned, they got it too. The unit is pretty straightforward. The fluid sump holds about 3.5 ml before it overflows. 4 ml will fit, but you cannot tip the thing at all or the excess will flood out of two channels at the sides of the sump and out of the fan opening. However, at loads past 2.5 ml, the fluid partially submerges the heater and it will not smoke well. Even then, the smoke performance is reduced. A load of 1.5 to 2 ml looks to be more practical so that the wick can regulate the amount of fluid that reaches the heater to allow the heater to reach a higher operating temperature.

AristoCraft FA Smoke Unit. The older FA series diesels (I have 5 of them) used a track voltage heater with a fan. These were not integrated units, the fan is mounted in the loco body and blows air into the smoke unit through a plastic tube. I choose to work on the freight FB unit as it smoked reasonably well. I found that I could pour 6 ml into the unit before the fluid started to submerge the heater and the smoke production decreased. However, the unit either consumed most of that really fast or leaked much of it somehow, because when I opened it to see how much was left, there was only 1 ml in the unit and smoke fluid sitting in the cavity in the loco body.

Just on a

whim, I bent the leads on the heater to raise it higher in the

smoke unit and the thing started to smoke better. I added drops

until it started to slow down. It took 100 drops, but after opening

it again, most of that was gone. The thing was smoking fiercely so

it must have consumed that fluid at a very high rate because is

surely didn't leak 3 ml of fluid.

Just on a

whim, I bent the leads on the heater to raise it higher in the

smoke unit and the thing started to smoke better. I added drops

until it started to slow down. It took 100 drops, but after opening

it again, most of that was gone. The thing was smoking fiercely so

it must have consumed that fluid at a very high rate because is

surely didn't leak 3 ml of fluid.

Bachmann. I have only four working Bachmann or Bachmann-like smoke units at the GIRR. One is in the Davenport but it is a different design that the others I have seen. One which doesn't work very well is in the Climax and the two Bachmann look alikes are in the USA Trains GP9.

This is a failed

Bachmann unit of the design used in most of their locos. The heater

coil is wrapped around some insulating layer around a metal tube.

The smoke is supposed to be ejected from the pinched end at the top

of the tube. This pinch varies from unit to unit and appears to

have a major impact on the performance of this unit.

This is a failed

Bachmann unit of the design used in most of their locos. The heater

coil is wrapped around some insulating layer around a metal tube.

The smoke is supposed to be ejected from the pinched end at the top

of the tube. This pinch varies from unit to unit and appears to

have a major impact on the performance of this unit.

The Davenport

uses a different design. The fluid tub is much smaller and the

heater appears to be wound very loosely around the center tube.

When I put more than about 0.15 to 0.2 ml of fluid in this unit, it

starts to spit heavily. I had the hood off the loco so I could see

inside the tub. When there is too much fluid, I can see the fluid

moving up between the heater coil and the tube. It spits off the

top in large drops or sometimes in large puffs accompanied by many

ejected small drops of boiling fluid that each leave a vapor trail.

When it spits out enough liquid to get the level down below the

bottom of the coil, it settles down and generates a steady stream

of smoke. This level appears to be about 0.15 ml (5 drops of Crest

or 10 drops of LGB fluid).

The Davenport

uses a different design. The fluid tub is much smaller and the

heater appears to be wound very loosely around the center tube.

When I put more than about 0.15 to 0.2 ml of fluid in this unit, it

starts to spit heavily. I had the hood off the loco so I could see

inside the tub. When there is too much fluid, I can see the fluid

moving up between the heater coil and the tube. It spits off the

top in large drops or sometimes in large puffs accompanied by many

ejected small drops of boiling fluid that each leave a vapor trail.

When it spits out enough liquid to get the level down below the

bottom of the coil, it settles down and generates a steady stream

of smoke. This level appears to be about 0.15 ml (5 drops of Crest

or 10 drops of LGB fluid).

The USA Trains and large Bachmann units hold about 2.5 ml to the brim but anything more than 0.5 ml seems to slow them down although they will still smoke with 2 ml in the cup. With the heater submersed, these don't seem to spit like the one in the Davenport.

Now that I know what kind of fluid works in most of the locos and how much they will hold, it is time to do the run time tests. I have elected to only test the locos that smoke well on lamp oil. This is because the ones that smoke well at all work with lamp oil and this is the stuff I am going to continue to use. There are a couple of reasons for selecting lamp oil. First, I have a 100 oz bottle of the stuff and 2nd, it costs $0.20 per oz vs Crest fluid which is $1/oz vs LGB fluid which I am not sure I can even get anymore. Further, I think that by looking around more, I can get more of this stuff for $0.05/oz but that may not be necessary for awhile because I still have nearly 100 oz to burn through first.

The one good smoker that had troubles on lamp oil, the LGB 22232, can be fixed with some modifications to the smoke stack. The Climax doesn't work well on anything, it's smoke unit either needs to be fixed or abandoned.

Be aware that paraffin lamp oil is ONLY SUITABLE FOR USE OUTDOORS. While the vapor is not immediately toxic, the vapor droplets are very small and can be inhaled deeply into the lungs where the material is virtually impossible to expel. On the GIRR Mtn Division, I don't use the smoke units much anyway so when I do I'll use the LGB or Crest fluids.

To test the durations of all the the types of smoke units, I used lamp oil and the results from the capacity tests above.

| Loco | Smoke Unit | Fluid Load (ml) | Duration (min) | Smoke Density | Notes |

|---|---|---|---|---|---|

| Bachmann Davenport | Stock Bachmann | 0.2 | 8 | medium | Works well but doesn't run very long. Overfilling can produce spectacular effects. |

| LGB 22232 | Stock LGB 5 volt running at 6.4 volts | 0.7 | 22 | medium | The smokestack cap that was restricting the smoke flow was removed exposing the whole top of the smoke unit. |

| AristoCraft 0-4-0 | Seuthe #7, 18 volt running at 18 volts | 0.7 | 13 | heavy | Overall, the best smoker considering density and duration. |

| AristoCraft RDC | Aristo Integrated | 2 | 18 | medium | All the similar smoke units seem to work about the same. |

| AristoCraft Blue Box ATSF Freight FB1 | Stock Aristo track powered unit | 3 | 6 | very heavy | Smokes with a vengeance but has short duration. |

| USA Trains GP9 | Stock Bachmann-like units but with wiring modifications | 0.5 each |

12 | medium heavy | Front unit typically smokes more heavily than the rear unit. |

| Bachmann Shay | LGB 24 volt running at 22 volts | 0.7 | 42 | medium | Best duration by far. |

As

I was running the duration tests, I tried changing the backdrop

that I used behind the photos. With this dark gray backdrop, the

visual indication of smoke roughly matched the visual indication. I

guess that the blue backdrop was changing the exposures.

As

I was running the duration tests, I tried changing the backdrop

that I used behind the photos. With this dark gray backdrop, the

visual indication of smoke roughly matched the visual indication. I

guess that the blue backdrop was changing the exposures.

This page has been accessed times since 17 Dec 1997.

© 1997-2010 George Schreyer

Created Dec 8, 1997

Last Updated September 2, 2010